SPYKER 88 User manual

Other SPYKER Spreader manuals

SPYKER

SPYKER S60-12020 User manual

SPYKER

SPYKER PRO Series User manual

SPYKER

SPYKER S100-12011 User manual

SPYKER

SPYKER S40 Series User manual

SPYKER

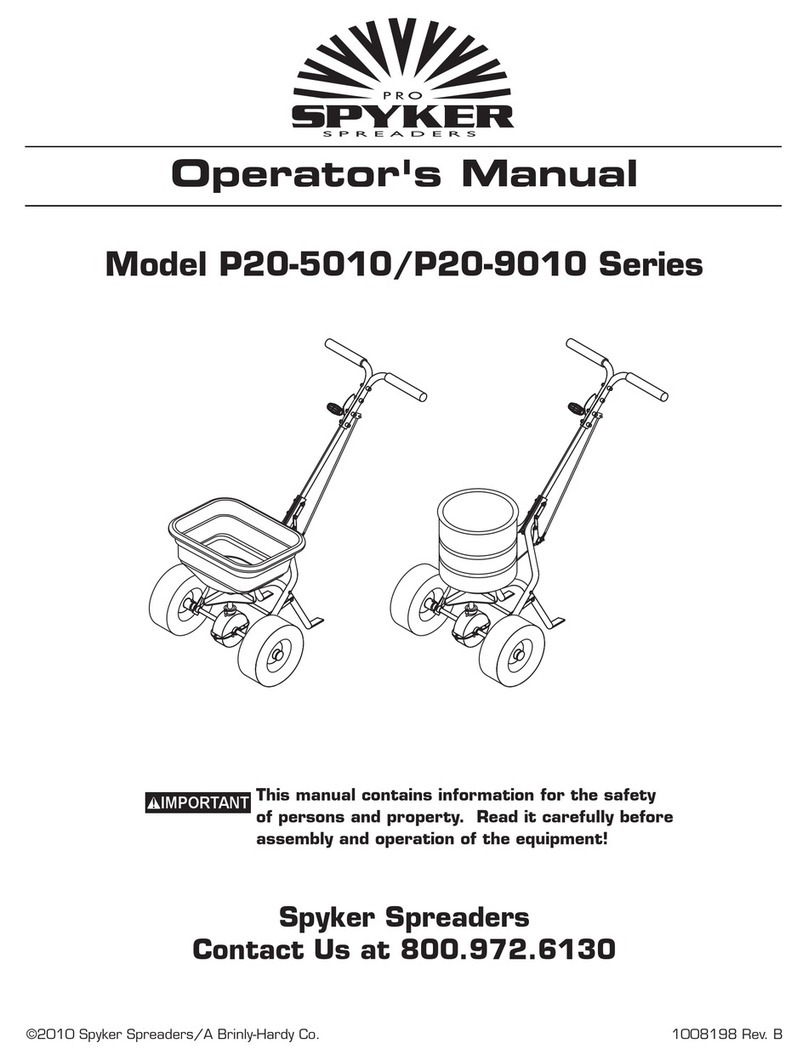

SPYKER P20-5010 Series User manual

SPYKER

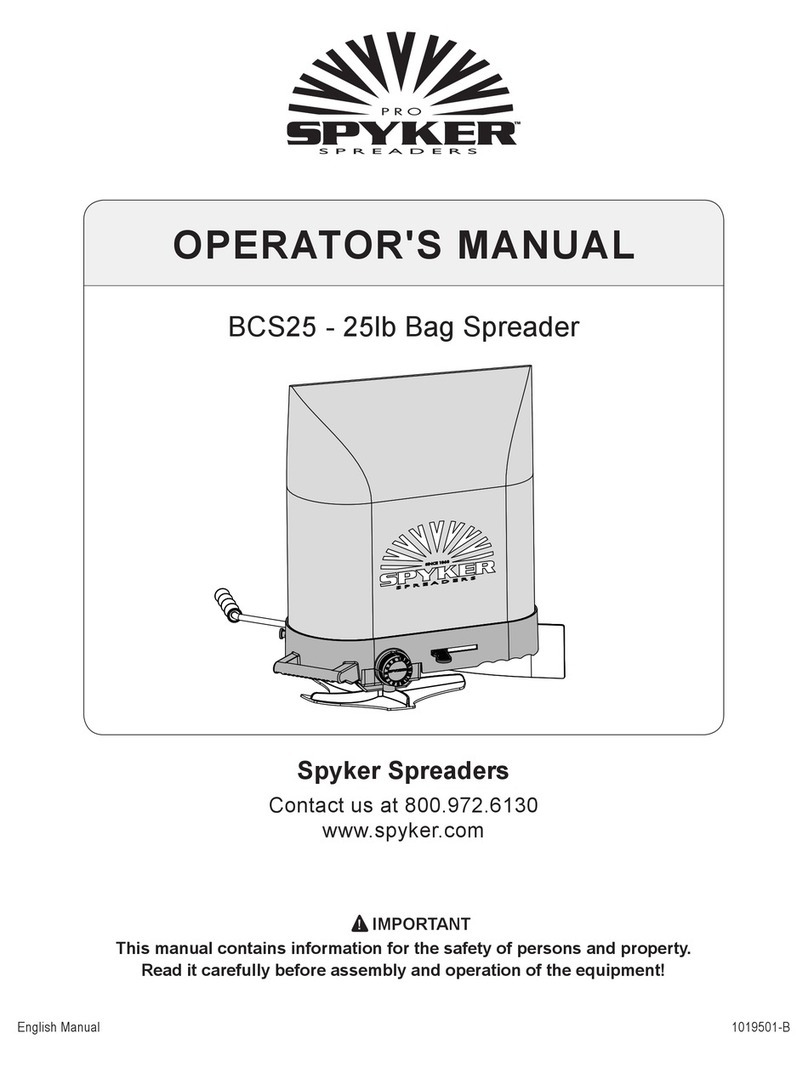

SPYKER BCS25 User manual

SPYKER

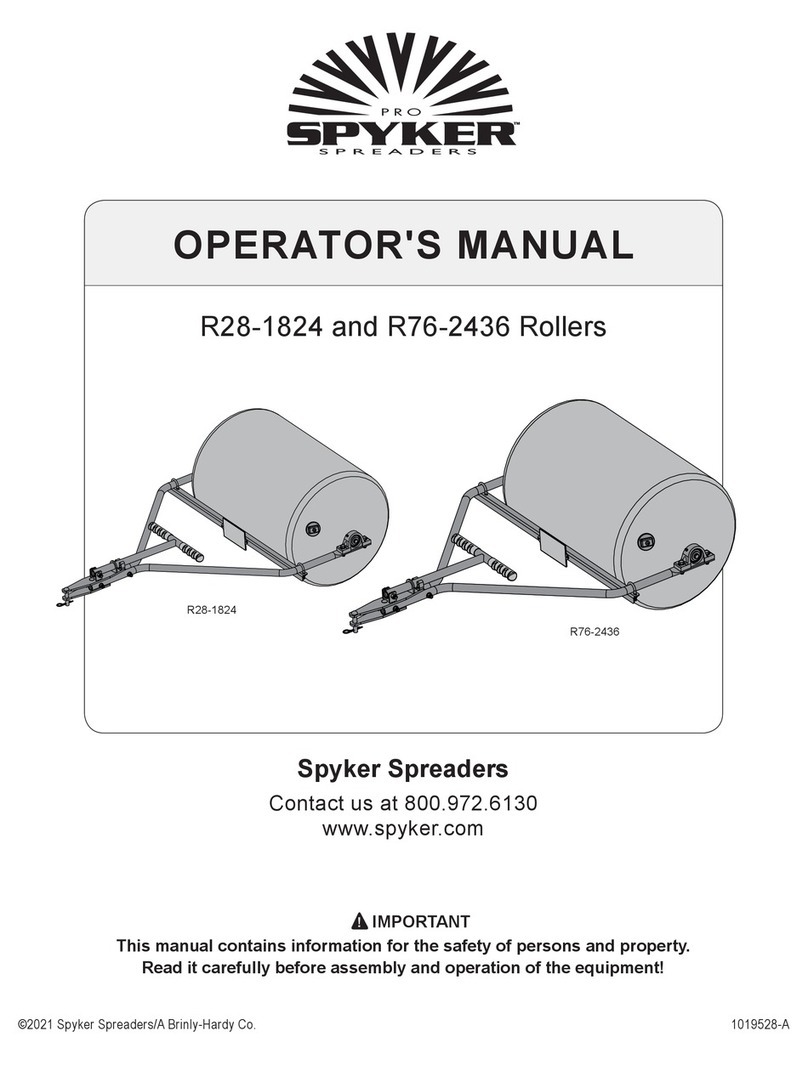

SPYKER R28-1824 User manual

SPYKER

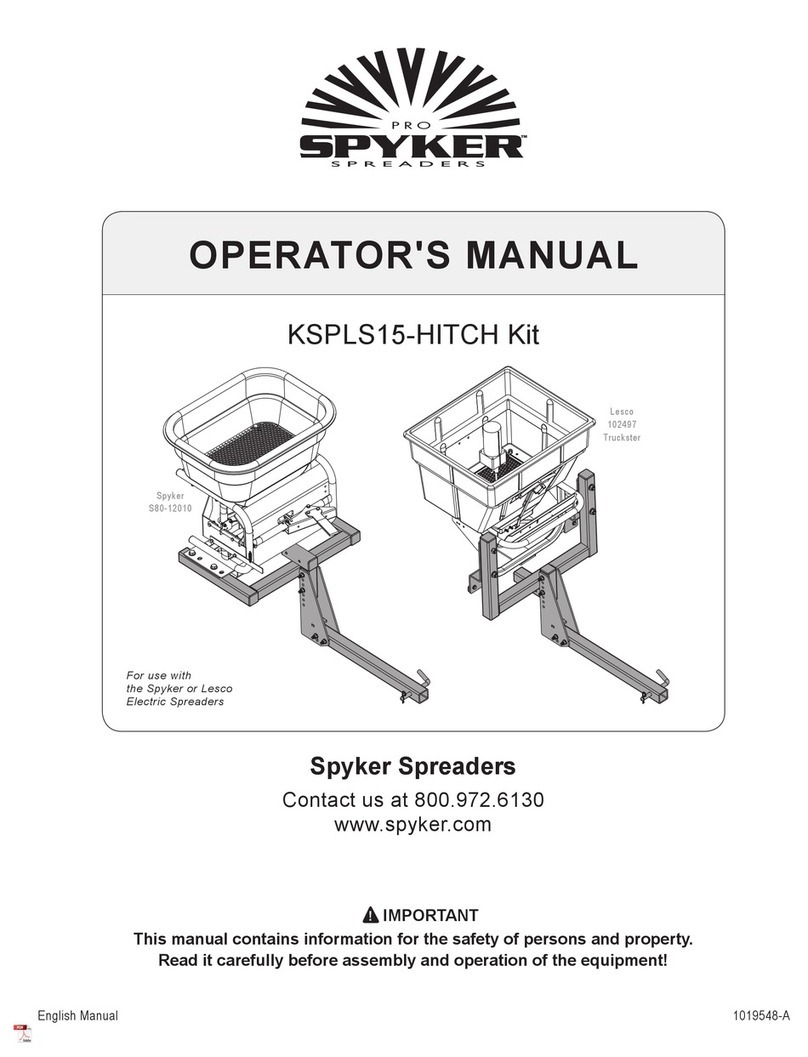

SPYKER KSPLS15 User manual

SPYKER

SPYKER S100-12010 User manual

SPYKER

SPYKER S80-12010 User manual

Popular Spreader manuals by other brands

Fisher

Fisher POLY-CASTER 78601 owner's manual

TurfEx

TurfEx RS7200 Owner's/operator's manual

Fayat Group

Fayat Group DYNAPAC S100 operation & maintenance

Art's-Way Manufacturing

Art's-Way Manufacturing X700 Operator's manual & parts list

Ferris

Ferris Pathfinder Series Operator's manual

EASTMAN

EASTMAN CR 500 instruction manual