SPX Waukesha Cherry-Burrell User manual

Waukesha ISR

INTEGRAL SPEED REDUCER SERIES

FORM NO.: 95-03010 REVISION: 08/1997 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

INSTRUCTION MANUAL

FPO

Triplex Sales

1-847-839-8442

www.triplexsales.com

295-03010

Triplex Sales

1-847-839-8442

www.triplexsales.com

3

95-03010

SAFETY

Warnings, cautions and notes are contained in this manual. To avoid serious injury and/or

possible damage to equipment, pay attention to these messages.

LEVELS OF HAZARDS

WARNING Hazards or unsafe practices which COULD result

in severe personal injury or death and how to avoid it.

CAUTION Hazards or unsafe practices which COULD result

in minor personal injury or product or property damage.

NOTE Important information pertaining directly to the subject.

(Information to be aware of when completing the task.)

WARNING

TO AVOID SERIOUS INJURY, DO NOT

INSTALL OR SERVICE REDUCER UNLESS

ALL POWER IS OFF AND LOCKED OUT.

WARNING

To avoid electrocution, ALL electrical should

be done by a registered Electrician, following

Industry Safety Standards.

All power must be OFF and LOCKED OUT

during installation.

CAUTION

CHANGING GEAR RATIOS MAY

AFFECT YOUR PUMP

PERFORMANCE AND MOTOR

REQUIREMENTS.

CAUTION

To prevent over hung load damage to the

pinion shaft bearing, the motor must be

supported by a chain hoist or jack until the

motorisseatedandboltedtotherearcase

C flange.

WARNING

All necessary precautions should be

taken prior to working on an

in-service pump.

1. Shut off and close all product to

pump lines.

2. Shut off pump power and lock out

at the control box to avoid any

unexpected start-up.

3. Remove pump drive system

Read and understand this manual prior to install-

ing, operating or maintaining this reducer.

Effective Date of this Manual:

8-13-1997

Triplex Sales

1-847-839-8442

www.triplexsales.com

495-03010

WAUKESHA CHERRY-BURRELL WARRANTY

Seller warrants its products to be free from defects in materials and workmanship for a period of

one (1) year from the date of shipment. This warranty shall not apply to products which require

repairorreplacementduetonormalwearandtearortoproductswhicharesubjectedtoaccident,

misuse or improper maintenance. This warranty extends only to the original Buyer. Products

manufactured by others but furnished by Seller are exempted from this warranty and are limited

to the original manufacturer’s warranty.

Seller’s sole obligation under this warranty shall be to repair or replace any products that Seller

determines,initsdiscretion,tobedefective.Sellerreservestherighteithertoinspecttheproducts

in the field or to request their prepaid return to Seller. Seller shall not be responsible for any

transportation charges, duty, taxes, freight, labor or other costs. The cost of removing and/or

installing products which have been repaired or replaced shall be at Buyer’s expense.

Sellerexpresslydisclaimsallotherwarranties,expressorimplied,includingwithoutlimitationany

warranty of merchantability of fitness for a particular purpose. The foregoing sets forth Sellers

entire and exclusive liability, and Buyer’ exclusive and sole remedy, for any claim of damages in

connection with the sale of products. In no event shall Seller be liable for any special consequen-

tialincidentalorindirectdamages(includingwithoutlimitationattorneys’ fees and expenses),nor

shallSellerbeliableforanylossofprofitormaterialarisingoutoforrelatingtothesaleoroperation

of the products based on contract, tort (including negligence), strict liability or otherwise.

WARRANTY

GENERAL INFORMATION

MANUAL FORMAT

This manual is laid out in sections. Each section addresses specific subjects. Familiarize yourself with

thesubjects byscanningthroughthemanual. Whetherinstalling,operating,troubleshooting,maintain-

ing or ordering parts, read through that section and follow instructions.

ORDERING/RETURNING PARTS

See page 28 for complete information on ordering and returning parts. Record EQUIPMENT and

DISTRIBUTOR INFORMATION immediately.

SHIPPING DAMAGE

Inspect your shipment immediately. If damage is found, note it on the drivers copy (packing slip) and

requestthedrivertoasktheInspectortocall.Youareresponsibleforinitiatingshippingdamageclaims.

HIDDEN DAMAGE OR WARRANTY CLAIM

Ifduringinstallation,youdiscoverapparentshippingdamage,contacttheShipperimmediatelyandask

for an Inspector to call. Notify your Distributor of the problem. In warranty claims you must have a

returned goods authorization from the manufacturer before any returns will be accepted. Your

Distributor will help you with a warranty problem. Please read the Warranty statement.

Triplex Sales

1-847-839-8442

www.triplexsales.com

5

95-03010

LIST OF CONTENTS

SAFETY ......................................................... 1

WARRANTY... .................................................. 4

GENERAL INFORMATION............................... 4

Manual Format

Ordering/Returning Parts

Shipping Damage

Hidden Damage or Warranty Claim

INTRODUCTION............................................... 6

Models..................................................... 6

Pump Speeds.......................................... 6

Integral Speed Reducer Components..... 7

SPECIFICATIONS ............................................ 8

Use on Pump Models.............................. 8

Construction ............................................ 8

Performance Characteristics................... 8

INSTALLATION

ISR to Pump Dimensions ........................ 9

Preparing ISR.......................................... 10

Preparing Pump ...................................... 11

Mounting Front Case to Pump ................ 11

ISR Rear Case to Front Case ................. 12

ISR Lubrication ................................ 12

Motor to ISR ............................................ 12

Motor Bolt Torque Table.......................... 12

Bushing, Key and Motor Bolt information 13

MAINTENANCE... ............................................ 14

Motor Replacement ................................. 14

ISR Disassembly..................................... 15-17

ISR Assembly.......................................... 18

Front Case ....................................... 18

Case to Pump .................................. 18

Changing Gear Ratio............................. 19

Idler Shaft Assembly ........................ 19

Rear Case........................................ 20

Bearing Chart................................... 20

Read and understand this manual prior to install-

ing, operating or maintaining this reducer.

PARTS LIST Model 49..................................... 22-23

Common Parts

Motor Attachment Parts

Ratio Components and Quantities

PARTS LIST Model 79..................................... 24-25

Common Parts

Motor Attachment Parts

Ratio Components and Quantities

PARTS LIST Model 239................................... 26-27

Common Parts

Motor Attachment Parts

Ratio Components and Quantities

PARTS ORDERING ......................................... 28

Returning Parts ....................................... 28

NOTES ......................................................... 29

SPEED REDUCER IDENTIFICATION ............. 30

Label Replacement (Pumps)........................... 30

Triplex Sales

1-847-839-8442

www.triplexsales.com

695-03010

INTRODUCTION WAUKESHA INTEGRAL SPEED REDUCER

The Waukesha Integral Speed Reducer is built for extremely durable service. It creates an

in-line link between the drive motor and the pump. Three models (sizes) are available: 49, 79

and 239.

The cast iron casing houses quality reduction gearing, presenting eight speed reduction ca-

pabilities using two standard motor RPM inputs on the 49 and 79 units, 10 speeds on the 239

unit. Speed ratios are changeable in the field.

All fittings, bushings, keys and fasteners are supplied to fit the Reducer to C-face motors with

frames from 145TC through 286TC.

The Waukesha ISR design will drive Waukesha Universal Pump Models as listed in SPECI-

FICATIONS and can be retrofitted to these models in the field.

This Manual addresses: Installation of the Integral Speed Reducer

Maintenance of Integral Speed Reducer

NOTE A separate Integral Speed Reducer is shipped without

lubricating oil as disassembly of the ISR is required to

mount it to a pump in the field.

See PARTS LISTING beginning on page 22 for:

Reducer Parts

Motor Attachment Parts

Gear Ratio Components

PUMP SPEEDS ATTAINABLE

Model 49 120 rpm to 287 rpm

Model 79 98 rpm to 390 rpm

Model 239 100 rpm to 320 rpm

Triplex Sales

1-847-839-8442

www.triplexsales.com

7

95-03010

INTRODUCTION

BEARING

PINION SHAFT

O-RING

SEAL RETAINER

BUSHING

SEAL

SPACER

REAR IDLER

BEARING

REAR OUTPUT

SHAFT BEARING

SUPPORT

CAP SCREW

AND JAM NUT

OIL DRAIN

PLUG

GEAR CASE

FASTENERS

KEY

IDLER SHAFT

NARROW GEAR

THIN SPACER NARROW GEAR

OUTPUT SHAFT

BEARING

KEY

OUTPUT GEAR

SPACER

RETAINING RING

MOTOR KEY

MOTOR

MOTOR FASTENERS (4)

ISR

ASSEMBLY

PUMP FASTENER

INTEGRAL SPEED REDUCER COMPONENTS

NOTE: Silicone Sealant is used as

a gasket between case halves.

REAR CASE

FRONT CASE

Figure 1

SNAP RING

FRONT IDLER BEARING

FRONT SPACER

WIDE GEAR

MOTOR KEY

KEY

OIL FILL (2)

(3 IN 049)

Triplex Sales

1-847-839-8442

www.triplexsales.com

895-03010

WARNING

TO AVOID SERIOUS INJURY, DO NOT

INSTALL OR SERVICE REDUCER UNLESS

ALL POWER IS OFF AND LOCKED OUT.

SPECIFICATIONS

ISR SIZE USE ON WAUKESHA PUMP

Model 49 Models 30, 32, 34, 33A, 5040

Model 79 Models 60, 62, 64, 130, 134, 132, 133A, 5050, 5060

Model 239 Models 220, 222,224, 223A, 5070

STANDARD CONSTRUCTION:

Housing: Cast Iron

Steel Shafts

Ball Bearings

Bushings

Paint: 2-part epoxy, TNEMEC 104, Sky Blue

#104-BB-42

PUMP MOTOR GEAR

RPM RPM RATIO

PUMP MOTOR GEAR

RPM RPM RATIO

PUMP MOTOR GEAR

RPM RPM RATIO

PUMP SPEEDS

97 1125 11.57:1

151 1125 7.47:1

151 1745 11.57:1

177 1125 6.35:1

234 1745 7.47:1

254 1125 4.43:1

275 1745 6.35:1

394 1745 4.43:1

PERFORMANCE CHARACTERISTICS

MODEL 49 1-1/2 TO 7-1/2 HP MODEL 79 3 to 10 HP MODEL 239 7-1/2 to 30 HP

119 1125 9.48:1

155 1125 7.25:1

184 1745 9.48:1

187 1125 6.01:1

241 1745 7.25:1

262 1125 4.30:1

291 1745 6.01:1

406 1745 4.30:1

100 1125 11.22:1

125 1125 9.01:1

146 1125 7.70:1

156 1745 11.22:1

169 1125 6.65:1

194 1745 9.01:1

210 1125 5.35:1

226 1745 7.70:1

262 1745 6.65:1

326 1745 5.35:1

CAUTION

CHANGING GEAR RATIOS MAY

AFFECT YOUR PUMP

PERFORMANCE AND MOTOR

REQUIREMENTS.

Triplex Sales

1-847-839-8442

www.triplexsales.com

9

95-03010

INSTALLATION

A11.71

B9.33

C.218

D9.13

E5.22

F6.3

G8.5

H18.18

K7.63

L10.6

1.375

Figure 2

MOTOR

FRAME

ISR

MODEL "U" OA

UNIVERSAL

PUMP MODEL

49

79

79

239

.875

1.125

1.125

1.125

1.375

1.125

1.375

1.375

1.625

1.875

8.5

8.5

10.5

8.5

8.5

4.5 15.91

9 35

.218

9.13

7.31

9.13

9.4

21.75

9.5

13.0

20.13

12.13

.218

11.12

9.38

11.68

11.9

27.38

13.75

17.0

16.85

9 35

.218

9.13

7.31

9.77

9.4

22.38

9.5

13.0

UNIVERSAL PUMP SERIES

30 60 130 220

All Dimensions in inches

220,

222, 224,

223A,

5070

220 SERIES

130 SERIES

60,

62, 64

60 SERIES

30, 32, 34,

33A, 5040

30 SERIES

MODEL 60 PUMP SHOWN

145TC

184C

182TCH

184TCH

182TC

184TC

213C

215C

213TC

215TC

182TC

184TC

213C

215C

213TC

215TC

182TC

184TC

213C

215C

213TC

215TC

213TC

215TC

254TC

256TC

284TC

286TC

31.75

35.0

35.0

35.0

33.25

34.25

35.25

37.0

36.40

38,.0

37.5

38.5

39.5

41.0

40.6

42.2

38.5

39.5

41.4

43.0

41.5

43.0

47.6

49.2

51.4

53.0

54.0

55.5

130,

132, 134,

133A, 5050,

5060

ISR TO PUMP DIMENSIONS

Triplex Sales

1-847-839-8442

www.triplexsales.com

10 95-03010

NOTES: 1.There is NO OIL IN ISR!

2. Pump fasteners are supplied in

a separate bag.

(On previously installed units, see in-service

pump preparation on page 11.)

1. Remove two 1/2-13 hex-head cap screws

and jam nuts from support foot of rear case.

(Figure 3)

NOTE: OnModel239supportfootscrews are

1/2-13 x 2 hex-head machine screws.

2. Remove six hex-head cap screws and

lockwashers from gear case assembly.

NOTE: On Model 239 there are eight hex-

head cap screws.

3. Separate rear case assembly from front

case assembly. (Figure 3)

NOTE: Use a brass or aluminum pry bar to

separate cases if necessary.

4. Remove old silicone sealant from case

halves. (Figure 3)

5. Remove the thin spacer from idler shaft.

6. Pull the idler shaft and the spacer from the

front case assembly. There are two different

idler shaft assemblies used depending on ra-

tio of ISR. (Figure 4)

NOTE: It may be necessary to use a brass or

aluminum pry bar to remove the idler shaft.

7. Remove the retaining ring from the output

gear shaft. Slide the spacer off the shaft.

(Spacer not used on Model 49 ISR.)

(Figure 5)

8. Slide the output gear and key off the shaft.

9. The front case is now ready to install on the

pump.

An ISR received as a separate unit will be attached to an existing pump.

23

4

Figure 3

KEY

OUTPUT GEAR

FRONT CASE

RETAINING RING

Figure 4

Figure 5

INSTALLATION

1

IDLER SHAFT

ASSEMBLY

5

6

SPACER

SPACER

PREPARING ISR FOR PUMP INSTALLATION

OUTPUT SHAFT

Triplex Sales

1-847-839-8442

www.triplexsales.com

11

95-03010

PUMP

RETAINING RING

KEYOUTPUT

GEAR

SOCKET HEAD CAP SCREW

FRONT CASE

SILICONE SEALANT

PUMP

DRIVE SHAFT

OUTPUT SHAFT

SPACER

key. Apply a film of Micro Plate 140 gear oil

to pump drive shaft.

4.Align keywayinspeed reduceroutputshaft

with key in pump drive shaft and slide output

shaft over pump drive shaft.

5. Seat front case to pump.

6. Fasteners

Model 49: Install six 5/16-18 x 1-1/4"

socket-headcapscrews.Torqueto17ft.Ibs.

Model 79: Install six 3/8-16 x 1-1/4

socket-headcapscrews.Torqueto30ft.Ibs.

Model 239: Install eight 3/8-16 x 2"

socket-head cap screws.Torque to 30 ft. Ibs.

7. Install key in output shaft.

8. Align output gear with key and slide onto

output shaft.

9. Slide on spacer and secure with retaining

ring.

NOTE: Model 49 does not use a spacer be-

tween the retaining ring and the output gear.

PUMP

KEY

Figure 6

(Figure 6)

(The speed reducer can only be assembled

to a lower drive shaft mounted pump.)

WARNING

All necessary precautions should be taken

prior to working on an in-service pump.

1. Shut off and close all product to pump

lines.

2. Shut off pump power and lock out at the

control box to avoid any unexpected start-

up.

3. Remove pump drive system

PREPARATION OF PUMP

1.Drain oil from pumpgear case and remove

pump gear case cover and sealant.

2. Clean sealant from gear case surface.

3.Applyabead ofsiliconesealanttothe pump

case.Rotate pumpdriveshaft andinstalldrive

INSTALLATION MOUNTING FRONT CASE TO PUMP

Triplex Sales

1-847-839-8442

www.triplexsales.com

12 95-03010

Fill unit with Microplate 140 gear oil. (Use re-

ducer fill hole located on either side). Figure 7

MICROPLATE 140 LUBE OIL CAPACITY

MODEL 49 1-1/4 PINTS

MODEL 79 3 PINTS

MODEL 239 6-1/2 PINTS

NOTE: Pump and reducer form a common oil

reservoir.

ISR ASSEMBLY - REAR CASE TO FRONT CASE

INSTALLATION

IDLER SHAFTS

2 GEAR

1 GEAR

THIN SPACER FRONT SPACER (THICK)

FRONT CASE

FRONT CASE

SILICONE SEALANT

REAR CASE

OIL FILL PLUG

Figure 7

Figure 8 OIL DRAIN

CAP SCREW

LOCK

WASHER

CASE ASSEMBLY

THIN SPACER

Lubricate all shaft surfaces with Micro Plate

140 gear oil prior to installing.

1. Place the front spacer on the long end of

the idler shaft. Install the idler shaft assem-

bly in the front case assembly. There are two

differentidlershaftassembliesuseddepend-

ing on ratio of ISR. (Figure 7)

NOTE: A front spacer is used on all idler

shafts, except 79 and 49 gear idler shafts.

Shaft is a light press fit. Use a soft hammer

to seat the shaft or press it in.

2. Install thin spacer onto idler shaft.

49 thickness = .060/.062 inch

79 thickness = .060/.062 inch

239 thickness = .133/.138 inch

INSTALL REAR CASE ASSEMBLY

4.Placeabead of silicone sealant on the rear

case edge.

Lubricate front and rear case bearings and

gears with Micro Plate 140 gear oil.

5. Seat rear case to front case. (Figure 7)

NOTE: Idler and output shafts may be a light

press fit in rear case bearings. The rear case

shouldbecompletelyassembled,withoutthe

motor coupling installed.

6. Attach with cap screws and lock washers.

Torque to 30 foot lbs.

7. Install the two hex-head cap screws with

jam nuts into support foot of rear case.

After screws are engaged in the base plate,

lock them in position with the jam nuts.

Install oil drain plug (1/2-20 cap screw with

fiber washer). (Figure 8)

SUPPORT

SCREW

JAM NUT

Triplex Sales

1-847-839-8442

www.triplexsales.com

13

95-03010

CAUTION

To prevent over hung load damage to the

pinion shaft bearing, the motor must be

supported by a chain hoist or jack until the

motorisseatedandboltedtotherearcase

C flange.

Figure 9

NOTE: SeeBushing andKeySelectionChart

for specific parts for each model. (Page 14)

1. Apply a generous coating of good quality

anti-seize compound to O.D. of pinion shaft

bushing. Figure 9

2. Align two counter-bored holes in pinion

shaft bushing with two tapped holes in pin-

ion shaft and install bushing into pinion shaft

bore.

3. Install two #10-32 x 1/2 socket-head cap

screws. Torque screws to 5 ft. Ibs.

4. Remove cover from pump.

INSTALLATION

SPEED REDUCER ASSEMBLY

MOTOR

MOTOR KEY

BUSHING

MOTOR BOLT

KEY WAY

MOTOR BOLT

TORQUE TABLE

SIZE TORQUE

1/2 - 13 30 ft. Ibs.

3/8 - 16 10 ft. Ibs.

FRAME HEX HEAD CAPSCREW WASHER

145 TC 3/8-16 X 1-1/4" 3/8"

182 TC 1/2-13 X 1-1/2" 1/2"

184 TC 1/2-13 X 1-1/2" 1/2"

213 TC 1/2-13 X 1-1/2" 1/2"

215 TC 1/2-13 X 1-1/2" 1/2"

254 TC 1/2-13 X 1-3/4" 1/2"

256 TC 1/2-13 X 1-3/4" 1/2"

284 TC 1/2-13 X 2" 1/2"

286 TC 1/2-13 X 2" 1/2"

MOTOR FASTENER REFERENCE

MOTOR TO SPEED REDUCER

5. Using a rotor nut wrench, rotate the pump

shaft so that the keyway in the pinion shaft

bushing is facing up.

6. Rotate the motor shaft so that the keyway

is facing up and install key.

7.Apply a generous coatof good quality anti-

seize compound to motor shaft and bore of

pinion shaft bushing.

8.Whilesupportingweightofmotor, align key

in motor shaft with keyway in pinion shaft

bushing and insert motor shaft into pinion

shaft bushing. Seat motor into rear case

flange and install four hex-head cap screws

with lockwashers. Torque screws per chart

below.

Triplex Sales

1-847-839-8442

www.triplexsales.com

14 95-03010

MAINTENANCE

INSPECTION

Inspect speed reducer for excessive noise and oil leaks during monthly inspections. Check oil

level at fill plug location. (Figure 10) Excessive oil use would require replacement of oil seals,

while excessive noise would indicate bearing and/or gear problems.

To prevent overhung load damage to the

pinionshaft bearing,supportthe motorwith

a chain hoist or jack until it is completely

removed.

MOTOR REPLACEMENT

The motor must be removed to service the

speed reducer.

CAUTION

ALL MODELS

NOTE: C-flanges have tapped pushoff holes

located inboard of the motor mounting holes.

After mounting screws have been removed,

install push-off screws into inboard push-off

holes. (Figure 11 ).

Thread push-off screws in alternately until

motor is forced out of speed reducer.

OIL FILL

Figure 10

Figure 11

49 79 239

ISR MODEL NO.

MOTOR, BUSHING, KEY INFORMATION

MOUNTING HOLES

PUSH-OFF

HOLES

MOTOR REPLACEMENT

FRAME SHAFT FACE BUSHING KEY KEY

SIZE SIZE DIA. NO. NO. SIZE

145 TC .875 4.5 • 049 116 000 000 037 001 3/16 x 3/16 x 1

182 TC 1.125 8.5 • • 079 116 001 000 037 015 1/4 x 1/4 x 1

184 TC • • 079 116 001 000 037 015 1/4 x 1/4 x 1

213 TC 1.375 8.5 • • 079 116 002 000 037 010 5/16 x 5/16 x 1-1/8

215 TC • • 079 116 002 000 037 010 5/16 x 5/16 x 1-1/8

213 TC 1.375 8 5 • • 239 116 002 000 037 012 5/16 x 5/16 x 1-1/4

215 TC • • 239 116 002 000 037 012 5/16 x 5/16 x 1-1/4

254 TC 1.625 8.5 • 239 116 003 000 037 013 3/8 x 3/8 x 1-3/8

256 TC • 239 116 003 000 037 013 3/8 x 3/8 x 1-3/8

284 TC 1.875 10.5 • 239 116 004 000 037 014 1/2 x 1/2 x 1-3/8

286 TC • 239 116 004 000 037 014 1/2 x 1/2 x 1-3/8

Triplex Sales

1-847-839-8442

www.triplexsales.com

15

95-03010

ISR DISASSEMBLY (Figure 12)

1. Remove two 1/2-13 hex-head cap screws

and jam nuts from support foot of rear case.

NOTE: OnModel239supportfootscrews are

1/2-13 x 2 hex-head machine screws.

2. Remove six hex-head cap screws and lock

washers from gear case assembly.

NOTE: On Model 239 there are eight hex-

head cap screws.

3. Separate rear case assembly from front

case assembly.

NOTE: Use a brass or aluminum pry bar to

separate cases if necessary.

4. Remove old silicone sealant.

REAR CASE DISASSEMBLY

1. Remove two 10-32 x 1/2 socket-head cap

screws from pinion bushing.

NOTE: Push-off holes are provided in the

bushing to facilitate removal.

2. Thread the socket-head cap screws re-

moved from bushing into the push-off holes

provided and turn alternately to force bushing

from pinion shaft. (Figure 13)

3. Remove the four 10-32 x 1/2 socket-head

cap screws from the seal retainer. (Figure 14)

4. Using two of the screws removed, thread

intopush-offholes and turnalternatelytoforce

seal retainer out of rear case.

5. Remove O-ring from outside diameter of

retainer and press seal out of retainer bore.

Figure 12

Figure 13

Figure 14

PUSH-OFF

HOLES

BUSHING

SILICONE SEALANT

SUPPORT SCREWS

CASE SCREWS

SEAL RETAINER

SEAL

O-RING

MAINTENANCE

PUSH-OFF

HOLES

ISR DISASSEMBLY

Triplex Sales

1-847-839-8442

www.triplexsales.com

16 95-03010

6.Remove pinion shaftspacer from rearcase

pinion shaft bore. (Figure 15)

7. Press pinion shaft and bearing out of rear

case pinion shaft bore.

8.Removeretaining ring from pinion shaft and

press shaft out of bearing.

9. Using an inside race puller, remove rear

idler bearings and output shaft bearings.

IDLER SHAFT FROM FRONT CASE

DISASSEMBLY (Figure 16)

1. Remove thin rear spacer from idler shaft.

2. Pull idler shaft out of front case assembly.

NOTE: It may be necessary to use a brass or

aluminum pry bar to remove the idler shaft.

3. Remove thick front spacer, (if used) from

idler shaft.

IDLER SHAFT DISASSEMBLY WITH ONE

PRESSED-ON GEAR (Figure 17)

NOTE: Wide gear is integral with shaft.

1. Press narrow gear off of shaft and remove

woodruff key.

IDLER SHAFT DISASSEMBLY WITH TWO

PRESSED-ON GEARS (Figure 18)

1. Press narrow gear off.

2. Press wide gear off.

3. Remove two woodruff keys.

MAINTENANCE

Figure 18

Figure 17

Figure 16

Figure 15

ISR DISASSEMBLY

PINION SHAFT

REAR IDLER AND OUTPUT

BEARINGS

RETAINING RING

BEARING

THICK SPACER

THIN SPACER

IDLER SHAFT

ASSEMBLY

FRONT

SPACER

WIDE GEAR

KEY

IDLER SHAFT

KEY

IDLER SHAFT

NARROW GEAR

NARROW GEAR

PINION SHAFT

SPACER

WIDE GEAR

Triplex Sales

1-847-839-8442

www.triplexsales.com

17

95-03010

1.Removeretainingringandspacerfromout-

put shaft. (Figure 19)

NOTE: Spacer is not required on Model 49.

2. Slide output gear off output shaft and re-

move key.

3. Remove the six socket-head cap screws

securing the front case to the pump.

NOTE: On Model 239 there are eight socket-

head cap screws.

4. Using a soft mallet, tap on case to separate

case from pump.

5. Remove silicone sealant and key.

FRONT CASE DISASSEMBLY (Figure 20)

1. Press output shaft out of case.

2. Press bearing off of output shaft.

3. Use inner race puller to remove two front

idler bearings.

MAINTENANCE

Figure 19

Figure 20

SILICONE

SEALANT

RETAINING RING

SPACER

OUTPUT GEAR

FRONT

IDLER

BEARINGS

OUTPUT

BEARING

FRONT CASE TO PUMP DISASSEMBLY

SOCKET HEAD

CAPSCREWS (6)

CASE

KEY OUTPUT SHAFT

OUTPUT

SHAFT

Triplex Sales

1-847-839-8442

www.triplexsales.com

18 95-03010

MAINTENANCE

Figure 23

DRIVE KEY

SILICONE SEALANT

SOCKET HEAD

CAP SCREWS

MODELS 49, 79, 239

FRONT CASE ASSEMBLY (Figure 21)

1. Press and seat two front idler bearings into

front idler bearing bore.

NOTE

To avoid damage to the bearings, press

against outer race when installing bearing in

case and inner race when installing bearing

on shaft.

2. Press and seat front output shaft bearing

onto output shaft.

3. Press and seat bearing and output shaft

assembly into output shaft bearing bore.

FRONT CASE TO PUMP ASSEMBLY

NOTE The speed reducer can only be as-

sembledto a lower driveshaftmountedpump.

1. Drain oil from pump gear case and remove

pumpgear case coverandcleansilicone seal-

ant from cover and case. (Figure 22)

2. Rotate pump drive shaft so that keyway

faces up and install drive key. Apply a film of

Micro Plate 140 gear oil to pump drive shaft.

(Figure 23)

3.Align outputshaftkey waywithkeyon pump

drive shaft and slide output shaft over drive

shaft. (Figure 23)

Apply silicone sealant bead on pump gear

case.

5. Seat front ISR case to pump.

6. Model 79: Install six 3/8-16 x 1-1/4 socket-

head cap screws- torque to 30 ft. Ibs. For

Model 49: Install six 5/16-18 x 1-1/4" socket-

head cap screws- torque to 17 ft. Ibs.

Model 239: Install eight 3/8-16 x 2" socket-

head cap screws-torque to 30 ft. Ibs.

Figure 22

SPEED REDUCER ASSEMBLY

Figure 21

FRONT IDLER

BEARING (2)

OUTPUT SHAFT

AND BEARING

INNER RACE

OUTER RACE

OUTPUT SHAFT

OIL DRAIN

Triplex Sales

1-847-839-8442

www.triplexsales.com

19

95-03010

MAINTENANCE

Figure 21

SPACER

RETAINING RING

KEY

OUTPUT GEAR

7. Install key in output shaft. (Figure 21)

8. Align keyway in output gear with key in

output shaft and slide output gear onto out-

put shaft.

9.Assemble spacer and retaining ring toout-

put shaft.

NOTE: Model 49 does not use a spacer be-

tweenthe retaining ringandtheoutput gear.

IDLER SHAFT ASSEMBLY

There are two types of idler shaft assem-

blies, depending on the gear ratio selected.

One type uses two pressed-on gears while

theother type usesonepressed-ongearand

one 21 tooth gear that is part of the idler

shaft.

NOTE: For Model 239 there is only one idler

shaft assembly and it uses two pressed-on

gears. (Figure 23)

IDLER SHAFT ASSEMBLY WITH ONE

PRESSED-ON GEAR (Figure 22)

1.Installwoodruffkey inshaft,pressandseat

narrow gear onto shaft.

IDLER SHAFT ASSEMBLY WITH TWO

PRESSED-ON GEARS (Figure 23)

NOTE: NARROWgearisassembledtoshort

endof shaft. WIDEgearisassembled tolong

end of shaft.

1. Install woodruff key in short end of shaft.

Press and seat NARROW gear onto shaft.

2. Install woodruff key in long end of shaft,

press and seat WIDE gear onto shaft.

Figure 23

FRONT

SPACER

WIDE GEAR

KEY

NARROW GEAR

IDLER

SHAFT

NARROW GEAR

KEY

INTEGRAL

GEAR

SHAFT

Figure 22 ONE GEAR IDLER

The output gear and the wide idler gear

can be changed to increase or decrease

pump RPM. Also, changing to a different

speed motor can effect the final pump

speed.

See PARTS LIST pages beginning on

page23, 25,27 forspecific gearsrequired

for RPM changes

CHANGING GEAR RATIO?

OUTPUT SHAFT

TWO GEAR IDLER

SPEED REDUCER ASSEMBLY

Triplex Sales

1-847-839-8442

www.triplexsales.com

20 95-03010

MAINTENANCE

REAR CASE ASSEMBLY

Refer to REAR CASE BEARING CHART for

idler and output shaft bearing configurations.

1. Press and seat rear output shaft bearing(s)

into output shaft bearing bore. (Figure 28)

2. Press and seat rear idler shaft bearing(s)

into idler shaft bearing bore. (Figure 28)

NOTE

To avoid damage to the bearings, press

against the OUTER RACE.

IDLER SHAFT TO FRONT CASE

ASSEMBLY (Figure 27)

Idler shaft to front idler bearing is a light press

fit.

Refer to chart for idler shaft configurations.

1. Install thick front spacer onto long end of

idler shaft.

2.Start longendofidler shaftintobearingbore

and align teeth on idler gear so they will mesh

with teeth on output gear.

3. Remove cover from pump. Using a rotor

nut wrench, rotate pump shaft while at the

same time tapping on end of idler shaft with a

soft mallet to seat idler shaft in bearing bore.

4. Install thin rear spacer.

REAR CASE

OUTPUT BEARING

IDLER BEARING/S

FRONT SPACER (THICK)

SPEED IDLER SPACER

REDUCER SHAFT TYPE &

MODEL CONFIGURATIONS LOCATIONS

2 Pressed Gears Thick Front and

79 Thin Rear Spacer

Integral Gear No Front Spacer

49 2 Pressed Gears Same Thickness

Spacer

Front and Rear

49 Integral Gear No Front Spacer

239 2 Pressed Gears Thick Front and

Thin Rear Spacer

Figure 27

THIN SPACER

2 GEAR

1 GEAR

FRONT CASE

OIL FILL PLUG

IDLER SHAFTS

REAR CASE REAR CASE

IDLER OUTPUT

SHAFT SHAFT

MODEL BEARINGS BEARINGS

49 ONE TWO

79 ONE ONE

239 TWO TWO

REAR CASE BEARING CHART

NOTES

All three bearings have same I.D.

Idler shaft bearing has larger O.D.

Both bearings have same O.D.

Output bearing has larger I.D.

All four bearings have same I.D. and O.D.

Figure 28

SPEED REDUCER ASSEMBLY

Triplex Sales

1-847-839-8442

www.triplexsales.com

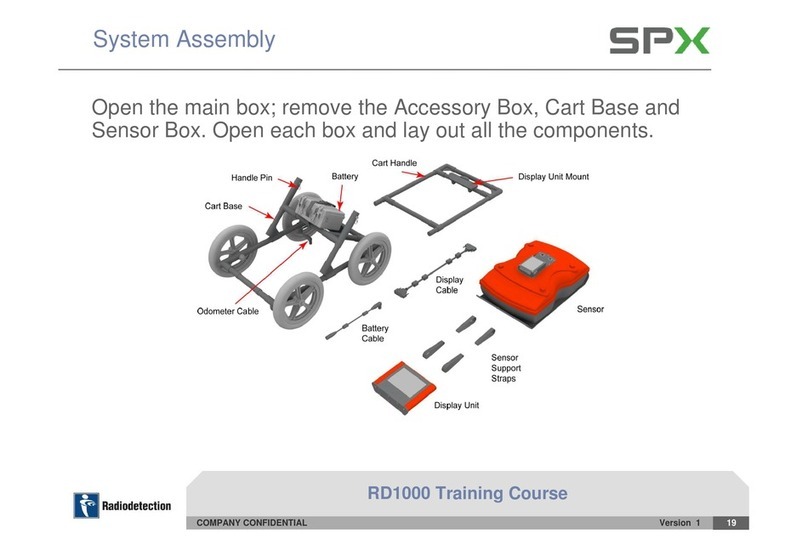

Table of contents

Other SPX Industrial Equipment manuals

SPX

SPX APV ParaFlow User manual

SPX

SPX Marley Geareducer 2800 Series User manual

SPX

SPX Marley Geareducer 32.2 Series User manual

SPX

SPX MARLEY Geareducer 2700 Series User manual

SPX

SPX CUES ACCUPOINT MS611 User manual

SPX

SPX Marley Geareducer 34.4 Series User manual

SPX

SPX APV Cavitator User manual

SPX

SPX RD1000 User manual

SPX

SPX Hankison Trip-L-Trap 505 User manual

SPX

SPX Waukesha Cherry-Burrell Votator II User manual