4Filters and key parameters

4.1 Input signals

The input signals (LINx and HINx), able to drive the internal MOSFETs, are active high. A 100 kΩ (typ.) pull-down

resistor is built-in for each input signal. In order to prevent input signal oscillation, an RC filter was added on each

input and placed as close as possible to the IPM. The filter is designed using a time constant of 10 ns (1 kΩ and

10 pF).

4.2 Bootstrap capacitor

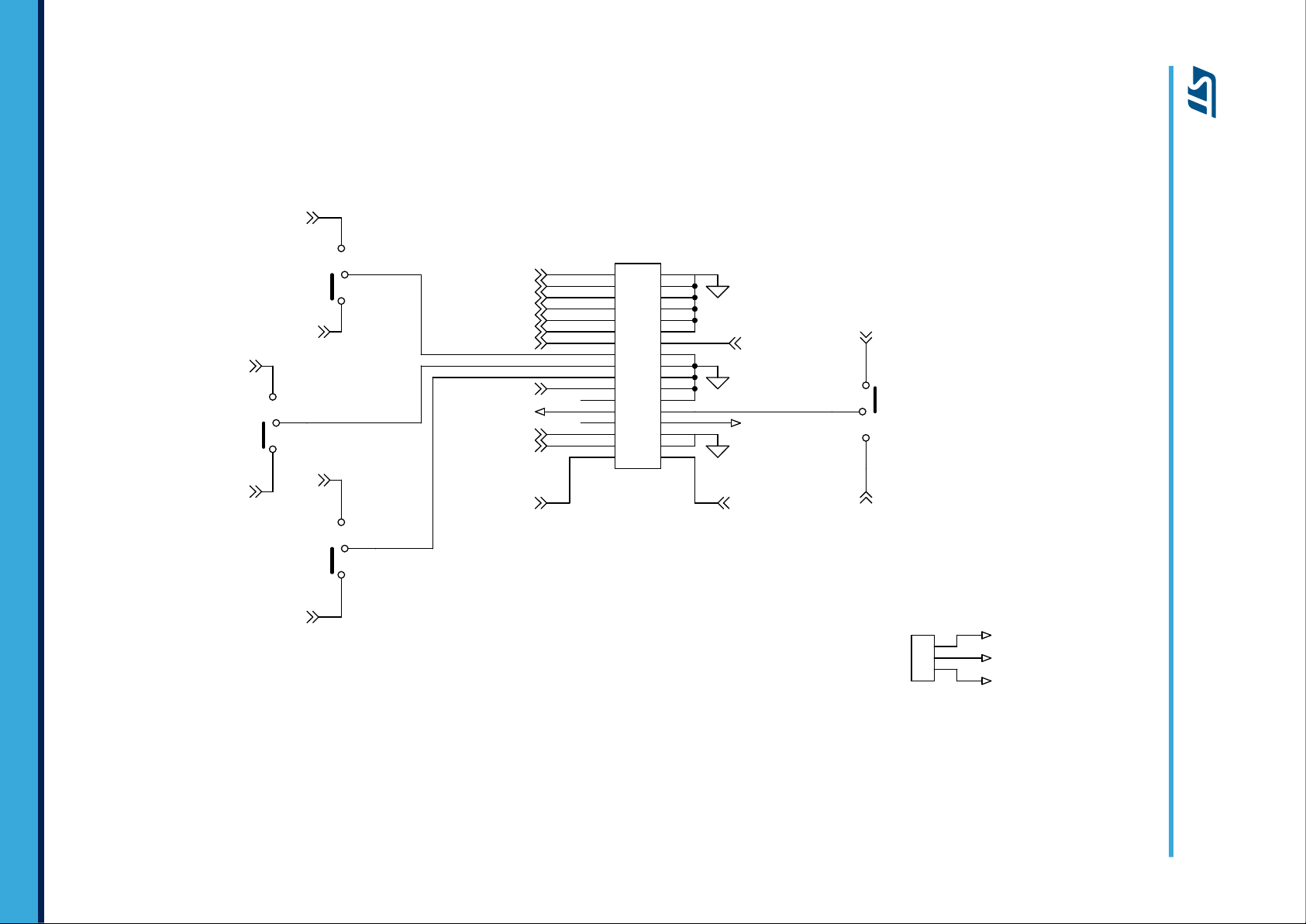

In the 3-phase inverter, the emitters of the low side MOSFETs are connected to the negative DC bus (VDC-) as

common reference ground, which allows all low side gate drivers to share the same power supply, while the

emitter of high side MOSFETs is alternately connected to the positive (VDC+) and negative (VDC-) DC bus during

running conditions.

A bootstrap method is a simple and cheap solution to supply the high voltage section. This function is normally

accomplished by a high voltage fast recovery diode. The SLLIMM 2nd series family includes a patented

integrated structure that replaces the external diode. It is realized with a high voltage DMOS functioning as diode

with series resistor. An internal charge pump provides the DMOS driving voltage. The value of the CBOOT

capacitor should be calculated according to the application condition.

This curve is taken from application note AN4768 (available on www.st.com); calculations are based on the

STGIB15CH60TS-L device, which represents the worst case scenario for this kind of calculation.

Figure Figure 9. CBOOT graph selectiongraph selection shows the behavior of CBOOT (calculated) versus

switching frequency (fsw), with different values of ΔVCBOOT for a continuous sinusoidal modulation and a duty

cycle δ = 50%.

The boot capacitor must be two or three times larger than the CBOOT calculated in the graph. For this design, a

value of 2.2 μF was selected.

Figure 9. CBOOT graph selection

4.3 Overcurrent protection

The SLLIMM 2nd series integrates a comparator for fault sensing purposes. The comparator has an internal

voltage reference VREF (510 mV typ.) connected to the inverting input, while the non-inverting input available on

the CIN pin can be connected to an external shunt resistor to implement the overcurrent protection function.

When the comparator triggers, the device enters the shutdown state.

The comparator output is connected to the SD pin in order to send the fault message to the MCU.

UM2702

Filters and key parameters

UM2702 - Rev 1 page 10/34