April 2006 Rev 2 1/35

UM0193

User manual

Getting Started with the ARMIC30 Evaluation Board

(ARM Core-based Industrial Controller using STR730 MCU)

Introduction

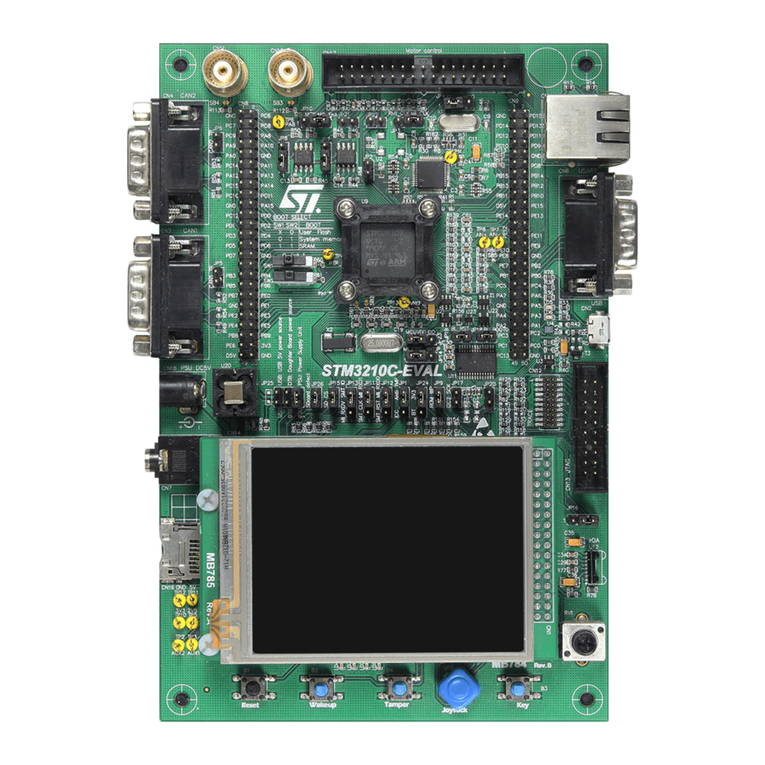

This user manual describes the implementation of the ARMIC30 Evaluation Board. The

ARMIC30 can be used to evaluate a variety of devices, especially microcontrollers, with the

added advantage that all pins are available on logically structured and well-documented

header pins.

Applications are based on 32-bit STR730F microcontroller that uses a powerful ARM7TDMI

core providing an extensive range of peripheral functions and enhanced I/O capabilities.

The ARMIC30 is equipped with RS-232, RS-485, CAN, SPI, I²C and JTAG communication

interfaces.

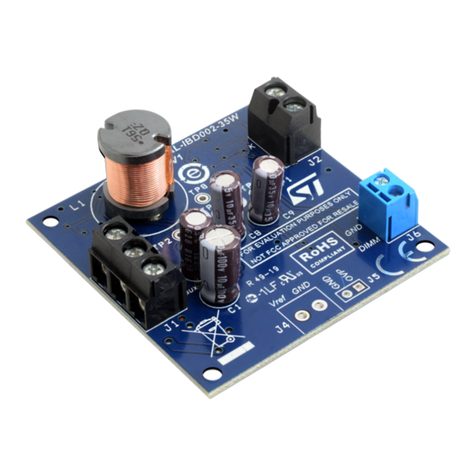

The evaluation board also includes digital input/output connectors and three motor control

connectors with a pinout compatible with PowerSpin evaluation boards (supporting L6205,

-6, -7, -8, and L6235 integrated motor drivers). The output interface is compatible with

VN808 and VN340 Reference Design Boards and the input interface can be used for CLT3-

4BT6 or PCLT-2A evaluation board connections.

Applications can be supplied from a standard DC power supply (7 to 30V DC) or directly

using a 24V DC industrial mains supply.

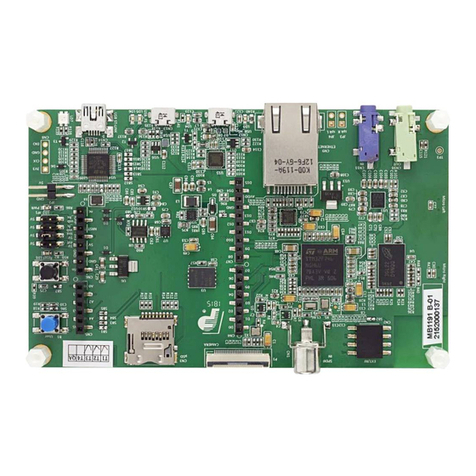

Complete solution is implemented on double-face board with only two copper layers for

increased cost-effectiveness. Routing accuracy is also cost-optimized.

The ARMIC30 evaluation board package includes a CD-ROM containing the standard

STR730 software library, source code examples, board fabrication data (Gerber files), this

user manual and other related documentation.

Key Features

■32-bit STR730FZ2T7 microcontroller with 36-MHz ARM7TDMI CPU core

■RS-232 interface with 15kV guaranteed ESD protection using ST202E transceiver

■RS-485 interface using ST485A high-speed transceiver with bit rates up to 30 Mbps

■L9616 high-speed CAN driver with communication speeds up to 1 Mbps

■SPI and I²C communication connectors

■8-bit digital input/output connectors

■3 Motor Control connectors

■STM811 small reset circuit

■Power supply using L5973AD DC/DC converter

■6 to 30V DC supply voltage range

www.st.com