Description UM1818

4/47 DocID026935 Rev 3

2 Description

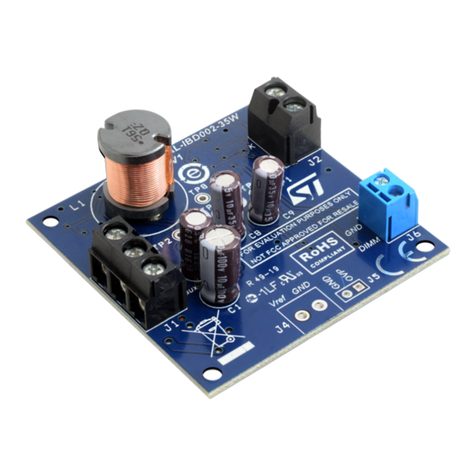

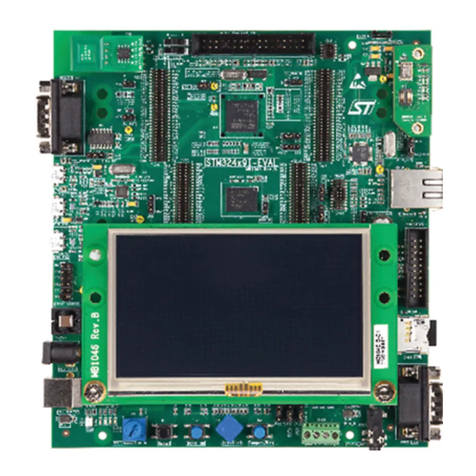

The STEVAL-IHP007V1 block diagram is shown in Figure 2. The general purpose power

line modem evaluation board is based on an ST7580 x-PSK power line modem device and

an ARM 32-bit Cortex™-M3 core based STM32F103xB microcontroller. The PLM

evaluation board is a fully functional communication evaluation board, with 8 programmable

I/Os, a real time clock and a Flash memory area for modem parameters and user data

storage. The firmware structure is made up of several layers, each dealing with a different

feature. The application layer engine is the general interface between the user program and

all the parts of the evaluation board. It manages the communication ports, the evaluation

board peripherals such as SCI, RTC, I/Os, LEDs and timing management. It is also the

interface between the PLM communication protocol and the user application layer. The PLM

communication protocol, itself made up of several layers, implements and manages the

power line communication, manages the conflicts, timing and repetitions, the addressing,

and so on. Please refer to AN4018 for details on the ST7580 communication protocol

features and application services provided. Some features are managed directly by the

application engine, and are transparent to the user, such as the RTC management or the

board parameter update, as well as the board programming and configuration, which is

done by particular programming or service commands managed and acknowledged directly

by the application engine. Even the remote firmware update is managed by the application

engine and allows the firmware being update remotely by power line modem.

The STEVAL-IHP007V1 is powered by a dual regulated DC power source, +12VDC (pin 1)

and +3.3 VDC (pin 2) from the power supply connector (J2). The pin 3 is the ground.

The communication is done via power line, which is applied to the board using the J1

connector, where the pin 1 must be connected to the neutral wire while the pin 3 to the

phase wires (refer to the Appendix A).

Figure 2. STEVAL-IHP007V1 block diagram

It is possible to connect the evaluation board in a three phase line (in case of

communication modules are connected in all three phases), in this case an external