SPX OTC 1875 User manual

Other SPX Industrial Equipment manuals

SPX

SPX Marley Geareducer 34.4 Series User manual

SPX

SPX Power Team HNS150A User manual

SPX

SPX Waukesha Cherry-Burrell Votator II User manual

SPX

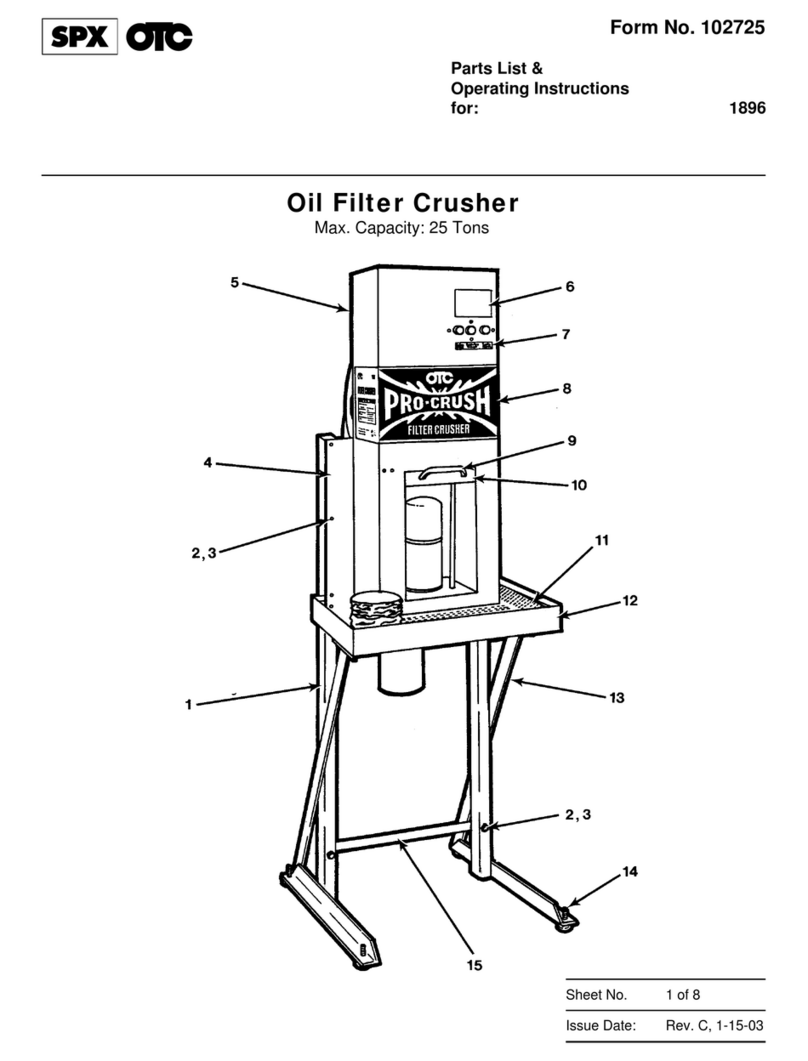

SPX OTC PRO-CRUSH 1896 User manual

SPX

SPX APV DELTA SDMU4 User manual

SPX

SPX Hankison Trip-L-Trap 505 User manual

SPX

SPX APV Cavitator User manual

SPX

SPX CUES ACCUPOINT MS611 User manual

SPX

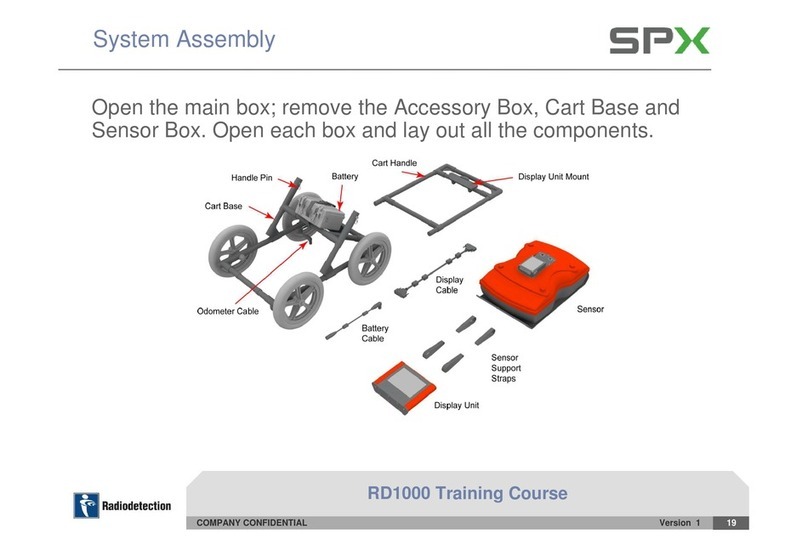

SPX RD1000 User manual

SPX

SPX MARLEY Geareducer 2700 Series User manual

Popular Industrial Equipment manuals by other brands

Armfield

Armfield FT74P instruction manual

Chicago Dryer

Chicago Dryer King Edge VAc instruction manual

HORST WAGONS

HORST WAGONS CHCF25 Operator's manual

Vestil

Vestil WTJ-4 Series instruction manual

CIPRIANI

CIPRIANI S020+ User and maintenance manual

Belden

Belden PPC CABLEREADY SR050 Installation instruction guide

Keysight Technologies

Keysight Technologies 11867A Operating and service guide

Geokon

Geokon 4800 Series instruction manual

Lechler

Lechler XactClean HP+ MAINTENANCE INSTRUCTIONS MANUAL

Fayat

Fayat Dynapac F1800W operation & maintenance

Parker

Parker Helac PowerTilt Series Service and repair manual

Schuck Group

Schuck Group SHD Installation & operation manual

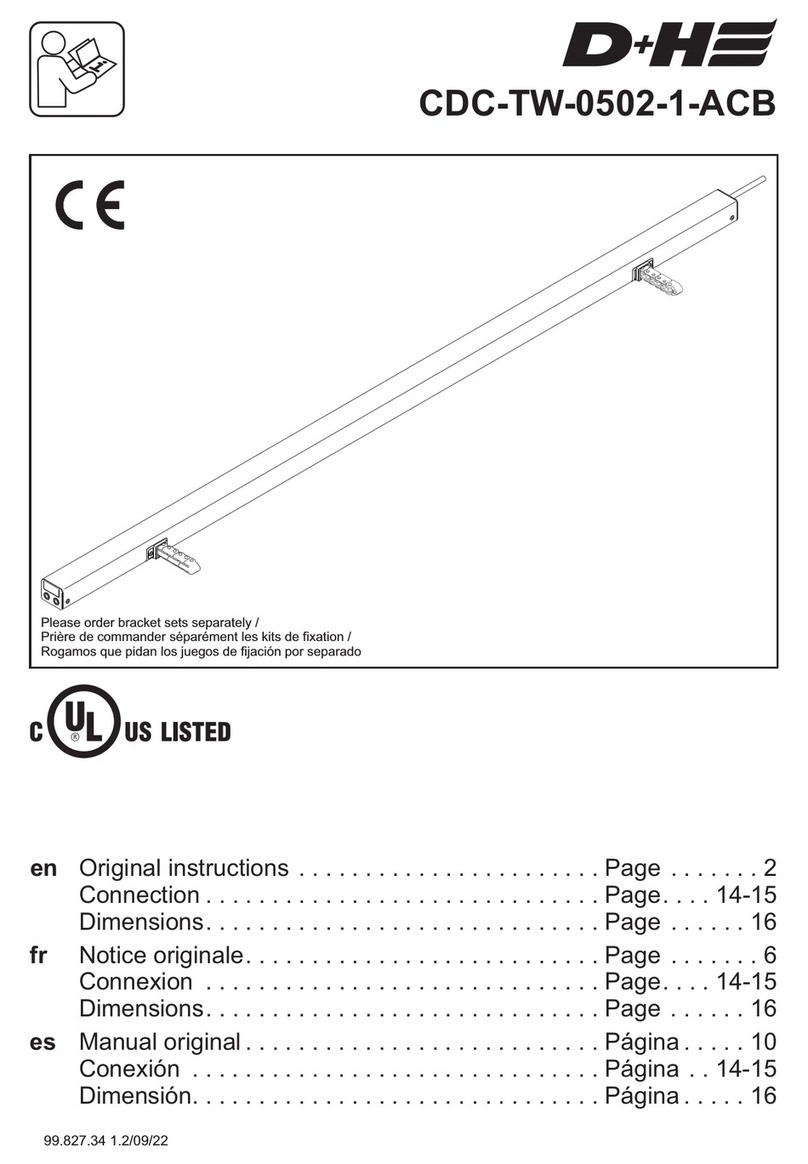

D+H

D+H CDC-TW-0502-1-ACB Original instructions, Connection, Dimensions

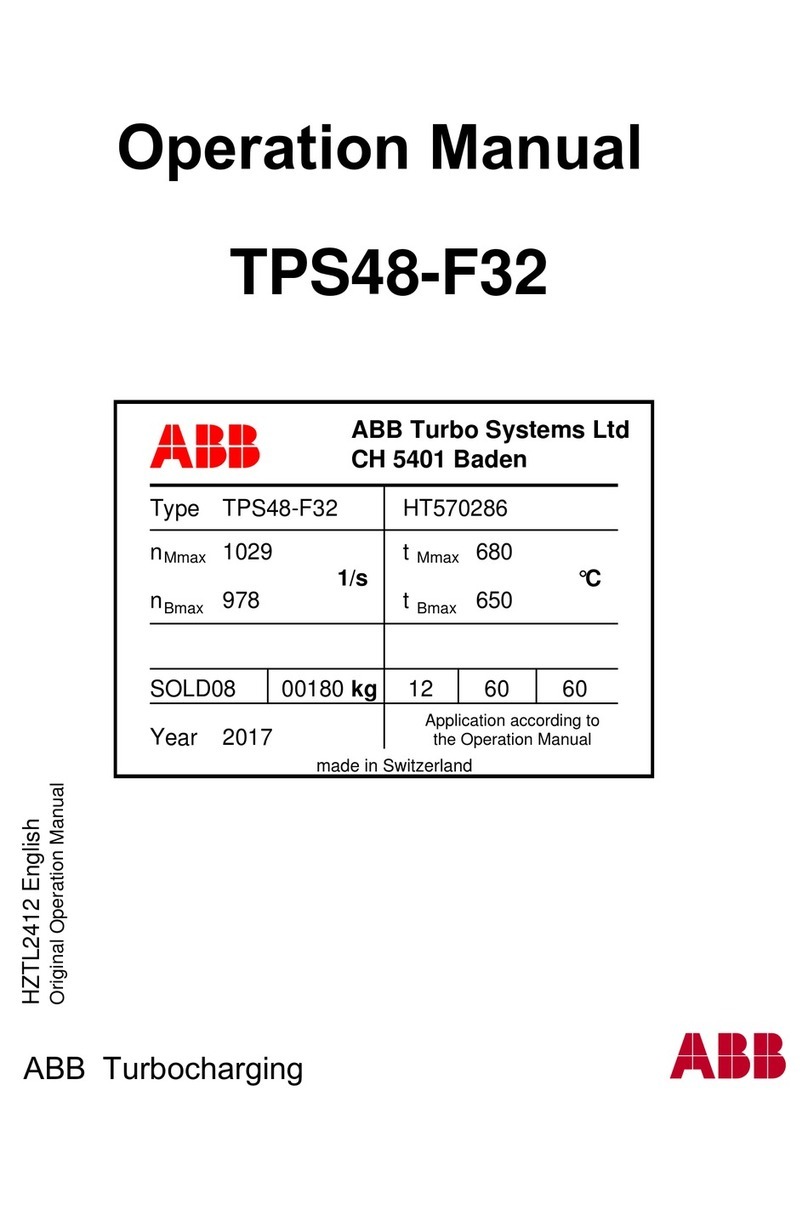

ABB

ABB HT570286 Operation manual

Hettich

Hettich AvanFit YOU 300 Operating and assembly instructions

Condux

Condux Fiber Optic Cable Puller Trailer User's guide & safety manual

JUKI

JUKI KE-2070 manual

Mayr

Mayr EAS-NC Installation and operational instructions