3

2M-Z19213; Rolling Tortilla Warmer Manual

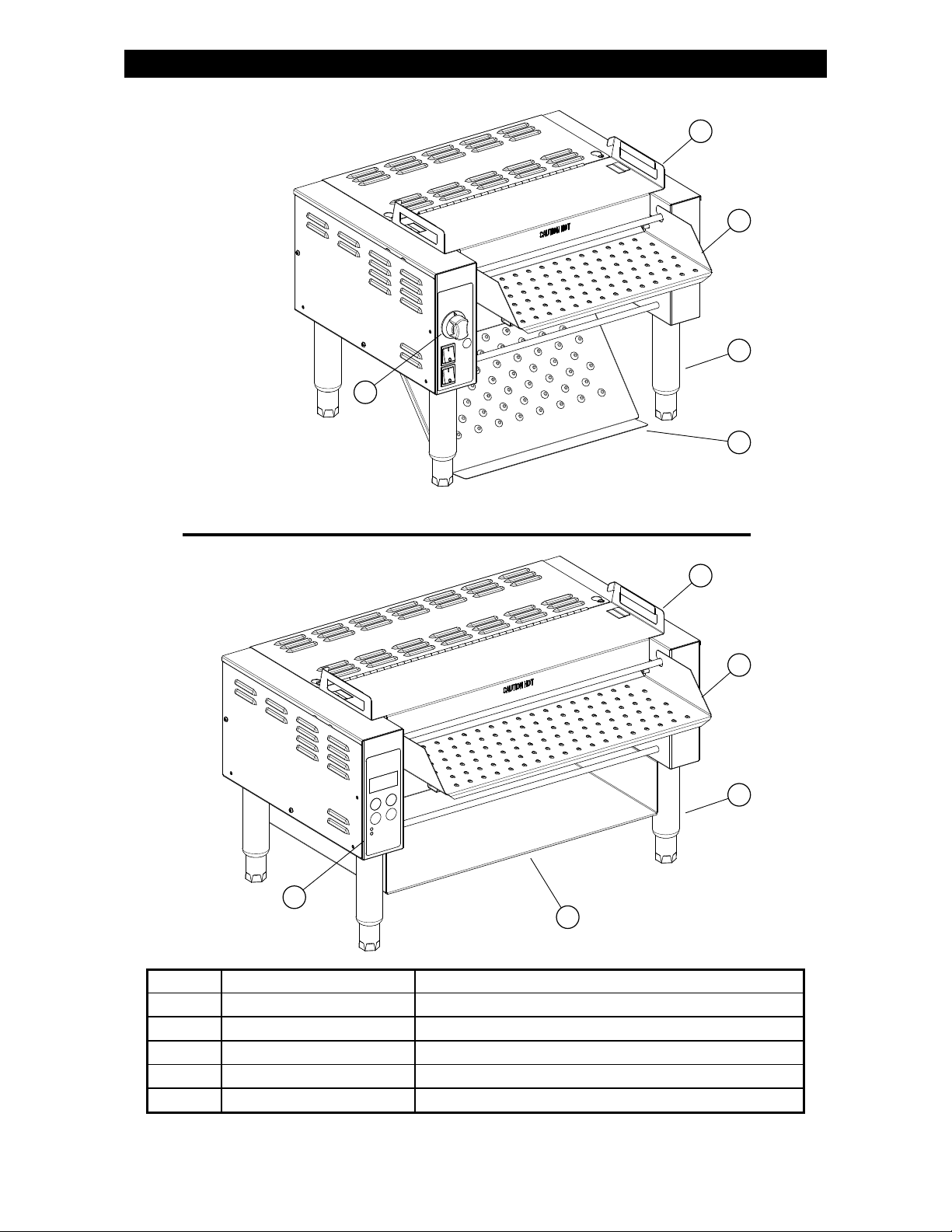

GENERAL INFORMATION

This equipment is designed and sold for commercial use only by personnel trained and

experienced in its operation and is not sold for consumer use in and around the home nor for

use directly by the general public in food service locations.

Before using your new equipment, read and understand all the instructions & labels associated

with the unit prior to putting it into operation. Make sure all people associated with its use

understand the units operation & safety before they use the unit.

INSPECTION

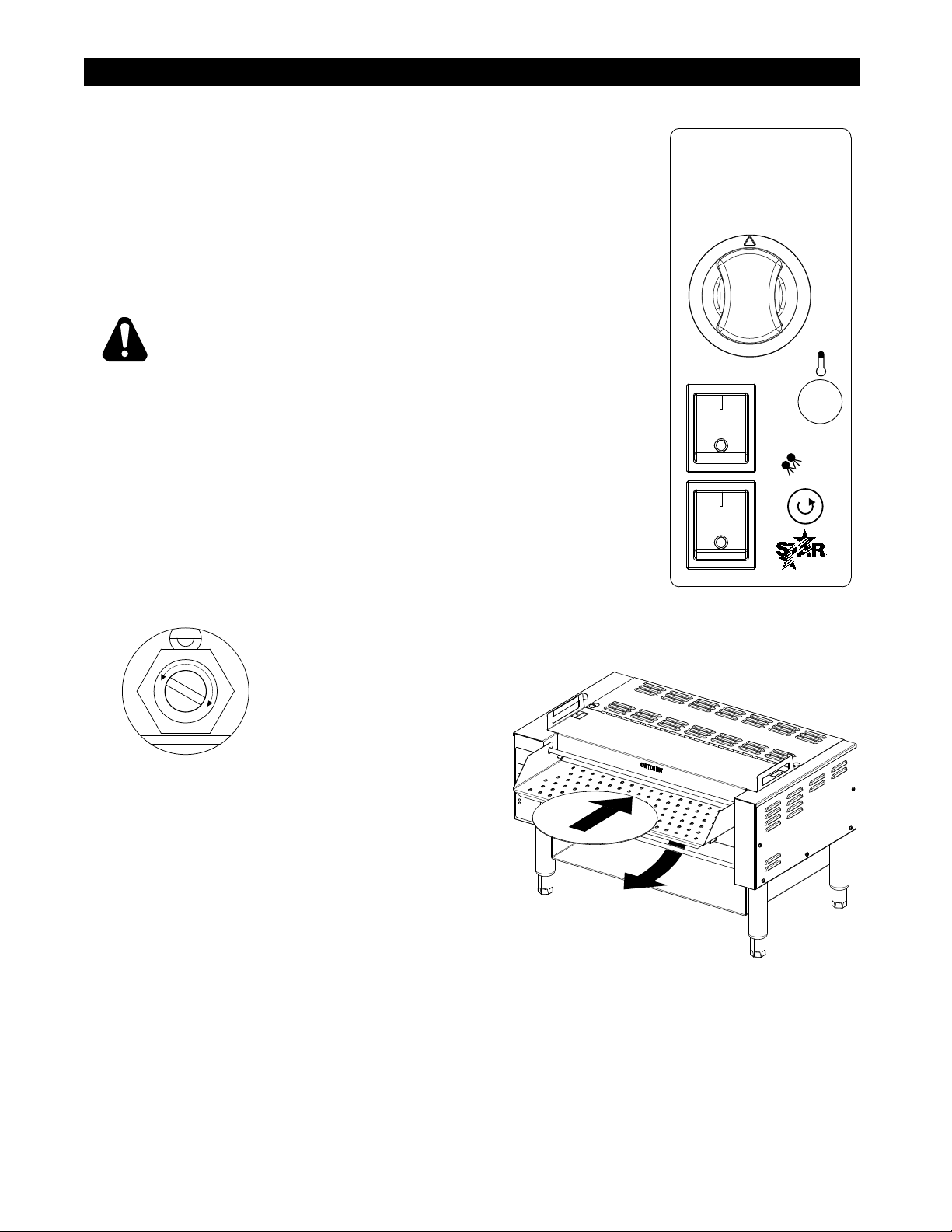

UN-CRATING AND INSPECTING

Unpack the unit and components from the shipping container. Remove all visible packing

material and those from inside the cooking chamber. If damage is discovered, le a claim

immediately with the carrier that handled the shipment. Do not operate the unit if it was

damaged during shipping. All shipping containers should be checked for freight damage both

visible and concealed. This unit has been tested and carefully packaged to insure delivery of

your unit in perfect condition. If equipment is received in damaged condition, either apparent or

concealed, a claim must be made with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is unpacked,

a request for inspection of concealed damage must be made with carrier within 15 days. Be

certain to retain all contents plus external and internal packaging materials for inspection. The

carrier will make an inspection and will supply necessary claim forms.

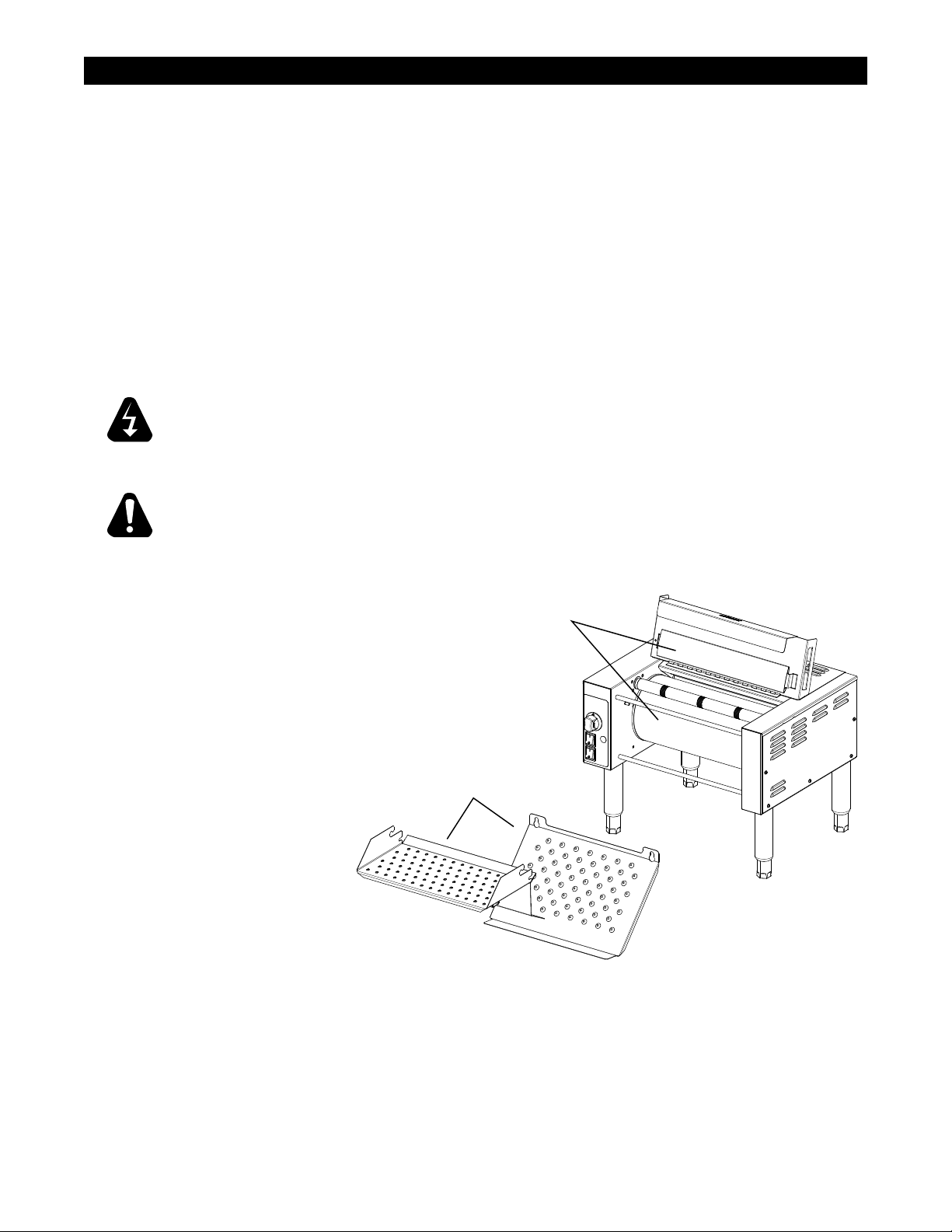

ELECTRICAL CONNECTION

Disconnect the unit from the power source before installing or removing any parts.

Be absolutely sure that the ground connection for the receptacle is properly wired.

Do not connect equipment to power without proper ground connections. Improper grounding

may result in personal injury or death.

CAUTION

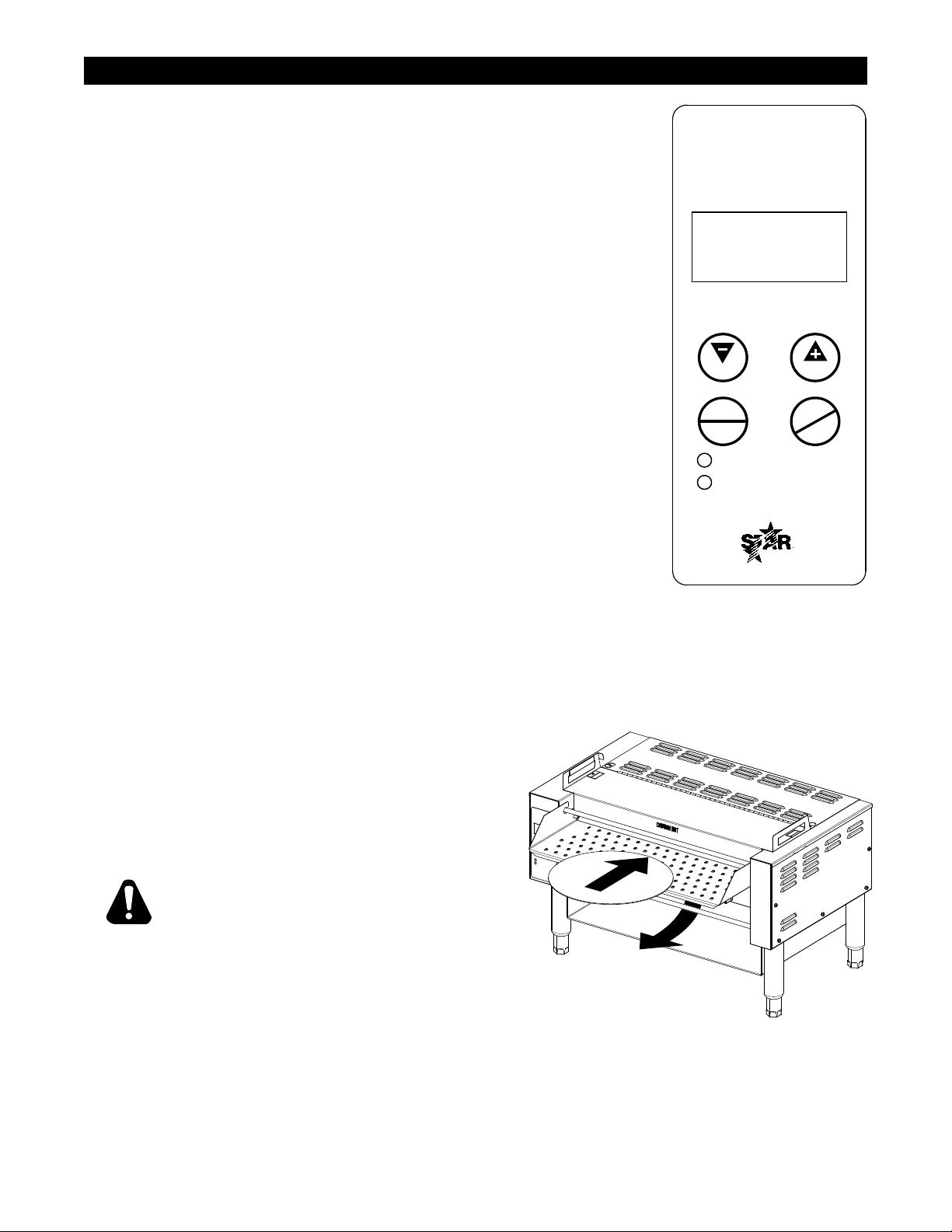

Allow enough space around the toaster for adequate ventilation. Do not operate the unit

without the crumb tray properly positioned. Overheating and poor toasting may occur.

Read all labels on the unit and follow their instructions.

WARNING

Before making any electrical connection to this unit, check that the power

supply is adequate for the voltage, amperage and requirements stated on

the rating plate. A wiring diagram is included.

WARNING

DO NOT CUT OR REMOVE THIS PLUG OR THE GROUNDING PRONG FROM

THE PLUG. FAILURE TO COMPLY MAY RESULT IN DEATH OR SERIOUS

INJURY.

WARNING

CONNECT/PLUG UNIT INTO DEDICATED A. C. LINE ONLY SPECIFIED ON

THE DATA PLATE OF THE UNIT.

CAUTION

SOME SURFACES ARE EXTREMELY HOT DURING OPERATION AND CARE

SHOULD BE TAKEN WHILE USING THIS UNIT.

CAUTION