Revision A 7

SECTION 2

Installing STE-8000 sensors

This section provides important instructions and guidelines for

installing the STE-8000 series sensors. Carefully review this

information before installing the controllers.

Installing the sensors includes the following topics that are covered in this

section.

◆Planning for motion sensing on page 7

◆Rough-in preparation on page 8

◆Installing the sensors on page 8

◆Maintenance on page 9

Planning for

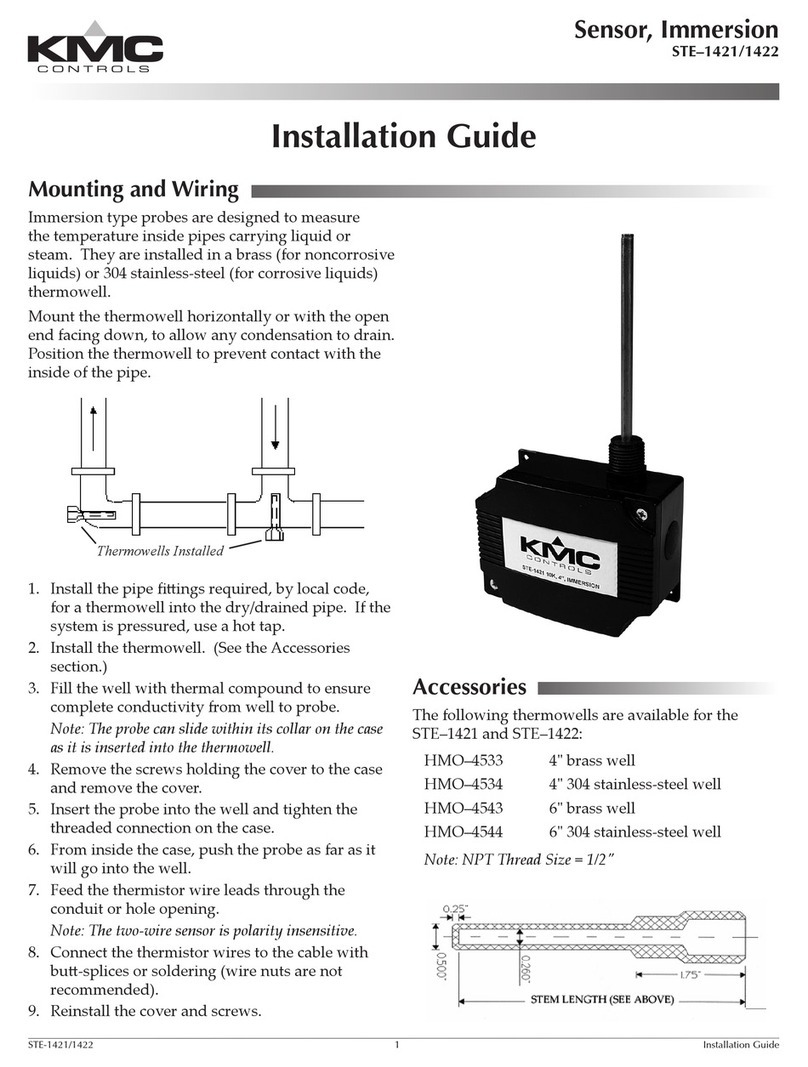

motion sensing For STE-8201 only—Mount the STE-8201 sensor on a wall that will have an

unobstructed view of the typical traffic in the coverage area. When choosing a

location, do not install the sensor in the following areas.

◆Behind curtains or other obstructions

◆In locations that will expose it to sunlight or heat sources

◆Near a heating/cooling duct.

For details on the coverage pattern, see Specifications on page 4.

The effective detection range is approximately 10 meters or 33 feet. Factors that

may reduce the range include:

◆The difference between the surface temperature of the object and the

background temperature of the room is too small.

◆Object movement in a direct line toward the sensor.

◆Very slow or very fast object movement.

◆Obstructions as shown in the illustration Typical motion sensing coverage area

on page 7.

Illustration 2-1 Typical motion sensing coverage area