- 3 -

Thank you for purchasing our product. Please carefully read this instruction manual before rst use.

Reproduction of this manual without the consent of the manufacturer is prohibited.

The photos and drawings are illustrative and may differ from the purchased device.

CAUTION: The manual should be kept in a safe place, available to the staff.

The manufacturer reserves the right to change the technical parameters of the device without prior notice.

1. SAFETY INSTRUCTIONS

Failure to follow this instruction may cause life-threatening situations.

• CAUTION: If the device was damaged during transport it should not be connected!

•In the case of a longer break in the operation of the device (night breaks, holiday breaks, etc.) it is necessary to disconnect

the device from the electrical power supply.

•Incorrect operation and improper use can cause serious damage to the device or injuries to persons.

•The device should only be used for the purpose for which it was designed.

•The manufacturer assumes no liability for any damages caused by incorrect operation and improper use of the device.

•During operation the device and the power cable plug must be protected against contact with water or other liquids. If the

device is accidentally fell into water or was ooded with water, it is necessary to immediately pull out the plug from the

socket, and then commission the inspection of the device to an expert technician.

•Do not insert any objects into the openings in the housing of the device.

•Do not touch the power cord plug with wet hands.

•Regularly inspect the condition of the plug and the power cord. In the case any damage to the plug or the cable is found, it

should be repaired in an authorized repair point.

•In case the device falls or is damaged in any other way, before further use it is always necessary for it to be inspected and

possibly repaired at a specialized repair point.

•Never open the housing of the device by yourself.

•Never try to repair the device by yourself – it could lead to life-threatening situations.

•It is prohibited for any changes and repairs to be performed by persons who are not professionally trained.

•Protect the power supply cable from contact with sharp or hot objects and keep it away from open ames.

•When disconnecting the device from the power supply socket, switch off the device rst. Always grab it by the plug and

never pull by the cord.

•Secure the power cable to ensure that no one pulls it from the socket by mistake and that no one trips over the cable.

• If the power cord is damaged, it has to be replaced. Non-detachable power supply cords should be replaced at

a specialized repair workshop or by a qualied person.

•Control the operation of the device during use.

•Do not allow for the device to be used by minors, people with physical or mental disabilities and people with impaired mo-

bility, as well as persons without the appropriate experience and knowledge regarding the proper use of the device. Such

persons can operate the device only under the supervision of a person responsible for safety.

•If the device is not currently in use or is cleaned, it is necessary to always unplug it from the power source by removing the

plug from the socket.

• CAUTION: If the plug of the power cord is connected to the electrical socket, the device remains energized.

•Never pull the device by the power cord.

•Do not move the dishwasher holding by the door handle.

2. PURPOSE OF THE DEVICE

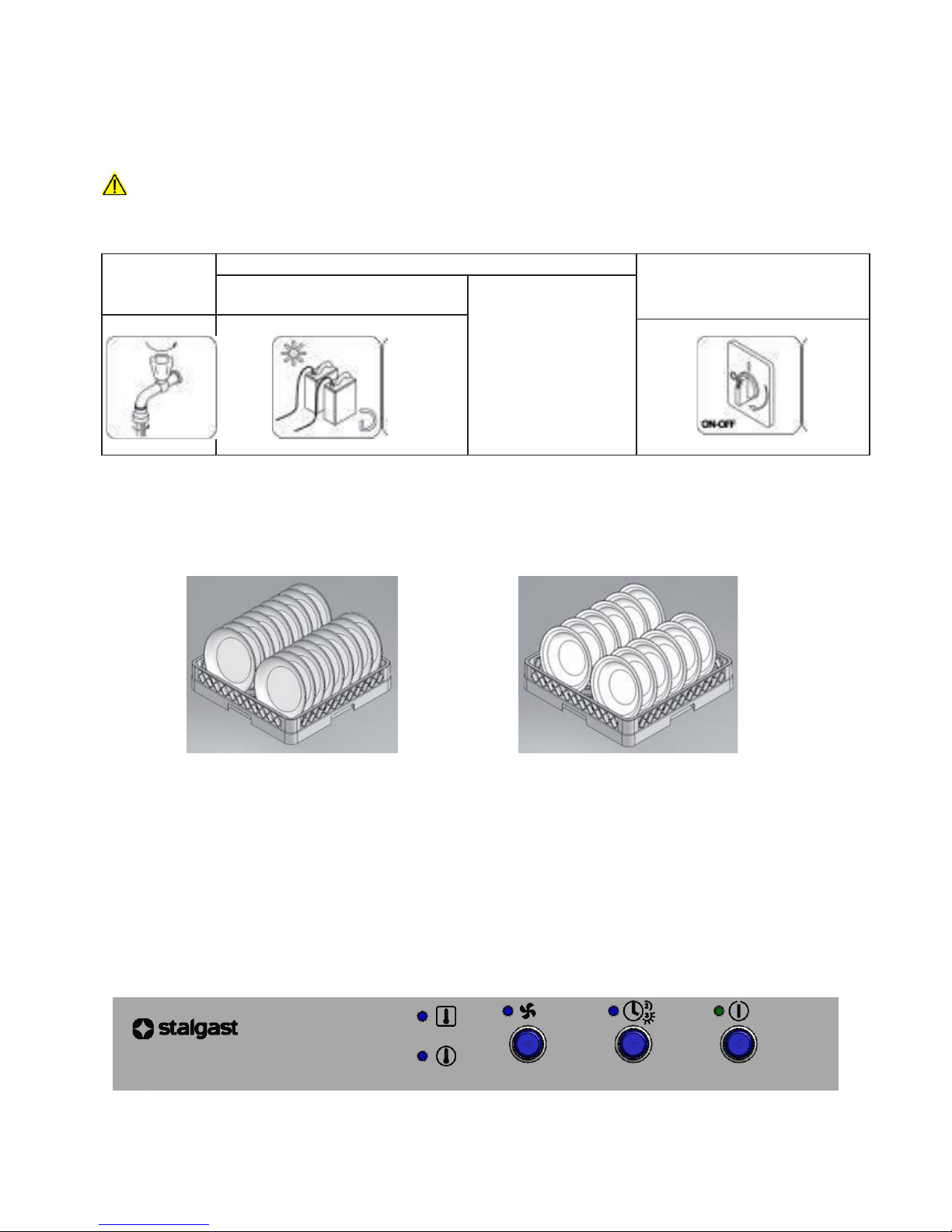

The dishwasher is exclusively intended for professional use and should be operated by trained personnel. The device is

intended for washing and sanitizing dishes (plates, bowls, cups, cutlery, trays, etc.) and other similar items used in the catering

industry and related branches, in compliance with the international regulations and standards relating to safety conditions in

the eld of electrical engineering, mechanics and electromagnetic compatibility.