Stack ST994 User manual

INSTALLATION INSTRUCTIONS

Wide-Band Exhaust Gas Oxygen

Sensor Interface

ST994 / ST996

CAUTION: CAREFULLY READ INSTRUCTIONS BEFORE PROCEEDING

OVERVIEW

The Control Unit is a dual channel air/fuel ratio

(AFR) metering system designed to be used with an exist-

ing data acquisition system. The system has two 0-5 volt

analog AFR outputs. The compact size and wide supply

voltage range also allow operation from small rechargeable

batteries in a broad range of applications.

By utilizing miniature surface mount electronics

technology, digital signal processing techniques, and a

switching power supply for the sensor heater, the Control

Unit provides the same level of accuracy as lab systems

costing much more.

REPLACEMENT SENSORS AND

ACCESSORIES

We offer replacement sensors with Deutsch

connector installed: ST269552.

If you plan to terminate your own sensors, use the

following color chart:

Terminal Wire Color

1 Red

2 Black

3 Yellow

4 White

5 Gray

6 Seal

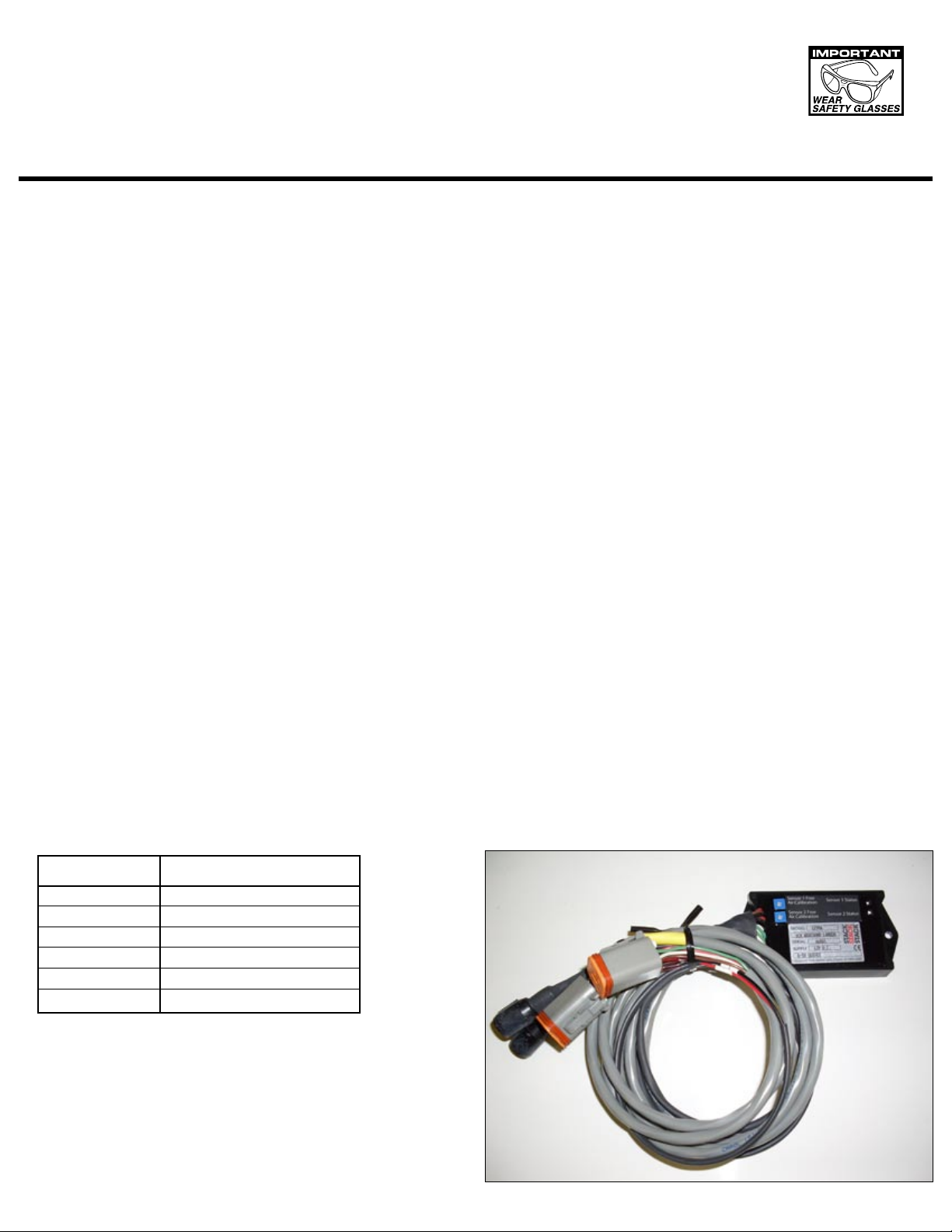

Figure 1 – Control Unit

INSTALLATION

1. Turn off the ignition switch and disconnect the battery

ground cable before proceeding.

2. The Bosch LSU 4.2 sensors should be located on the

header pipe about 6-8 inches from the head ange.

Ideally the sensor tip should face down to avoid accu-

mulation of condensation. When choosing a mounting

location, allow several inches clearance for the sensor

wire harness. The wire harness must exit straight out

from the sensor. Do not loop the harness back onto the

sensor body.

3. 18 x 1.5 mm weld nuts must be welded onto the ex-

haust pipe. After welding, run an 18 x 1.5 mm tap

through the threads. Failure to clean the threads may

result in sensor damage. Note that most automotive

mufer shops are familiar with oxygen sensor weld nut

installation on custom pipes. Do not install the sensors

until after the free air calibration procedure described in

STACK

STACK

STACK

®

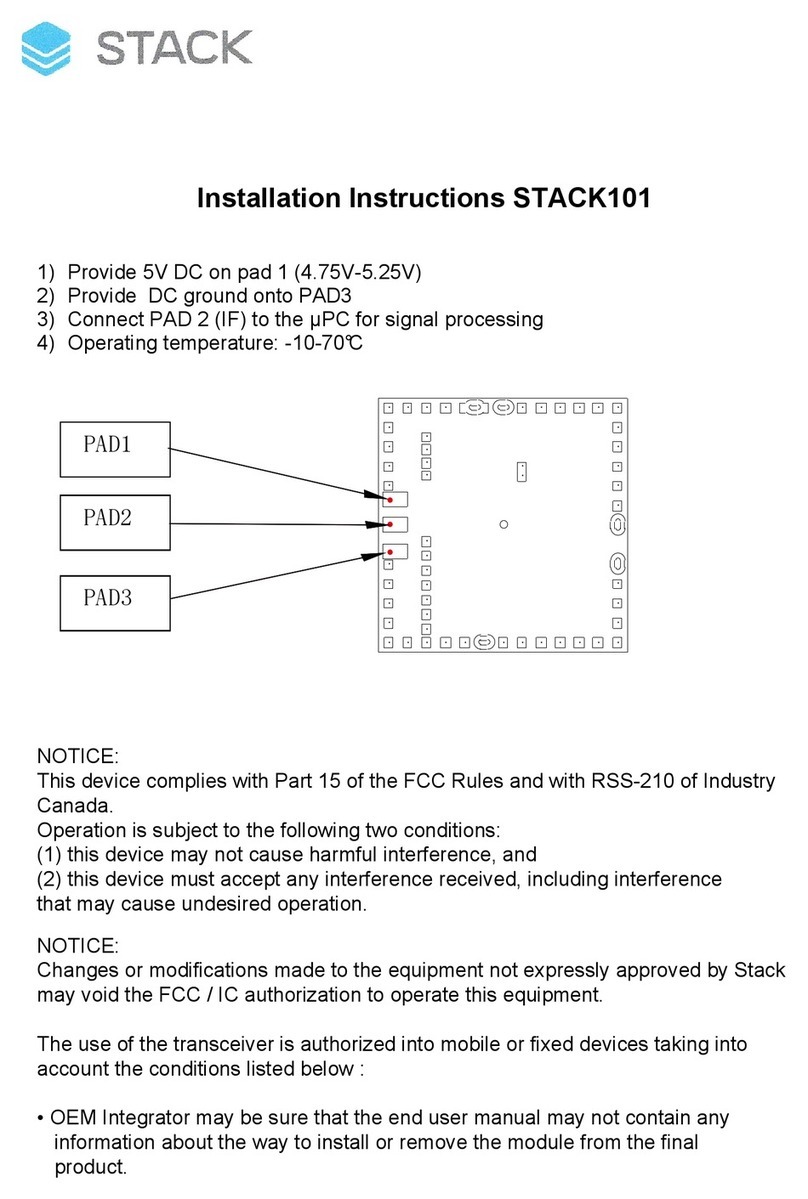

5. Connect the Bosch sensors to the 6 pin mating connec-

tors on the Control Unit wire harness. Extension cables

are available. The cable for sensor 1 exits at the top of

the Control Unit and is identied with a yellow band.

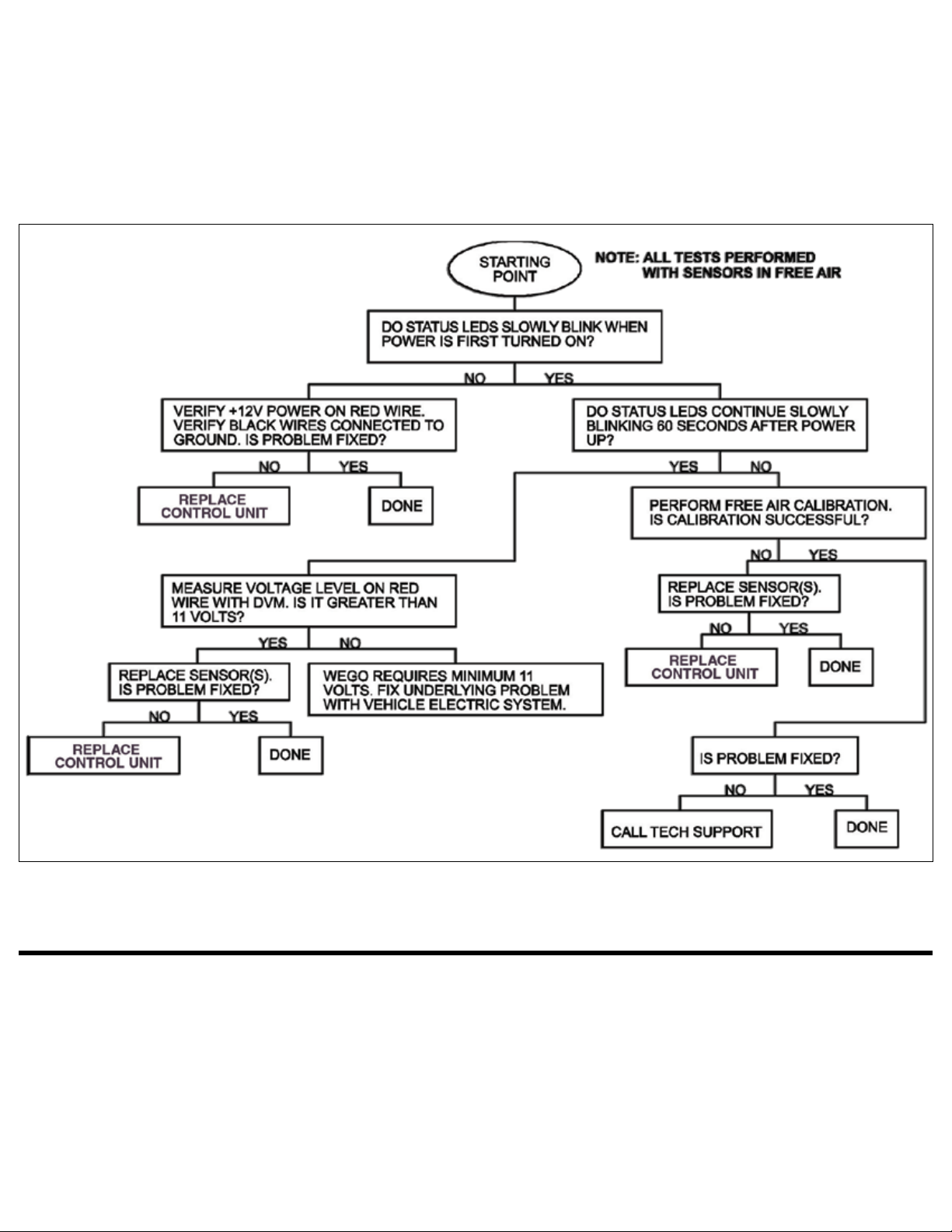

6. Refer to Figure 2. Connect the heavy black wire to a

good chassis ground location. Keep the ground

connection as short as possible.

7. If your race vehicle uses any type of CD (capacitive

discharge) ignition such as the MSD 6, 7, or 8 series,

you must properly ground and lter the ignition unit. Un-

less your ignition unit is directly connected to the battery

terminals, you must install a lter capacitor such as MSD

P/N 8830.

8. Connect the red wire to switched +12 volt power.

9. Reconnect the battery ground cable.

SENSOR 1 CABLE

IDENTIFIED BY

YELLOW BAND

TO SWITCHED

+12V POWER

0-5V OUTPUT SCALED

AFR = 10 + (2 x VOLT)

RED

S1

S2

HEAVY BLACK

SENSOR 1

INPUT

SENSOR 2

INPUT

SENSOR 1 AFR

OUTPUT

SENSOR 2 AFR

OUTPUT

INPUT

INPUT

POWER

GROUND

SENSOR

Figure 2 - Controller Hookup

DATA ACQUISITION

SYSTEM

SENSOR

SENSOR LIFE AND CALIBRATION

When used in a racing application with leaded

petrol, sensor life will probably be less than 10 hours.

Free air calibration should be performed on a regular

basis, such as before the start of every test session or

race event. If free air calibration fails, the sensor should

be replaced. Free air calibration must be performed in

an environment free of hydrocarbon vapors. Typical race

shop environments may prove to be too contaminated.

Even outdoors, free air calibration can fail if a carburetor

bowl has recently been removed or another vehicle is

running nearby. In general, sensors that are at the end of

their useful life will fail free air calibration.

OPERATION

The Control Unit has red status LEDs for each

channel. When power is turned on, the LEDs blink at a

slow rate until the corresponding sensor has reached

normal operating temperature.

After installation, the Control Unit requires free air

calibration. This should be done with the sensors dangling

in free air. The environment must be free of hydrocarbon

vapors. We suggest that you perform the free air

calibration outdoors. Turn the free air calibration trimpots

on the Control Unit full counterclockwise. Turn on power

and wait for 60 seconds so the system can fully stabilize.

Then slowly turn each free air calibration trimpot clockwise

until the corresponding LED starts ashing at a rapid rate.

Try to set each trimpot at the point where its LED just

starts to ash.

The free air calibration procedure should be

performed at reasonable intervals (every 250-500 hours if

using unleaded petrol or every 2-5 hours if using leaded

racing petrol) or whenever a sensor is replaced. If you

cannot get an LED to ash when its trimpot is turned full

clockwise, you either have a damaged sensor or very high

hydrocarbon levels in your environment.

The Control Unit includes internal diagnostics for

abnormal battery voltage (less than 11 volts or greater

than 16.5 volts), sensor open circuit, and sensor short

circuit conditions. A fault condition causes the status LEDs

to blink at the slow rate.

EXHAUST CONSIDERATIONS

The Control Unit system may give inaccurate

results in certain situations:

Excessive exhaust back pressure. Wide-band

sensors are affected by back pressure. Excessive back

CAUTION: Racing petrol containing lead

will quickly degrade the sensors. Under

these conditions, expected sensor life is

less than 10 hours. There is no warranty

on sensors.

pressure causes exaggerated AFR indications under

rich and lean conditions, but has little effect at 14.7 AFR

(stoichiometric). Race vehicle exhaust systems are free

owing and problems with exhaust back pressure are not

likely.

Exhaust reversion. Reversion is the term for a

negative pressure wave that can suck ambient air back into

the exhaust and cause an erroneous lean AFR indication.

Open “drag pipes” usually suffer from reversion effects and

may not be suitable for use with the this system except at

or near wide open throttle. Reversion effects will be most

noticeable at idle, part throttle low RPM, and deceleration.

Excessive scavenging. Tuned exhausts in

combination with a high overlap camshaft prole can pull

unburned air and fuel mixture through the cylinder into the

exhaust and cause an erroneous rich AFR indication. The

same effect can occur with high boost turbo/supercharger

applications.

Misring. If the AFR is so rich that the engine

misres, high levels of oxygen will remain in the exhaust

gas and result in an erroneous lean indication.

ENGINE TUNING GUIDELINES

Higher AFR values correspond to a leaner (less fuel)

condition. The practical operating range for most engines

using gasoline fuel is from approximately 11.5 to 14.7 AFR.

Combustion of a stoichiometric mixture (exactly enough

air to burn all the fuel) results in 14.7 AFR indication.

Automotive engines with catalytic converters operate near

14.7 AFR during cruise and idle. Race engines usually

require a richer mixture to limit cylinder head temperature

and prevent detonation. The table below lists reasonable

AFR values for race engines without emission controls.

Operating Mode Recommended AFR

Cold Start (rst 30 sec) 11.5-12.5

Idle 12.8-13.5

Part Throttle Cruise 13.0-14.0

Wide Open Throttle 12.5-12.8 (values down to

11.5 may be used to

reduce detonation)

TROUBLESHOOTING FLOWCHART

Follow the troubleshooting owchart shown on the next page. Experience has shown that most units returned for war-

ranty are OK and another problem, such as user error, degraded sensors, or bad power connections is later identied.

WARRANTY

Stack Limited warrants this product (excepting associated sensors which are consumable items - there is no warranty on sensors.) to be free from defects caused

by faulty materials or poor workmanship for 1 year from the date of consumer purchase. This warranty applies only to the original purchaser of product and is

non-transferable. All implied warranties shall be limited in duration to the said warranty periods above. Breaking the instrument seal, improper use or installation,

accident, water damage, abuse, unauthorized repairs or alterations voids this warranty. Stack Limited disclaims any liability for consequential damages due to

breach of any written or implied warranty on all products manufactured by Stack Limited.

www.stackltd.com

Stack Ltd. Wedgwood Road, Bicester OX26 4UL UK

© 2010 STACK, Ltd. ST54115-001 03/03/10

This manual suits for next models

1

Other Stack Accessories manuals

Popular Accessories manuals by other brands

Multibrackets

Multibrackets M Wall installation manual

Popp

Popp Ei600ZW quick start

Thule

Thule Omnistor 9200 3026 Series instructions

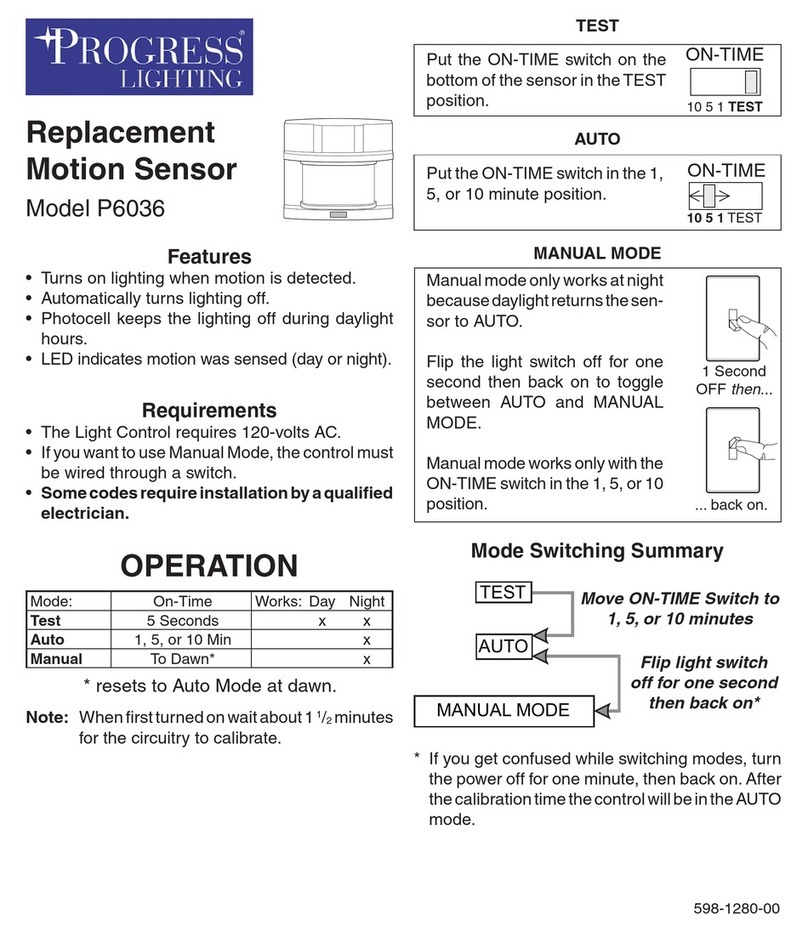

Progress

Progress Replacement Motion Sensor P6036 owner's manual

Porter

Porter 1235 Installation, operation & maintenance manual

KMC Controls

KMC Controls STE-8001 installation guide