Hardware layout and configuration UM0488

10/48

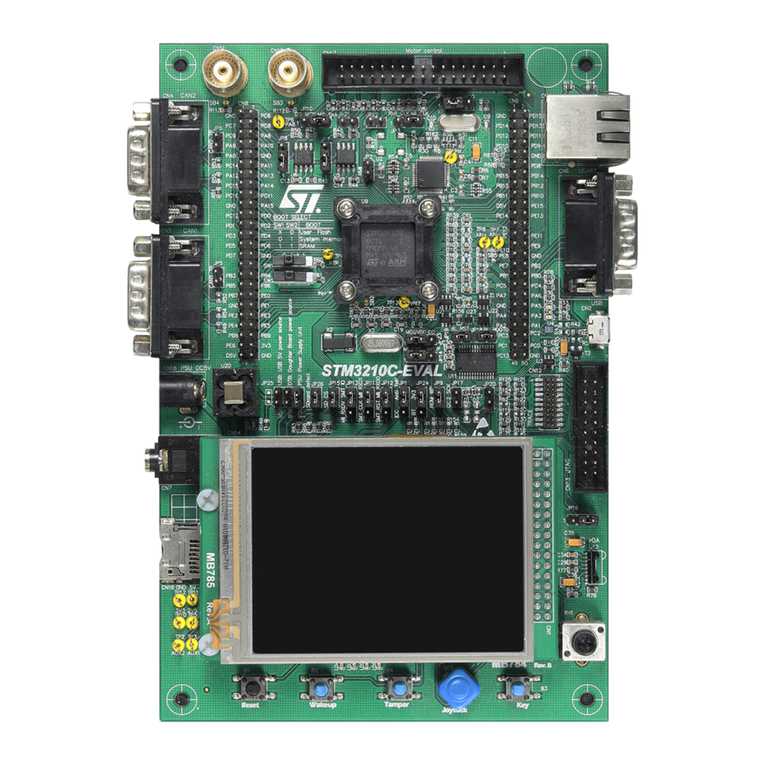

2.8 RS232 connectors

Two D-type 9-pin connectors CN12 (USART1) and CN8 (USART2) are available on the

STM3210E-EVAL evaluation board.

●USART1 connector is connected to RS232 transceiver U7

●USART2 connector with RTS/CTS handshake signal support is connected to RS-232

transceiver U5. The USART2_CTS is multiplexed with motor control, it can be enabled

by setting the jumper JP4. Refer to Section 2.9: Motor control for details.

2.9 Motor control

The STM3210E-EVAL evaluation board supports three-phase brushless motor control via a

34-pin connector CN1, which provides all required control and feedback signals to and from

the motor power driving board. Available signals on this connector include emergency stop,

motor speed, three-phase motor current, bus voltage, heatsink temperature coming from the

motor driving board and 6 channels of PWM control signals going to the motor driving

circuit.

JP 20 allows to choose between two synchronization methods for power factor correction

(PFC).

The I/O pins used on the motor control connector CN1 are multiplexed with some

peripherals on the board; either the motor control connector or multiplexed peripherals can

be enabled by setting the jumpers JP3, JP4, JP11, JP15 and JP16 as described in Table 6.

Table 6. Motor control related jumpers

Jumper Description Multiplexed

peripherals

JP20 JP20 allows to have a PFC synchronization signal redirected to the timer 3 input capture 1

pin, and additionally to the timer 3 external trigger input. JTAG debugging is disabled when

JP20 is fitted. Default setting: not fitted

JP2 JP2 should be kept on open when encoder signal is input from pin 31 of CN1 while it

should be kept on close when analog signal is from pin 31 of CN1 for special motor.

Default setting: not fitted

JP4

MC_EnA is enabled when JP4 is set as shown to the right

(default setting):

USART2_CTS is enabled when JP4 is set as show to the

right:

USART2

JP3 MC_EmergencySTOP is enabled when JP3 is closed. The pin PA6 is used

as SPI1_MISO when JP3 is open. Default setting: not fitted SPI1

JP11 MC_PFCpwm is enabled when JP11 is open. The pin PB5 will be used as

interrupt input from temperature sensor when JP11 is closed. Temperature

sensor

JP15 MC_UH or I2S_MCK are enabled when JP15 is open. The pin PC6 is used

as Smartcard_CMDVCC when JP15 is closed. I2S and

smartcard

JP16 MC_VH is enabled when JP16 is open. The pin PC7 is used as

Smartcard_OFF when JP16 is closed Smartcard

1 2 3

1 2 3