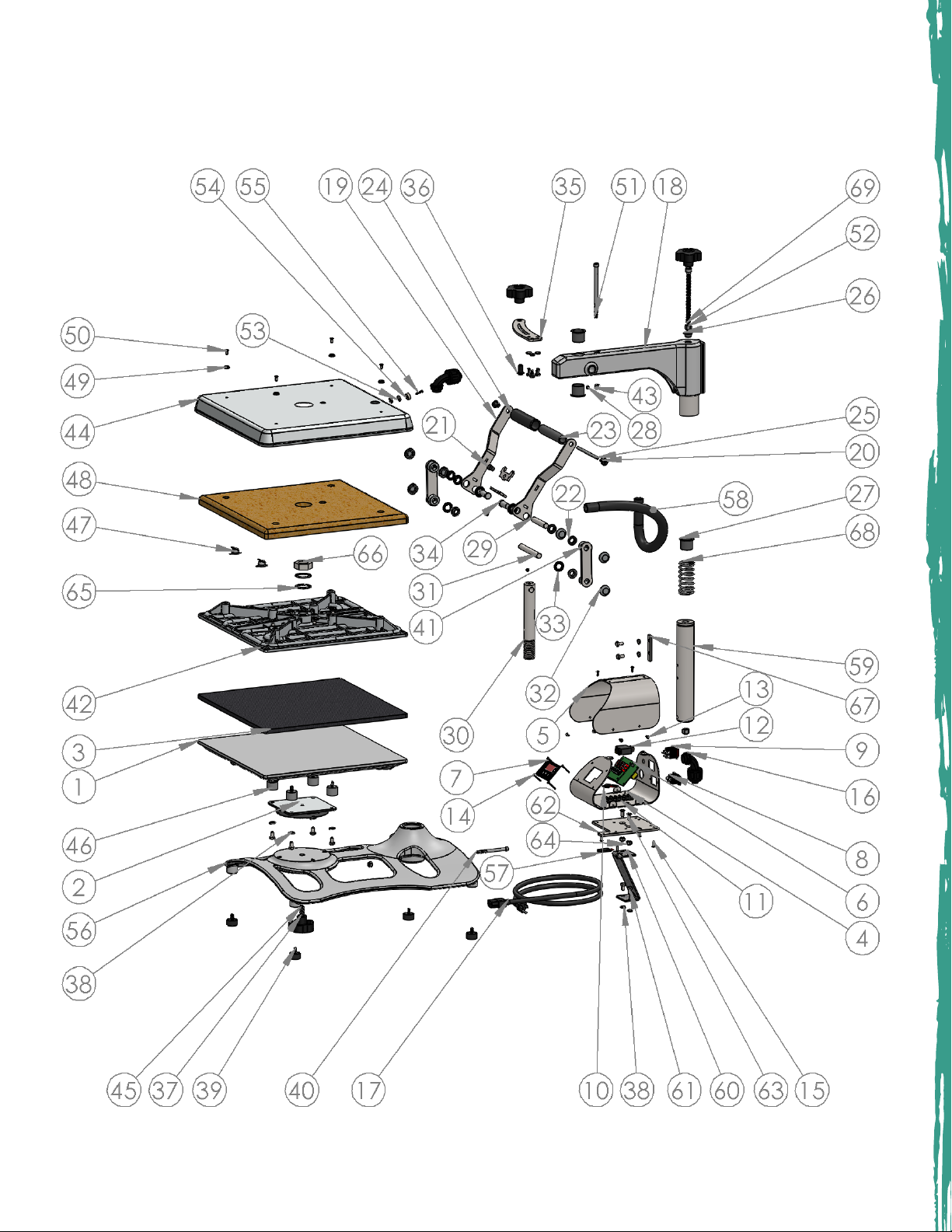

10

Replacement Parts List

# DESCRIPTION PART # QTY

1 A2Z Lower Platen, 15" X 15" 3-1384 1

2 Skinny Adapter Plate 3-1336-1 1

3 Silicone Pad 15" x 15" Black 1-2622 1

4 A2Z Control Cradle 1-2595 1

5 A2Z Control Cover 1-2594 1

6 Controller, Craft 1-2604 1

7 Controller Overlay, A2Z 1-2623 1

8 Power Inlet 1-1759 1

9 Power Switch 1-2076 1

10 TRIAC, STX/MAXX 2-1675 1

11 Terminal Block, 5 Contact 1-1290 1

12 Circuit Breaker 20A 1-1331-3 1

13 Screw, Machine #6-32 x 1/2" 3-1011-19 8

14 Screw, Pan Phillips #4-40 x 1" 3-1011-130 4

15 Screw, Machine #6-32" x 1/4" 3-1011-25 4

16 Conduit Fitting, 1/2"Elbow HPASC 1-2618 2

17 Power Cord, 120V Locking 2-1671 1

17 Power Cord, 220V 1-2186 1

17 Power Cord, 230V European

Locking 2-1672 1

18 A2Z Arm Casting 3-1382 1

19 A2Z Handle 2

20 JCN Nut, 1/4"-20 2-1006-2 2

21 Rubber Foot, Small Push-In 1-1056 2

22 Nylon Bushing, Flanged 1/2” x 1/4” 1-2627 4

23 PVC Spacer, 1/2” x 4.5” 1-1049-16 1

24 Foam Grip, Black 1-1540 1

25 Threaded Rod 1/4”-20 x 4.50 1-1042-2 1

26 Nylon Bushing, Flanged 1/2"x 3/8" 1-2628 3

27 Nylon Bushing, Flanged 1" x 1" 1-2282 3

28 Set Screw, 1/4"-20 x 1/4" 3-1011-258 2

29 Pin, 1/2" x 2-3/4" 2-1055-30 1

30 A2Z Heater Spindle 3-1387 1

31 Pin, 1/2" x 4" 2-1055-31 1

32 Hub Cap 1/2" 1-1107-1 6

33 Nylon Washer 1-1048-3 4

34 Zinc Plated Clevis Pin, 1/2"D x 1"L

Usable 1-2629 2

35 A2Z Swing Arm 1

# DESCRIPTION PART # QTY

36 3/8-16" x 3/4" HHCS ZINC 3-1011-41 1

37 Knob with Cap, 3/8"-16 Thread 1-2621 3

38 Washer, Split Lock 1/4" 2-1006-44 11

39 Rubber Foot, 1"D with 1/4"-20 Stud 1-2620 4

40 Screw, 1/4"-20 x 3" Socket Head

Cap, Zinc 3-1011-280 1

41 A2Z Pressure Link 2

42 Heater, 15" x 15" A2Z 5-1000-1 1

43 Nylon Bushing, Flanged 7/16" x

3/8" 1-2630 1

44 A2Z Heater Cover, 15" x 15" 3-1351 1

45 Screw, 3/8"-16 x 2", Socket

Head Cap 3-1011-281 1

46 Vibration Damper 1-1056 4

47 Thermostat 1-2076 2

48 Insulation 15" x 15" x 1/2" 1-2257 1

49 Washer, Plastic Finishing 1-1063 4

50 Screw, #10-24" x 1/2", Phillips Flat

Head Thread Rolling 3-1011-217 4

51 Screw, 5/16"-18 x 5", Socket Head

Cap Zinc Plated 3-1011-282 1

52 Nut, Hex 3/8"-16 Nylok 2-1006-10 2

53 Washer, 1/4" Faucet PTFE 2-1006-111 2

54 Magnet, Neodymium

0.625" x 0.25" with #6 CSK 1-2486 1

55 Screw, #6 x 3/4" Self Tapping 3-1011-154 1

56 A2Z Base Casting 3-1381 1

57 Proximity Switch 1-1211 1

58 Conduit, 1/2" x 20" 2-1048-3 1

59 A2Z Spine 1

60 A2Z Control Box Support 1-2596 1

61 Screw, 1/4"-20 x 1/2" Hex

Head Cap 3-1011-11 11

62 A2Z Control Adapter Plate 1

63 Screw, 1/4"-20 x 5/8"Flat

Socket Head 3-1011-283 2

64 1/4”-20 Nylok Nut 2-1006-7 3

65 Nord-Lock Washer 1" 2-1006-94 1

66 Nut, 1"-12 Thin Jam 2-1006-110 1

67 A2Z Swing Stop 1

68 Spring, 1.4" x 3" 1-2631 1

69 Screw, 3/8"-16 x 5", Socket

Head Cap 3-1011-284 1