Istruzioni Instructions Betriebsanleitung

16

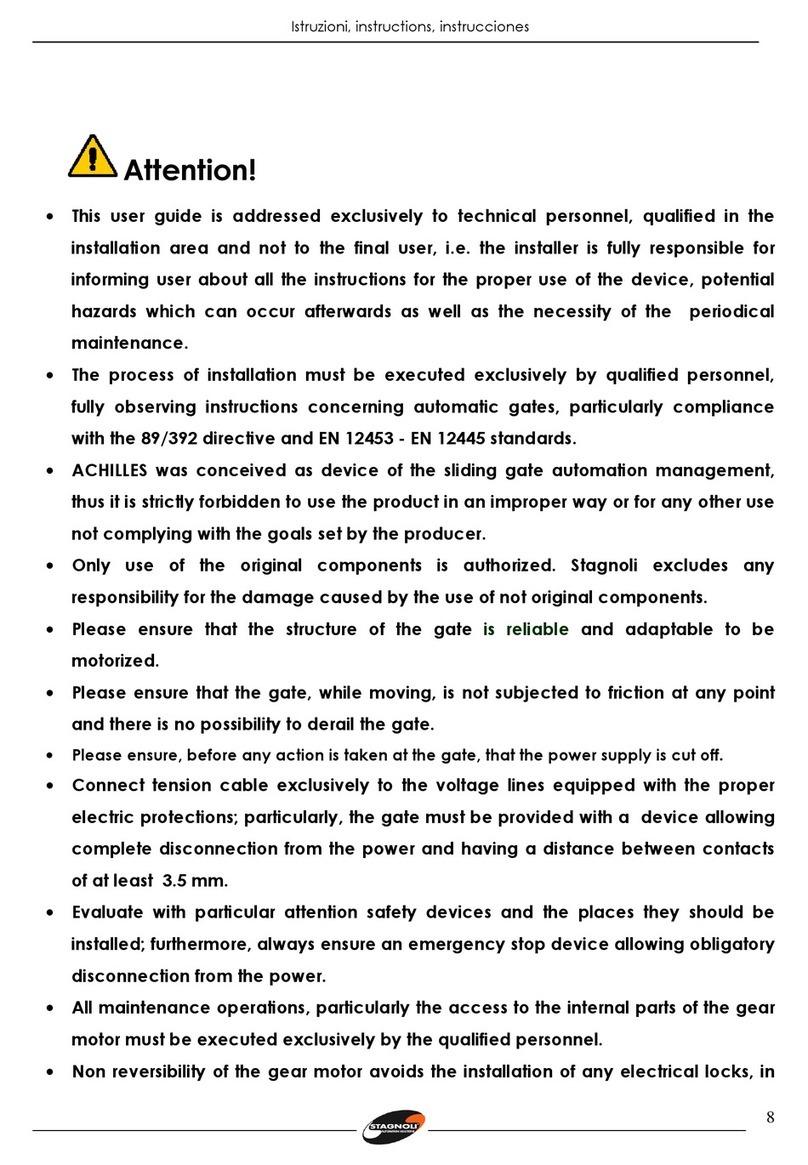

FUNCTIONING MODES

The unit may control various functions based on the combinations of the

Dip Switches:

DIP FUNCTION ON OFF

SW –1

ELECTRONIC FRICTION

M1 The motor M1 supplies the

maximum thrust. The motor M1 supplies

the minimum thrust.

SW –2

ELECTRONIC FRICTION

M2 The motor M2 supplies the

maximum thrust. The motor M1 supplies

the minimum thrust.

SW –3

COMMAND

OPEN/CLOSE impulse opens –impulse blocks –

impulse closes impulse opens –impulse

closes

SW –4

AUTOMATIC CLOSING The automatic operation is

activated The semi-automatic

operation is activated

SW –5

BATTERING RAM The M1 shutter is closed for a

second to free the electric lock

and then the opening restarts.

The opening phase is not

provided for the use of

the battering ram.

SW –6

SHUTTER DELAY

During the closing operation, the

M1 shutter is activated after 3

seconds of the activation of the

M2 shutter.

During the closing

operation, the M1 shutter

is activated after 7

seconds of the

activation of the M2

shutter.

SW –7

FUNCTIONING ½

MOTORS Activated two –motors operation

mode. Activated one–motor

operation mode.

SW -8

AUTOMATIC

LEARNING

Proceeds the operation of

automatic learning of the shutter

movements and bringing to

automation the closing time.

The automatic learning

phase is deactivated.

PROGRAMMING

The programming of the central unit requires the following steps:

•Manual opening of the gate.

•Program SW –8 = ON, the blinking unit will emit a steady light to inform the user that the

programming procedure has been started.

•Press the Open/Close button or the radio control button once; the M2 shutter will close

completely, followed, after 2 seconds, by the other one(M1). If the shutters are activated

in the opening phase, power supply should be cut off and invert the connections in the

motors in order to enable proper programming.

•After closing the two shutters, starts the opening phase(automatically), first activating the

M1 shutter and then the M2 one until reaching the mechanical positive stops in the

opening phase (the process of reaching the end points proceeds in slow motion).

•From the moment when the shutters have reached the mechanical stops in the opening

phase, the counting of automatic closing time starts; when the requested time has

passed, one should press once again the Open/ Close button or the radio control button,

in order to control the closing of the gate.

•When the closing operation has come to an end, program SW –8 = OFF;

•End of programming.