Starfire SF-HC25C3 User manual

SF-HC25C3HeightController

Directory

1.Preface

1.1Purpose

1.2Importantstatement

1.3warning

2.Overview

2.1Technicalfeatures

2.2Functionalfeatures

2.3main technicalindicators

3.Install

3.1Install

3.2Electricalinstallationconnect

4.Parametersillustration

4.1Parametersettinginstruction

4.2Parameterspecification

5.Useguide

5.1Manualoperation

5.2Automaticoperation

6.CNC systemand block adjustmentforMinstructions

6.1CNC systemcontrol directoutputportoftheMfunction

6.2FixedcycleofMfunction

6.3CNC systemrecommendedsettings(STARFIRECNC)

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

SF-HC25C3HeightController

1

1introduction

Bothflamecuttingand plasmacutway,in theprocess ofcuttingtorchbetween

nozzleand thedistance(heighten)ofcuttingboardisveryimportanttothe

stability, itwill directly affectthecuttingspeedand thequality oftheincision.

SF-HC25C3 Plasma cuttingtorchheightcontroller

1.1Purpose

SF-HC25C3plasmacuttingtorchheightcontrollerisspeciallydesignedfor

portableplasma cuttingmachinecuttingtorchheightautomaticcontrol module.

SF-HC25C3plasmacuttingtorchheightcontroller,simpleoperation,convenient

debugging,affordable,adoptsdigitalcontrol,reliableperformance.Itisanideal

productofformacompletesetofweldingequipmentmanufacturers.Adoptthe

hostand thepanelsplittypestructure,especiallysuitableforportablecutting

machine.

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

SF-HC25C3HeightController

2

1.2Importantstatement

SF-HC25C3plasmacuttingtorchheightcontrollerand thecontentofthemanual

may betherearesomedifferences, pleasein kind prevail.Afterthisproductorits

accessorieshave anychanges,withoutpriornotice.Needtorefertoupdate

content.

Pleasebesuretoreadthesafetywarningsandprecautions,so astoavoid

improperuseleadtodangerousaccidents.

Beforeinstall and usethisproduct,mustbestrictlycarriedoutin accordancewith

thedetailsoftheproductsystemmanualoperation,in ordertoensurethe

correctuseoftheproduct.

AboutSF-HC25C3plasmacuttingtorchheightcontrollerand thecontentsofthis

manual,becarriedoutifanyspecificillegaluse,donotrepresentthepositionof

thecompany,and refusedtoacknowledgeitslegalliability,theconsequences

shall beborneby theusers.

Safety warningisusedtopreventthehumanbodyand property damage.

In theuseofSF-HC25C3cuttingtorchheightcontroller,ifthereisanyquality

problem,consumerscancontactourservicecenterorauthorizedoffice,dealers,

agentstogetthecorrespondingproductsand services.

1.3Warning

Tosafeoperation ofthisproduct,and achieve thedesignoftheproductcontrol

accuracy,toavoiddamagetoits,carefullyreadtherelatedwarningand strictly

abideby it.

Installation personmustberelatedindustryorrelatedexperienceoftechnical

personnel.

Youmustbecarefully readthismanualbeforeinstallation.

Toconfirmtheselectedpowersupplyisconsistentwithhisrequirement

specification.

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

SF-HC25C3HeightController

3

Youarestrictlybeenprohibitedundertheconditionsofelectricityinstallation or

plugorunplug.

Installation position should asfaraspossibleaway from heatsource.

Controllerenclosuremustbegoodgrounding, orinfluencethecontrollerin work.

Thebecuttingsteelplatemustbein goodgroundingandkeepgoodconnection

withcontrollershell, toensuretheaccuracy oftheheightcontrol.

Pleasecareful carryaway,and pleasedonotintensecollision,vibration,in order

toavoiddamagetotheproduct.

Pleasedonnotdosomethingwithoutauthorization toopencuttingtorchheight

controllerorchangeitsinternalstructure,topreventtheaccidentorfailure.

Note:thecontrollercasingand cutsteelwithoutgoodgrounding,heightcontrol

will notbeabletowork properly.

Withouttheexplicitwrittenpermission touseanyofthisinformation maynotbe

copied, reproducedorcontent, theoffenderswill befullyliabletodamage.

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

SF-HC25C3HeightController

4

2.Overview

2.1Technicalfeatures

SF-HC25C3plasma cuttingtorchheightcontrollerisaftermany yearsof

practiceandseveralgenerationsofrelatedproductsintoplay.

Thisproductadoptsthe32-bitarmasthecore, twogroupsofthree digitaltube

display, adoptsdigitalcontrol mode.Donotcontain linearadjustmentdevice

internal,greatly improvingthestability.

Velocity parameterscanbemodified, accordingtotheliftingmechanism with

powersupply and any modification.

Circuitadoptsthetechnology ofthepatch. Thereisnotinternaladjustment

device,full digitalcontroltechnologytoensurethattheproducthashigh

reliability.

Operation simple, twogroupsofdigitaltubedisplay settingarcvoltageandthe

arcpressurerespectively,conciseand straightforward. Settingparameters

operatingintotalofthree knobs.

Interfacesimply andcontrol convenient, itsuitableforall plasma cutting

numericalcontrol system,canalso beusedalone.

Itadoptstheproximity switchinitialalignmentmethod.

PWMoutput, speedadjustableoflevel255, control ofmotorspeedprecise,

severalcurrentsetting, shortcircuitprotection.

Cuttingwiththefunction ofcollision. Whencutlipstouchthesteelplate,the

controllercanquickly cutraisea certain distance, effectiveprotection ofnozzle.

All inputand outputadoptphotoelectricisolation, plasma voltagefeedback using

linearphotoelectricisolated, independentpowersupply,canverygood

compatibility withthepartialpressureofvariousbrandsofimportedplasma

powersupply.

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

SF-HC25C3HeightController

5

Itisintegration startingarcsuccessful judgmentfunction,and arcsuccessful

feedback function.

2.2Functionalfeatures

Automaticinitialpositioning

real-timearcvoltagefeedback.

inputlogiclevelcanbesetfreely.

two-speedinitialalignment.

manual, automatic, positioningoftheup and downspeedcanbesetrespectively.

Grade255 lPwmoutput, adjustablespeed, precisecontrol ofmotorspeed,

severalcurrentsetting, shortcircuitprotection.

all inputand outputadoptphotoelectricisolation, plasmavoltagefeedback using

linearphotoelectricisolated, independentpowersupply,canverygood

compatibility withthepartialpressureofvariousbrandsofimportedplasma

powersupply.

integration andarcsuccessful judgmentfunction, and arcsuccessful feedback

function.

Lsetelementslinkingpiece, withoutspecialshieldingbox.Plasma powersupply

onthebackoftheterminalcontrol all meetinthiscontroller, convenient

connection.

all interfacesusingpluggableterminal, don't needwelding.

built-in softwarecalibration pressureratio.

self-learningfunction, usethefool,convenientdebuggingand use.

2.3Main technicalindicators

Powersupply requirements:DC24V +/-10%3A

Suitablemotor:24V withDCmotor

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

SF-HC25C3HeightController

6

Drive mode:PWM

Outputcurrent: <2A

Initialalignmentmethod:proximityswitch(normallyopennormallyclosed

throughthejumpercapset)

Highestaccuracy:+/ -1V

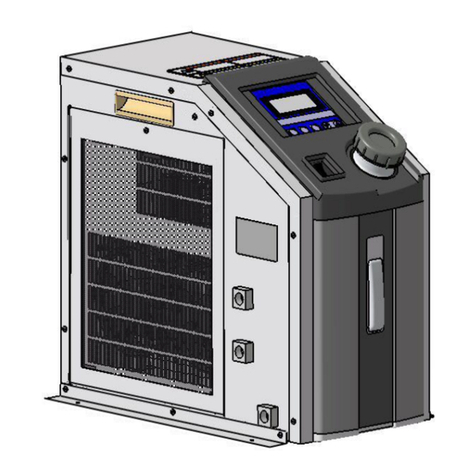

Box body size:271X221X70.5

Workingenvironmenttemperature:-10 ~60 ℃

Weight: 2.5Kg

Detection system:Built-in electricsubsection platen(specialedition)

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

SF-HC25C3HeightController

8

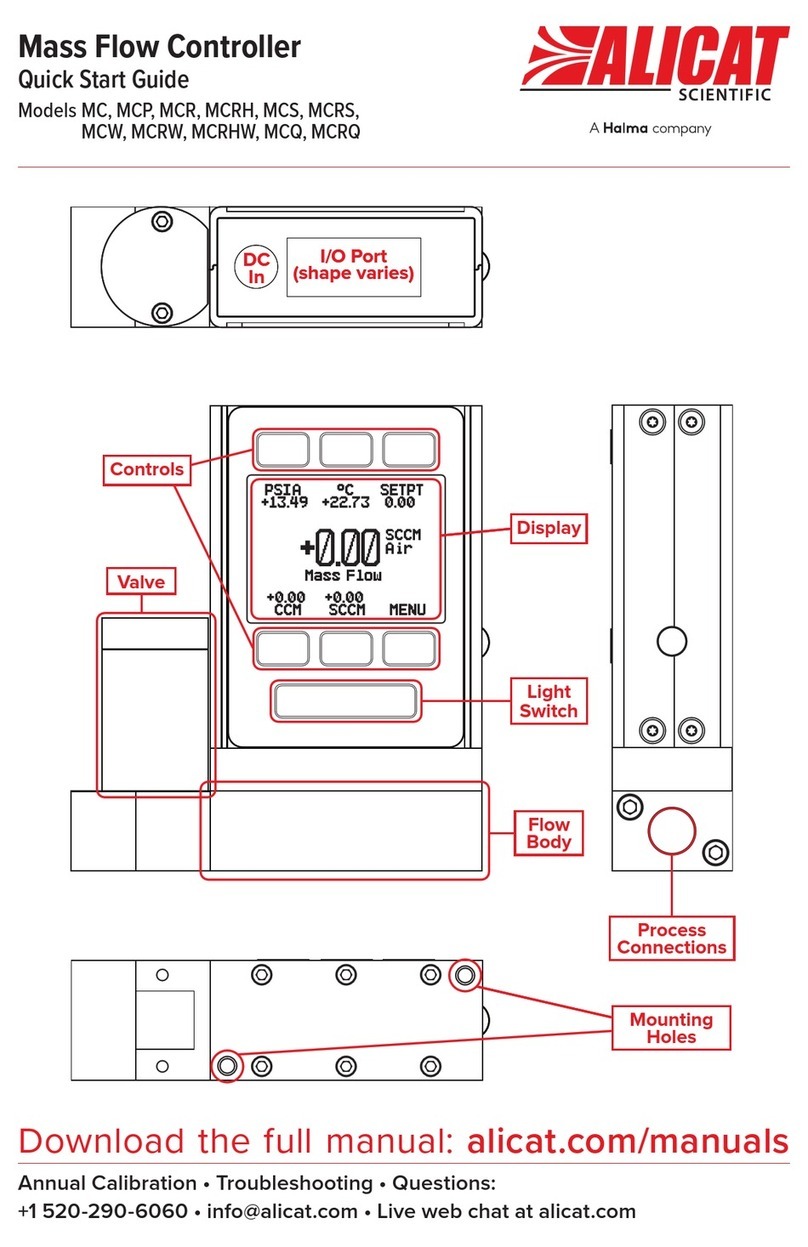

3.2.1 The interface definition

P1 P2 P3

figure3-2-1

table3-2-1

label

attribute

explain

note

P1 Control

input

CNC systemcontrol input: automatically,

lift, rev arcand success feedback, this

interfaceonthe24 vpowersupply is

isolatedandP1, providedby theCNC.

figure

3-2-2

P2 Input/outpu

t Improve motorandcollisionsignalandlimit

signals. figure

3-2-3

P3 Thepower

input

24 vpowersupply, itspowerconsumption,

improve themotorpower, impactsignals

and limittheinterfacesprovideelectricity.

figure

3-2-4

Thepower

input

Connected

liftingmotor

ConnectCNC

system

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

SF-HC25C3HeightController

9

figure3-2-2ConnectCNCsystem

label attribute

explain note

automatic

input CNC output Automatic signal

(M38)

rising input CNC outputrising signal (M14)

falling input CNC outputfalling signal (M16)

Rev arc input CNC output Rev arc Signal (M12)

Successfu

lfeedback

output Rev arcsuccessful feedback

+24V power IO powersupply isprovidedbythe

CNC

24VG power IO powersupply providedbythe

CNC

figure3-2-3Connectingtheliftingmechanism

label attribute explain note

24V- POWER Offer 3lines closeto the

switch power supply

Cannotbeused

forother

equipment

ZERO INPUT Theinitialinputand

proximity -switchpositioning

way

24V+ POWER Offer3linesclosetothe

switchpowersupply

Cannotbeused

forother

equipment

M+ OUTPUT Liftingmotor+

M- OUTPUT Liftingmotor-

UP

limit INPUT UP limit

DOWM

limit INPUT DOWM

limit

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

SF-HC25C3HeightController

10

24VG COM the public end of the

limit

switch ,Positioning

Ofthelimitswitchisrecommendedtousenormally opentype.

Theinitialposition switchesisrecommendedtousetypeNPNnormally

open.(see appendix wiringmethods, 23 pages)

Initialposition switchescanalso usetheprotectivecap+ relay mode.

figure3-2-4POWERSUPPLY

label attribute

explain note

24VG input Switchpowersupplyoutput

negativeside Bytheswitch

powersupply

provide

24V+ input Theanodeswitchpowersupply

output

Requirements:switchingpowersupplycapacityisgreaterthan3.5Aabove.

Note:whenusingstarFCNCsystem,thistableallwiringisdirectnumericalcontrol

input/outputinterface,don'tneedtorelayequipmenttransformation.Itisbesttouse

shieldedcable.

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

SF-HC25C3HeightController

11

figure3-2-5Connecttheplasmapowersupply

label attribute

explain note

arcout

+ output Connection pointslinking

piece"rev arccontrol" Theoutputfor

relay normally

openoutput

output

arcout

- output Connection pointslinking

piece"rev arccontrol"

plasma

arc + input Connection points

linking piece "partial

pressure output" +

Pointslinking

piecebydefault

Thepartial

pressurethan1:50

plasma

arc - input Connectionpointslinking

piece"partialpressure

output"-

Plasma arc "+"connectthemainloopoftheplasma anode, Plasma arc "-"connect

theprimaryloopoftheoutputoftherectifierdiode.

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

SF-HC25C3HeightController

12

4. Parametersshows

4.1 Parametersset

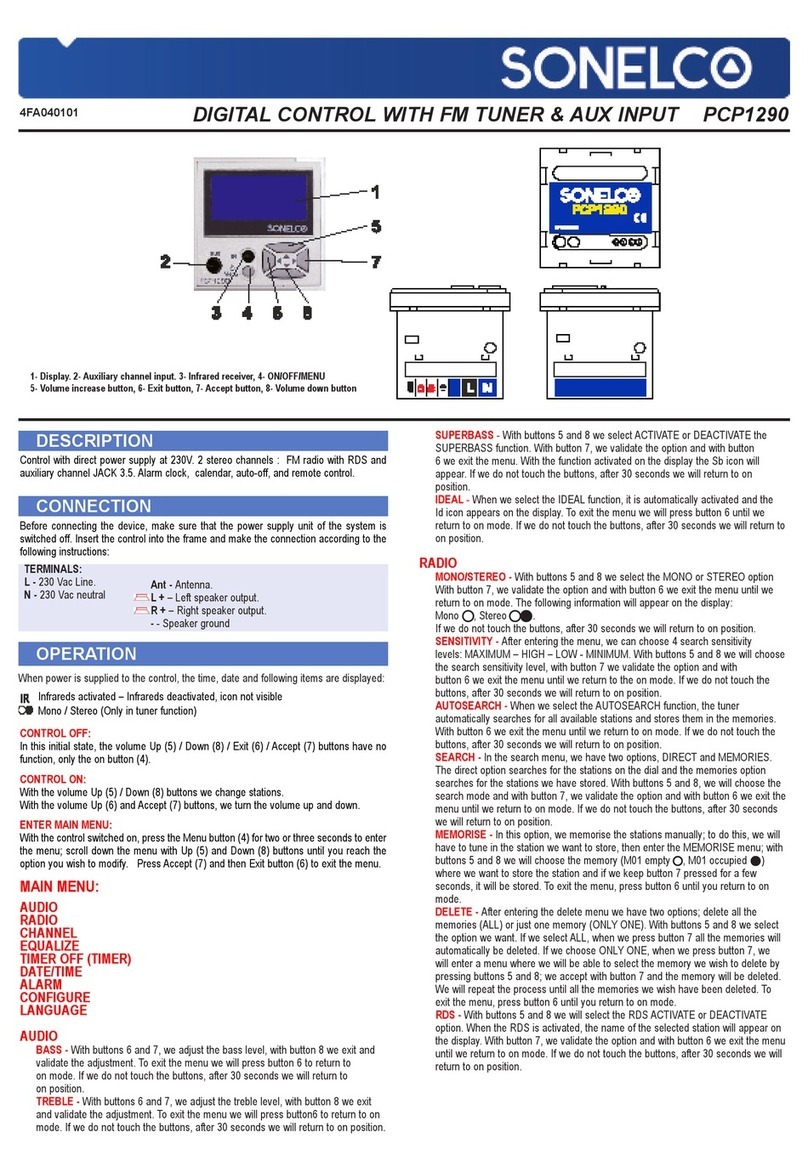

Therearethree commonlyusedparametersand30enhancedparameters:1.Set

voltage.2.Startingarcdelay.3.Locatelatency.Theseparameterscanbedirectlyset

correspondingknobonthepaneltoadjustadjustment.

1, setvoltage,canatanytimeby theknob GIVEN VOLTAGE to adjustthe"height",on

theleftsideofthedigitaltubedisplayvoltagevalueset,theunit:(v),clockwiseto

increase thevoltage,counterclockwisetoreducevoltage.Automaticcuttingaccordingto

theparametersofthecontrolleradjustthedistancebetweenthenozzleandthesteel

plate,makethearcvoltage isalways closertosetthevoltage.Thisparametercanbe

directlyas asetofhighly.Specificsetnumberaccordingtotheselected powersupply

manufacturersprovide technicalparameterSettings.

2, revarclatency, punchtimeshouldbe usedaccordingtotheactualperforatedtime

Settings,differentthicknessofsteelplateanddifferentcurrentwhenthetimeisalso

different. Setbytheknob ARCDELAY ,Clockwisetolengthentheperiodofrevarc,

counterclockwise toreducearcingtime.

3, positioningdelay,initialpositioningtime istheinitialpositioning,cutdown totouch

withsteelplate,afterascendingtothetime requiredfor settingheight.Thetimerequired

fordifferentliftingmechanismtopromoteacertaindistanceisdifferentalso,shouldbe

setaccordingtotheactualsituation.Setbytheknob IHSDELAY ,Clockwiserotationfor

higherpositionheight,counterclockwiseto reducepositioningheight. Thedisplay

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

SF-HC25C3HeightController

13

windowabove aftertherotationshowsthatthevalueisabout3seconds.Afterthetimer

isfinished,thearcpressureisshow.

4.2 Parameterspecification

theknob GIVEN VOLTAGE :In theworkingcondition ofparametersetting: when

pressed,enterthemenu cursorswitch;Whenrotating,rotatecounterclockwise

and rotateclockwise.

Press (GIVEN VOLTAGE)button3secondstoentertheparametermenu

withoutanyaction. Theupperdigitaltubedisplaystheparameternumberand

flashes,rotatingthe(GIVEN VOLTAGE)knobcanchangetheparameternumber.

Thenumberis32 withPbeginning,indicatingP01~P32.Thedigitaltubebelow

showsthevalueofthecurrentparameternumber,withamaximum ofthree

digits.Clickthe(GIVEN VOLTAGE)buttontoswitchtothedisplaywindowbelow,

and rotatethesettingofthearcknobtochangetheparametervalue.Save and

exittheparametermenu atp00-001.

For example: modify manualascentspeed(P03)for 99.

1.Press (GIVEN VOLTAGE)buttonfor3secondsand entertheparameter

Settings.ThedisplaywindowdisplaysP01 and flashes,and thenextwindow

shows01.0.

2.Rotate(GIVEN VOLTAGE)knobtoP03 andblink.Thelowerwindow

shows080 (default).

3.Click(GIVEN VOLTAGE)buttontoswitchthecursor,theupperwindowis

alwaysbright, thenextwindowisflashing.

4.Rotate(GIVEN VOLTAGE)knobto099.

5.Click(GIVEN VOLTAGE)buttontoswitchthecursor,theupperwindow

flickerand thewindowisalwaysbright.

6.Rotate(GIVEN VOLTAGE)knobtoP00.

7.Click(GIVEN VOLTAGE)buttontoswitchthecursor,theupperwindowis

alwaysbright, thenextwindowisflashing.

8.Rotate(GIVEN VOLTAGE)knobto001.

9.Press (GIVEN VOLTAGE)buttontosaveand exit.

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

SF-HC25C3HeightController

14

Modify multipleparameterstorepeat2, 3, 4, 5stepsandsave themtogether.

Whentheinputlevelsettingerrorcausesthefailuretooperate,press(GIVEN

VOLTAGE)buttontoadd electricitytoentertheparametermenu.

Declaration: parameterP00 canflashingstatusindicatorlighton/off onbehalfof

thecorrespondingstateofinputsignals,suchasrosesaidthelighttonestorise

ontheinputterminalblock behindthesignalislow(connectedwith24G).

Enhancedparameterlist

Above

LED

Below

LED

Setthe

range instruction

P00 0 0-4

0donotsave,1save,2restoreuserdefault,3

restorefactorydefaultvalue,4save asuser

defaultvalue

P01 2.0

0.1-9.9

Unit: V.Accuracyofarcpressureadjustment.

P02 5 1-10 Thesensitivitycoefficient,thegreaterthe

coefficient, thehigherthesensitivity.

P03 80 10-99 Manual(CNC)increasespeed, 0min, 99 Max.

P04 80 10-99 Manual(CNC)dropspeed, 0min, 99 Max.

P05 80 10-99 Automaticrisingspeed,0min, 99 Max.

P06 80 10-99 Automaticdescentspeed, 10 min, 99Max.

P07 80 10-99 Location downspeed, 10 min, 99 Max.

P08 80 10-99 Locatetheupliftspeed, 10 min, 99Max.

P09 50 0-99 Unit: V (V), thearcfeedbackreferencevoltage

P10 0 0-9.9 Unit: second,doublespeedpositioningspeed

droptime.

P11 255 0-255 Unit: volt(V), arcvoltageprotectionvoltage.

P15 0 0-1 Motorforwardand reverseswitching.

P16 0 0-20 Brakingforce.

P17 10 0-10 Unit: seconds,impacttime,0donotusethis

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

SF-HC25C3HeightController

15

function.

P18 5 0-2.0 Unit: second,timetointroducearcpressure

delay.

P19 0 0-9.9 Unit: seconds, startingup time,0donotusethis

feature.

P20 0 0-9.9 Unit: seconds,turnoff thearctime,0donotuse

thisfunction.

P21 0 0-9.9 Unit: second,dynamicpunchrisetime,0donot

usethisfeature.

P22 50 30-99 Dynamicpiercingincreasesspeed.

P23 1 0-1 Output2function definition.

P24 128 32-

255

Partialpressureratio calibration,settingrangeof

32~255.

P26 0 0-1 Upperand lowerlimiteffective level,0is

effective,1iseffective.

P27 0 0-1 Thepositioningswitchiseffectivelevel,lowand

effective,1highandeffective.

P28 0 0-1 Therisedropiseffective level,0iseffective,1is

effective.

P29 0 0-1 Cornersignaleffective level,0lowand effective,

1highefficiency.

P30 0 0-1 Arcsignaleffective level,0lowand effective,1

highand effective.

P31 1 0-1 Thearcbeltpositioningmovement,zero

positioningmovement, 1positioningmovement.

Detaileddescription:

P00:0donotsave, 1save, 2restoreuserdefault, 3restorefactory defaultvalue, 4

save asuserdefaultvalue.Whenentering,display6.Inthisinterface,youcan

also viewthestateoftheinputsignal,and use7statusindicatorstorepresent

thestateof7inputs,indicatingthatthecorrespondinginputsignalisconnected

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

SF-HC25C3HeightController

16

to24V whenthelightison.

P01:arcpressureadjustmentprecision. Example:thearcpressureadjustment

precision issetto1V,and thearcpressureissettobeless than1Vunderthe

actualarcpressure,so itisnotnecessarytohavetheautomaticheight

adjustment,theunit: V (V), settherangeof0.1V~10V.

P02:thesensitivitycoefficient,thegreaterthecoefficient,thehigherthe

sensitivity.Thesensitivityistoo hightocausethetorchtovibratein abalanced

position. Defaultvalue2, setrange1~10.

P03:manual(key and CNC control)increasespeed, settingrange10~99.

P04:manual(key and CNC control)dropspeed, setrange10~99.

P05:automaticrisingspeed, automatictrackingspeed, settingrangeof10~99.

P06:automaticdescentspeed, automatictrackingspeed,settingrangeof10~99.

P07:locatethespeedofdescent,thespeedofdecreaseafterthearcsignalis

effective,settherangeof10~99.

P08:positioningtherisingspeedand therisingspeedofthearcsignal,setting

therangeof10~99.

P09:thearcsuccess feedbackreferencevoltage,actualarcpressure<(setting

voltage+voltage)oractualarcpressure>(settingvoltage-thisvoltage),unit:V

(V), setrange0~99.

P10:two-speedpositioningspeeddecreasetime,arcsignaltheneffective use

P07 declinein acertain timeafterfallingattherateofhalfP07,until meetsteel

plate,theparameterssuggestthatless thanthetimeofP20,settozerowithout

thisfeature, unit:second, settingrange0~9.9.

P11:arcvoltageprotection voltage.Thevoltageisaddedtothesetvoltageto

preventthearcpressurefrom increasingabruptlyand thecuttingtorchis

reduced, unit:V.Setrange0~255.

P12-- -p14 systemreservation

P15:motorforwardand backwardswitching,whenthemomentofmomentof

cuttingand liftingisinconsistent,itcanchangethedirection ofoperation ofthe

motorby thisparameter, settinga rangeof0~1.

P16:brake,motorinertiabigcansetthisparameterunderthecondition of

properbraking,thedefaultis0,thelargerthevalueofparkingthenasty,this

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

SF-HC25C3HeightController

17

parameteriscareful, theSettingsmaycauseshock, settherange0to20.

P17:thetimeoftheimpactofthecollision,thetimeofliftingafterthestopstate

cuttingmomentimpactplate,0doesnotusethisfunction,theunit:seconds,the

settingrangeis0~10.

P18:arcrollingintotime,whentheblocktotheplasmapowersourcesignaland

thearcafterwaitingforaperiod oftimetodetectarcpressure,toavoidthe

punchwhenunstablevoltage,canbeunderstoodasrevarcdelay,aspartofthe

unit: second, settingtherangeof0~10.

P19:startup time,preventthepanfrom scrapingtothecuttinggun,when

startingup,youcansetaliftdistance,0donotusethisfunction,theunit:

seconds, setrange0~10.

P20:thetimeofthearcraisinggun,aftercuttingcompletion,raiseadistanceto

preventthescrapinggun,0donotusethisfunction,theunit:seconds,setthe

rangeof0~10.

P21:dynamicperforation risetime,setthistimecanbecutmomentin

perforatedwhileincreasingacertain distance,thenfell totheheightofthe

original,canavoidtheslagsplashingupappropriatelycutmouthadhesion. 0do

notusethisfunction,thespeedofP22 isusedwhenlifting,and P04 speedis

usedwhendescending, unit: seconds, settingrange0~2.

P22:dynamicperforation isrisingfaster,usewithP21 P21iszerothisparameter

meaningless,becausethemotorfordcmotorusedthisspeedisgreaterthanthe

appropriateP04 speed,settherange0to120.

P23:output2function definition,setto0,output2isdefinedastheinitial

location tocompletethefeedbacksignal, settingrange0~1.

P24:partialpressureratio calibration, block and plasma display voltagedifference

from theactualvoltagecanadjusttheparameters,thenumericalincreasethe

block showsthevoltageincrease, and vice, setrange32 ~255.

P26:upperand lowerlimiteffective level,0lowandeffective,1highand

effective,ifnotusedpleasesetto0.

P27:location switcheffectively level, 0iseffective, 1iseffective.

P28:risedowneffective level, 0loweffective, 1higheffective.

P29:cornersignaleffective level,0lowand effective, 1highand effective.

PDF 件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.cn

Table of contents

Other Starfire Controllers manuals