SRS Labs SR785 User manual

Revision 1.2 (October, 2004)

Service Guide

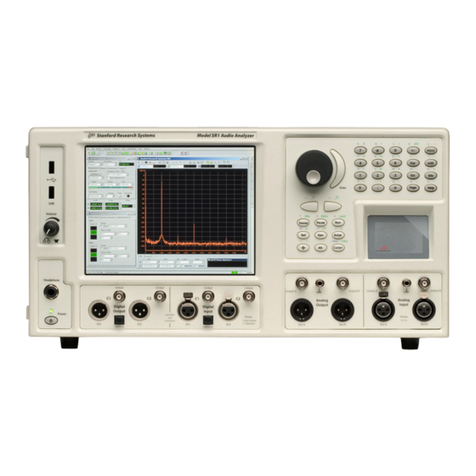

Model SR785

Dynamic Signal Analyzer

1290-D Reamwood Avenue

Sunnyvale, CA 94089 U.S.A.

Phone: (408) 744-9040 • Fax: (408) 744-9049

Copyright © 1995, 1996, 1998

Stanford Research Systems, Inc.

All Rights Reserved

SR785 Dynamic Signal Analyzer Service Guide

Certification

Stanford Research Systems certifies that this product met its published specifications at the time

of shipment. Stanford Research Systems further certifies that its calibration measurements are

traceable to the United States National Institute of Standards and Technology (NIST).

Warranty

This Stanford Research Systems product is warranted against defects in materials and

workmanship for a period of one (1) year from the date of shipment.

Service

For warranty service or repair, this product must be returned to a Stanford Research Systems

authorized service facility. Contact Stanford Research Systems or an authorized representative

before returning this product for repair.

Information in this document is subject to change without notice.

Copyright © Stanford Research Systems, Inc., 1998. All rights reserved.

Stanford Research Systems, Inc.

1290-D Reamwood Avenue

Sunnyvale, California 94089

Printed in U.S.A.

i

Service Guide SR785 Dynamic Signal Analyzer

Safety and Preparation For Use

WARNING!Dangerous voltages, capable of causing injury or death, are

present in this instrument. Use extreme caution whenever the

instrument cover is removed. Do not remove the cover while

the unit is plugged into a live outlet.

Caution This instrument may be damaged if operated with the LINE VOLTAGE SELECTOR set

for the wrong AC line voltage or if the wrong fuse is installed.

Line Voltage Selection

The SR785 operates from a 100V, 120V, 220V, or 240V nominal AC power source

having a line frequency of 50 or 60 Hz. Before connecting the power cord to a power

source, verify that the LINE VOLTAGE SELECTOR card, located in the rear panel fuse

holder, is set so that the correct AC input voltage value is visible.

Conversion to other AC input voltages requires a change in the fuse holder voltage card

position and fuse value. Disconnect the power cord, open the fuse holder cover door and

rotate the fuse-pull lever to remove the fuse. Remove the small printed circuit board and

select the operating voltage by orienting the printed circuit board so that the desired

voltage is visible when pushed firmly into its slot. Rotate the fuse-pull lever back into its

normal position and insert the correct fuse into the fuse holder.

Line Fuse Verify that the correct line fuse is installed before connecting the line cord. For

100V/120V, use a 1.5 Amp fuse. For 220V/240V, use a 3/4 Amp fuse.

Line Cord The SR785 has a detachable, three-wire power cord for connection to the power source

and to a protective ground. The exposed metal parts of the instrument are connected to

the outlet ground to protect against electrical shock. Always use an outlet which has a

properly connected protective ground.

Service Do not attempt to service or adjust this instrument unless another person, capable of

providing first aid or resuscitation, is present.

Do not install substitute parts or perform any unauthorized modifications to this

instrument. Contact the factory for instructions on how to return the instrument for

authorized service and adjustment.

Fan The fans in the SR785 are required to maintain proper operation. Do not block the vents

in the chassis or the unit may not operate properly.

ii

SR785 Dynamic Signal Analyzer Service Guide

iii

Service Guide SR785 Dynamic Signal Analyzer

Contents

Safety and Preparation For Use i

Contents iii

Table of Figures v

Chapter 1 Performance Tests

Getting Ready 1-3

Self Tests 1-7

DC Offset 1-9

Common Mode Rejection 1-11

Amplitude Accuracy 1-13

Amplitude Linearity 1-17

Anti-alias Filter Attenuation 1-19

Frequency Accuracy 1-21

Phase Accuracy 1-23

Noise and Spurious Signals 1-25

Sine Source 1-29

Harmonic Distortion 1-31

Performance Test Record 1-32

Chapter 2 Circuit Description

Overview 2-3

CPU Board 2-5

Video/IO Board 2-8

Power Supply Board 2-10

DSP Board 2-12

Analog Input Boards 2-15

Chapter 3 Service

Before Proceeding With Service 3-3

Troubleshooting Table 3-4

Circuit Board Locations 3-8

Service Procedures 3-10

Caution 3-10

Required Equipment 3-10

Power Supply Board Replacement 3-10

Power Supply Check 3-11

CRT Replacement 3-13

CRT Check 3-14

Keypad Check 3-14

Knob Check 3-15

CPU Board Replacement 3-16

Battery Check 3-17

Video/IO Board Replacement 3-17

iv Contents

SR785 Dynamic Signal Analyzer Service Guide

DSP Board Replacement 3-18

Analog Board Replacement 3-18

Checking the Analog Inputs 3-19

Checking the Amplitude 3-20

Checking the Trigger 3-20

Checking the Source 3-21

DSP Memory Module Replacement 3-21

Replacing the Disk Drive 3-22

Adjusting the DC Offset and CMR 3-24

Chapter 4 Parts List

CPU Board 4-3

Video/IO Board 4-6

Power Supply Board 4-9

System Backplane 4-11

Disk Card 4-12

DSP Board 4-13

Analog Input Board 4-20

Analyzer Backplane 4-29

Chapter 5 Schematic Diagrams

Schematic Diagram List 5-3

CPU Board MCPU-1

Video/IO Board MVID-1

Power Supply Board MPWR-1

System Backplane MBKPL-1

Disk Card MBKPL-24

Keypad Board MKEY-1

DSP Board D785-1

Analog Input Board A780-1

Analyzer Backplane M780-1

Demo Filter F780-1

v

Service Guide SR785 Dynamic Signal Analyzer

Table of Figures

Figure 3-1 System Components 3-3

Figure 3-2 Analyzer Components 3-4

Figure 3-1 System Components 3-8

Figure 3-2 Analyzer Components 3-9

Figure 3-3 Analog Adjustments 3-24

vi

SR785 Dynamic Signal Analyzer Service Guide

1-1

SR785 Dynamic Signal Analyzer

Chapter 1

Performance Tests

The performance tests described in this section are designed to verify with a high degree of confidence

that the unit is performing within the specifications.

The results of each test should be recorded on the test sheet at the end of this section.

In This Chapter

Getting Ready 1-3

[Hardkeys] 1-3

<Softkeys> 1-3

Knob 1-3

Reset 1-3

Serial Number 1-3

Firmware Revision 1-4

Necessary Equipment 1-4

Warm Up 1-4

The Test Record 1-4

If A Test Fails 1-4

1. Self Tests 1-7

2. DC Offset 1-9

3. Common Mode Rejection 1-11

4. Amplitude Accuracy and Flatness 1-13

5. Amplitude Linearity 1-17

6. Anti-alias Filter Attenuation 1-19

7. Frequency Accuracy 1-21

8. Phase Accuracy 1-23

9. Noise and Spurious Signals 1-25

10. Sine Source 1-29

11. Harmonic Distortion 1-31

SR785 Performance Test Record 1-32

1-2 Performance Tests

SR785 Dynamic Signal Analyzer

Performance Tests 1-3

SR785 Dynamic Signal Analyzer

Getting Ready

[Hardkeys]

The keypad consists of four groups of hardkeys (keys with printed labels).

Hardkeys are referenced in braces like [Active Display] or [Input].

The ENTRY keys are used to enter numeric parameters which have been highlighted by

a soft key. The MENU keys select a menu of soft keys. Pressing a menu key will change

the menu boxes which are displayed next to the soft keys. Each menu presents a group of

similar or related parameters and functions. The CONTROL keys start and stop data

acquisition, toggle the active display and link parameters and functions. These keys are

not in a menu since they are used frequently and within any menu. The FUNCTION keys

perform common functions such as Auto Scale and Auto Range. These keys can be

accessed at any time.

<Softkeys>

The SR785 has a menu driven user interface. The Menu keys each display a menu of

softkeys. The softkeys are at the right of the video display and have different functions

depending upon the displayed menu.

Softkeys are referenced in brackets like <Span> or <Units>.

There are three types of softkeys - buttons, lists and numeric values. A button performs a

function, such as <Full Span>. A list presents a list of choices or options in the entry

field (at the top of the screen). Use the knob to make a selection and press [Enter].

<Measurement> is an example of a list. A numeric value presents the current value in the

entry field and awaits numeric entry. Enter a new value with the entry keys and press

[Enter]. <Start Freq> is an example of a numeric value.

Knob The knob normally moves the markers within the displays. If a parameter has been

highlighted by its softkey, the knob adjusts the parameter. List parameters are most

easily modified with the knob. Numeric parameters may also be adjusted with the knob.

Knob list selections are referenced in parenthesis like (Hanning).

Reset

Throughout this section, it will be necessary to reset the analyzer into a known default

state. To do this, press [System] to display the System menu and then press <Preset> and

[Enter] to confirm. The unit will perform power up tests and then assume the default

settings. Each test generally starts with a reset.

Serial Number

If you need to contact Stanford Research Systems, please have the serial number of your

unit available. The serial number is printed on a label affixed to the rear panel. The serial

number is also displayed on the screen when the unit is powered on.

1-4 Performance Tests

SR785 Dynamic Signal Analyzer

Firmware Revision

The firmware revision code is displayed on the screen when the unit is powered on.

Necessary Equipment

The following equipment is necessary to complete the performance tests. The suggested

equipment or its equivalent should be used.

Frequency Synthesizer

Freq Range 1 Hz to 1 MHz

Freq Accuracy better than 5 ppm

Amplitude Accuracy 0.2 dB from 1 Hz to 100 kHz

Harmonic Distortion ≤-65 dBc

Spurious ≤-55 dBc

Recommended SRS DS345

AC Calibrator

Freq Range 10 Hz to 100 kHz

Amplitude 1 mV to 10 V

Accuracy 0.1%

External phase locking capability

Recommended Fluke 5200A

Feedthrough Terminations

Impedance 50 Ω

Warm Up

The analyzer should be turned on and allowed to warm up for at least an hour before any

tests are performed. The self test does not require any warm up period.

It is necessary to turn the unit off and on to reset it. As long as the unit is powered within

a minute, this will not affect the test results.

Auto Offset must be left enabled (On) in the [Input] <More> menu. Disabling Auto

Offset may invalidate the results of some tests.

The Test Record

Make a copy of the SR785 Performance Test Record at the end of this section. Fill in the

results of the tests on this record. This record will allow you to determine whether the

tests pass or fail and also preserve a record of the tests.

If A Test Fails

If a test fails, you should check the settings and connections of any external equipment

and, if possible, verify its operation using a DVM, scope or some other piece of test

equipment.

After checking the setup, repeat the test from the beginning to make sure that the test was

performed correctly.

Performance Tests 1-5

SR785 Dynamic Signal Analyzer

If the test continues to fail, contact Stanford Research Systems for further instructions.

Make sure that you have the unit serial number and firmware revision code handy. Have

the test record on hand as well.

1-6 Performance Tests

SR785 Dynamic Signal Analyzer

Performance Tests 1-7

SR785 Dynamic Signal Analyzer

1. Self Tests

The self tests check the analyzer hardware. These are functional tests and do not relate to the

specifications. These tests should be run before any of the performance tests.

Note that the Test menu offers more tests than are required here. Only those tests, which require no

additional equipment, are discussed in this section. The computer interface and disk drive tests are not

required but should be periodically checked. See the System menu for more information about those

tests.

Setup

No external setup is required for this test.

Procedure

1) Reset the unit by pressing [System] <Preset> and then [Enter] to confirm.

During re-boot, the DSP memory and calibration tests should all be OK.

To review this power on screen, use [System] <Show Version>.

2) Press the keys in the following sequence:

1-8 Performance Tests

SR785 Dynamic Signal Analyzer

[System]

<Diagnostics>

<Keypad Test>

Press all of the front panel keys until all of the boxes are filled in.

Then press any key to exit this screen.

<Knob Test>

Rotate the knob to verify rotation and direction.

<Return>

<Memory >

<System RAM>

<Begin>

All of the system memory chips should Pass.

<Return>

<System ROM>

<Begin>

All of the system memory chips should Pass.

<Return>

<Video RAM>

<Begin>

All of the video memory chips should Pass.

<Return>

<Help ROM>

<Begin>

All of the memory chips should Pass.

<Return>

<Return>

3) This completes the functional hardware tests. Enter the results of this test in the test record at the

end of this section.

Performance Tests 1-9

SR785 Dynamic Signal Analyzer

2. DC Offset

This test measures the DC offset of the input.

Setup

Connect a 50Ωfeedthrough termination to the Ch1 A and Ch2 A inputs. This shorts the inputs so the

analyzer's own DC offset will be measured.

Procedure

1) Reset the unit by pressing [System] <Preset> and then [Enter] to confirm.

2) Press the keys in the following sequence:

[Freq]

<Span>

[1] [.] [6] select (kHz) [Enter]

[Marker]

<Marker>

Select (Link) [Enter]

Use the knob to move the markers to 0 Hz.

[Average]

<Averaging Type>

Select (Linear/Fixed Length) [Enter]

<# Avgs>

[1] [0] [Enter]

<Display Average>

Select (RMS) [Enter]

3) a) Press

[Input]

<Input Configuration>

<Ch1 Input Range>

<Channel>

Select (Both) [Enter]

<Ch1 Input Range>

[-] [3] [0] [Enter]

[Start/Reset]

Wait for the average to finish.

[Auto Scale A]

[Auto Scale B]

b) Record the marker Y values for both displays on the -30 dBV range.

c) Press

<Ch1 Input Range>

1-10 Performance Tests

SR785 Dynamic Signal Analyzer

[-] [5] [0] [Enter]

[Start/Reset]

Wait for the average to finish.

[Auto Scale A]

[Auto Scale B]

d) Record the marker Y values for both displays for the -50 dBV range.

4) This completes the DC measurement test. Enter the results of this test in the test record at the end

of this section.

Performance Tests 1-11

SR785 Dynamic Signal Analyzer

3. Common Mode Rejection

This test measures the common mode rejection of the analyzer inputs.

Setup

We will use the frequency synthesizer to provide the signal.

Connect the frequency synthesizer output to both the Ch1 A and Ch1 B inputs of the analyzer. Use equal

length cables from A and B to a BNC TEE. Connect the cable from the synthesizer output to the TEE.

Procedure

1) Reset the unit by pressing [System] <Preset> and then [Enter] to confirm.

2) Set the frequency synthesizer to a frequency of 1 kHz and an amplitude of 500 mVrms.

3) Setup the measurement. Press the keys in the following sequence:

[Freq]

<Span>

[1] [.] [6] Select (kHz) [Enter]

<Center Freq.>

[1] Select (kHz) [Enter]

[Input]

<Input Config>

<Ch1 Input Range>

[-] [2] [Enter]

[Average]

<Averaging Type>

Select (Linear/Fixed Len) [Enter]

<# Avgs>

[1] [0] [Enter]

<Display Avg>

Select (RMS) [Enter]

Wait for the average to finish.

[Auto Scale A]

[Marker Max]

[Marker Ref]

[Input]

<Input Config>

<Ch1 Input Mode>

Select (A-B) [Enter]

1-12 Performance Tests

SR785 Dynamic Signal Analyzer

[Start/Reset]

Wait for the average to finish.

4) Record the marker Y reading. This is the Ch1 CMRR (in dB) at 1 kHz.

5) Move the input cables from Ch1 A and B to Ch2 A and B.

Repeat the measurement for Ch2.

Press the keys in the following sequence:

[Active Display]

Make DisplayB the active display.

[Input]

<Channel>

Select (Ch2) [Enter]

<Ch2 Input Range>

[-] [2] [Enter]

[Start/Reset]

Wait for the average to finish.

[Auto Scale B]

[Marker Max]

[Marker Ref]

[Input]

<Input Config>

<Ch2 Input Mode>

Select (A-B) [Enter]

[Start/Reset]

Wait for the average to finish.

6) Record the marker Y reading. This is the Ch2 CMRR (in dB) at 1 kHz.

7) This completes the CMRR measurement test. Enter the results of this test in the test record at the

end of this section.

Table of contents

Other SRS Labs Measuring Instrument manuals

SRS Labs

SRS Labs Nitrogen Laser NL100 Operation manual

SRS Labs

SRS Labs QMS 100 Series User manual

SRS Labs

SRS Labs UGA100 User manual

SRS Labs

SRS Labs SIM922A Operation manual

SRS Labs

SRS Labs SIM940 Operation manual

SRS Labs

SRS Labs SR780 User manual

SRS Labs

SRS Labs SXMCMTU64 User manual

SRS Labs

SRS Labs SR625 User manual

SRS Labs

SRS Labs BGA244 User manual

SRS Labs

SRS Labs SR715 User manual