D2186-02-08 CN5232 SEM210 User Guide Page 1 of 2

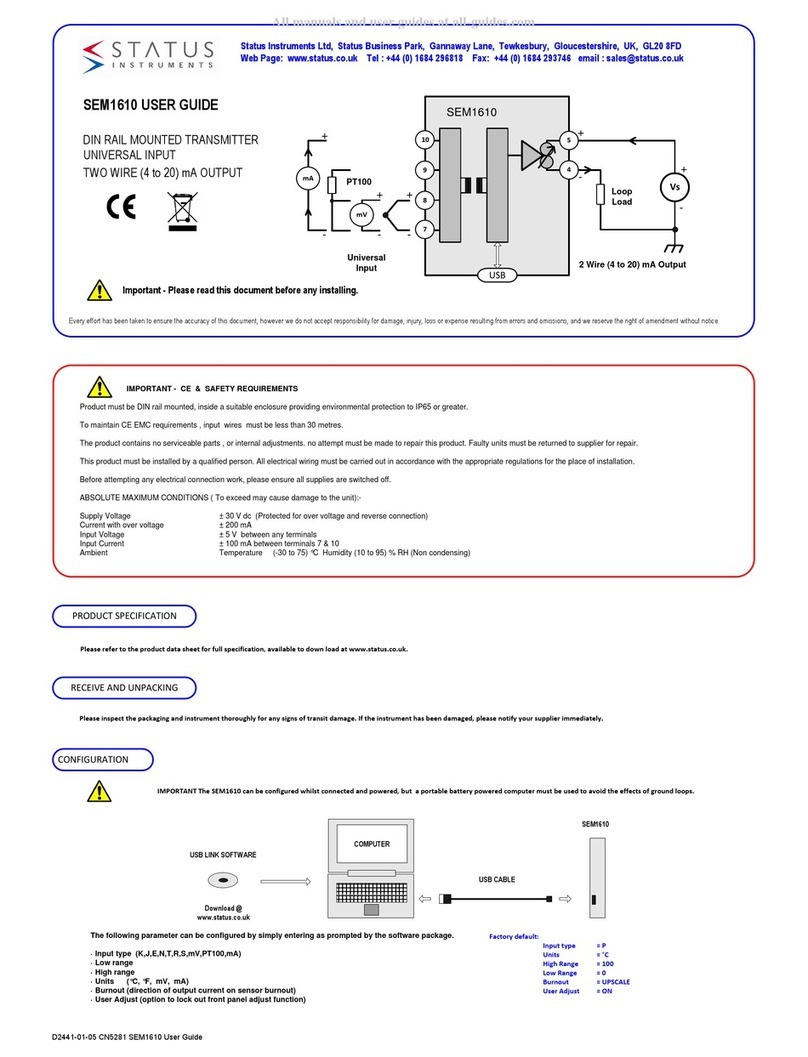

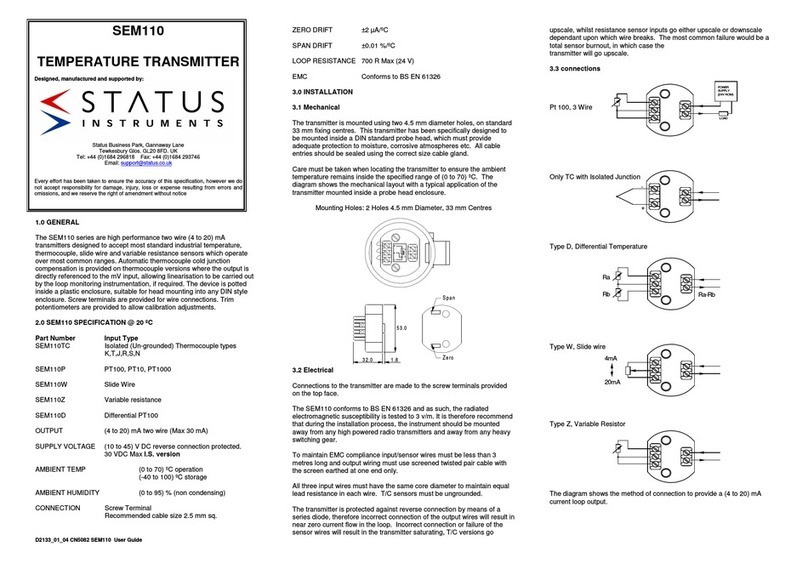

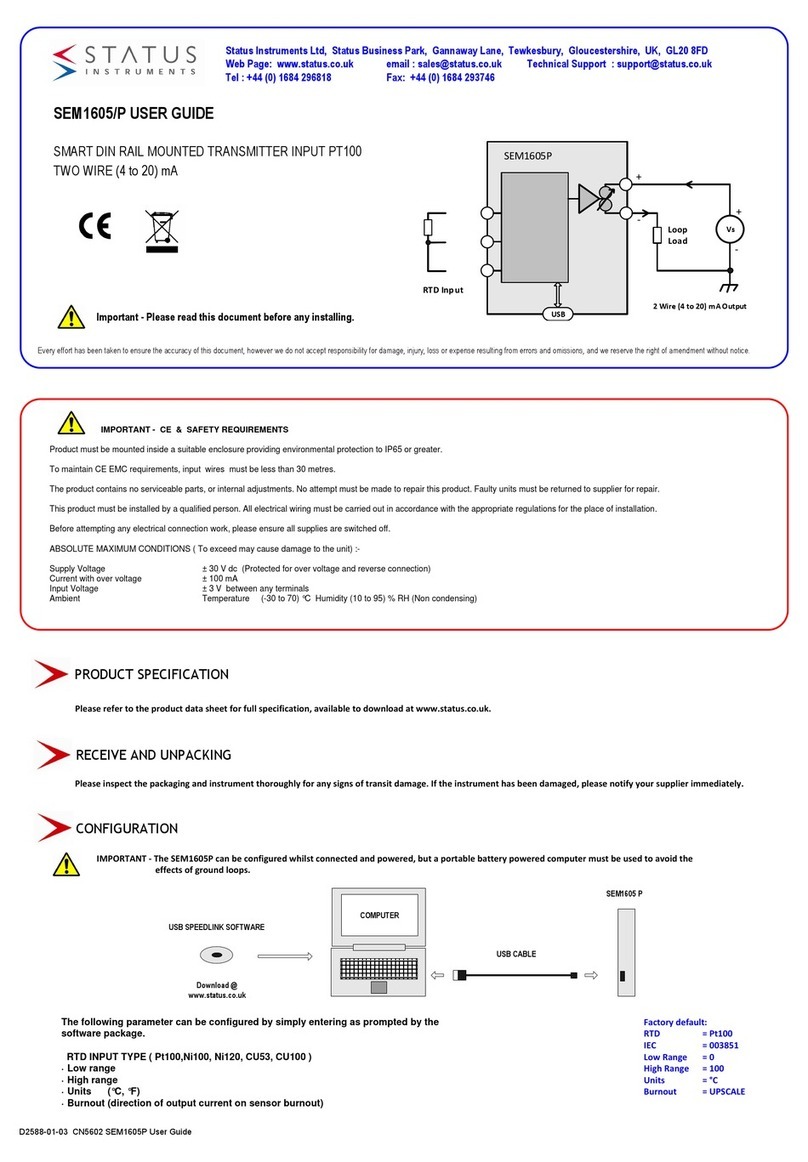

1.0 GENERAL

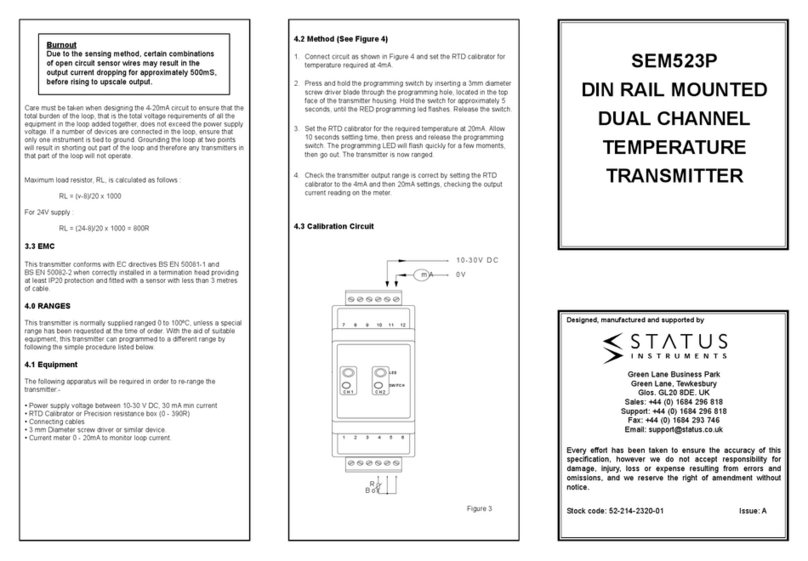

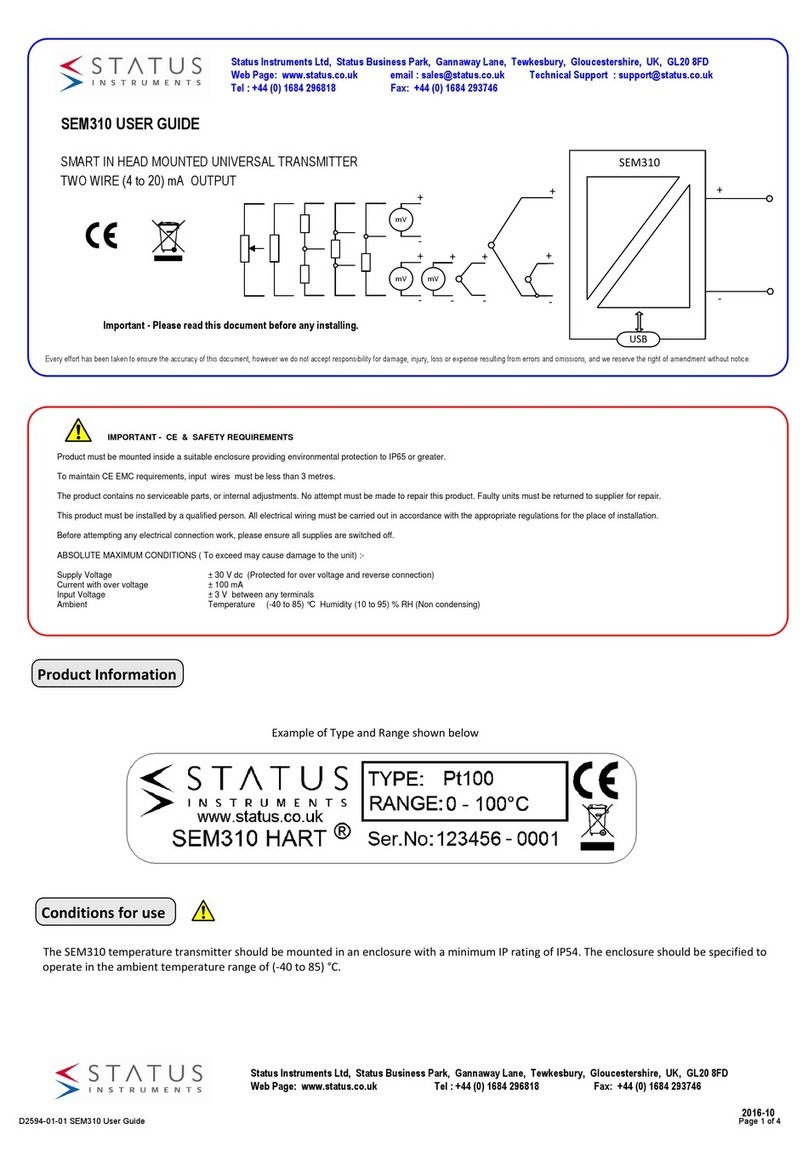

The transmitter is a second generation 'Smart' in head temperature transmitter that

accepts any commonly used temperature sensor, slidewire transducer or millivolt

signal and converts the output to the industry standard (4 to 20) mA transmission signal.

The software package M-Config with the USB Configuration module can be used to

program the unit.

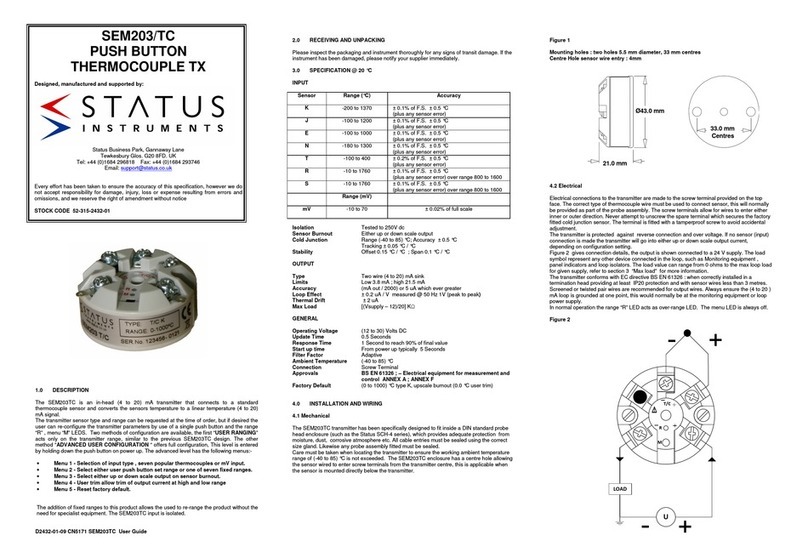

2.0 SPECIFICATION@ 20 °C

2.11 RTD Input (Pt100)

Sensor Range (-200 to +850) °C (18 to 390) Ω

Minimum Span¹ 25 °C

Linearisation BS EN 60751 (IEC 751)

BS 1904 (DIN 43760)

JISC 1604

Basic Measurement Accuracy ²± 0.01 % FRI ± 0.05 % Rdg

(FRI = Full Range Input), (Rdg = Reading)

Thermal Drift Zero (0.008 °C / °C) Span (0.01% / °C)

Excitation Current 300 µA to 550 µA

Maximum Lead Resistance 50 Ω/ leg

Lead Resistance Effect 0.002 °C / Ω

2.12 Thermocouple Input

Sensor Ranges Thermocouple

Type Measuring

Range 3°C Minimum

Span 1°C

TC Type K -200 to 1370 50

TC Type J -200 to 1200 50

TC Type T -210 to 400 25

TC Type R -10 to 1760 100

TC Type S -10 to 1760 100

TC Type E -200 to 1000 50

TC Type L -100 to 600 25

TC Type N -180 to 1300 50

Linearisation BS 4937 / IEC 584, EN60584

Basic Measurement Accuracy ²± 0.04 % FRI ±0.04 % Rdg or 0.5 °C

(Which ever is greater)

(FRI = Full Range Input), (Rdg = Reading)

Thermal Drift Zero 0.1 µV / °C Span 0.01% / °C

Cold Junction Error ± 0.5 °C

Cold Junction Tracking 0.05 °C / °C

Cold Junction Range (-40 to +85) °C

2.13 Millivolt Input

Input Voltage Source

Range (-10 to +75) mV

Characterisation Linear

Minimum Span¹ 5 mV

Basic Measurement Accuracy ²± 10 µV ± 0.07 % Rdg

Input Impedance 10 MΩ

Thermal Drift Zero (0.1 µV / °C) Span (0.01% / °C)

2.14 Slidewire Input

Input 3 Wire potentiometer

Resistance Range (10 Ωto 390 Ω) (End to End)

Larger values can be accommodated by

external resistor

Characterisation Linear

Minimum Span ¹5 % of FRI

Basic Measurement Accuracy ²0.1 % of FRI

Thermal Drift 0.01 % / °C

Notes.

1. Any span may be selected, full accuracy is only guaranteed for spans

greater than the minimum recommended.

2. Basic Measurement Accuracy includes the effects of calibration,

linearisation and repeatability.

3. Consult thermocouple reference standards for thermocouple material

limitation.

2.2 Output

Output Range (4 to 20) mA (>3.8 to <20.2) mA

Maximum Output 23 mA

Accuracy ± 5 µA

Voltage Effect 0.2 µA / V

Thermal Drift 1 µA / °C

Supply Voltage (10 to 35) VDC

Maximum Output Load [(Vsupply -10)/20] KΩ(eg 700 Ω@ 24V)

2.3 General

Input/Output Isolation 500 VAC rms (galvanically isolated)

Update Time 250 ms Maximum

Time Constant (Filter Off) < 1 s (Time to reach 63% final value)

Filter Factor Programmable Off, 2 s, 10 s or adaptive

Warm-up Time 120 s to full accuracy

Environmental

Ambient Operating Range (-40 to 85) °C

Ambient Storage Temperature (-50 to 100) °C

Ambient Humidity Range (10 to 90) % RH non condensing

Approvals

Emc BS EN 61326

Mechanical

Enclosure DIN standard terminal block size

Material ABS

Weight 35 g

Dimensions 43 mm diameter x 21 mm

Communications

PC Interface USB via configurator

Maximum Cable Length 1000 m

Configurable Parameters Sensor type: Burnout: °C / °F: Output:

Hi / Lo: Filter: Tag: User Offset

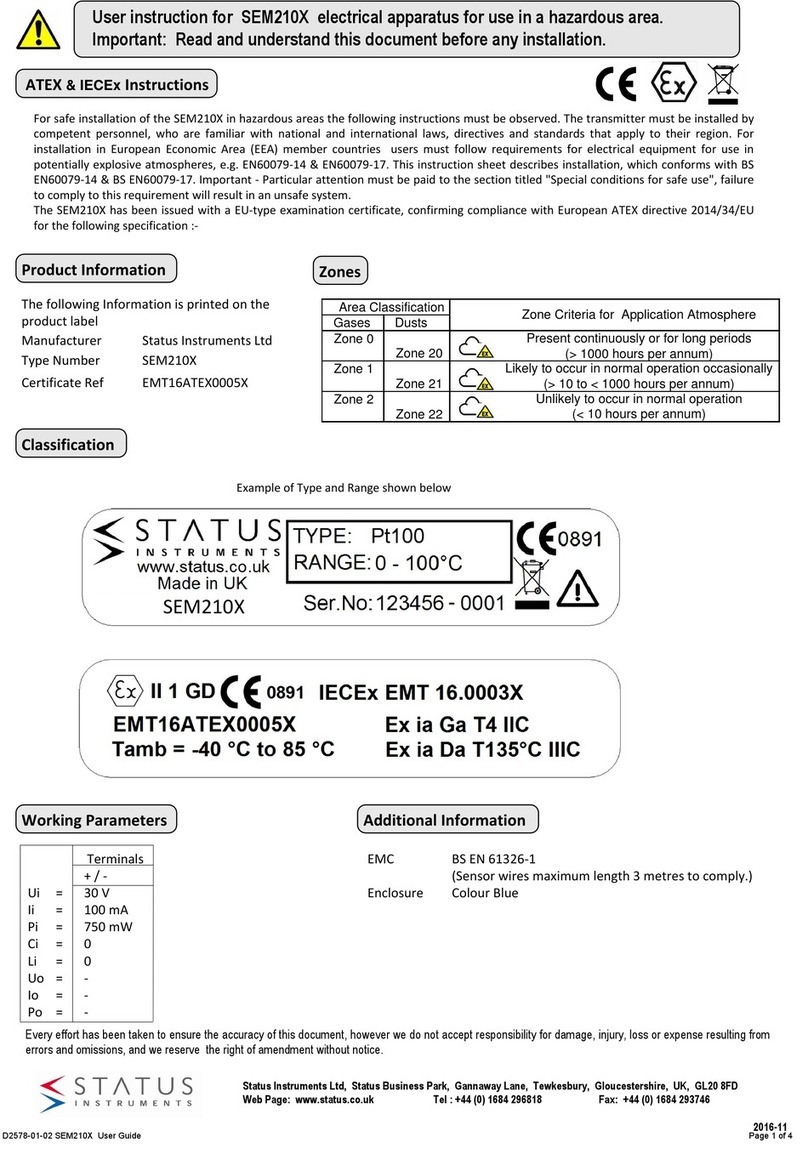

2.4 SEM210X VERSION - FOR USE IN POTENTIALLY EXPLOSIVE ATMOSPHERES

2.4.1 ATEX Certificate

The SEM210X, has been issued with a EC-type examination certificate, confirming

compliance with the European ATEX directive 94/9/EC for :-

Intrinsic safety II 1 G EEx ia IIC T4…T6.

The equipment bears the Community Mark and subject to local codes of practice, may be

installed in any of the European Economic Area (EEA) member countries. The SEM210X

housing is coloured light blue to identify the equipment as suitable for Hazardous area

use. The equipment must be installed and maintained in

accordance with local requirements for electrical equipment for use in potentially

explosive atmospheres, eg EN60079-14 & EN60079-17. This instruction sheet describes

installation which conforms with BS EN60079-14 & BS EN60079-17 Electrical Installation

in Hazardous Areas. When designing systems outside the UK, the local Code of Practice

should be consulted.

2.4.2 ATEX Marking

Common Information

Manufacturer Status Instruments Ltd

Type Number SEM210X

CE marking 0891

Explosive Protection Marking

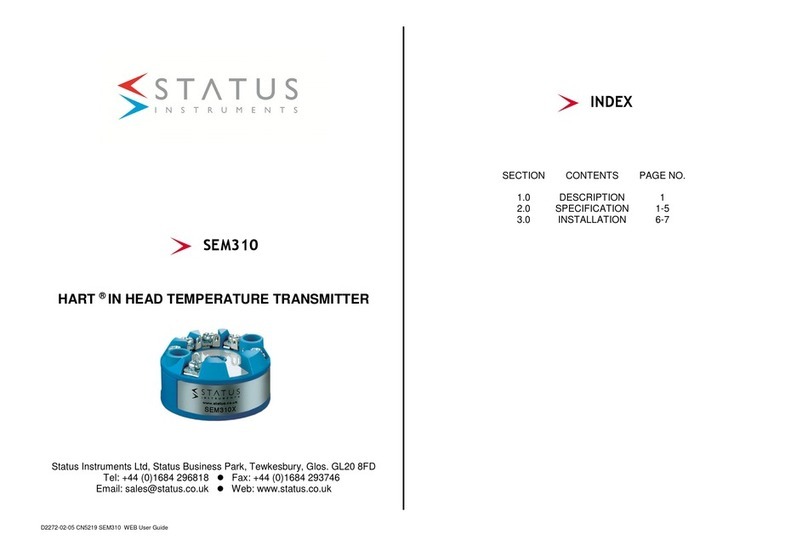

SEM210

PROGRAMMABLE IN HEAD

TEMPERATURE

TRANSMITTER

Designed, manufactured and supported by:

Status Business Park, Gannaway Lane

Tewkesbury Glos. GL20 8FD. UK

Tel: +44 (0)1684 296818 Fax: +44 (0)1684 293746

Every effort has been taken to ensure the accuracy of this specification, however we do

not accept responsibility for damage, injury, loss or expense resulting from errors and

omissions, and we reserve the right of amendment without notice

Stock code 51-214-2186-02 Issue 8