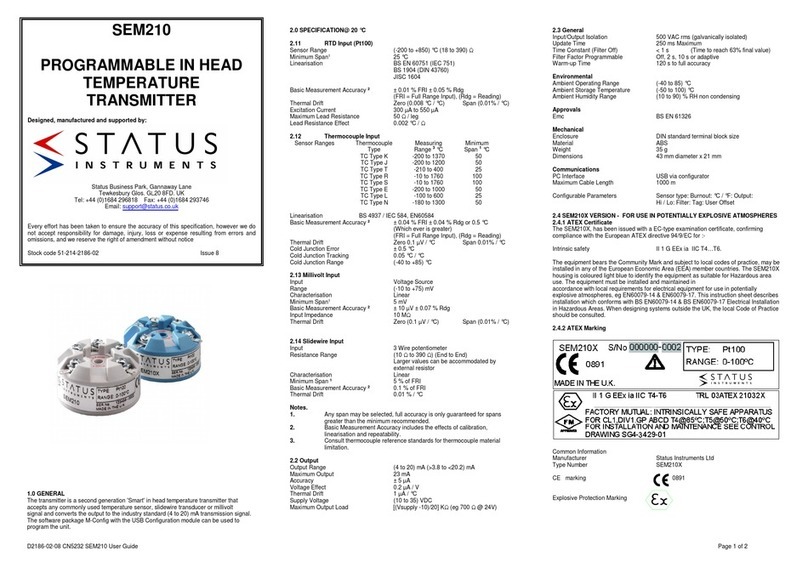

D2133_01_04 CN5082 SEM110 User Guide

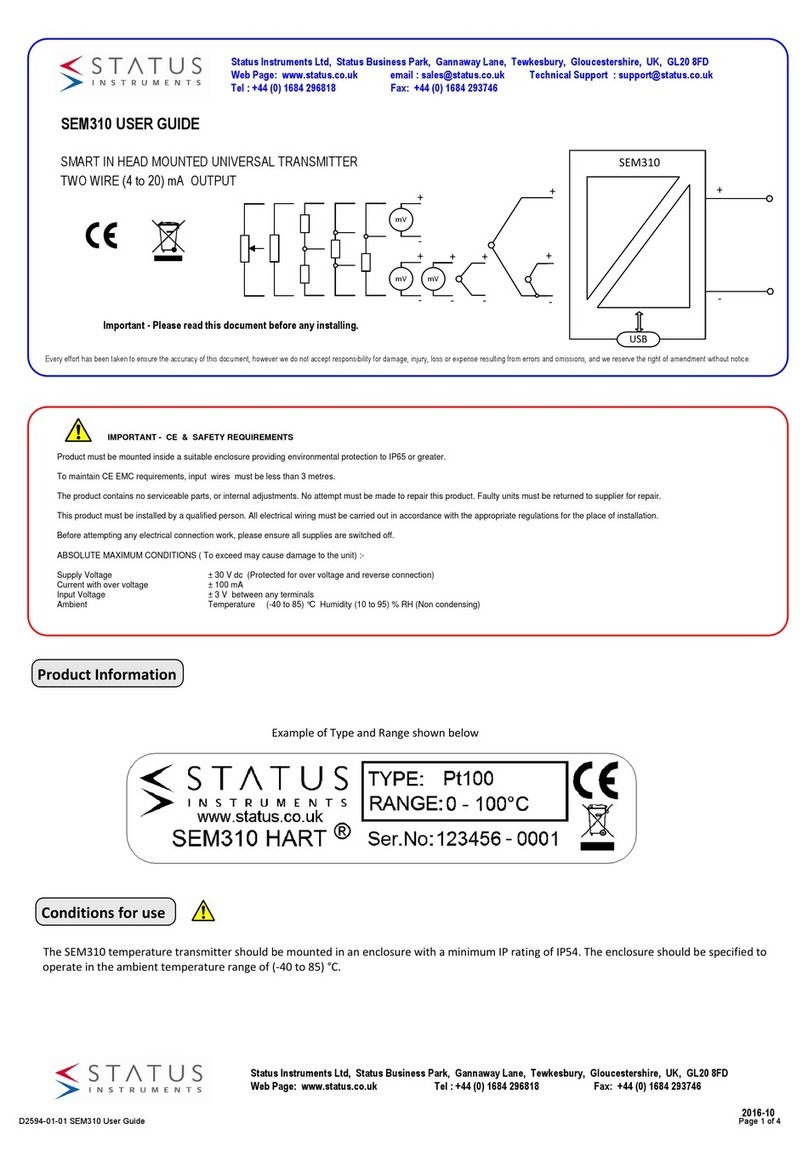

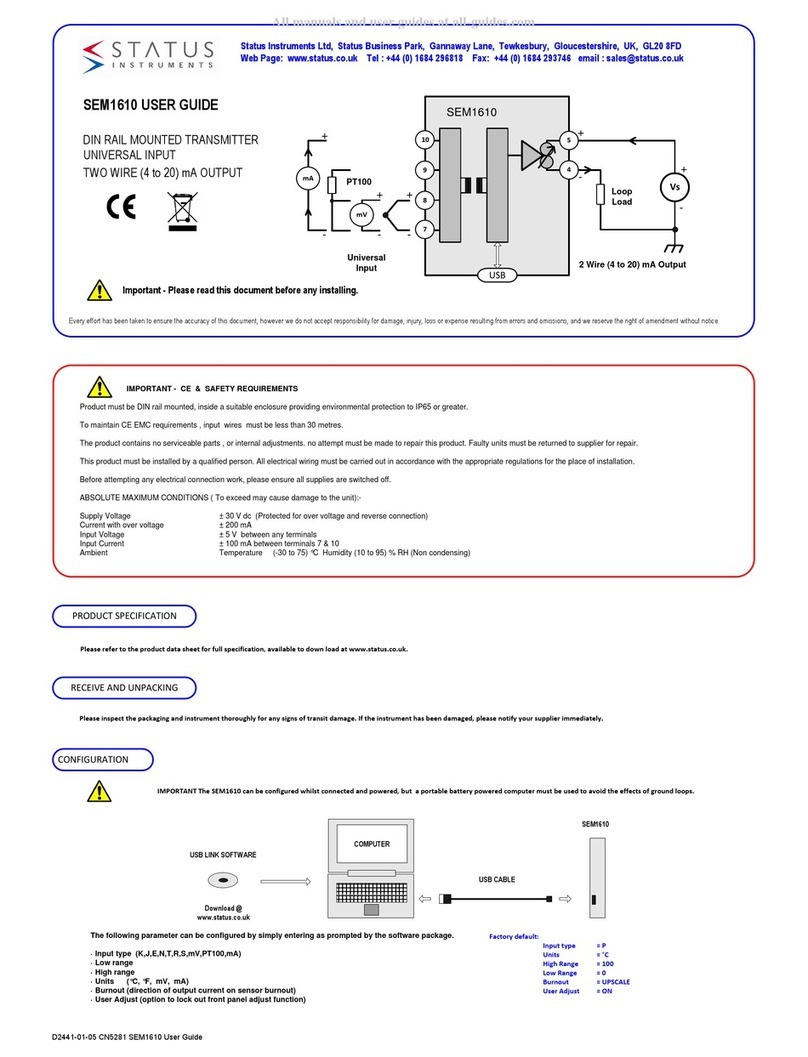

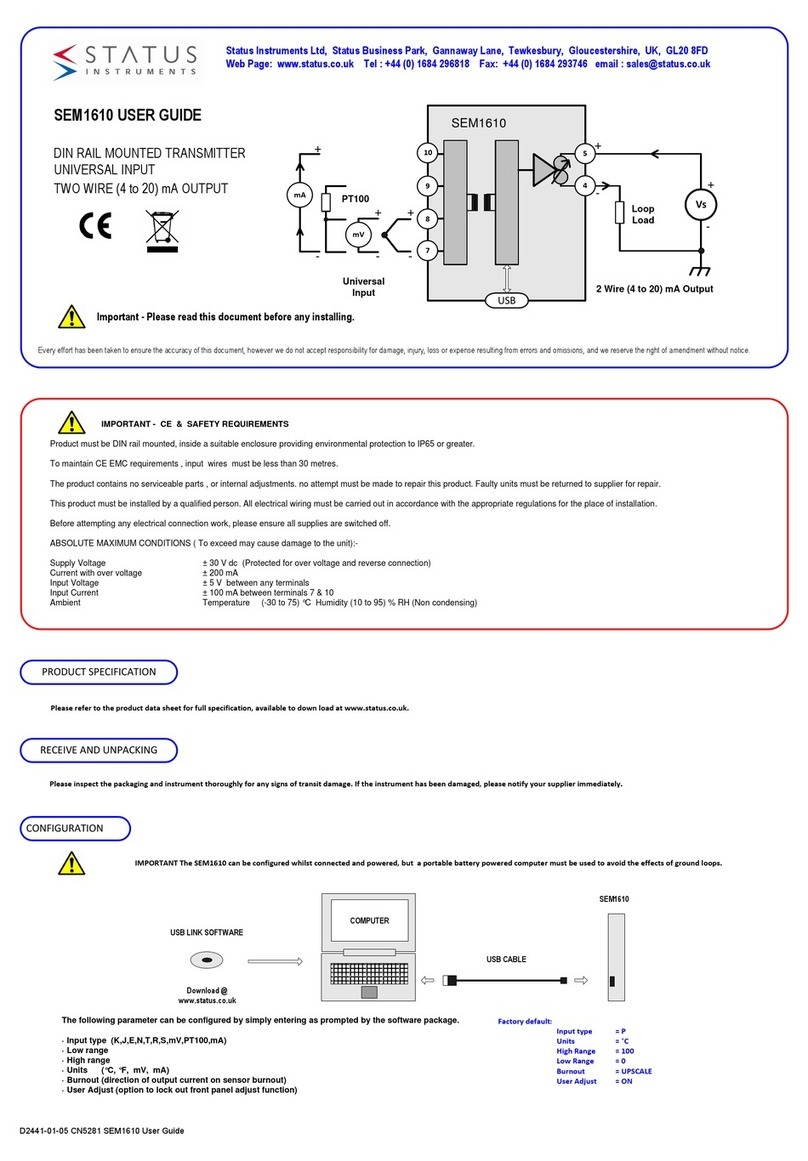

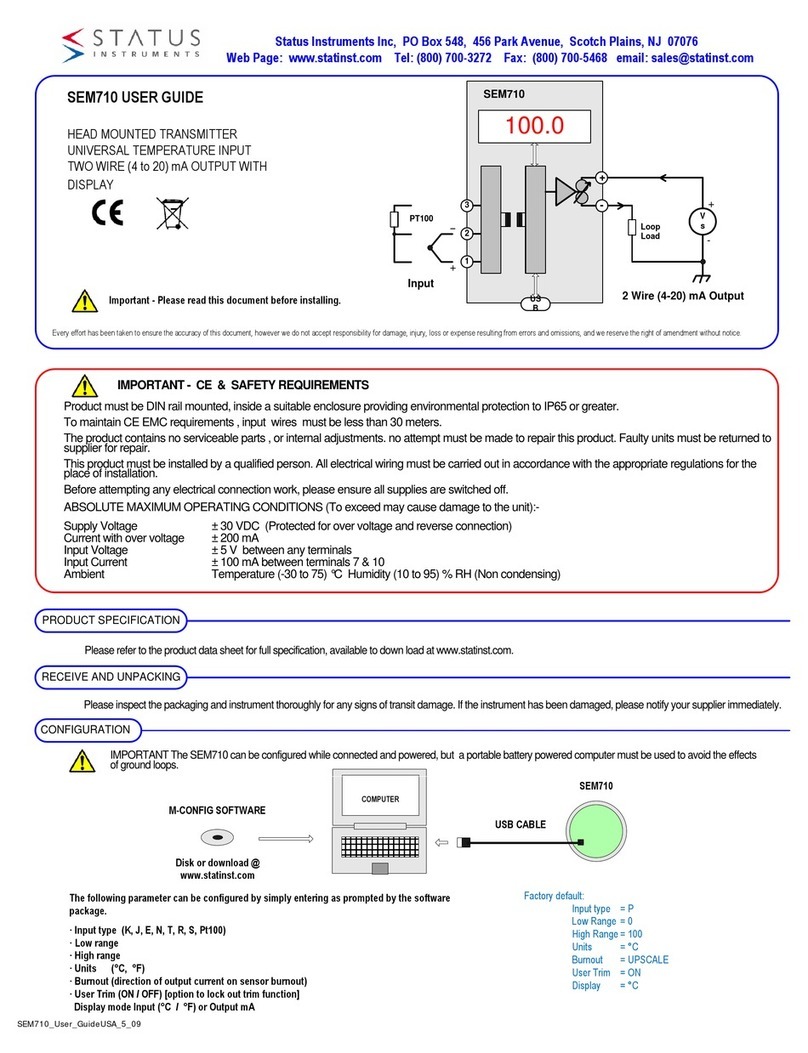

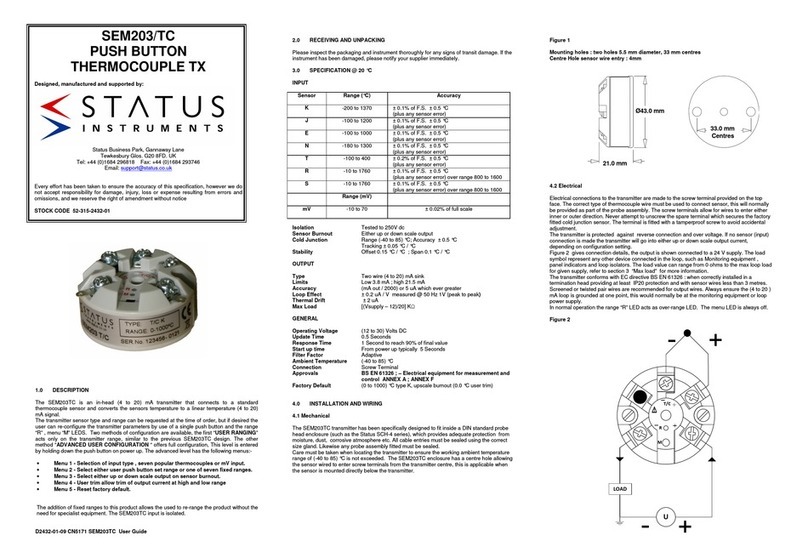

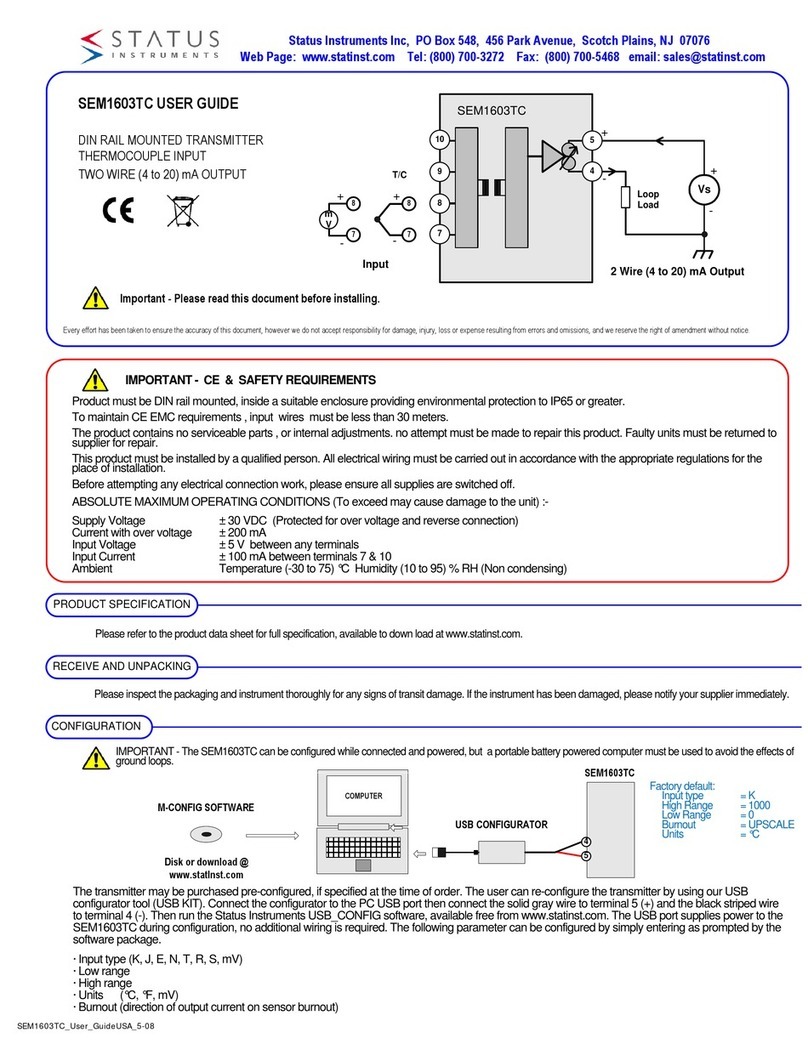

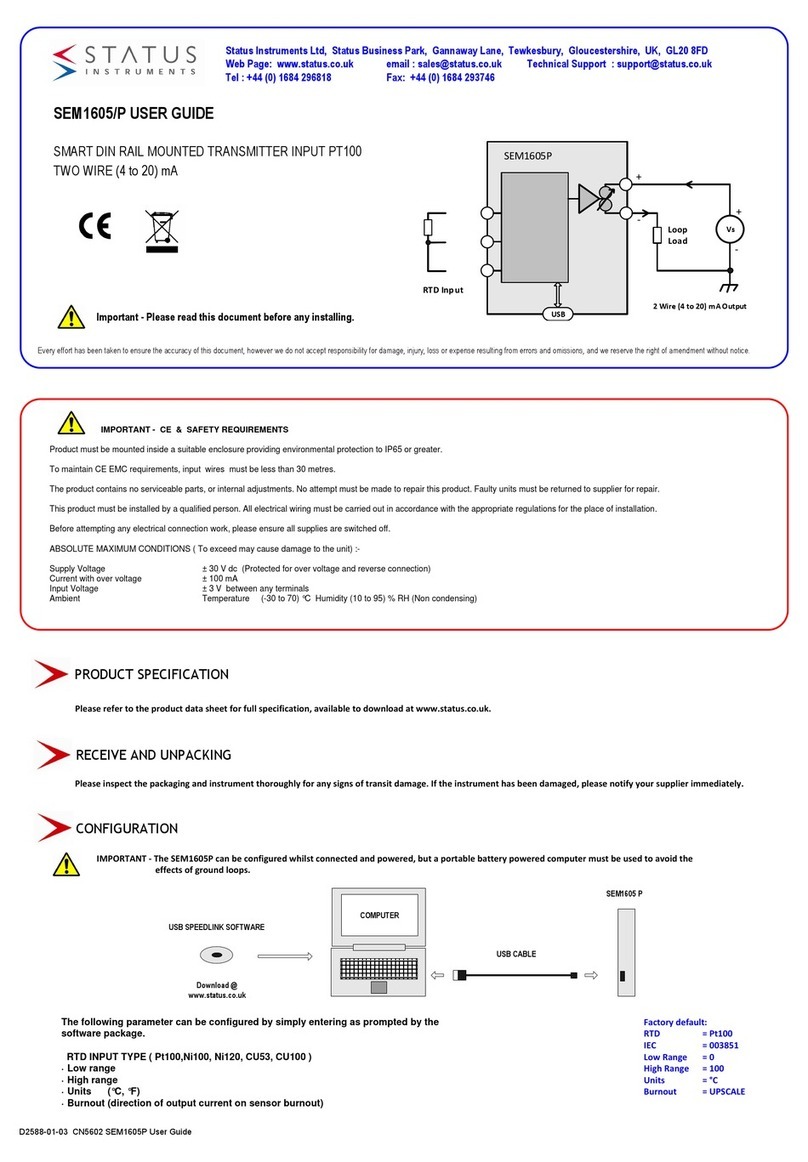

The Pt100 sensor shown as an example would normally take the form of a

probe assembly with a three wire output. Refer to connection drawing for

other connection types. The output loop shows a 24 V DC power supply

used to provide loop excitation, the transmitter and a load all connected in

series. The load symbol represents other equipment in the loop e.g.

indicators, controllers, loggers etc. Sometimes these instruments come

with the 24 V supply built in as standard, this simplifies wiring and reduces

cost. Care must be taken when designing the (4 to 20) mA circuit to

ensure that the total burden of the loop, that is the total voltage

requirements of all the equipment in the loop added together, does not

exceed the power supply voltage. If a number of instruments are

connected in the loop, ensure that only one instrument is tied to ground.

Grounding the loop at two points will result in shorting out part of the loop

and therefore any instruments in that part of the loop will not operate.

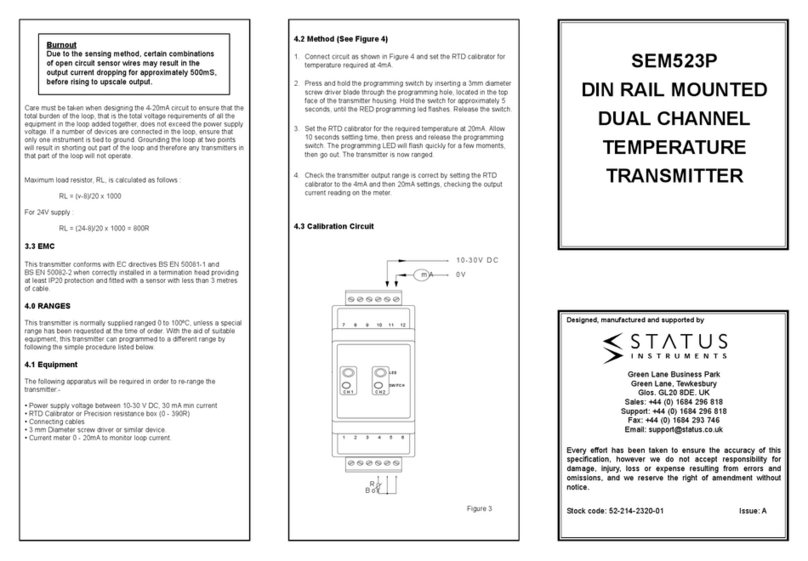

4.0 Calibration

Calibration is only recommended when the user has access to suitable

equipment, together with a reasonable knowledge of instrumentation

calibration techniques. The following instructions act as a guideline to

calibration.

4.1 A precision calibrator will be required, to simulate the type of

sensor the transmitter is designed for, together with a set of

tables giving the sensor output against process variable, (e.g.

resistance against temperature for a PT100 sensor). A

precision digital current meter together with a 24 V DC supply

will also be needed. Read the SEM110 label to establish the

transmitter range i.e. the process variable input for 4 mA and

20 mA. The side label also indicates the location of the span

and zero pots.

4.2 Connect calibrator to input terminals, using the correct

compensation wire for thermocouples inputs and three wire

connection for RTD inputs. Connect the output positive to +24

V, negative to 0 V via current meter. Turn power on.

4.3 Set simulator to 4 mA process variable and adjust ZERO

trimmer for 4.000 mA output. ±0.002mA

4.4 Set simulator to 20 mA process variable and adjust SPAN

trimmer for 20.000 mA output ±0.002 mA.

4.5 Repeat steps 4.3 and 4.4 until both points are in calibration.

4.6 Turn power off and remove calibration equipment.

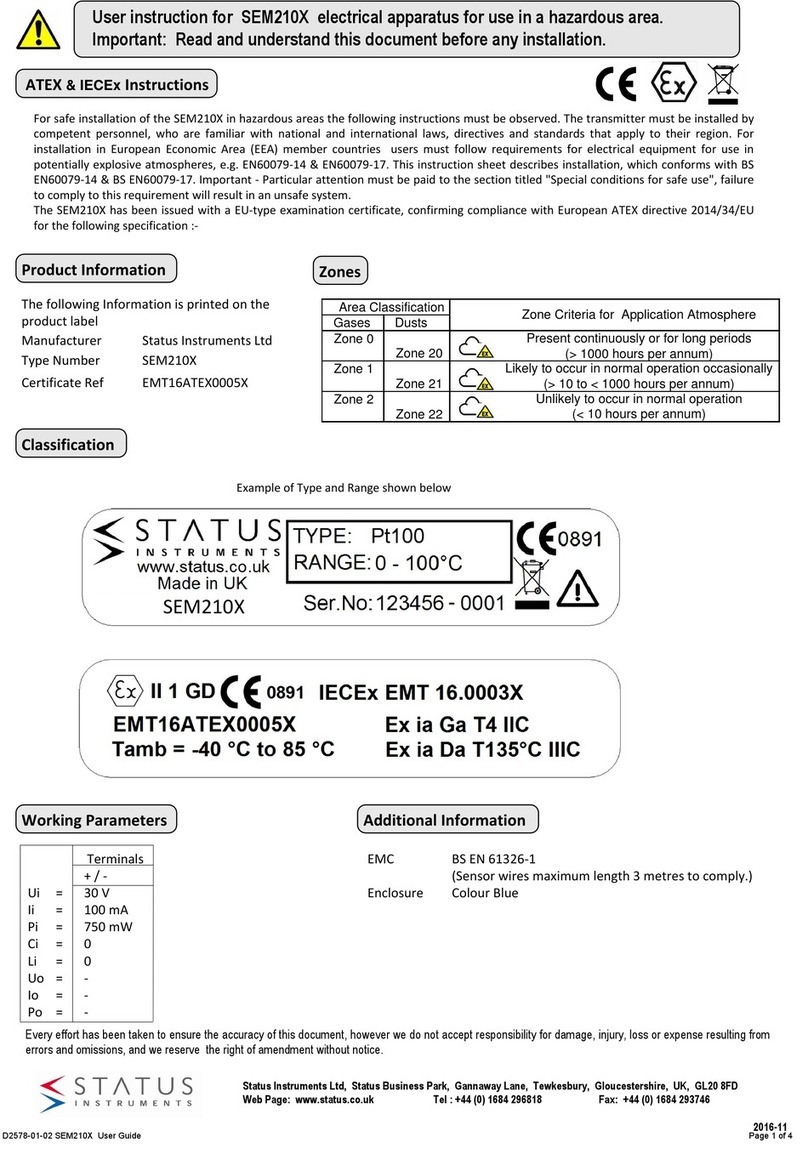

5.0 SEM110X\* VERSIONS - FOR USE IN POTENTIALLY EXPLOSIVE

ATMOSPHERES

5.1 ATEX Certificate

The SEM110X/* models has been issued with a EC-type examination

certificate, confirming compliance with the European ATEX directive

94/9/EC for :-

Intrinsic safety II 1 G EEx ia IIC T5.

The equipment bears the Community Mark and subject to local codes of

practice, may be installed in any of the European Economic Area (EEA)

member countries. The SEM110X housing is coloured light blue to identify

the equipment as suitable for Hazardous area use. The equipment must

be installed and maintained in accordance with local requirements for

electrical equipment for use in potentially explosive atmospheres, eg

EN60079-14 & EN60079-17. This instruction sheet describes installation

which conforms with BS EN60079-14 & BS EN60079-17 Electrical

Installation in Hazardous Areas. When designing systems outside the UK,

the local Code of Practice should be consulted.

5.2 Atex marking

Common Information

Manufacturer Status Instruments Ltd

Type Number SEM110X/P

SEM110X/TC

SEM110X/W

CE Marking 0891

Explosive Protection Marking

(Type ia) Intrinsic Safety

II 1 Equipment Group and category

G Type of explosive atmosphere (Gas)

EEx ia IIC T5 Intrinsic safety information

TRL03ATEX21004X Certificate reference

5.3 Special Conditions for Safe Use

As indicated by the Certificate Reference "X" suffix, special conditions

apply for safe use for both intrinsic safety and energy limitation

applications. They are as follows:-

5.4 Zones, Gas Groups, and T rating.

When connected to a approved system the SEM110X/* may be installed

in:-

Zone 0 explosive gas air mixture continuously present

Zone 1 explosive gas air mixture likely to occur in normal use

Zone 2 explosive gas air mixture not likely to occur and if it does, it will

only occur for a short time.

Be used in gas groups;-

Group A propane

Group B ethylene

Group C hydrogen

Allowable Temperature classification / ambient temperature:-

Intrinsic safety (Type ia)

Class

T5 100°C : Ta = -20°C to +40°C

T4 135°C : Ta = -25°C to +55°C

T3 200°C : Ta = -25°C to +55°C

T2 300°C : Ta = -25°C to +55°C

T1 450°C : Ta = -25°C to +55°C

5.5 Environmental Protection

This equipment must be housed in an enclosure which provides a degree

of protection of at least IP54. The enclosure must be suitable for the

atmosphere and environment in which it is installed (eg If of plastic

material, must be resistant to chemical corrosion, UV light, temperature,

humidity etc.)

5.6 Maintenance

This intrinsically safe equipment contains no user serviceable, adjustable

or replaceable parts. No attempt should be made to repair a faulty

SEM110X/* transmitter, all units must be returned to the manufacture for

repair or replacement. Attempt service or replacement of parts may

invalidate the explosive protection features of the equipment.

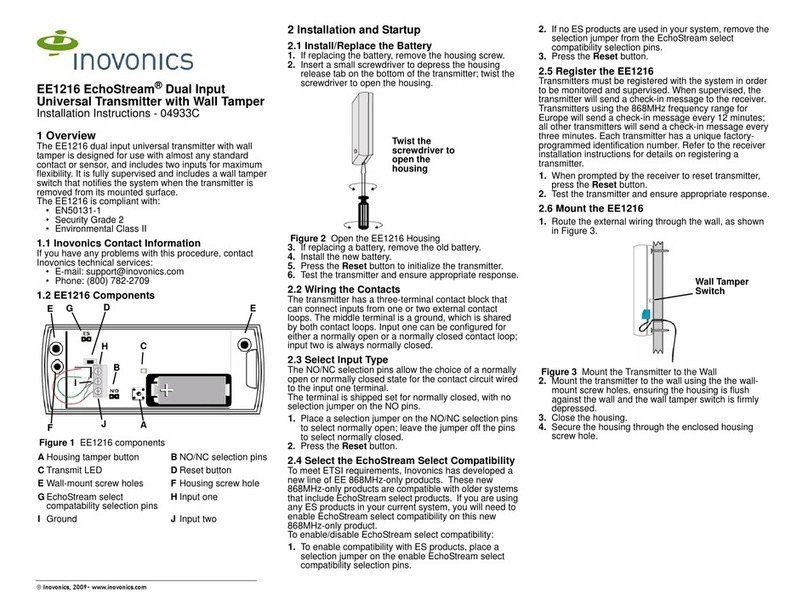

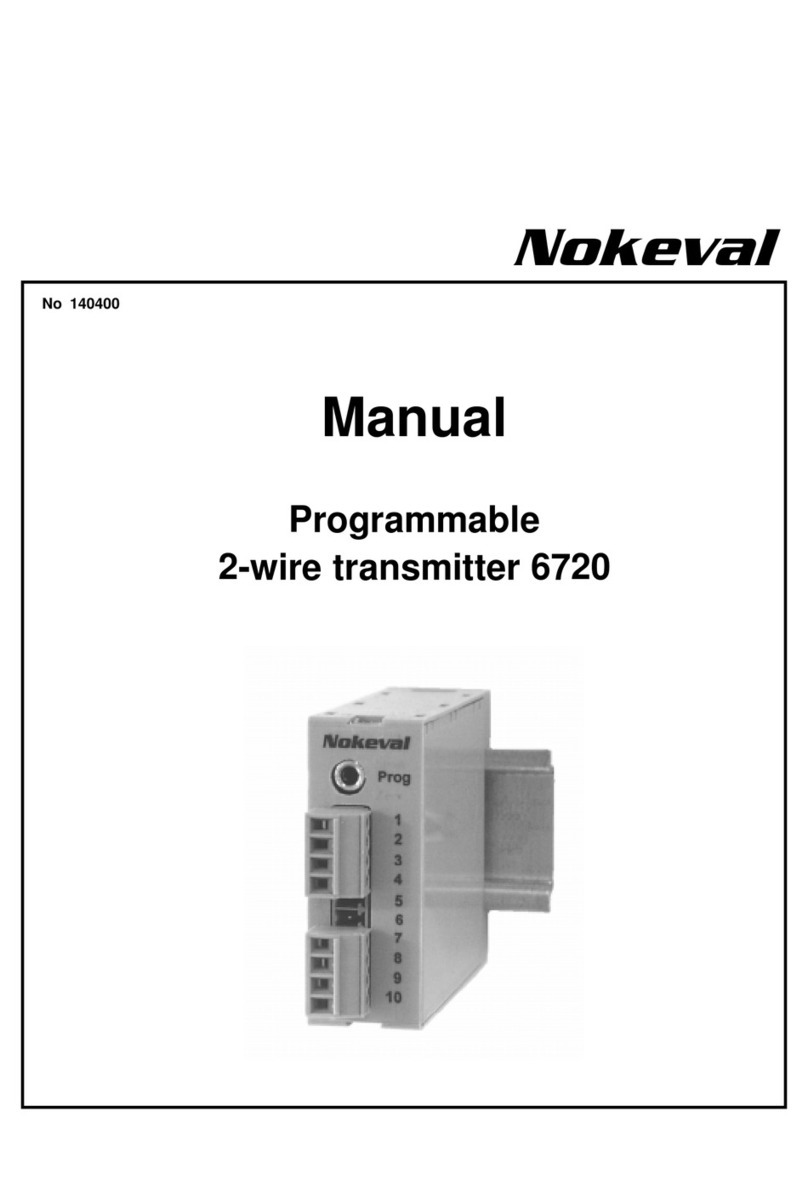

5.7 Connection Diagram

They equipment must be electrically connected as shown below:-

SEM110X\* Working Parameters

Ui 28 V

I i 93.3 mA

Pi 0.653 W

Ci 0 nF

Li 0 uH

-

SE M110XCALIBRAT O R

D C

+ - +24V

A

SENSOR

SEM110X

3 1

4

5

2

BARRIER

Maximum

output

Vo 30V

Io 100mA

Po 750mW

DC

SUPPLY

+

-