STALGAST Radom sp. z o.o. ul. Staniewicka 5 03-310 Warsaw

tel.: 22 517 15 75 fax.: 22 517 15 77 www.stalgast.com email: stalgast@stalgast.com

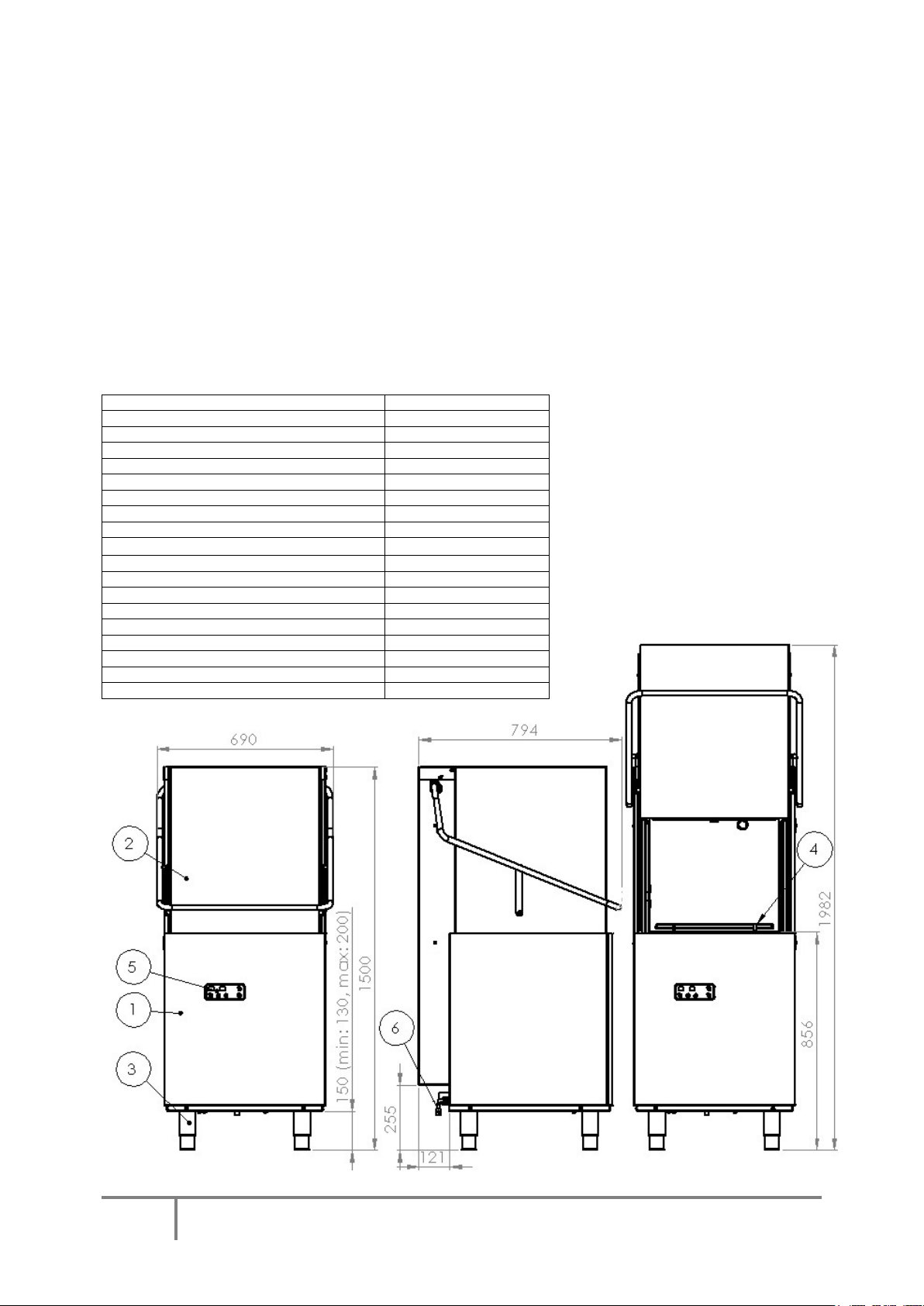

1 – Body

2 – Hood

3 – Adjustable feet

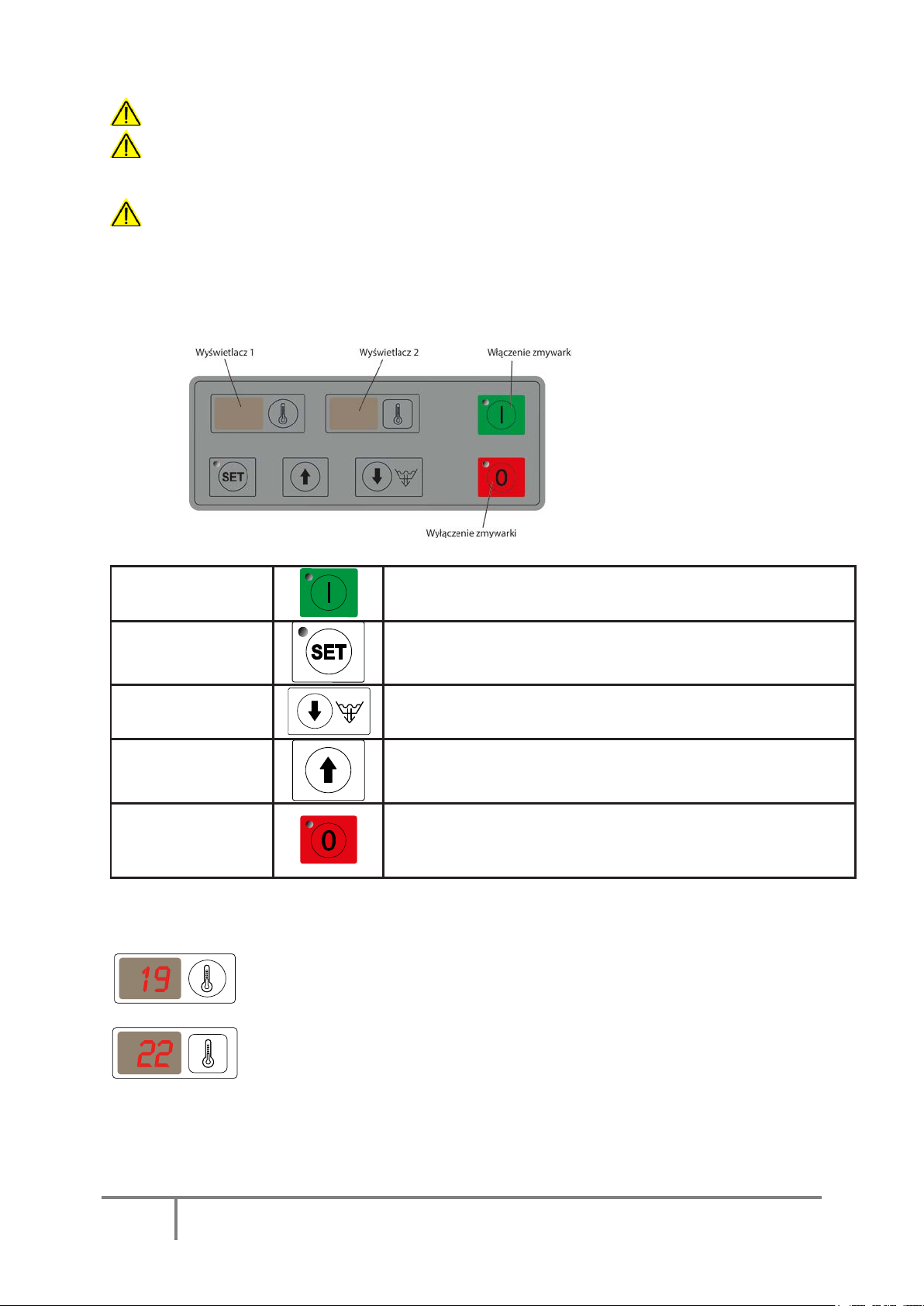

4 – Basket guide

5 – Control panel

6 – Supply: electricity and water

Dishwasher has an automatic

steam feature (it is

an integral part of the washing

cycle).

4. INSTALLATION

I. Connecting the appliance to a power source

Connecting the appliance to the mains can only be carried out by the technical service personnel in accordance

with applicable law. The electrical parameters of the appliance are included in the table in section 3. It is

forbidden to make one electrical safeguard for two appliances. It is necessary to install a main circuit breaker

and an earth fault breaker.

Both switches must be installed in an easily accessible location in such a way as to guarantee disconnecting the

appliance from power supply in accordance with the category II.

The appliance is fully disconnected from the power supply only when the main switch is set to OFF. The

appliance must be connected via the terminal placed in the rear, lower part of the appliance. Protective earth

(PE) is marked in yellow-green, neutral (N) in blue, and phase conductors (L1, L2, L3) in black, gray, and brown,

respectively.

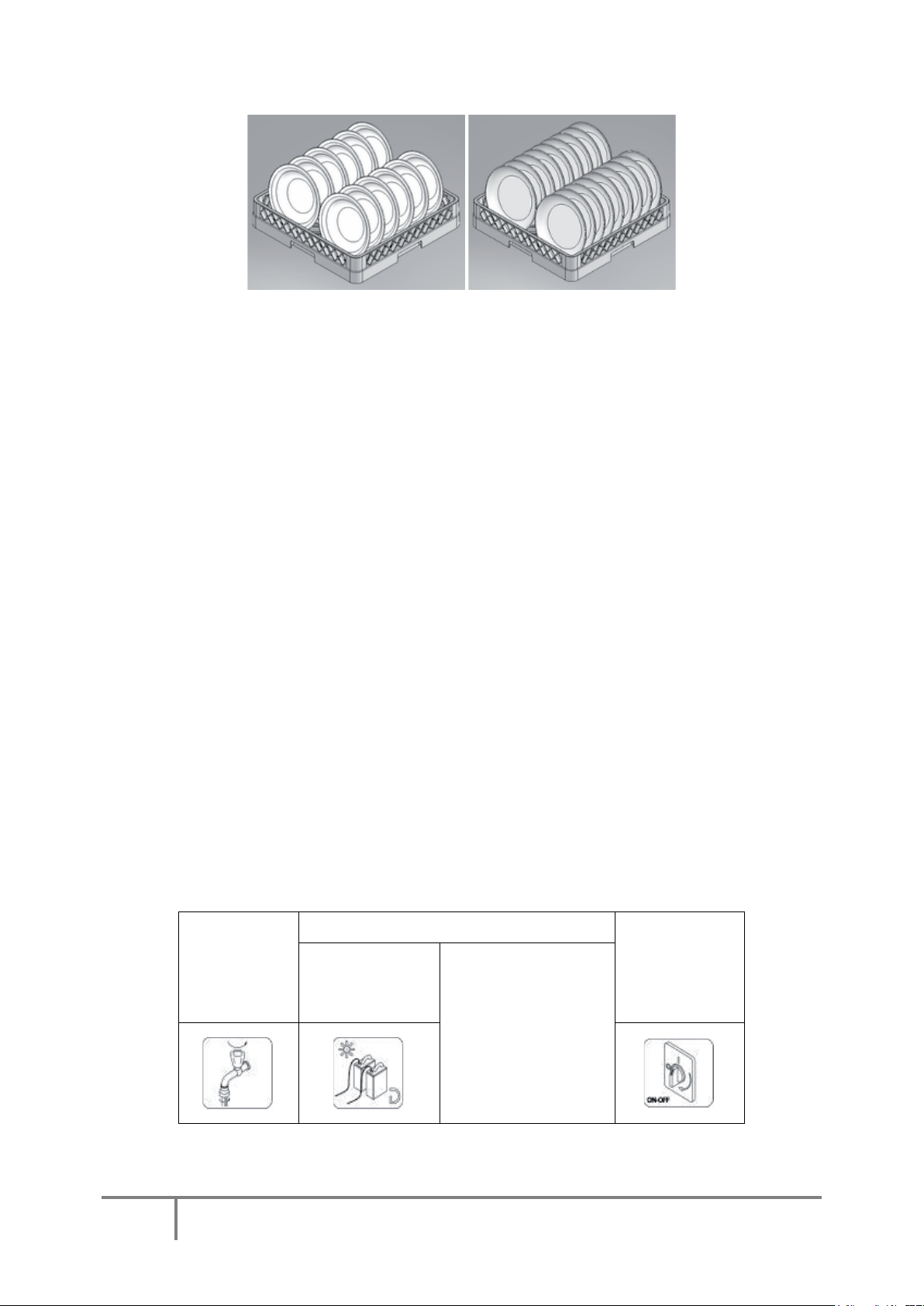

II. Connecting the appliance to the water mains

Water hoses and the power cord are protruding from the rear. The water supply hose must be connected to a

3/4" outlet. The connection should be closed only with the use of a brand new hose. In order to observe

safety, water pressure should be between 2-4 bar. Should the pressure be higher, a pressure reducer should be

installed. The main valve should be installed above the hose feeding water into the appliance. The main valve

should be installed in an easily accessible location; therefore it should not be installed behind the appliance. The

duration of the cycle is given for the supply water temperature of 50°C. When the appliance is connected to

cold water, the duration of the cycle may be increased, because the appliance is equipped with a constant

temperature pressure rinsing system.

III. Drain hole

The appliance is equipped with a drain pipe which should be installed at floor level with the use of a vent.

Before starting the appliance, make sure that the supply and drain hoses are not bent, blocked or

otherwise damaged during installation.

IV. Setting the appliance

The appliance must be delivered to the installation site, unpacked and its condition should be checked. In case

of damage to the appliance or any of its components, the shipping company must be notified immediately.

Connections to the devices must conform to the standards in force at the installation site. The manufacturer is

not liable for any injury or damage to the product resulting from failure to comply with the standards in force

at the installation site. Before installing the appliance, make sure that the moisture-sensitive components are

properly protected against wetting, e.g.: during the washing of the appliance.

The appliance should be set at a desired location and then the protective packaging should be removed. The

appliance should be leveled using a spirit level and the four adjustable feet, thus ensuring stable operation. Any

other way of leveling the appliance should be approved by the manufacturer.

The packaging materials should be kept away from children and pets, as they can cause an accident. All

materials used to pack the product are environmentally friendly and can be safely stored in a suitable place.

Recyclable components are marked as follows:

•PE – polyethylene: external packaging components, manual jacket, fastening components;