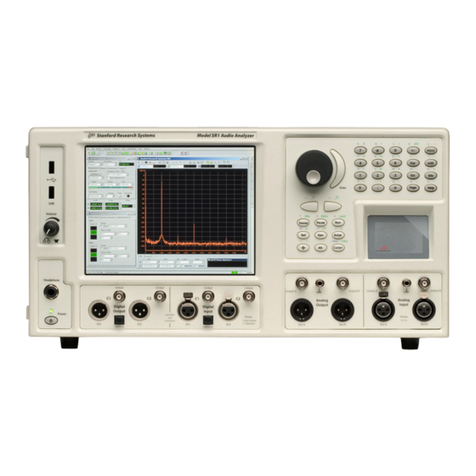

Stanford Research Systems

UGA Series Universal Gas Analyzers

UGA Basics1 – 2

1.1 Introduction

Universal Gas Analyzer (UGA) series instruments are modern mass

spectrometers designed for the analysis of light gases. The three

systems, 100, 200 and 300, dier only in the mass range they can

detect. A quadrupole mass spectrometer (also called a residual gas

analyzer or RGA) performs the task of analyzing the gas.

The spectrometer operates at high vacuum and therefore, pumps

are required to draw the gas out of the instrument and maintain the

vacuum. A turbomolecular pump (TP) is commonly used to gen-

erate the high vacuum region (<10-5 Torr) required to operate the

ionizer and quadrupole of RGA. The inlet continuously samples

gases at low ow rates (several milliliters per minute) making the

instrument ideal for on-line analysis. Not only is data acquired

continuously (as opposed to batch sampling employed by gas chro-

matographs) but also very quickly. A change in composition at the

inlet can be detected in about 0.2 second. The system allows data

to be collected quickly - a complete spectrum can be acquired in

under one minute and individual masses can be measured at rates

up to 25 ms per point.

The SRS UGA systems enable many new applications where tradi-

tional mass spectrometers were too large and heavy. More recently,

a variety of applications for atmospheric sampling were developed

including fuel cell research, Freon detection, specialty gas produc-

tion monitoring, fermentation process monitoring, and catalysis

studies.

To accommodate atmospheric sampling, a pressure reduction

scheme is required. A two-stage pressure reducing inlet samples

gases at high pressure - from atmospheric pressure to a few Torr at

the rst stage and then to a mass spectrometer operating pressure

(about 10-6 Torr) at the second stage. In order to achieve this per-

formance, most commercially available systems employ a capillary

tube, pinhole, high vacuum pump (generally TP), and single back-

ing pump. The single backing pump performs double duty, evacu-

ating a bypass line (the rst stage) and backing the TP (the second

stage). The drawback to this architecture is that the bypass ow is

recombined with the sample ow at the backing pump, which al-

lows backstreaming through the TP. This backstreaming can cause

real problems for users measuring low molecular weight gases (e.g.

hydrogen, helium). When high concentrations of corrosive gases

are used, this backstreaming pathway also allows a higher fraction

of the corrosive gas to reach the RGA and TP. Exposure to corro-