Max height - ram to table.............................................1030mm

Min height - ram to table................................................150mm

Work table aperture.......................................................164mm

Work table depth ...........................................................184mm

Work table width............................................................695mm

Overall height ..............................................................1801mm

Weight .............................................................................166kg

Gauge included ...................................................................Yes

Air consumption.................................................................9cfm

Working pressure ....................................................108-123psi

4. ASSEMBLY

REFER TO PARTS LIST DIAGRAM

4.1. Unpack the product and check the contents. Should there be any damaged or missing parts, contact your supplier immediately. Take

care to ensure safety when removing main frame from its packing, as the unit is very heavy.

4.2. Use the parts diagram as your guide to assembly. Lay all parts and assemblies out before beginning assembly. The following

procedure is recommended.

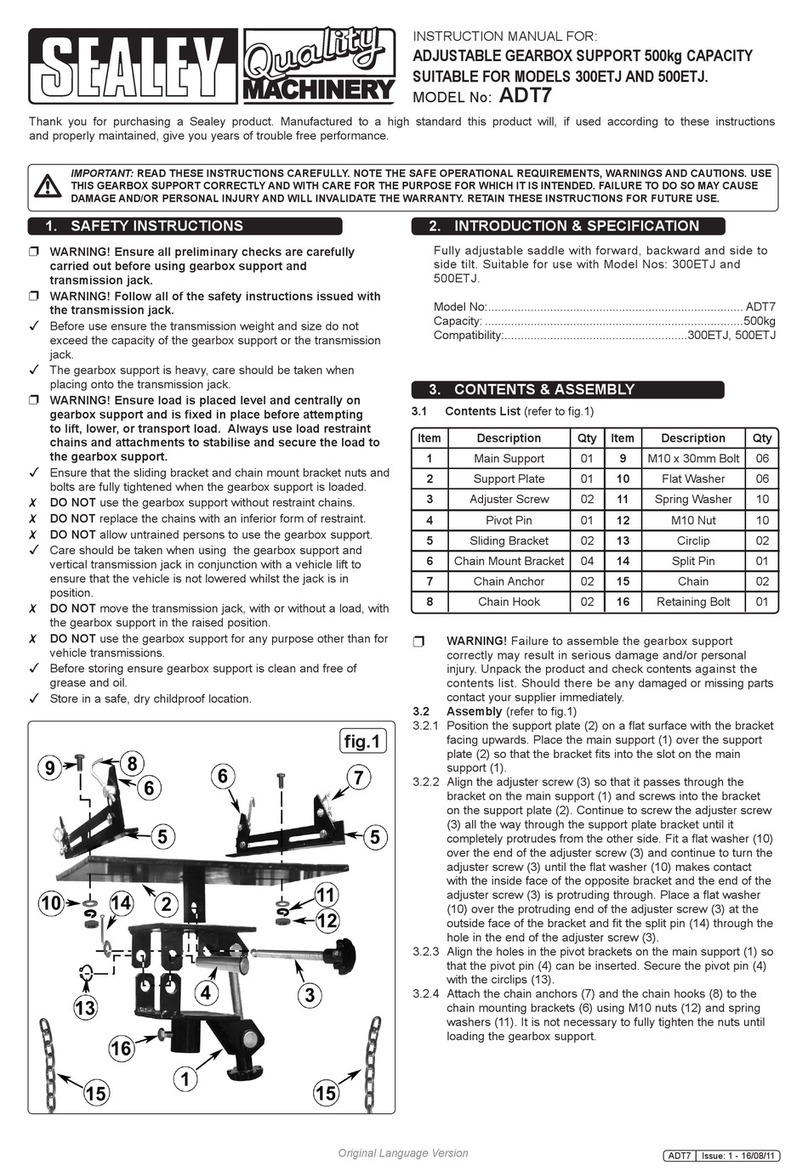

4.3. Attach one of the base sections (5) to the left post and lower cross member (7) using bolts (8), washers (2), lock washers (3) and

nuts (4). Add two supports (6) to the post and base sections, using bolts (1), washers (2), lock washers (3) and nuts (4).

Repeat the operation for the right hand side.

4.4. Lifting from the upper cross beam end lift the press into an upright position.

WARNING! Ensure help is available and use slings and a suitable hoist or gantry to raise the press to an upright position.

4.5. Insert the bed frame pins (9) and circlips(10) into the holes in each of the posts, ensuring that they are level and then with the help of an

assistant insert the bed frame (11) into the press frame resting on to the pins and add further pins (9) and use circlips (10) to lock in place.

4.6. Attach the pump and air motor to the right hand post using bolts (18) and washers (2).

4.7. Attach the ram assembly (15) to the upper cross beam using bolts (21) and compression springs (20).

4.8. Connect the hydraulic hose (27) to the ram (15) (A to A) and assemble the pressure gauge (13) to the ram assembly (C to C).

4.9. Tighten all nuts, bolts and screws.

5. INSTALLATION

▲DANGER! The press is top heavy. If it requires moving after assembly or for relocation, use suitable slings around the top

crossbeam, or lift direct with a forklift with the forks located under the top crossbeam. DO NOT use a pallet truck.

5.1. Securely attach the press to a flat, firm, level surface taking into account clearance for working pieces.

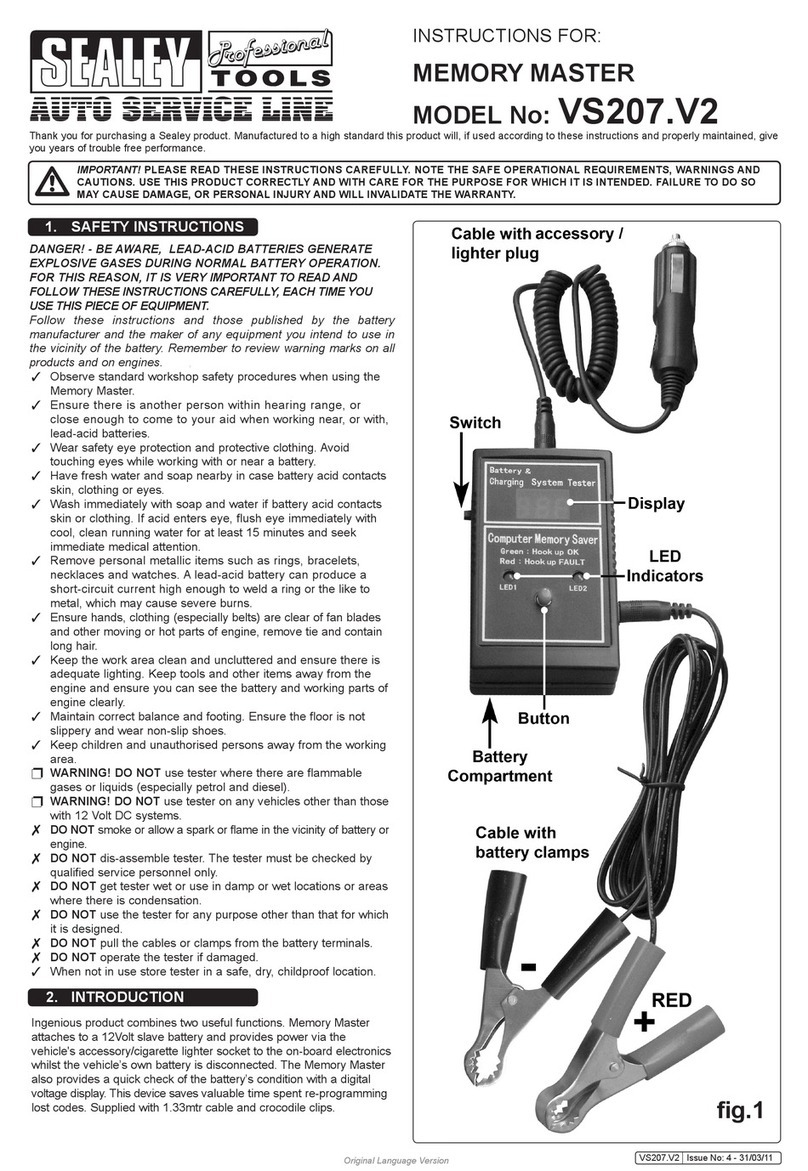

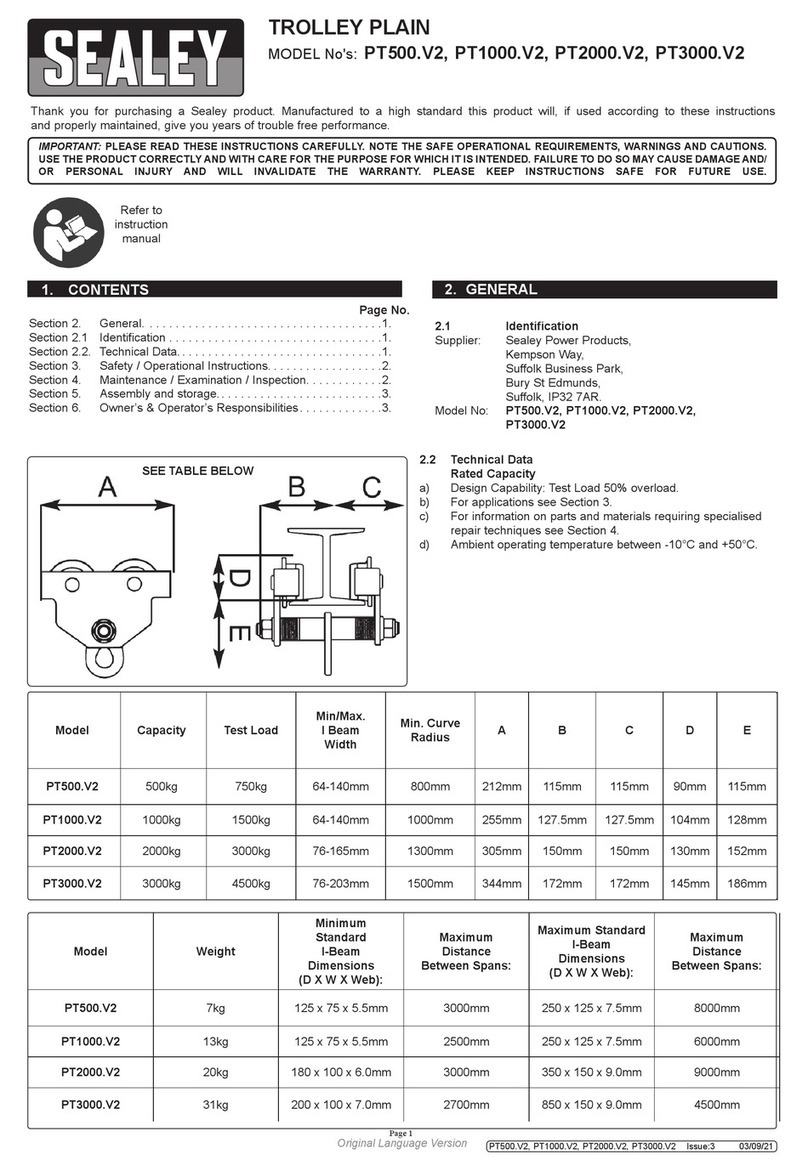

5.2. Connect to an air supply as recommended in fig.1. The air supply must be capable of 108 to 123psi and 9cfm.

5.3. Purge hydraulic system. Before operating the press, the hydraulic system may require purging in order to eliminate any air that may have

built up during transit.

5.4. Manual Operating System: Open the release valve (33) by turning anti-clockwise and pump the handle several times.

5.5. Air Operating System: Open the release valve (33) by turning anti-clockwise and connect the air valve to the air line system, operate the

air valve, allowing the pump to operate until the air has been purged. Should the system malfunction at any time, repeating either of

these procedures may resolve the problem.

6. OPERATION

▲DANGER! This model is purpose designed to withstand greater loads than the hydraulic units can develop. For safety reasons, always

ensure the workpiece and press tools are secured on the table and will not flex or suddenly “give way” causing danger to operator or the

component.

6.1. Connect the air valve to the air supply.

6.2. Check that the release valve on the hydraulic unit is fully closed, ready for operation.

6.3. Locate the flat pressing plates or the v-blocks on to the bed frame, push down the locating pins to ensure the plates do not slip. Place

workpiece onto the plates and position the head of the hydraulic unit on the centre of the workpiece using an appropriate extension.

NOTE: Care must be taken to ensure the plates do not fall from the bed frame.

WARNING! DO NOT apply off centre loads.

6.4. When work is complete turn the release valve anti-clockwise to release the pressure and the piston and the ram head will retract

automatically. NOTE: Always keep the piston retracted after use.

6.5. Disconnect the air valve from the air supply.

7. MAINTENANCE

NOTE: Maintenance and repair must only be carried out by qualified person. Contact your Sealey stockist for details.

7.1. When the press is not in use, the hydraulic unit ram must be fully retracted to minimise corrosion. Remove the handle to inactivate the

press.

Original Language Version

© Jack Sealey Limited

fig.1.

YK309FAH Issue 2 (H, F) 30/11/18