SRS Labs SR715 User manual

User’s Manual

Model SR715

Model SR720

LCR Meters

1290-D Reamwood Avenue

Sunnyvale, California 94089

Phone: (408) 744-9040 • Fax: (408) 744-9049

Copyright © 1991 by SRS, Inc.

All Rights Reserved.

Revision 1.5 (09/2001)

TABLE OF CONTENTS

i

GENERAL INFORMATION

Safety and Preparation for Use iii

Specifications v

Basic Operation viii

Passive Devices viii

Series and Parallel Circuit Models ix

Typical Measurement Setups x

How the SR715/720 Works xi

Abridged Command List xii

Status Bytes xiii

GETTING STARTED

SR715/720 1-1

Display 1-2

Keypad 1-3

Fixture 1-5

Rear Panel 1-6

OPERATION

Display 2-1

Displayed Parameters 2-1

Series & Parallel Equivalent Circuits 2-2

Display Types 2-2

Status & Binning 2-3

Test Conditions 2-4

Default Conditions 2-4

Setting Test Conditions 2-4

Frequency 2-4

Output Voltage 2-4

Range 2-6

Autoranging 2-6

Range Hold 2-6

Constant Voltage 2-7

Bias 2-8

Internal Bias 2-8

External Bias 2-9

Measurement Rate 2-9

Settling Time 2-10

Triggering 2-10

Store and Recall 2-11

Connecting a Device 2-12

Radial Leaded Parts 2-12

Axial Leaded Parts 2-12

Component Dimensions 2-13

Optional Fixtures 2-13

Fixture Adapter 2-13

Kelvin Clips 2-14

SMD Tweezers 2-14

BNC Adapter 2-15

Open & Short Calibration 2-16

Suggestions for Calibration 2-16

Radial Fixture 2-16

Axial Fixture Adapter 2-16

Kelvin Clips 2-16

SMD Tweezers 2-17

Other Fixtures 2-17

Binning 2-18

Setting Up the Bins 2-19

Examples 2-20

Binning Worksheet 2-21

Option 01: GPIB Handler Interface 2-22

ACCURACY

Conditions 3-1

Impedance Accuracy 3-2

R+Q Accuracy 3-4

L+Q Accuracy 3-5

C+D Accuracy 3-6

C+R Accuracy 3-7

Accuracy With Range Hold 3-8

PROGRAMMING

GPIB Communications 4-1

RS232 Communications 4-1

Front Panel LEDs 4-1

Command Syntax 4-1

Programming Errors 4-2

No Command Bit 4-2

Detailed Command List 4-3

Measurement Setup Commands 4-3

Measurement Control Commands 4-4

Measurement Result Commands 4-4

Binning Commands 4-6

Setup & Control Commands 4-7

Status Reporting Commands 4-7

Test & Calibration Commands 4-8

Status Byte Definitions

Serial Poll Status Byte 4-10

Standard Event Status Byte 4-11

LCR Status Byte 4-11

Program Examples

Microsoft C, Nat'l Instruments GPIB 4-12

Microsoft C, CEC GPIB 4-14

Binning 4-17

IBM BASIC, RS232 4-21

TESTS and CALIBRATION

Functional Tests 5-1

Front Panel Test 5-1

Self Test 5-2

TABLE OF CONTENTS

ii

Output Voltage 5-2

Resistance Measurement 5-2

Capacitance Measurement 5-2

Performance Tests 5-4

Frequency Accuracy 5-4

Amplitude Accuracy 5-5

Impedance Accuracy 5-5

Resistance Accuracy 5-5

Capacitance Accuracy 5-6

Performance Test Record 5-8

Calibration 5-10

Introduction 5-10

Calibration Enable 5-10

Calbytes 5-10

Amplitude Calbytes 5-11

Floating Point Calbytes 5-11

Amplitude Calibration 5-12

Frequency Calibration 5-13

Standard Resistor Calibration 5-13

TROUBLESHOOTING and

MAINTENANCE

Nothing Happens at Turn On 6-1

Reset 6-1

Internal Fuse 6-1

External Bias Fuse 6-1

Error Messages 6-2

Operations Errors 6-2

Self-test Errors 6-2

Calibration Errors 6-4

GPIB Problems 6-4

RS232 Problems 6-4

Fixture Maintenance 6-5

Cleaning 6-5

Removing Leads 6-5

Changing Radial Contacts 6-5

SMD Tweezer Maintenance 6-7

Cleaning 6-7

Tip Replacement 6-7

PARTS and SCHEMATICS

Parts List 7-1

Schematic Diagrams 7-13

SR715/720 LCR METER

iii

SAFETY AND PREPARATION FOR USE

WARNING

Dangerous voltages, capable of causing injury or death, are present in this instrument. Use extreme caution

whenever the instrument cover is removed. Do not remove the cover while the unit is plugged into a live outlet.

CAUTION

This instrument may be damaged if operated with

the LINE VOLTAGE SELECTOR set for the wrong

AC line voltage or if the wrong fuse is installed.

LINE VOLTAGE SELECTION

The SR715/720 operates from a 100V, 120V,

220V, or 240V nominal AC power source having a

line frequency of 50 or 60 Hz. Before connecting

the power cord to a power source, verify that the

LINE VOLTAGE SELECTOR card, located in the

rear panel fuse holder, is set so that the correct AC

input voltage value is visible.

Conversion to other AC input voltages requires a

change in the fuse holder voltage card position and

fuse value. Disconnect the power cord, open the

fuse holder cover door and rotate the fuse-pull

lever to remove the fuse. Remove the small

printed circuit board and select the operating

voltage by orienting the printed circuit board so that

the desired voltage is visible when pushed firmly

into its slot. Rotate the fuse-pull lever back into its

normal position and insert the correct fuse into the

fuse holder.

LINE FUSE

Verify that the correct line fuse is installed before

connecting the line cord. For 100V/120V, use a 1/2

Amp fuse and for 220V/240V, use a 1/4 Amp fuse.

LINE CORD

The SR715/720 has a detachable, three-wire

power cord for connection to the power source and

to a protective ground. The exposed metal parts of

the instrument are connected to the outlet ground

to protect against electrical shock. Always use an

outlet which has a properly connected protective

ground.

BIAS VOLTAGE ON CAPACITORS

Verify that polarized capacitors are installed with

the correct polarity before applying a bias voltage.

Failure to do so can result in damage to the unit,

the device under test, or possible injury. The

SR715/720 fixture and remote fixtures are marked

with '+' and '-' signs, or by red leads for the positive

connectors. Capacitors charged by an external

bias voltage should be discharged after making the

measurement. A 40 volt external bias can charge a

capacitor to a high enough voltage that it can

cause injury if it is accidentally discharged. See the

section on BIAS for more information on how to

safely apply external bias voltage.

When connecting the external bias voltage to the

unit, observe the correct polarity and make certain

that the bias supply is floating (neither side is

connected to ground). Be certain to use a supply

current limited to 250 mA or less.

PROTECTION FUSES

In addition to the line fuse, the SR715/720 has two

other protection fuses. The external bias fuse

(3AG 0.25 A) is installed on the rear panel, next to

the bias terminals. If unstable readings occur when

making measurements with an external bias,

check this fuse. The other fuse is an output

protection fuse (2AG 0.25 A) located internally on

the main PCB. If unstable or erratic readings occur

or an 'outPut Err' (output err) occurs during self

test, this fuse may be damaged. See the

maintenance section for more information.

SERVICE

Do not attempt to service or adjust this instrument

unless another person, capable of providing first

aid or resuscitation, is present. Do not install

substitute parts or perform any unauthorized

modifications to this instrument. Contact the

factory for instructions on how to return the

instrument for authorized service and adjustment.

SR715/720 LCR METER

iv

SR715/720 LCR METER

v

GENERAL INFORMATION

The SR715/720 LCR Meters are multifrequency impedance measuring instruments, capable of measuring

resistance, capacitance or inductance over a range of more than 13 orders of magnitude. The SR720 has a

basic accuracy of 0.05% and has 5 test frequencies. The SR715 has a basic accuracy of 0.2% and 4 test

frequencies.

The LCR meters are controlled by a high speed microcontroller that operates the display, keypad, RS232 and

GPIB computer interfaces, and handler interface, as well as setting measurement conditions and performing

calculations. In addition, non-volatile storage is provided for 9 complete instrument settings.

SPECIFICATIONS

DISPLAY

Measurement Modes Auto, R+Q, L+Q, C+D, C+R

Equivalent Circuit Series or Parallel

Parameters Displayed Value, Deviation, % Deviation or Bin Number.

Deviation and % deviation are calculated from a stored relative value.

Averaging 2 - 10 Measurements

Measurement Range R+Q: R 0.0001 Ω- 2000 MΩ

Q 0.00001 - 50

L+Q: L 0.0001 µH - 99999 H

Q 0.00001 - 50

C+D: C 0.0001 pF - 99999 µF

D .00001 -10

C+R: C 0.0001 pF - 99999 µF

R .00001 - 99999 kΩ

TEST CONDITIONS

Test Frequency 100 Hz, 120 Hz, 1 kHz, 10 kHz, 100 kHz (100 kHz - SR720 only).

Frequency accurate to ±100ppm.

Drive Voltage Preset Levels: 0.10, 0.25, and 1.0 Vrms.

Vernier: 0.1 to 1.0 Vrms with 50 mV resolution.

Drive levels accuracy ±2%.

Measurement Rate Slow, Medium, Fast: 2, 10, or 20 measurements per second at test

frequencies of 1 kHz and above and about 0.6, 2.4, or 6 measurements per

second at 100 Hz and 120 Hz.

Ranging Auto or Manual

Triggering Continuous, Manual, or Remote over RS232, GPIB or Handler Interface

Bias Voltage Internal: 2.0 VDC ±2%

External : 0 to +40 VDC (fused @ 0.25 A)

SR715/720 LCR METER

vi

ACCURACY

Conditions At least 30 minute warm up, 23 °C ± 5 °C.

Basic Accuracy SR715: 0.20%

SR720: 0.05%

See the Accuracy section for detailed accuracy specifications.

The table below summarizes the typical use accuracy.

Accuracy SR720 SR715

better than 1% 0.125 Ω< R < 16 MΩ0.143 Ω< R < 14 MΩ

2.5 µH < L < 25 kH 2.9 µH < L < 22 kH

1.25 pF < C < 12.8 mF 1.43 pF < C < 11.2 mF

better than 5% 21 mΩ< R < 96 MΩ21 mΩ< R < 94 MΩ

420 nH < L < 150 kH 426 nH < L < 150 kH

0.21 pF < C < 77 mF 0.21 pF < C < 75 mF

The following conditions apply:

1) 1.0, 0.5 or 0.25 V output voltage

2) Slow or medium measurement speed

3) Q and D < 0.1 for R and C

4) Q > 10 for L

5) 100 Hz, 120 Hz or 1 kHz test frequency for R

6) 100 Hz test frequency for Lmax and Cmax

7) 10 kHz test frequency for Lmin and Cmin

FEATURES

Fixture 4-Wire Kelvin fixture for radial leaded parts with adapters for axial leaded

parts.

Protection Protected up to 1 Joule of stored energy, 200 VDC max (for charged

capacitors).

Fused at 0.25 A output current for biased measurement.

Zeroing Open and Short Circuit Compensation.

Compensation Limits Short: R < 20 Ω, Z < 50 Ω

Open: Z > 10 kΩ

Binning Up to 8 Pass Bins, QDR and General Fail Bins, all defined from the front

panel or over the computer interfaces. Binning setups may be stored in non-

volatile memory.

Self Test Tests the ROM, CPU, Non-Volatile RAM, Clock Generator, A/D Converter,

Internal Bias, Multiplier, Output Drive Circuitry, Gain Circuitry, and Source

Resistances.

Store and Recall Stores 9 Complete Instrument Setups. Recall 0 recalls Default Setup.

RS232 Interface All instrument functions can be controlled or read over the interface.

GENERAL

Operating Conditions 0 - 50 °C, <85% relative humidity.

Power 20 Watts, 100/120/220/240 VAC, 50 or 60 Hz.

Dimensions (W x H x L) 13.5" x 4" x 14" (343 x 102 x 356 mm)

Weight 10 lbs (4.55 kg)

Warranty One year parts and labor on materials and workmanship.

SR715/720 LCR METER

vii

OPTIONS

GPIB / Handler Interface Option 01 provides both an IEEE-488 interface and a Handler interface.

IEEE-488 Interface: All instrument functions can be controlled or read

over the interface.

Handler/Sorter Interface: DB25 male connector provides output lines

to indicate binning information and

instrument status and an input trigger line.

Output lines include 8 Pass Bins, QDR Fail

Bin, General Fail Bin, Busy, and Bin Data

Available. Output lines are Open Collector

and are rated to 40 volts. The trigger input is

negative edge triggered TTL and is

protected to +/- 15 Volts.

SR726 Kelvin Clips Provides connection to devices that are not easily accommodated in the

fixture. Polarity is indicated for biased measurements. Connects to

SR715/720 fixture.

SR727 SMD Tweezers Provides connection to Surface Mount Device parts. Polarity is indicated for

biased measurements. Connects to SR715/720 fixture.

SR728 BNC Fixture Adapter Provides a means to connect a remote fixture or other device to the

SR715/720. Connects to SR715/720 fixture and has four 1 meter BNC

cables. Polarity is indicated for biased measurements.

SR715/720 LCR METER

viii

BASIC OPERATION

This section is designed to help the user begin

making measurements with the SR715/720 LCR

meter and to familiarize them with some of its

features. For more information on the different

features, see the operations section.

To operate the SR715/720, first verify that the

correct line voltage has been selected on the

power entry module on the rear panel (See page

1-3). Verify that no parts are in the fixture; the

unit's self test routines will fail if any components

are in the test fixture. After connecting the line cord

to the power entry module, switch on the power

switch, located on the rear right hand side of the

unit. The unit will display the ROM version on the

left display and the serial number on the right

display for about 3 seconds. Next, the unit will

begin its self test procedure. If all tests are OK,

'tESt PASS' will be displayed. See the

Troubleshooting section if the self test fails. Press

[Recall] [0] [ENTER], to recall the default setup.

This will set the unit as follows:

Parameter AUTO

Frequency 1 kHz

Drive Voltage 1.0 Vrms

Bias OFF

Measurement Rate SLOW

Averaging OFF

Range Hold OFF

Equivalent Circuit SERIES

Display VALUE

Trigger Mode CONT

Binning OFF

At this point a part can be placed in the fixture and

measurements can be made. The unit will

automatically decide which type of component is in

the fixture (R, C or L), change to the correct range,

and display the part value with the correct units. If

any of the test conditions need to be changed for a

measurement, press the appropriate keys. Most

functions are easy to change, but if more

information is needed, see the operating section.

The SR715/720 comes with a built in fixture for

measuring radial leaded components, like most

capacitors, and adapters for measuring axial

leaded components, like most resistors. To

measure a radial leaded component, remove any

adapters and put one lead of the component in

each side of the fixture. To measure an axial

leaded component, first install the fixture adapters.

Put the adapters on in the middle of each side of

the fixture, and then slide them until they are

separated by the appropriate distance. Insert the

one lead of the component into each side of the

fixture.

After changing the fixture configuration, it is a good

idea to perform an open and short circuit

calibration. See the operation section for

instructions. If the component leads are

excessively dirty or are coated with wax, clean

them before inserting them in the fixture. The

fixture contacts will usually make contact through

coatings, but can eventually get gummed up.

If biased measurements are being made on

capacitors, be certain that the part is installed

with the correct polarity, as marked on the unit.

What is a passive device?

All non-ideal passive devices (resistors, inductors

and capacitors) can be modeled as a real

component (resistor) either in series or in parallel

with a reactive component (capacitance or

inductance). The impedance of these components

change as a function of frequency. The series and

parallel models are mathematically equivalent and

can be transformed back and forth with the

equations shown below.

Usually one model is a better representation of the

device under operating conditions. The most

accurate model depends on the device and the

operating frequency. Certain devices are tested

under conditions defined by the manufacturer or

industry standard. For example, electrolytic

capacitors are often measured in series at 120 Hz

in the C+R mode, so the ESR (equivalent series

resistance) can be measured.

SR715/720 LCR METER

ix

Series and Parallel circuit models

Rs in capacitors is often referred to as ESR or

equivalent series resistance. It includes things like

dielectric absorption in addition to the ohmic losses

due to the leads. It is often listed on data sheets

for electrolytic capacitors used in switching power

supplies. At high frequencies, the ESR is the

limiting factor in the performance of the capacitor.

The quality factor, Q, is the ratio of the imaginary

impedance to the real impedance. For inductors, a

high Q indicates a more reactively pure

component. A low Q indicates a nearly pure

resistor. Q varies with frequency. Q is commonly

used to describe inductors. With resistors, often all

that is stated is that the resistor has low

inductance.

The dissipation factor, D, is equal to 1/Q and is the

ratio of the real impedance to the imaginary

impedance. A low D indicates a nearly pure

capacitor. D is commonly used when describing

capacitors of all types.

SR715/720 LCR METER

x

Typical measurement setups

The table below lists suggested test conditions for various types of components. This is by no means the only

set of conditions for measuring, but is a good general "rule of thumb".

Setups for Measuring Typical Parts

Component

Type Value

Parameter

Type

Equivalent

Circuit Frequency

Unknown: Any Auto series 1 kHz

Resistors: < 1 kΩR+Q series 1 kHz

> 1 kΩR+Q series 100 or 120 Hz

< 10 µHL+Q series 100 kHz

10 µH – 1 mH L+Q series 10 kHz

1 mH – 1 H L+Q series 1 kHz

> 1 H L+Q series 100 or 120 Hz

<10 pF C+D parallel 10 kHz

10 pF – 400 pF C+D series or parallel 10 kHz

400 pF – 1 µFC+D series 1 kHz

> 1 µFC+R or C+D series 100 or 120 Hz

SR715/720 LCR METER

xi

How the SR715/720 Works

The SR715/720 measures the impedance of a

component by measuring the voltage across the

part and the current through it. This is done for

both the real and imaginary (90° phase shifted)

components of the signals. The complex ratio of

voltage to current is equal to the complex

impedance. The processor calculates the various

parameters that are displayed, R, C, L, Q or D.

The voltage across the part is generated by Vs.

Both the amplitude and frequency of Vs can be

set. This voltage is applied to the device under test

(DUT) through source resistance Rs, which varies

according to the measurement range. The current

flows to the virtual ground of A1, and through Rr,

the current conversion resistor. The output of A1

provides a signal proportional to the current, I x Rr.

The voltage across the DUT is measured with a

separate signal path providing a 4-wire Kelvin

connection.

The real and imaginary signals are obtained by

multiplying the voltage and current signals with a

reference signal in phase with Vs and one shifted

90 degrees from Vs. These signals are measured

by an integrating A/D converter which is read by

the microprocessor. These values are corrected by

calibration factors, converted to impedances and

finally converted to the appropriate parameters for

display by the processor.

SR715/720 LCR METER

xii

COMMAND LIST

VARIABLES i,j Integers

x Real Number

MEASUREMENT SETUP

$STL(?) {i} Set (query) settling time to between i=2 and i=99 milliseconds.

AVGM(?) {i} Set (query) averaging on (i=1) or off (i=0).

BIAS(?) {i} Set (query) DC bias to internal (i=1), external (i=2), or off (i=0).

CIRC(?) {i} Set (query) equivalent circuit to series (i=0) or parallel(i=1).

CONV(?) {i} Set (query) constant voltage mode on (i=1) or off (i=0).

FREQ(?) {i} Set (query) drive frequency to 100Hz(0), 120Hz(1), 1kHz(2), 10kHz(3) or 100kHz(4).

MMOD(?) {i} Set (query) measurement mode to continuous (i=0) or triggered (i=1).

NAVG(?) {i} Set (query) number of measurements to be averaged from i=2 to i=10.

PMOD(?) {i} Set (query) parameter mode to Auto(0), R+Q(1), L+Q(2), C+D(3), or C+R(4).

RATE(?) {i} Set (query) measurement rate to Fast(0), Medium(1) or Slow(2).

RNGE(?) {i} Set (query) measurement range to 100kΩ(0), 6.4kΩ(1), 400Ω,(2) or 25Ω(3).

RNGH(?) {i} Set (query) range hold to enabled (i=1) or disabled (i=0).

VOLT(?) {x} Set (query) drive voltage to 0.1V ≤x ≤1.00V with 0.05V resolution.

MEASUREMENT CONTROL

PREL(?) {x} Set (query) nominal parameter value for deviation and %deviation to x (Ω,F,H).

STRT Starts a measurement.

STOP Stops the current measurement.

*TRG Same as STRT.

MEASUREMENT RESULT

OUTF(?) {i} Set (query) the output format to verbose (0) or concise (1) ASCII, or verbose (2) or

concise (2) binary.

XALL? Returns major and minor parameters plus bin number.

XBIN? Returns bin number of current measurement.

XDLT? Returns deviation between major parameter and nominal value.

XMAJ? Returns value of the major parameter.

XMIN? Returns value of the minor parameter.

XPCT? Returns percent deviation between major parameter and nominal value.

BINNING

BCLR Clears nominal values and limits for all bins. All bins are closed.

BING(?) {i} Set (query) binning to enabled (i=1) or disabled (i=0).

BLIM(?) i,j {,x} Set (query) upper (i=0) or lower (i=1) limit of bin j (0-7) to x%.

BNOM(?) i {,x} Set nominal value of bin i to x.

SETUP CONTROL

*IDN? Returns the SR715/720 identification string.

*OPC(?) Set bit in Standard Event Status byte when measurement complete.

*RCL i Recall setting i.

*RST Reset unit to default configuration.

*SAV i Save current setup as setting i.

*WAI Wait until all measurements are completed before proceeding.

STATUS

*CLS Clear all status registers.

*ESE(?) {i} Set (query) the Standard Event Status Byte Enable register to value i (0-255).

*ESR? {i} Query Standard Status byte. If i is included, only bit i is queried.

*PSC(?) {i} Set (query) power-on status clear bit to clear (i=1) or maintain (i=0) status values.

*SRE(?) {i} Set (query) the Serial Poll Enable register to value i (0-255).

*STB? {i} Query Serial Poll status byte. If i is included, only bit i is queried.

SR715/720 LCR METER

xiii

SENA(?) {i} Set (query) LCR Status Enable register to value i (0-255).

STAT? {i} Query LCR Status byte. If i is included, only bit i is queried.

STATUS BYTE DEFINITIONS

SERIAL POLL bit name usage

STATUS BYTE 0 Ready The SR7XX is ready to perform a measurement.

1 unused

2 unused

3 LCR An unmasked bit in the LCR status register has been set.

4 MAV The GPIB output queue is non-empty

5 ESB An unmasked bit in the standard status byte has been set.

6 RQS/MSS SRQ (Service Request)bit.

7 No Command There are no unexecuted commands in the input queue

STANDARD EVENT bit name usage

STATUS BYTE 0 OPC Set by the OPC command when all measurements are

complete

1 unused

2 Query Error Set on output queue overflow (Too many responses waiting

to be transmitted.)

3 unused

4 Execution err Set by an out of range parameter, or non-completion of some

command due a condition such as an incorrect operating

mode.

5 Command err Set by a command syntax error, or unrecognized command

6 URQ Set by any key press

7 PON Set by power on

LCR bit name usage

STATUS BYTE 0 Math Error Set on a floating point error.

1 A/D Error Set when an A/D conversion fails.

2 Overload Set when the gain stage is overloaded.

3 Underrange Set when a measurement is below the nominal range of

values for the present range.

4 Overrange Set when a measurement is above the nominal range of

values for the present range.

5 Out of Range Set when the unit is unable to make a valid measurement on

the current range.

6 unused

7 mem err the stored settings were invalid on power up.

GETTING STARTED

1-1

SR715/720 LCR METERS

This section of the manual provides an overall view

of the SR715/720. For detailed operating

information on specific features, see the Operating

and Programming sections.

GETTING STARTED

1-2

DISPLAY

The LED display shows measured values, entered

parameters, instrument status, and user

messages. There are two 5-digit LED displays and

25 indicator LEDs. When making normal

measurements, the major parameter (L, C, or R) is

shown on the left display and the appropriate

minor parameter (Q, D or R) is shown on the right

display. The number of displayed digits and the

location of the decimal points are automatically

adjusted according to the range and resolution.

The measured parameters (L, C, or R and Q, D, or

R) are indicated by the LEDs above each numeric

display. If the AUTO LED is also on, the unit is in

the auto parameter mode. The % LED indicates

that the measurement is displayed as a relative

deviation from an entered nominal value. Units are

indicated by the LEDs located between the two

displays: Ω, kΩ, MΩ, µH, mH, H, pF, nF or µF. The

minor parameter is dimensionless (Q and D) or

has the units of Ohms for resistance, unless the

kΩLED on the right is on. Status information

(REM, ACT and ERR) is shown to the right of the

minor parameter. Beneath the major parameter

display are indicators for entering binning values,

NOMinal, +LIMit and -LIMit.

GETTING STARTED

1-3

KEYPAD

The keypad is used to select measurement

conditions and to enter values. LEDs indicate the

actual

measurement conditions.

PARAMETER

The [R+Q], [L+Q], [C+D], [C+R], and [AUTO] keys

select the parameter being measured. The

selected parameter pair is indicated above the

major and minor parameters in the display. If

AUTO is selected, the unit will select the most

appropriate parameter pair and turn on the AUTO

LED above the major parameter display.

FREQUENCY

The [UP Arrow] and [DOWN Arrow] keys select

one of the following output frequencies: 100 Hz,

120 Hz, 1 kHz, 10 kHz or 100 kHz (SR720 only).

The LEDs indicate the selected frequency.

DRIVE VOLT

The [Select] key cycles through the three output

drive voltages, 0.1 V, 0.25 V and 1.0 V. The

selected voltage is indicated by the LEDs. If no

LED is on then the output drive voltage is in the

vernier mode.

The [Cons Volt] key places the unit in the constant

voltage mode.

BIAS

[Internal] selects a 2.0 VDC internal bias. [External]

selects an external bias source. Pressing the

active key ([Internal] when internal bias is already

selected or [External] when external is selected)

turns the bias off.

Note that the bias is used only for capacitance

measurements. Pressing either of these keys in

any other mode, including the auto mode, will

display the error "bias for C".

MEAS RATE

The [Rate] key selects a slow, medium or fast

measurement. These rates correspond to 2, 10, or

20 measurements per second at measurement

frequencies of 1 kHz or higher.

AVERAGE

The [Average] key places the unit in the averaging

mode. Pressing it a second time returns the unit to

the non-averaged mode. The number of readings

averaged is set to between 2 and 10 from the entry

display.

RANGE HOLD

[Range Hold] holds the unit in its current

measurement range. Pressing the key a second

time returns the unit to autoranging or normal

GETTING STARTED

1-4

mode. The range can also be entered with the

numeric keys in the entry display.

EQUIV CIRCUIT

The [Equiv Circuit] key selects between a series or

parallel equivalent circuit model of the component

being measured.

DISPLAY

The [Display] key selects the parameter on the

display. Pressing [Display] cycles through the

following display types.

VALUE the value being measured

DEV the deviation of the value from an

entered value

%DEV the percent deviation from the

nominal

ENTRY for entering parameter values

BINS the bin number when binning is

enabled

Certain displays are not accessible unless data

has been entered. For example DEV and %DEV

are not available unless a nominal value has

already been entered. Also, BINS is not available

unless binning data has been entered.

<-

The [<-] (backspace) key is used for correcting

mistakes when entering numeric data. The [<-]

also serves as the LOCAL key. If the [<-] is held

down when the unit is powered on, the instrument

settings revert to the factory set defaults.

ENTER KEYS

[ž, µ

µµ

µH, pF] [kž, mH, nF] [Mž, H, µ

µµ

µF]

The three enter keys are used when entering

numeric parameters in the entry display, such as

nominal values of R, C, or L. The [Mž, H, µF] key

acts as a general purpose [ENTER] key for

parameters with units not listed on any key, such

as percent. This key is labeled on the panel above

the key.

NUMERIC KEYS [0]..[9], [.], [+/-]

The numeric keys enter parameters and are only

active when the unit is in the entry display.

STORE and RECALL

The unit can store up to 9 complete instrument

setups in non-volatile memory. To store the

present configuration as setup #n, press [Store] [n]

[ENTER] where n ranges from 1 through 9. To

recall an instrument configuration, press [Recall]

[n] [ENTER]. Recall 0 returns the instrument to its

default values.

CALIBRATE

The [Calibrate] key allows access to a series of

calibration features and special configurable

parameters, including open/short circuit calibration,

standard calibration, settling time, vernier output

drive amplitude, and the internal self tests.

BIN#, NOMINAL and LIMIT

These keys are used to enter binning parameters.

The BINNING LED is on when binning is enabled

and the optional handler is active.

TRIGGER and MODE

The [Mode] key selects between continuous

(CONT), or triggered measurements.

Measurements are triggered by the [Trigger] key,

the handler interface or either of the computer

interfaces.

GETTING STARTED

1-5

FIXTURE

A versatile test fixture is provided with the

SR715/720 that provides a 4 wire Kelvin

connection to most types of leaded devices. (A

Kelvin connection uses two wires to carry the test

current to and from the device and two

independent wires to sense the voltage across the

device.) This prevents the voltage drop in the

current carrying wires from affecting the voltage

measurement.

Radial leaded components (where the leads are on

the same side) are simply inserted into the test

fixture, one lead in each side.

Axial leaded devices (leads at opposite ends)

require the use of the axial fixture adapters.

Surface mount (SMD) devices or components with

large or unusually shaped leads can be measures

with SMD tweezers or Kelvin Clips. A BNC adapter

is available for interfacing to remote fixtures.

If the device leads are dirty or coated with wax,

clean them before inserting them in the fixture.

See the maintenance section for information about

cleaning the fixture.

Radial Fixture (with part) Axial Fixture (with part)

GETTING STARTED

1-6

REAR PANEL

POWER ENTRY MODULE

The Power Entry Module is used to fuse the line

power, select the input voltage, and filter high

frequency electrical noise.

POWER SWITCH

The power switch is located on the rear right side

of the unit. Depressing the front side of the switch

turns the unit on.

EXTERNAL BIAS INPUT

The two banana plugs are the input connections

for the external bias voltage. The bias supply must

be floating and well filtered. Neither side can be

ground referenced. The applied voltage must be

40 VDC or less and current limited to 250 mA max

EXTERNAL BIAS FUSE

Protects the external bias input from currents

greater than 250 mA.

RS232 DB25 CONNECTOR

This connector allows for computer control of the

unit over an RS232 interface. The connector is

configured as a DCE (transmit on pin 3, receive

Computer serial adapter, which is usually a DTE,

use a straight thru serial cable. See the

programming section for more information.

SW1

These switches set baud rate, parity and word

length for the RS232 interface. See the

programming section for details on setting the

interface.

HANDLER INTERFACE (OPTION 01)

This provides control lines to a component handler

for sorting. The interface has an input trigger line

and output lines indicating bin data available, busy

and 10 separate bins. The connector is a male

DB25. See the Handler section for more detail.

IEEE-488 (GPIB) CONNECTOR (OPTION 01)

This connector allows for computer control of the

unit over the GPIB or IEEE-488 interface. See the

programming section for more information.

SW2 (OPTION 01)

These switches set the instrument address for the

GPIB interface. See the programming section for

detail on how to set up the interface.

This manual suits for next models

1

Table of contents

Other SRS Labs Measuring Instrument manuals

SRS Labs

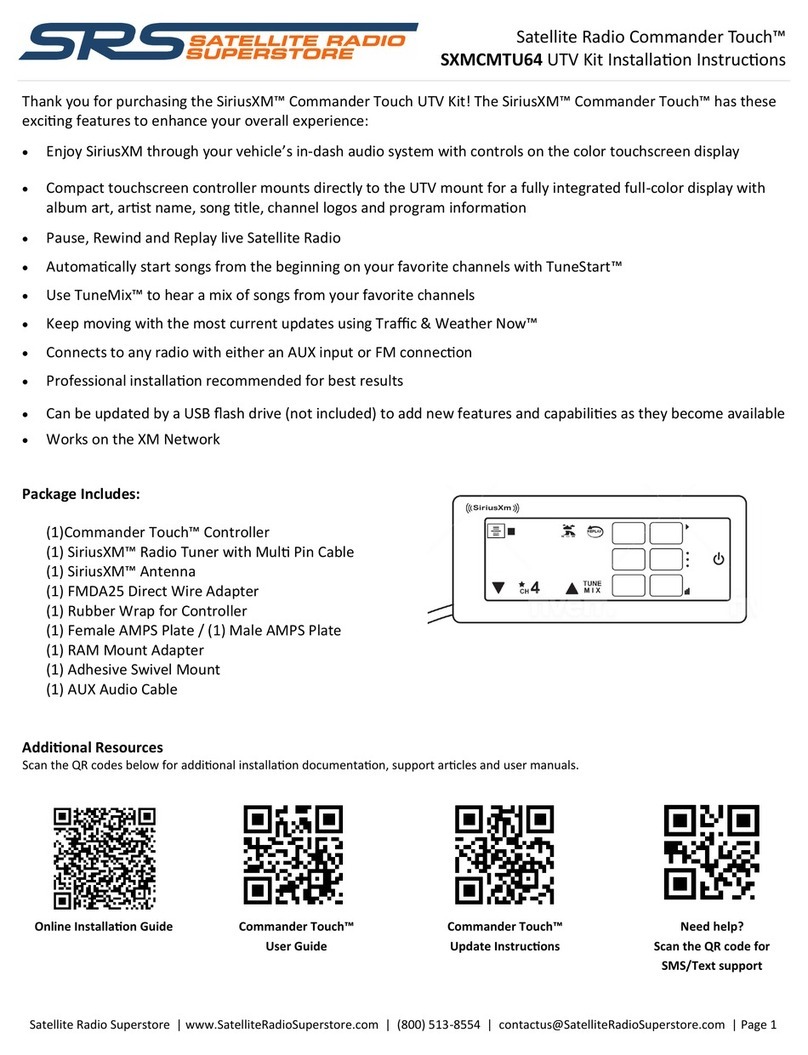

SRS Labs SXMCMTU64 User manual

SRS Labs

SRS Labs SR780 User manual

SRS Labs

SRS Labs SR785 User manual

SRS Labs

SRS Labs UGA100 User manual

SRS Labs

SRS Labs BGA244 User manual

SRS Labs

SRS Labs SIM922A Operation manual

SRS Labs

SRS Labs QMS 100 Series User manual

SRS Labs

SRS Labs SIM970 Operation manual

SRS Labs

SRS Labs SR1 Manual

SRS Labs

SRS Labs SIM940 Operation manual