Contents UM0686

2/58 Doc ID 15451 Rev 1

Contents

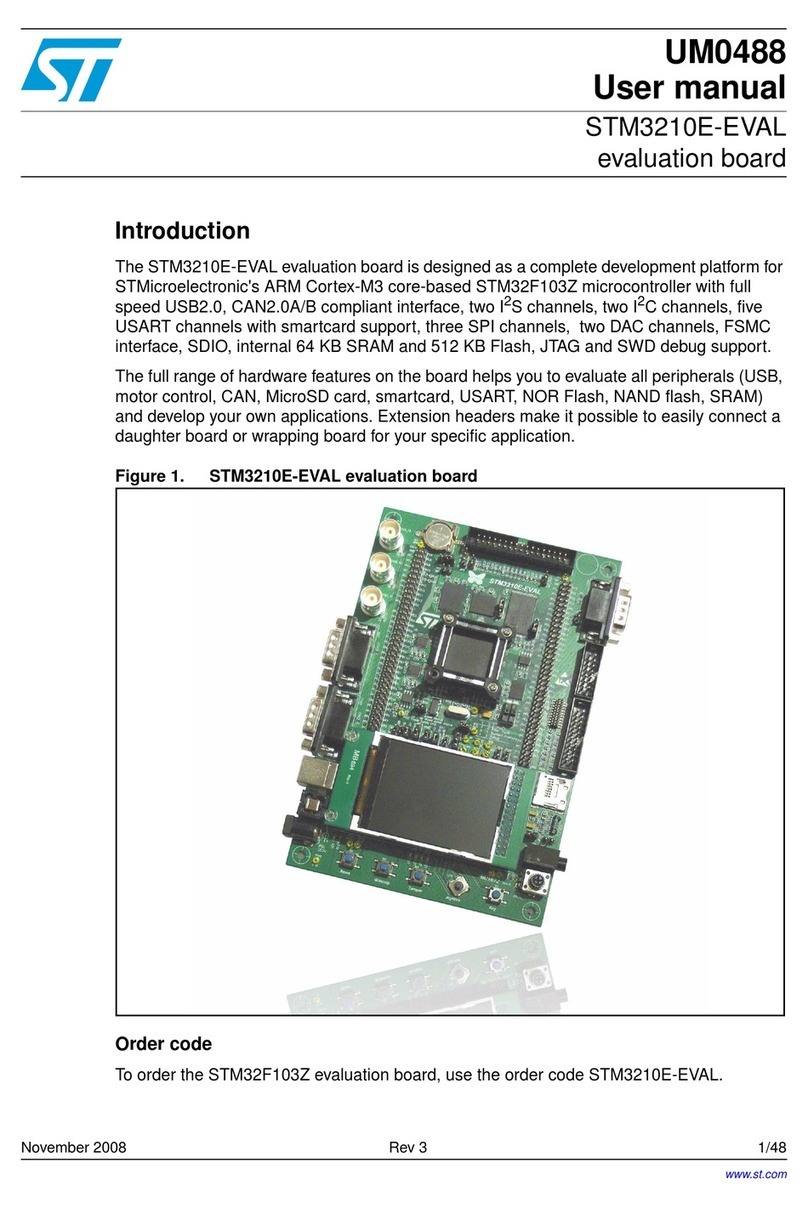

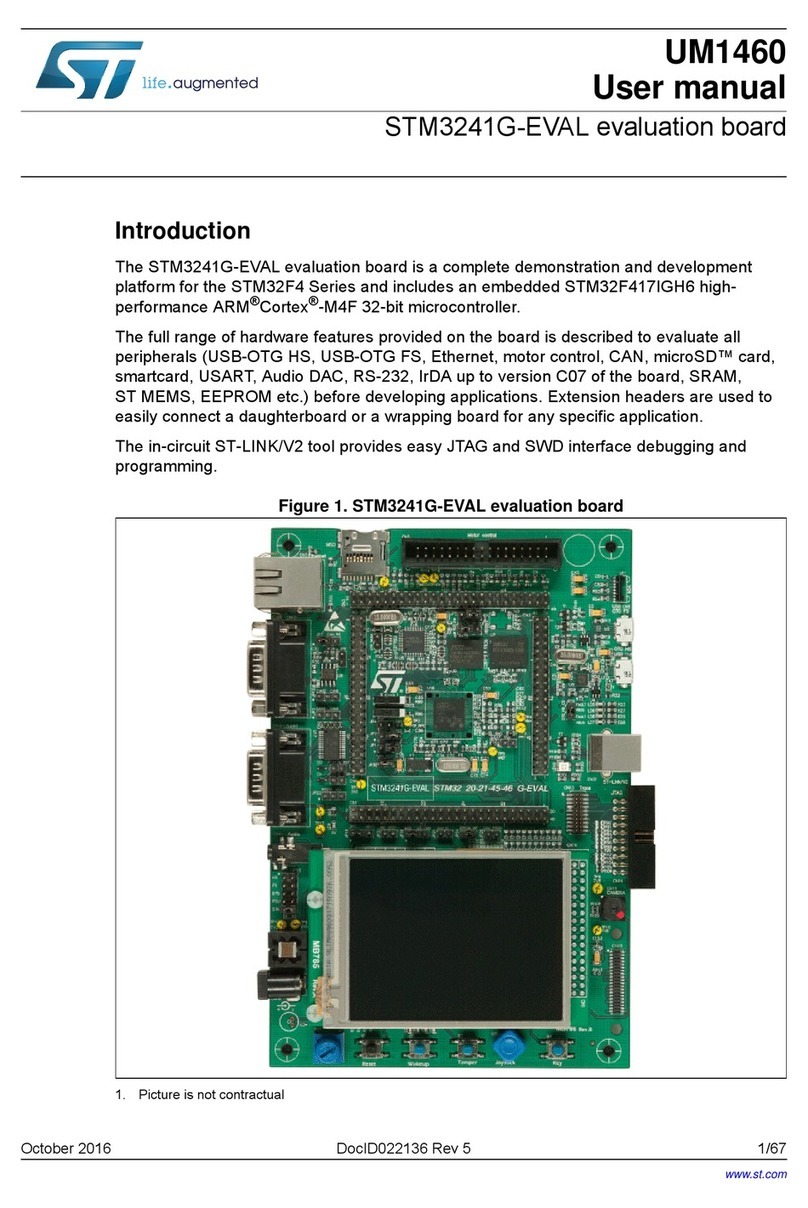

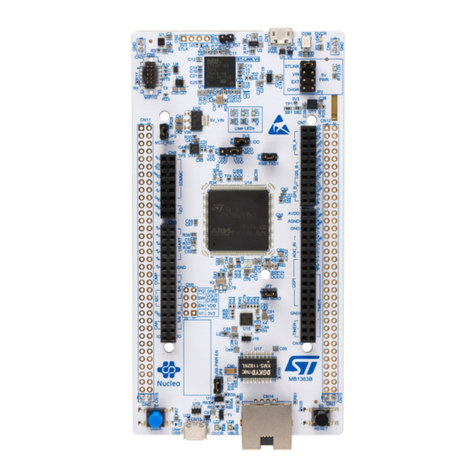

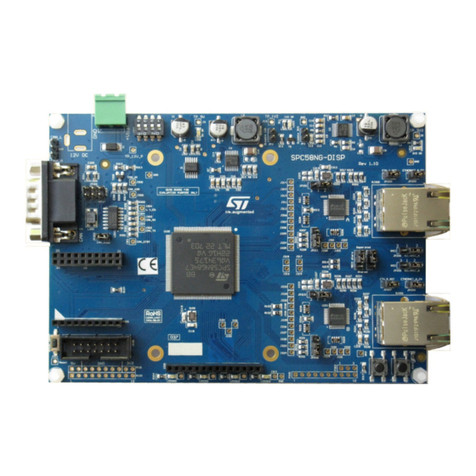

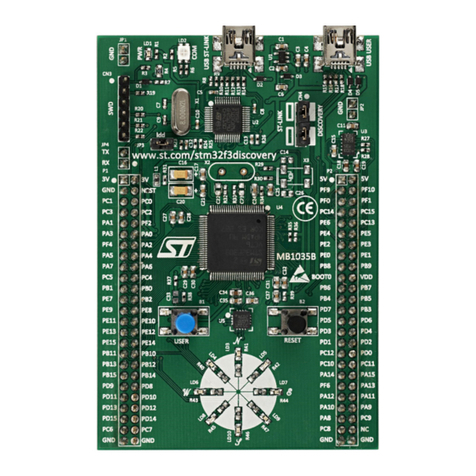

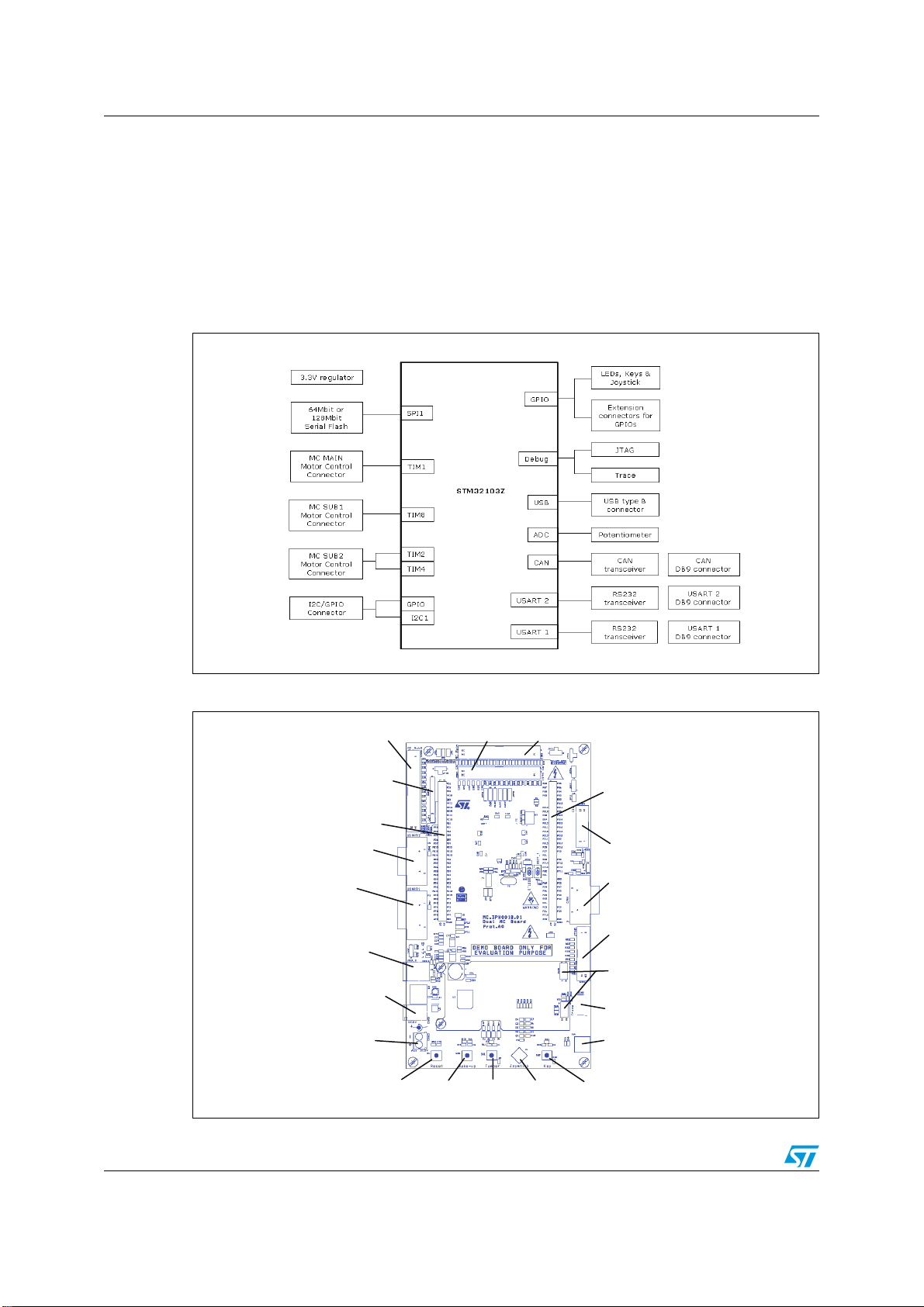

1 Hardware layout and configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

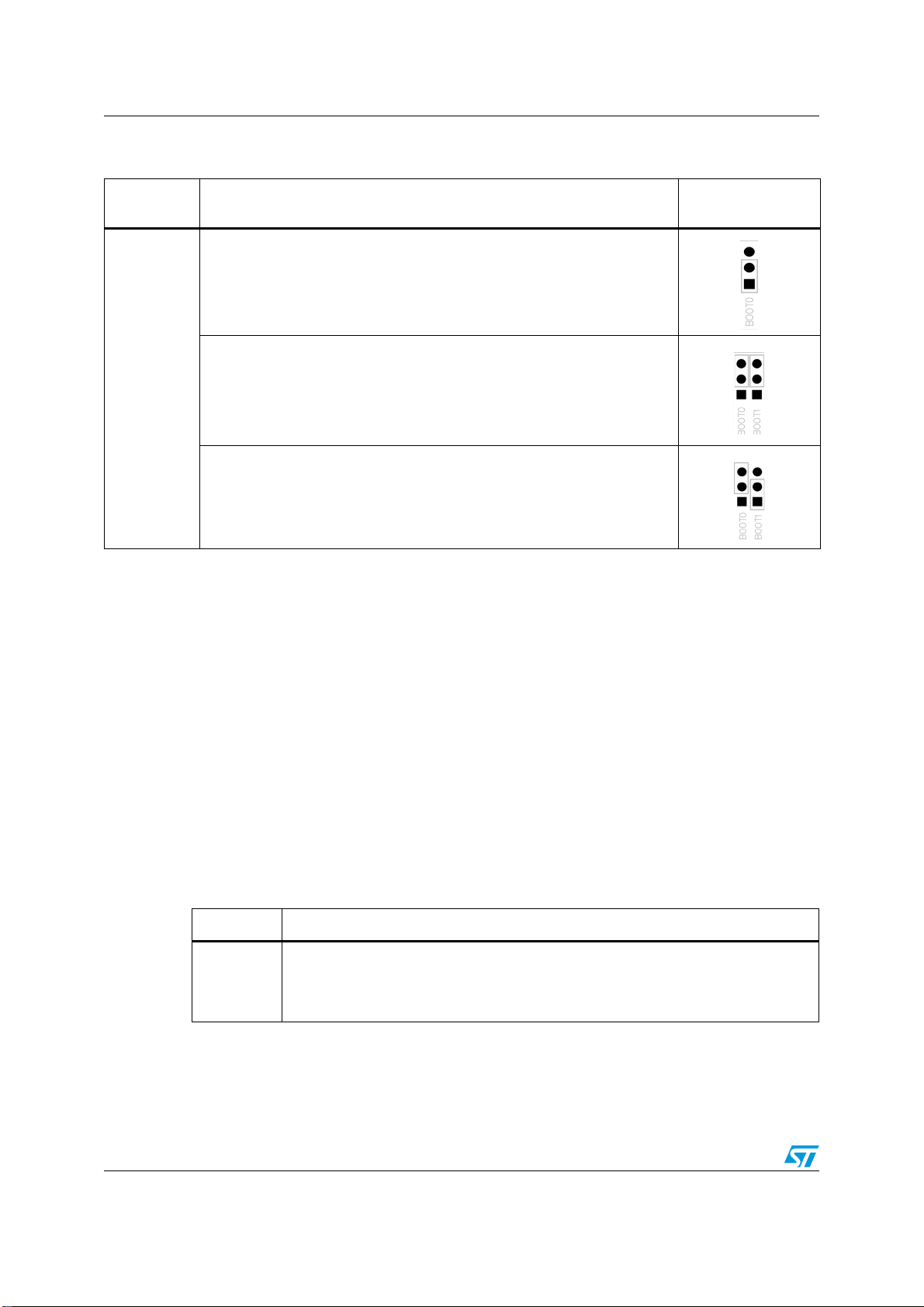

1.2 Boot options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Clock sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Reset sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5 Serial Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6 CAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.7 RS-232 connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

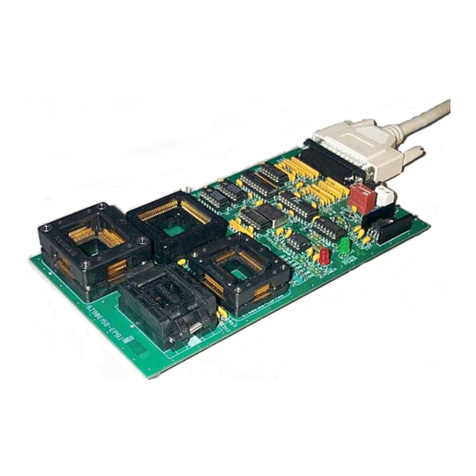

1.8 Motor control connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.9 USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.10 Development and debug support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.11 Display and input devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1 Motor control connector CON8 (MC main) . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2 Motor control connector CON9 (MC sub1) . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3 Motor control connector CON10 (MC sub2) . . . . . . . . . . . . . . . . . . . . . . . 19

2.4 Auxiliary motor control connector CON14 . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5 CAN D-type 9-pin male connector P1 . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.6 I2C and I/O connector CON2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.7 Trace debugging connector CON5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.8 RS-232 connector P2 with RTS/CTS handshake support . . . . . . . . . . . . 23

2.9 RS-232 connector P3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.10 JTAG debugging connector CON6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.11 Daughterboard extension connectors CN10 and CN11 . . . . . . . . . . . . . . 25

2.12 USB type B connector CON11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.13 TFT LCD connector CON4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.14 Power connectors CON12 and CON13 . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3 Schematic diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4 Bill of material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44