SRS Labs FCX Series User manual

FCX SERIES POINT TYPE

GAS DETECTOR

INSTRUCTION MANUAL

2

CONTENTS

SUMMARY.......................................................................................................................................................................... 3

NOTICE............................................................................................................................................................................... 5

PARTS VIEW........................................................................................................................................................................ 6

REMOTE CONTROLLER ....................................................................................................................................................... 7

OPERATION INSTRUCTION.................................................................................................................................................. 8

ADJUSTMENT INSTRUCTION ............................................................................................................................................ 10

PARAMETERS INSTRUCTION............................................................................................................................................. 11

COMMON GAS INSTRUCTION .......................................................................................................................................... 12

PRODUCT SIZE.................................................................................................................................................................. 13

INSTALLATION .................................................................................................................................................................. 14

WIRE TERMINAL INSTRUCTION ........................................................................................................................................ 15

INSTALLATION PRINCIPLES ............................................................................................................................................... 16

TROUBLESHOOTING......................................................................................................................................................... 17

SERVICE COMMITMENT ................................................................................................................................................... 18

3

SUMMARY

FCX SERIES INCLUDING FOLLOWING PRODUCT INFORMATIONS

a) FCX POINT POINT TYPE COMBUSTIBLE GAS DETECTOR RANGE 0~100%LEL

b) FCX/APOINT TYPE GAS DETECTOR

c) FCX/B POINT TYPE GAS TECTOR

d) FCX/B2 POINT TYPE GAS DETECTOR

The detector is capable of continuous monitoring of the gas under industry environment that can be

measured, and transfer the concentration of gas into the 4-20mA signal, transmitte to the gas alarm

controller or DCS system for display and processing.

4

This series of product design, manufacturing, test verification regulation of national standards, to comply

with the following

GB15322.1-2003 《combustible gas detector PART ONE:combustible point type gas tector for testing range

0~100%LEL》

GB12358-2006 《General requirements of technology for gas detection and alarm instruments under

workplace ambient》

JJG 693-2011 《Combustible gas detection alarm》

JJG 551-2003 《Sulfur dioxide gas detector》

JJG 915-2008 《Carbon monoxide detection alarm》

JJG 695 -2003《Hydrogen sulfide gas detector》

JJG 365 -2008《Electrochemical oxygen measuring instrument》

5

NOTICE

Be sure to read this manual carefully before installation,operation and maintainess

The installation and operation must strictly comply with the relevant national standards.

Any operation on the detector must be performed by professional people.

Operation with power is strictly forbidden(such as installation, changing parts)

The detector must be safely grounded, to avoid influence by radio frequency interference.

The sensor may contain corrosive solution, should be particularly careful when handling.

Never disassemble sensor.

Do not put the detector working in ambient termperature exceed its range

The impact of high concentration gas to sensor is prohibited.

Change the sensor in time when the lifetime expires

6

PARTS VIEW:

Exploded view

No.

Part name

1

Top lid

2

seal

3

glass

4

Pressure ring

5

Display modular

6

Sensor connector

7

Bottom cabinet

8

Holow screw

9

Wire box cover

10

Wire box

11

Hollow screw

12

Grounding screw

Note :This chart is for models FCX、FCX/A、FCX/B、FCX/B2

7

Remote controller:

Picture

Items

Description

Mute

Back

Ok

Confirm

Bit selection

Bit selection

▲

Bit value added

▼

Bit value reduced

1

The infrared

emission tube

8

Operation instruction:

Parameter

setting

password

operation

“LOW ALARM”

“1111”

Press “FUNCTION”BUTTON 》》 Input password - - - - 》》 Press“ok”„„

Press“LOW ALARM”button,low alarm“AL”flash 》》 “ ”、“ ”bit selection,

“▼”、“▲”adjust low alarm value „„

press“ok”, show“good”, saved and exit

press“ ”,show“ESC”, exit without saving

“HIGH ALARM”

“1111”

press“function”button 》》 input password - - - - 》》 press“ok”„„

press“HIGH ALARM”button,high alarm“AL”flash 》》 “ ”、“ ”bit selection,

“▼”、“▲”adjust high alarm value „„

press“ok”, show“good”, save and exit

press“ ”,show“ESC”, exit without saving

“TESTING

RANGE”

“0911”

press“function”button 》》 input password - - - - 》》 press“ok”„„

Testing range:( testing range setting)

Press “TESTING RANGE”button,concentration value flash,》》 “”、

“ ”bit selection,“▼”、“▲”adjust value „„

9

“Zero

calibration”

“Spam”

“calibration

”

“6677”

Press “function”button 》》 input password - - - - 》》 press“ok”„„

Zero calibration:( Zero calibration of detector)

press“Zero calibration”button,show“ ”、“zero value”》》 press

“ok”button after the value is stable

spam:( standard gas concentration)

Press “spam”button,show“”、“ spam value”》》 “ ”、“ ”bit

selection,“▼”、“▲”adjust value 》》 press“ok”to save and exit

calibration:( calibration gas)

Press“calibration”button,show“ ” 》》 inlet the standard gas 》》

press“ok”after the value is stable,show“good”and save the setting

and exit, and shut off the standard gas.

10

Description of calibration:

picture

Items

Description

①

Gas tank and

pressure relief valve

②

Standard gas hose

③

Standard gas cover

④

Gas detector

11

Parameter instruction:

Model No.

Target

gas

Working

power

Sampling

method

Detection

principle

Communication

mode

Display

mode

Alarm

mode

Signal

output

Explosion

proof

grade

FCX

methane

DC24V ±

15%

Free

diffusion

Catalytic

combustion

Three wires

4-20mA

LCD

Alarm

lamp

(option)

Passive

normally

open

contact

EXd IIC T6

Gb

FCX/A

Flammable

liquid,

organic

vapor

DC24V ±

15%

Free

diffusion

Catalytic

combustion 、

semiconductor

Three wires

4-20mA

LCD

Alarm

lamp

(option)

Passive

normally

open

contact

EXd IIC T6

Gb

FCX/B

Toxic and

harmful

gas

DC24V ±

15%

Free

diffusion

Electrochemical,

infrared,

semiconductor

Three wires

4-20mA

LCD

Alarm

lamp

(option)

Passive

normally

open

contact

EXd IIC T6

Gb

FCX/B2

Toxic and

harmful

gas

DC24V ±

15%

Free

diffusion

electrochemical

Two wires

4-20mA

LCD

EXd IIC T6

Gb

12

COMMON GAS INSTRUCTION:

GAS

Testing

range

resolut

ion

Alarm

point

Working

temp

Working

himidity

Working

pressure

Resp

onse

time

Lifeti

me

(month

s)

Gas

interfere

nce

methane

0-100%LEL

1%LEL

25%LEL

-40℃~70℃

10~95%RH

86~106kpa

≤30

24

Flammable

liquid,

organic vapor

0-100%LEL

1%LEL

25%LEL

-20℃~50℃

10~95%RH

86~106kpa

≤30

24

CO

0-1000ppm

1ppm

80ppm

-20℃~50℃

10~95%RH

86~106kpa

≤60

12

NO2、HCN 、

Ethylene

H2

0-1000ppm

1ppm

80ppm

-20℃~50℃

10~95%RH

86~106kpa

≤60

12

CO、H2S、NO、

HCN、Ethylene

H2S

0-50ppm

0.1ppm

8ppm

-20℃~50℃

10~95%RH

86~106kpa

≤60

12

SO2、CL2

CL2

0-20ppm

0.1ppm

8ppm

-20℃~50℃

10~95%RH

86~106kpa

≤60

12

NO2

SO2

0-50ppm

0.1ppm

8ppm

-20℃~50℃

10~95%RH

86~106kpa

≤60

12

H2S、HCN、HCL

O2

0-30%VOL

0.1%VOL

18%VOL

-20℃~50℃

10~95%RH

86~106kpa

≤60

12

NH3

0-1000ppm

1ppm

80ppm

-10℃~40℃

10~95%RH

86~106kpa

≤60

12

H2S、SO2、CL2、

NO

NO2

0-20ppm

0.1ppm

8ppm

-20℃~50℃

10~95%RH

86~106kpa

≤60

12

CL2

HCL

0-20ppm

0.1ppm

8ppm

-20℃~45℃

10~95%RH

86~106kpa

≤60

12

HBr、H2S

PH3

0-20ppm

0.1ppm

8ppm

-20℃~45℃

10~95%RH

86~106kpa

≤60

12

SO2、SIH4

13

PRODUCT SIZE

MODELS

FCX、FCX/A, FCX/B

FCX/B2

SIZE:

190mm×130mm×75mm;

14

INSTALLATION:

longitudinal transverse wall mounting

The detector installation can adopt longitudinal, transverse, wall mounting, make sure the installation is

stable

The installation hole size is Φ8mm

The mounting hole spacing (see above the installation location of hole size

Make the sensor downwards fixed

After correcting line, the detector cover should be fixed so to achieve explosion-proof

requirement.

15

WIRE TERMINAL INSTRUCTION

Picture

INSTRUCTION

Three wires system 4-20mA

communications:

FCX

FCX/A

FCX/B

Two wires system 4-20mA

communications:

FCX/B2

16

INSTALLATION PRINCIPLES:

The effective coverage radius for combustible gas detector, indoor 7.5 meter, outdoor 15 meter. One detector can be

set within the effective coverage area.

The distance between toxic gas detector and the gas source: less than 2 meters outdoor, less than 1 meter indoor.

The detector installation position should be selected within one meater near to valve, pipe interface, air outlet,

and as closer as possible but no influence to other equipment.

Detectors should be installed in place that gas is easy to leak, easy flow of andd easy to stay, installation

location should be based on the measured gas density, on-site installation direction of flow, temperature and

other conditions to determine.

Detection of methane, hydrogen air fuel ratio of light and / or poisonous gas, its installation height should be

higher than the release source 0.5~2m, horizontal distance and the release of the source should be less than

5m.

Detection combustible gas or toxic gas which is heavier than air, the recommended installation height should be

higher than floor by 0.3~0.6m, and the horizontal distance to the gas source shoulbe be less than 5 meter. Too low

installation may lead water and too high will beyond its accumulation height.

17

When the molecular weight of detection gas is similar to natural air and easy to mix(like carbon monoxide),

the detector should be located within one meter higher or lower of the gas source. The detector should be

installed higher than the gas source when toxic gas is lighter than natural air, and otherwize lower than the gas

source.

TROUBLE SHOOTING:

Open the detector top cover and check if the power is normal, then make treatment as following:

Error

Reasons

Resolution

remark

“E1”

Sensor fault

1.Re-connect the sensor

2.Change sensor

“E3”

Memory chip fault

Send memory chip back to factory for reparing

18

SERVICE COMMITMENT:

We provide one year warranty from the date of leaving factory.(human factors and force majeure excepted)。

The liftime of the sensor in normal use: 2 years for catalytic combustion type sensor, 1 year for

electrochemistry type. The actual service life of the sensor is directly related to the work environment, the

environment is different, the service life of the sensor will change

To assure the reliability of the product, we suggest to make regular maintenance and adjustment.

SRS INTL Direct, Inc.

Web:www.srsintldirect.com

Add:41590 Winchester Rd, Ste 200-249, Temecula, CA. 92590

Tel:866-477-7372

Table of contents

Popular Gas Detector manuals by other brands

Sensitron

Sensitron SMART3G instruction manual

SANJIANG

SANJIANG JTQ-BF-06TLLoRa user manual

GEV

GEV FlammEx 003149 manual

BEINAT

BEINAT SGM595-H2CH Installation and user guide

Elsner

Elsner Intra-Sewi TWIN L-Pr Installation and startup

International Gas Detectors

International Gas Detectors TOC-635 Installer's guide

Inficon

Inficon GAS-Mate operating manual

Emerson

Emerson MRLDS-250 Installation and operation manual

Medem

Medem AGDS-M installation instructions

Southern Cross

Southern Cross 46 HAWK 3.0 manual

BW Technologies

BW Technologies GasAlertClip Extreme H2S instruction sheet

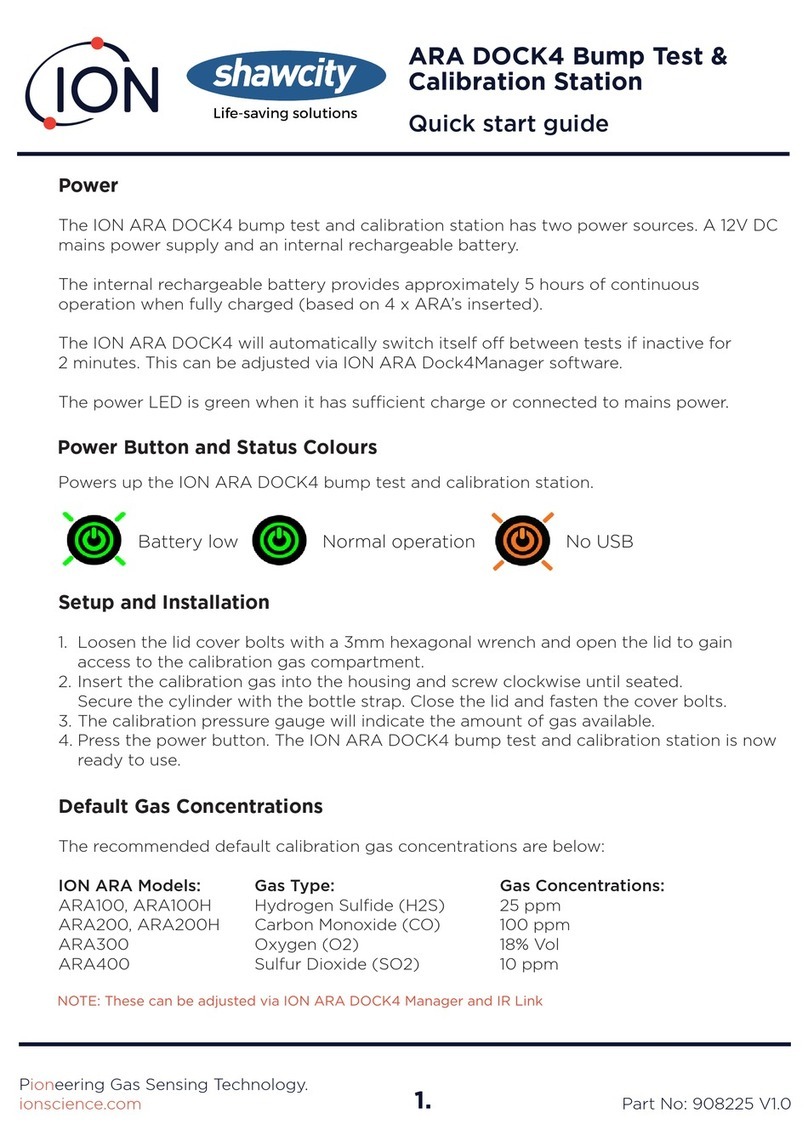

ION

ION shawcity ARA DOCK4 quick start guide