1. Fully inate Ball and position on

Ball Mount. Turn on press and

enter recommended settings:

8 sec @ca .113°C

WARNING: Prinng above 120°C will

scorch most balls.

4. Align the transfer material on the

ball to printed.

WARNING: Transfer material will not

adhere to stched seams or recessed

features.

5. Lower and lock the handle to print.

The timer will count down and

automatically raise the heater

when the press cycle is complete.

When the handle lifts, the timer

will re-set and you are ready for

the next application.

6. Pebbled products (e.g. basketballs

and footballs) require a secondary

press using Flex Application Pad.

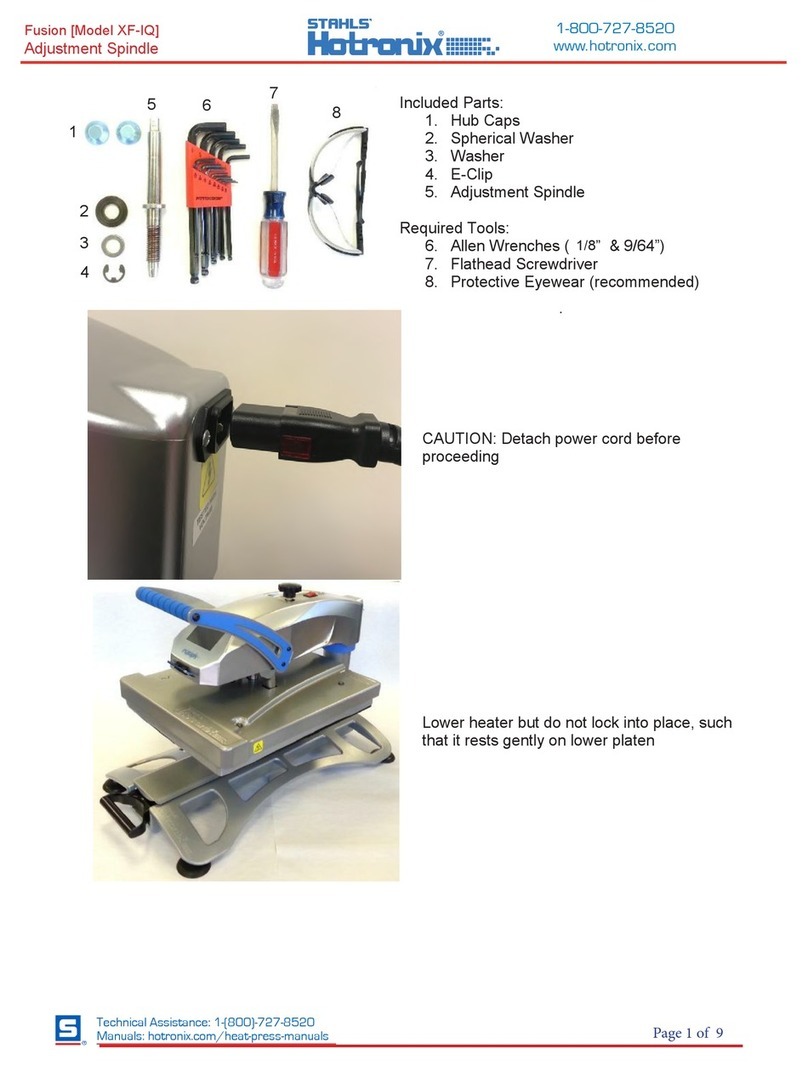

2. Lower the handle until the heater

touches the ball, then unlock the

Ball Mount by rotating the Ad-

justment Handle counter-clockwise.

3. Using the handle to raise or

lower the Ball Mount will adjust

print pressure. Most balls will print

well with about 5cm of space bet-

ween the Electromagnet and the

steel plate on the handle.

All copyright, trademarks and all other intellectual property rights in this document and its content (including without

limitation the design, text, graphics and all equipment and patents described within the document) are owned by or

licensed to Hotronix, Inc. or otherwise used by Hotronix, Inc. as permitted by law.

Printing with your Ball Press

Printing with your Press