Instructions and warnings for installation

• Before commencing installation read the SAFETY INSTRUCTIONS AND WARNINGS chapter carefully.

• The person who installs the operator is responsible for performing risk analysis and regulating the automation’s safety devices consequentially.

• Before commencing installation, check whether further devices or materials are needed to complete the automation in order to suit the specic situation in which it will be used.

• Itisstrictlyforbiddentomotoriseagatethatisnotalreadyefcientandsecureastheautomationcannotresolvefaultscausedbyincorrectinstallationorpoormaintenanceofthegate.

• Duringinstallation,makeconstantreferencetoharmonisedstandardsEN12453andEN12445.

• Ensurethattheindividualdevicestobeinstalledaresuitablefortheautomationthatoneintendstocreate,payingcarefulattentiontothepointsraisedintheTECHNICALDATAchapter.Donotproceed

if even just one device is unsuitable for the intended use.

• Ensurethattheplaceofinstallationisnotpronetoooding,doesnotcontainsourcesofheatornakedames,resorhazardsituationsingeneral.

• Duringinstallation,protectautomationcomponentstopreventliquids(e.g.rain)and/orforeignbodies(earth,gravel,etc)penetratinginside.

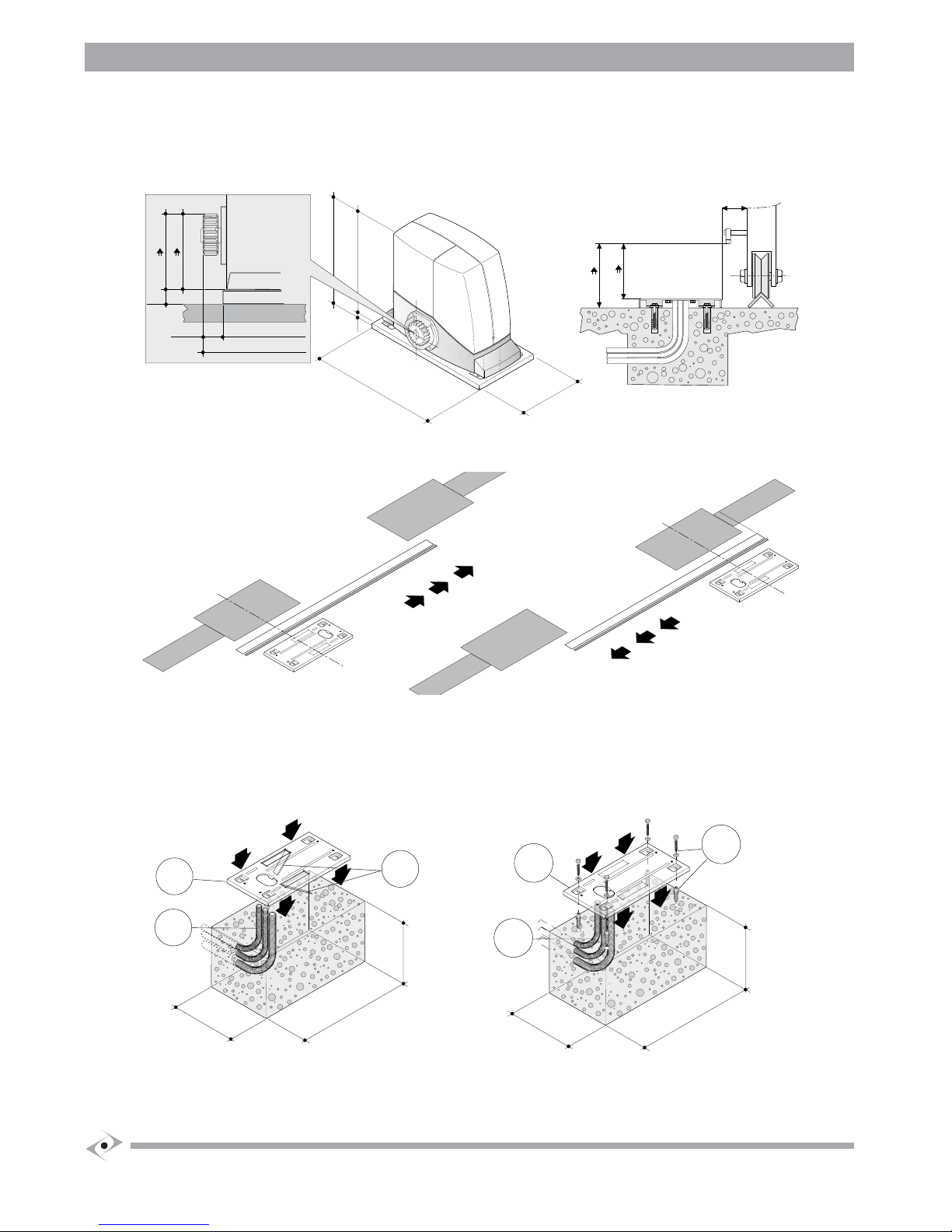

Preliminary checks

Beforecommencinginstallation,thefollowingpreliminarychecksmustbeperformed:

1)Theweightanddimensionsofthegatemustnotexceedthelimitsforuse(seetheTECHNICALDATAchap.),iftheyexceedsuchlimits,theoperatormaynotbeinstalled.

2)Thegatestructuremustbesuitablefortheinstallationoftheoperatorandconformtocurrentstandards.

3)Thegate’smovementinbothopeningandclosuremustbeuniform,withoutpointsofgreaterresistanceorfriction.

4)Thegatemustbeproperlyhungandwithoutrisksofderailment,thiscanbecheckedbyslidingthegatebackandforthseveraltimes.

5)Thegatemustbehungat,i.e.itmustnotmovewhenleftinanypointoftheslidingtracks.Ensurethatthegatedoesnotbendordeviatefromitscourseduringmovement.

6)Thegatemustbeperfectlyatintotheplanetowhichtheslidingtrackisxed,inordertopreventirregularmovementduringoperation.

7)Thelimitswitchesmustbesufcientlysturdyandtheremustbenoriskofderailmentshouldthegatecollidewiththelimitswitches.

8)Theoperatorinstallationareamustnotbepronetooodingandthereforeitmaynotbeinstalledinpotholes,trenches,dipsintheground,etc.

9)Thecementbaseonwhichtheoperatormustbeinstalledmustbeadequatelysolidandcompact.

MAINTENANCE INSTRUCTIONS AND WARNINGS

• Once the automation has been tested, the parameters set must not be altered. If further adjustments (e.g. alterations to the voltage value) are made, all the checks required for testing

and compliance with standards must be repeated.

• The Manufacturer declines responsibility for damage or injury caused by non-compliance with the information provided in this manual and the safety instructions provided below.

• The Manufacturer declines all responsibility for damage and malfunctions deriving from non-compliance with the maintenance instructions.

• In order to keep the operator efcient and safe, follow the cleaning, checking and routine maintenance procedures as described in this manual. This is the owner’s duty.

• Any checking, maintenance or repair work must be conducted by a PROFESSIONAL FITTER

• Always switch of the electricity supply in the event of malfunctions, breakdowns and before any other operations in order to avoid the gate from being activated.

• The owner is not authorised to remove the operator lid as it contains live parts.

• If the power cable is damaged, it must be replaced by the Manufacturer or its technical Assistance service or in any case a person with a similar qualication in order to avoid risks.

• TheownerisNOTauthorisedtousetheprogrammingkeyboard.

• Useoriginalpareparts,accessoriesandclampingmaterialonly.

• Donotperformtechnicalorprogrammingmodicationsontheoperator.Operationsofthistypemaycausemalfunctionsand/orriskofaccidents.TheManufacturerdeclinesresponsibilityfordamage

derivingfrommodiedproducts.

• Intheeventofinterventionofautomaticorfuseswitches,beforerestoringfunctionconditionsidentifyandeliminatethefault.RequesttheinterventionofaPROFESSIONALFITTER.

• Ifafaultthatcannotbesolvedfollowingtheinformationcontainedinthepresentmanual,contactthemanufacturer’sassistanceservice.

• Allmaintenance,repairorreplacementofpartsmustberecordedinthemaintenancelog,whichisSUPPLIEDANDINITIALLYFILLEDINBYTHEFITTER.

• Inspecttheinstallationfrequentlytoensurethattherearenosignsofmechanicalunbalance,wearordamagetothewiresandassembledparts:nonotusetheautomationuntilanynecessaryrepairs

or adjustments have been made.

Cleaning the automation

ATTENTION:

•Never wash the operator using water sprays or washing devices.

•Do not use corrosive substances, solvents, thinners or spirit to clean the operator.

•Switch off the electricity supply to the operator before cleaning.

a)Automationsarealmostalwaysinstalledoutdoorsandthereforetheyaresubjecttoclimaticvariationsandexposedtotheelements,whichtransportdebristhatmaycauseproblems.

b)Theentireareainwhichtheautomationisinstalledmustbekeptcleantoavoidmalfunctionsand/orfaults.

c)Keepthetrackonwhichthegaterunscleanbysweepingstones,gravel,andmudoffusingabroom.

d) C

lear the area in which the operator is installed to prevent stones, gravel, mud, dry leaves, pine needles etc. from accumulating around the pinion, thus causing damage to the pinion, rack, limit switch and operator.

Routine maintenance

EverysixmonthscontactaPROFESSIONALFITTERtoperformthefollowingoperations.

• Aseriesofopeningandclosingchecksusingradiocontrolsandselectors,usingallthesystem’scomponents(photocells,ashinglight,etc.).Ensurethattheoperatorperformsthedesiredaction.

• Greasetheoperator’snut-screw-bushingunitandthegatehinges.

• Repeattheseriesoftestsenvisagedforoperatortesting(seeINSTALLATIONMANUAL–Testingandrstrunchapter.

DEMOLITION AND DISPOSAL

ACERoperatorsareconstitutedbyvariousmaterials,whichimplicatesdifferentdisposalmodes.Materialssuchasaluminium,plastic,electriccables,etc.,canberecycled;batteries,electroniccards,

etc. must be disposed of.

ATTENTION:

• The disposal of batteries, cards and electric and electronic components must comply with legislation and local regulations on toxic, harmful and polluting substances.

• Disconnection from the main supply must always be performed by a qualied electrician using suitable equipment.