tel.: 22 517 15 75 fax.: 22 517 15 77 www.stalgast.com email: stalgast@stalgast.com

Before starting the appliance, make sure that the supply and drain hoses are not bent, blocked or

otherwise damaged during installation.

IV. Setting the appliance

The appliance must be delivered to the installation site, unpacked and the contents of the package should be

checked. In case of damage to the appliance or any of its components, the shipping company must be notified

immediately. The packaging materials should be kept away from children and pets, as they can cause an

accident. All materials used to pack the product are environmentally friendly and can be safely stored in a

suitable place.

Recyclable components are marked as follows:

•PE – polyethylene: external packaging components, manual jacket, fastening components

•PP – polypropylene: grips

•PS – polystyrene foam: edge protection, package cover.

•Wooden and cardboard components must be left in places intended for this purpose in accordance

with applicable law.

It is forbidden to store the appliance and its components directly in the environment. The appliance was made

of stainless steel (alloy) and metal elements that can be easily removed. Plastic parts of the appliance are

marked with an appropriate symbol.

Connections to the devices must conform to the standards in force at the installation site. The

manufacturer is not liable for any injury or damage to the product resulting from failure to comply with the

standards in force at the installation site. Before installing the appliance, make sure that the moisture-sensitive

components are properly protected against wetting, e.g.: during the washing of the appliance. The appliance

should be set at a desired location and then the protective packaging should be removed. The appliance should

be leveled using a spirit level and the four adjustable feet, thus ensuring stable operation. Any other way of

leveling the appliance should be approved by the manufacturer.

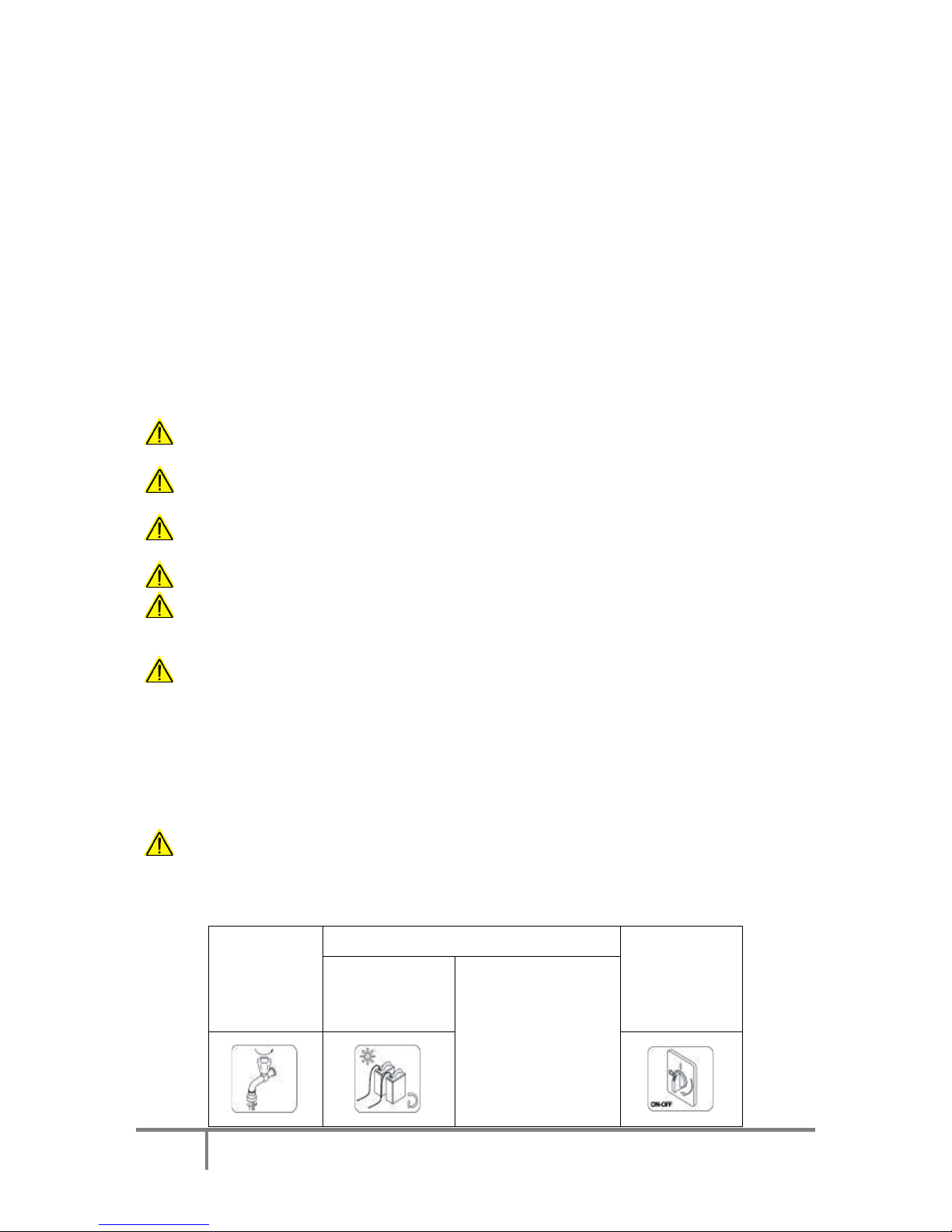

V. First start-up

Before starting the appliance, check the correct operation of the electronic safety system. The above steps

and the first start-up may only be done by technical service personnel, who will also conduct a short training in

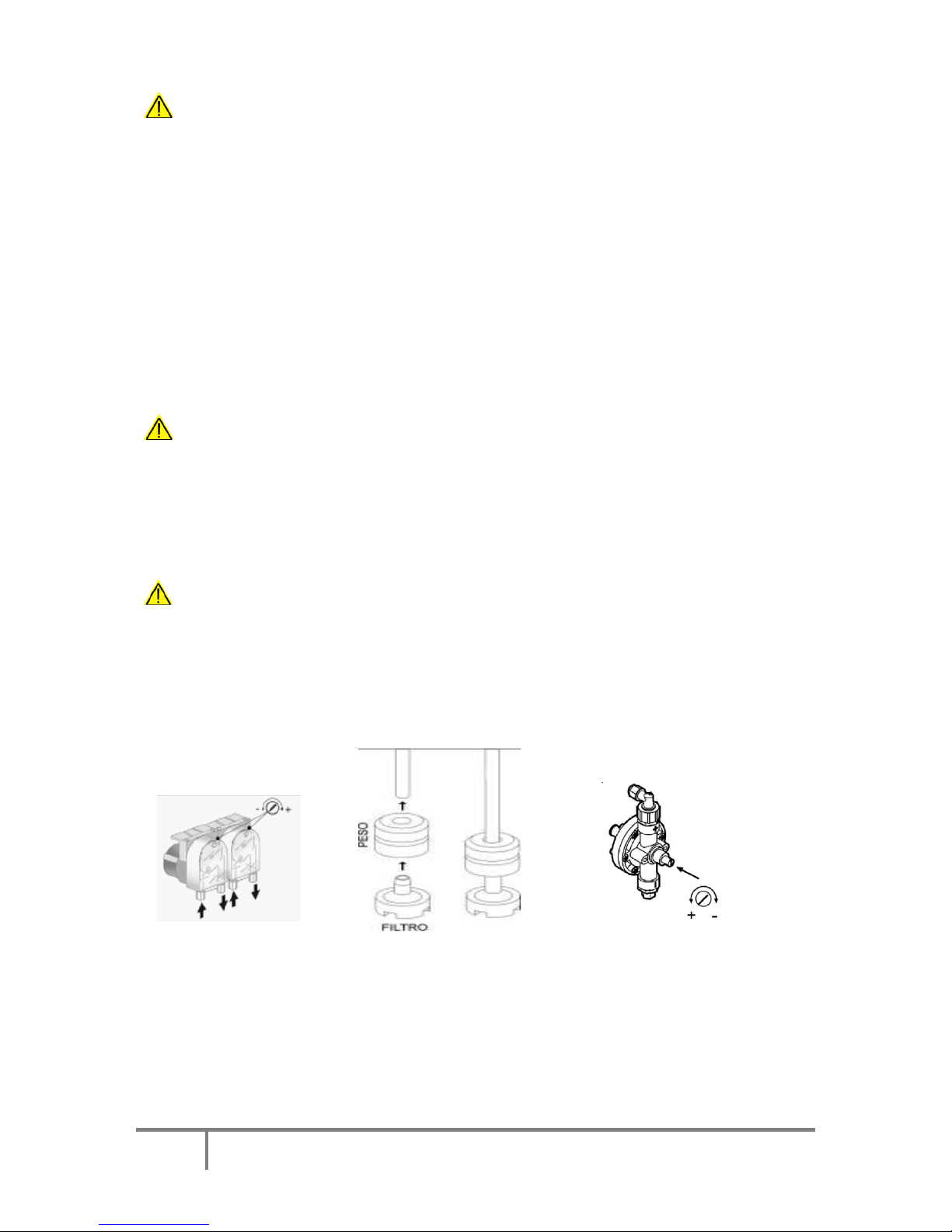

the operation of the appliance. Each appliance is equipped with an adjustable rinse aid dispenser. In contrast,

the adjustable washing liquid dispenser is only supplied with some models. A container for the washing liquid

and rinse aid must be put in place and then connected to suction tubes: the transparent one to the washing

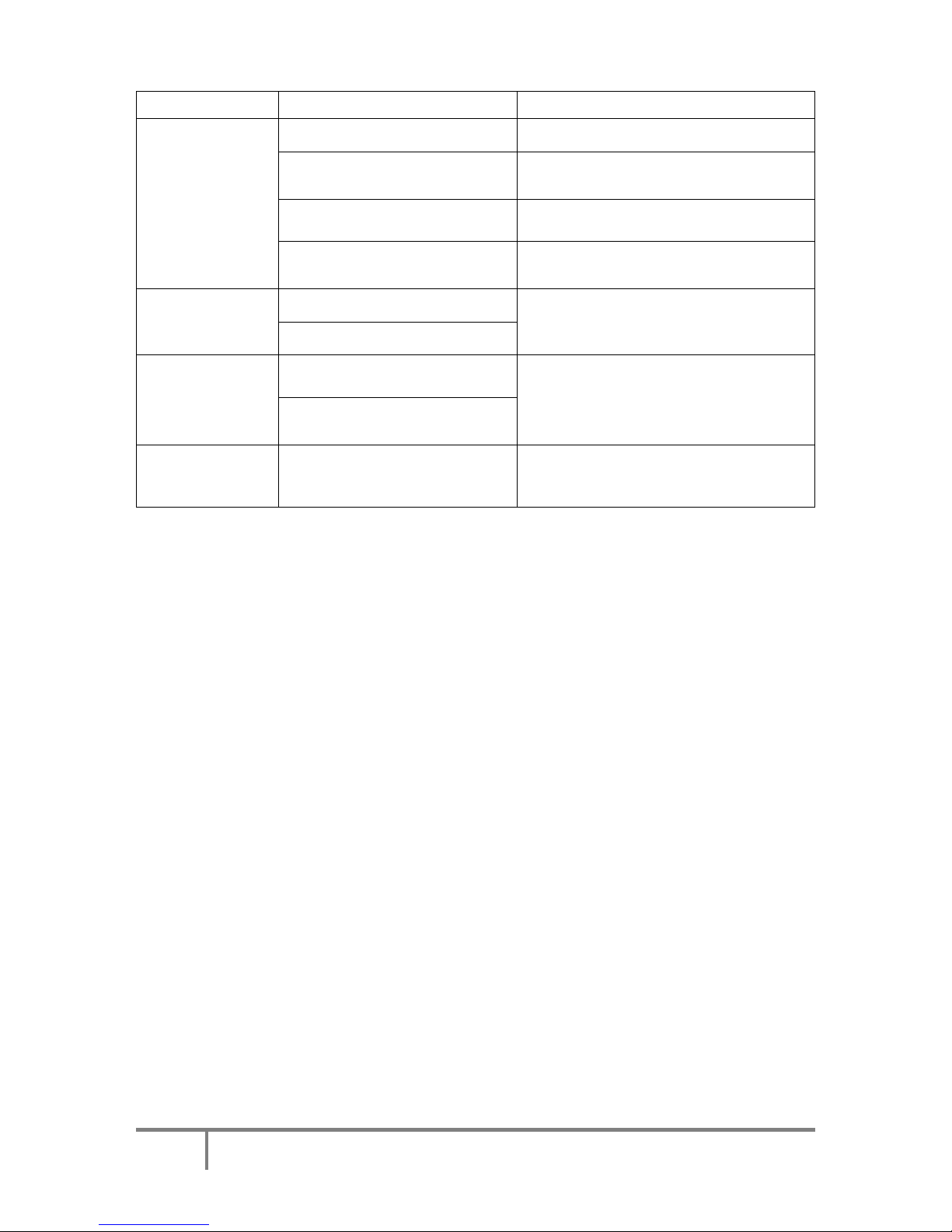

liquid, and the blue one to the rinse aid. To adjust, use the adjustment screws shown in (Fig. 3 and 5). It is

recommended that adjustments be made by the staff of the company providing the rinse aid and washing liquid.

Before connecting the suction tubes, weights should be attached (to keep the tube at the bottom of the

container) and filters should be installed. (Fig. 4)

Figure 3Figure 4Figure 5

If the liquid dispensers have not been installed prior to installing the appliance, it can be done at a later time

using a suitable tool set.

Alternatively, an external washing liquid dispenser can be connected through an electrical connection via a

2x0.5mm H07 RN-F cable. The cable must be connected through the passage indicated in the technical data

diagram, in accordance with the electrical parameters of the appliance and with the laws and regulations in

force. Dispenser parameters: 230V/50Hz, 15W. The washing liquid dispenser is connected to the dishwasher

through a transparent tube.