1.0 DESCRIPTION

The transmitter is a dual channel DIN rail mounted 4-20mA transmitter

that connects to any standard Pt100 sensor and converts the sensor

temperature to a 4-20 mA signal.

An LED provides a visual indication of sensor fault and programming

mode. The transmitter is simply ranged and calibrated on the bench by

using a single on-board push button switch, without the need for soldering

links. Digital technology ensures accurate and drift free linearisation to all

common curves, providing a level of performance not possible with earlier

analogue types.

2.0 SPECIFICATION @ 20ºC

2.1 Input

Input Type 3 Wire Pt100

(Pt500 or Pt1000 to special order)

Linearisation BS EN 60751 (IEC751)

BS 1904 (DIN 43760)

JISC 1604

Excitation Current 1mA Maximum

Range -200 to 850ºC

Minimum Span 20ºC

Lead Resistance <10 R per leg (balanced)

Burnout Upscale 22mA

(Downscale preset current to order)

Red programming LED illuminates when

temperature is outside -200 to 850ºC range

Accuracy ±0.1ºC ± 0.1% of reading range -100 to 500

±0.2ºC ± 0.1% of reading range -200 to 850

Thermal Drift Zero ± 0.01C / ºC

Span 50 ppm

Connections Screw Terminals Two part

2.2 Output

Output 4 to 20 mA, 2 wire loop powered

Maximum Output Range 3.8 to 22 mA

Operating Voltage 8 to 30 V DC

Accuracy ± 5uA

Thermal Drift ± 1uA/°C

Response Time 500mS to reach 70% of final value

Loop Resistance 800R @ 24 V DC

Loop Sensitivity 0.4 µA / volt

Loop Noise ±0.001 µA

Protection Reverse Polarity Protected

Connections Screw Terminals

Input/Output Isolation Not isolated

Channel to

Warm-up Time 2 Minutes to full accuracy

EMC Emissions BS EN50081-1

Susceptibility BS EN50082-2

Ambient Temp. Range 0 to 70 ºC

Ambient Storage -40 to 70 ºC

Ambient Humidity 0 to 95 % (Non condensing)

Default Range 0-100ºC. Contact sales office for factory

configuration to any other range.

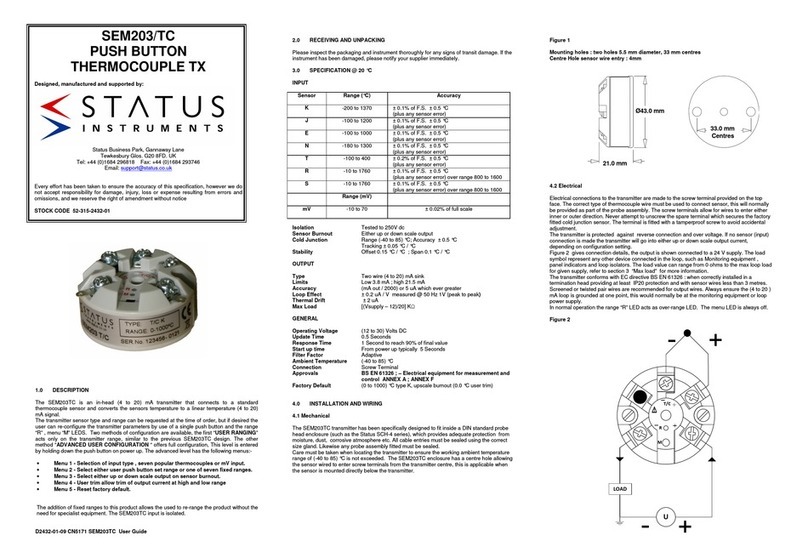

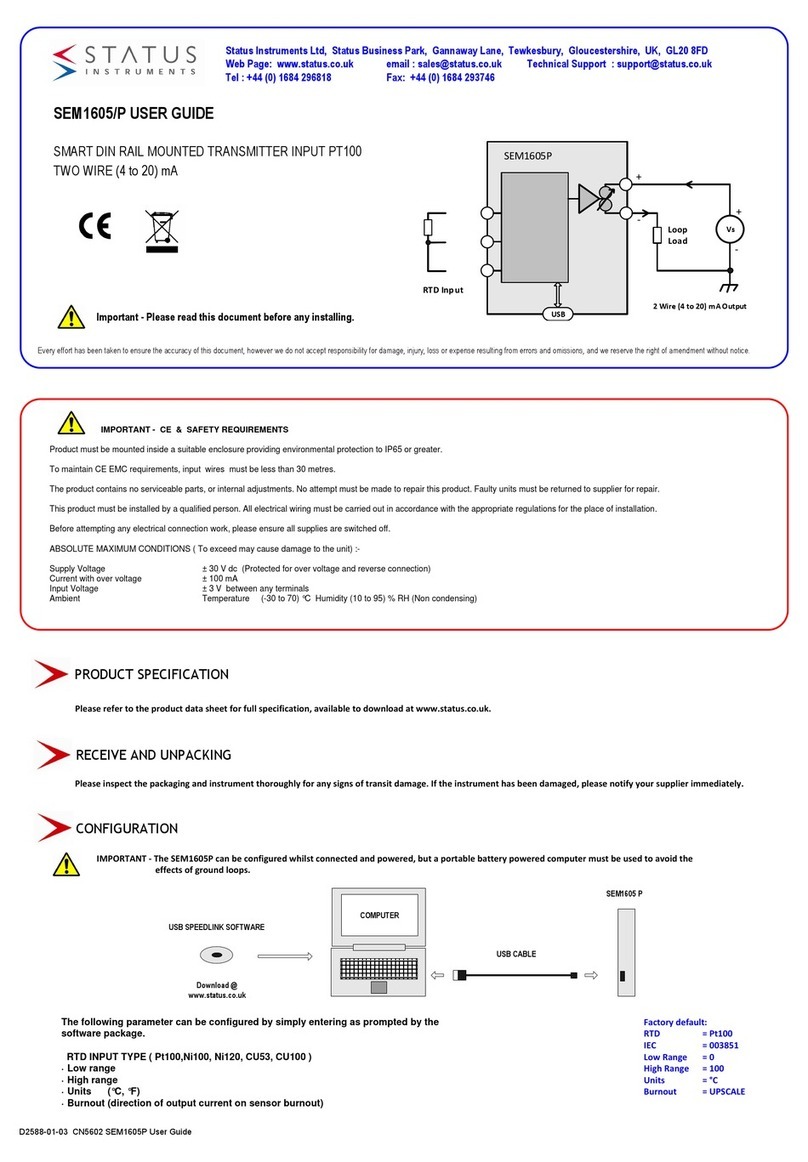

3.0 INSTALLATION

3.1 Mechanical

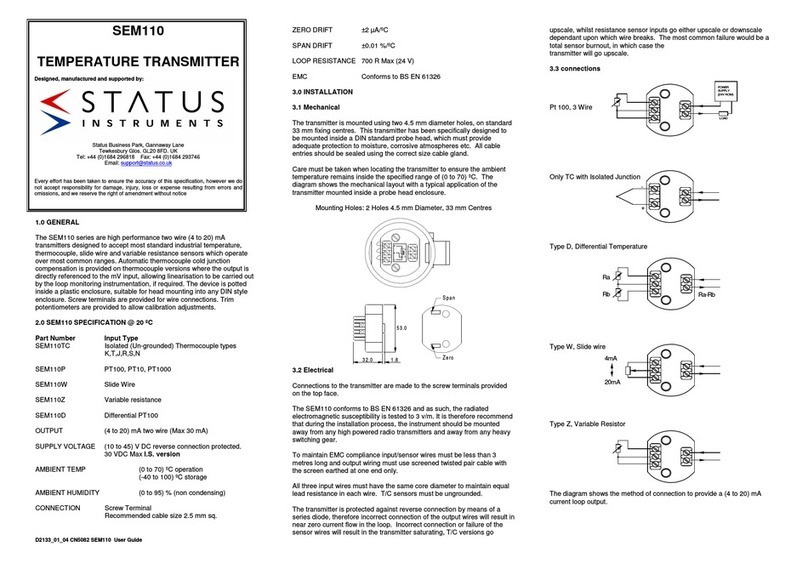

This transmitter has been specifically designed to be mounted on a

universal DIN rail inside an enclosure, which must provide adequate

protection from moisture, corrosive atmosphere etc. All cable entries

should be sealed using the correct size cable gland. Care must be taken

when locating the transmitter to ensure the ambient temperature will

remain inside the specified range of 0 to 70 ºC. The diagrams show the

mechanical layout and a typical application of the transmitter mounted on

a universal DIN rail, with sensor wires entering at the top and bottom of

the unit.

Side View Front View

Rail (DIN EN 50022-35)

3.2 Electrical

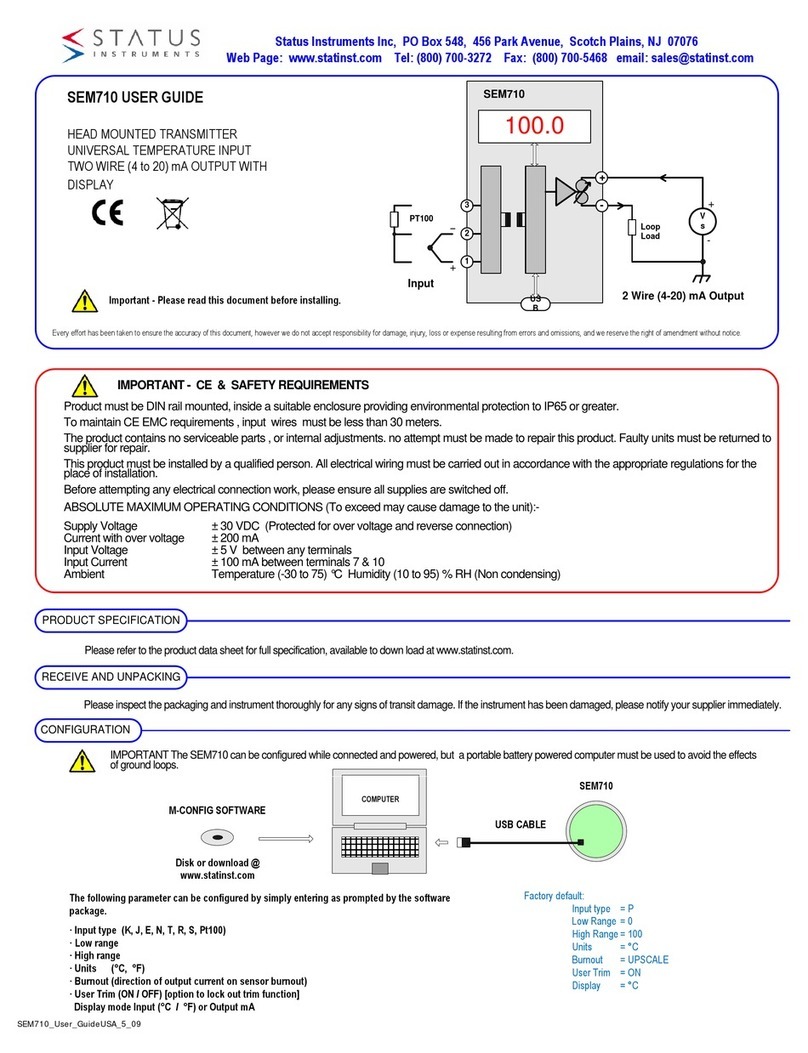

Connections to the transmitter are made by screw terminals. To maintain

CE compliance, input and output wiring must be screened cable with the

screen earthed at one end only. All three input wires must have the same

core diameter to maintain equal lead resistance in each wire.

The transmitter is protected against reverse connection, therefore

incorrect connection of the output wires will result in near zero current

flowin the loop. Incorrect connection of the sensor wires will result in the

transmitter output going to burnout condition.

Figure 2 shows the method of connection to provide a 4-20 mA current

loop output. The Pt100 sensor shown would normally take the form of a

probe assembly with a three wire output. The output loop shows a 24

VDC power supply, used to provide loop excitation, the transmitter, and a

load, all connected in series. The load symbol represents other equipment

in the loop e.g. indicators, controllers, loggers etc.