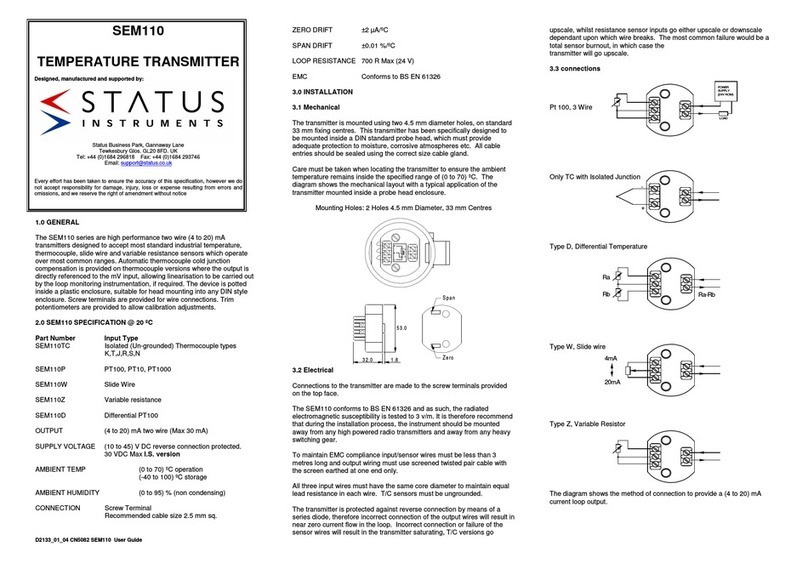

Installation

For SEM210X specification please refer to product data sheet. Installation is normall performed in the following order. If the SEM210X has

been purchased as part of a probe assembl ,steps (1 to 3 ) will have been completed. The user ma wish to reconfigure the transmitter

range, in this instance the SEM210X range can be changed on a completed probe assembl b following step 1.

1. Configuration

2. Mount Transmitter into head

3. Wire Sensor

4. Install Assembl

5. Wire (4 to 20) mA Loop

REFER TO CONDITIONS FOR SAFE USE

Factory default setting Sensor PT100 range (0 to 100) °C,

Visit

www.status.co.uk

download latest

version of

USBSpeedLink

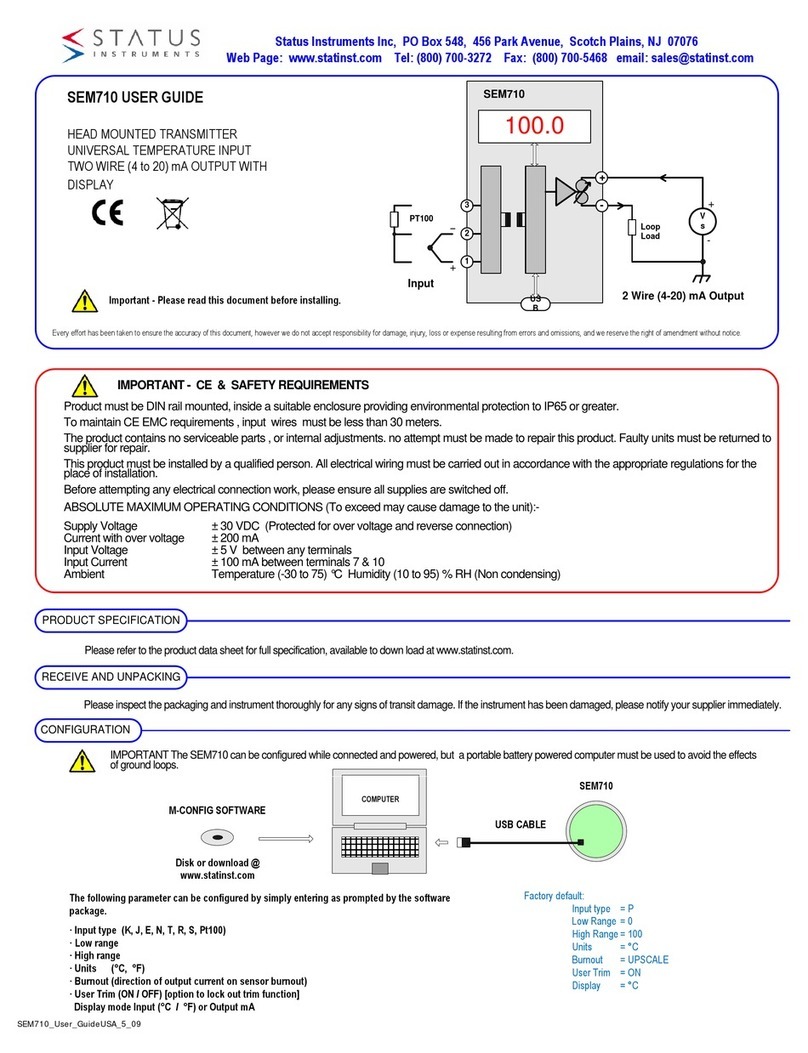

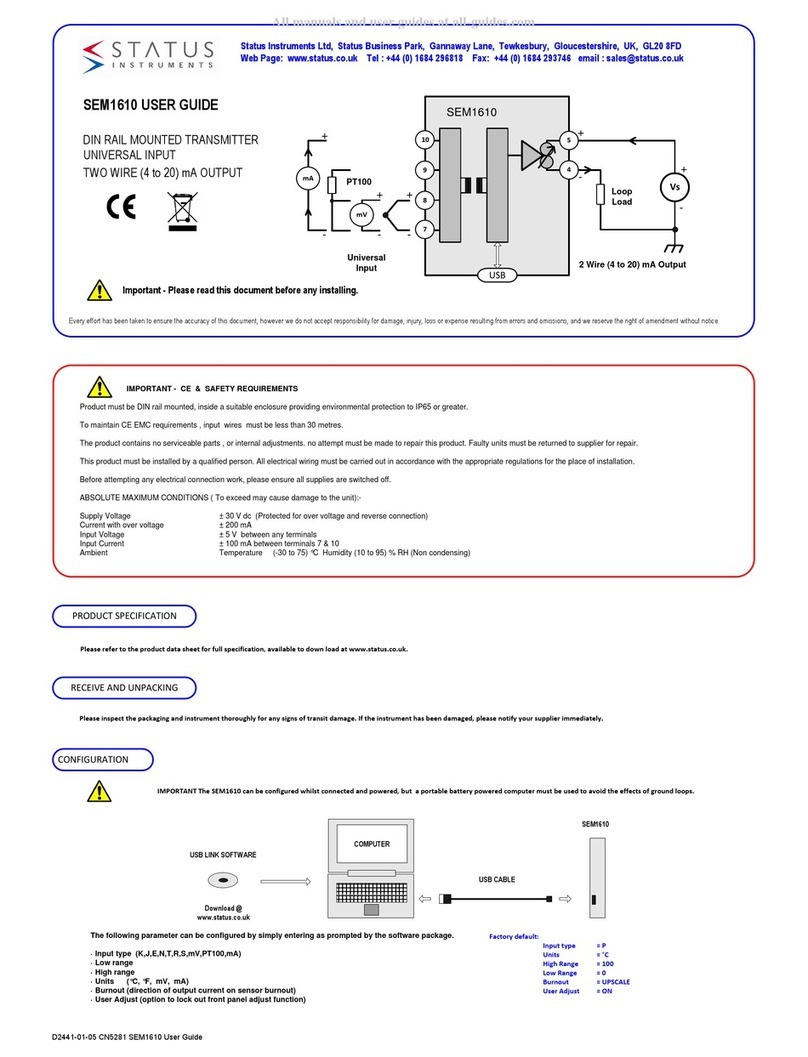

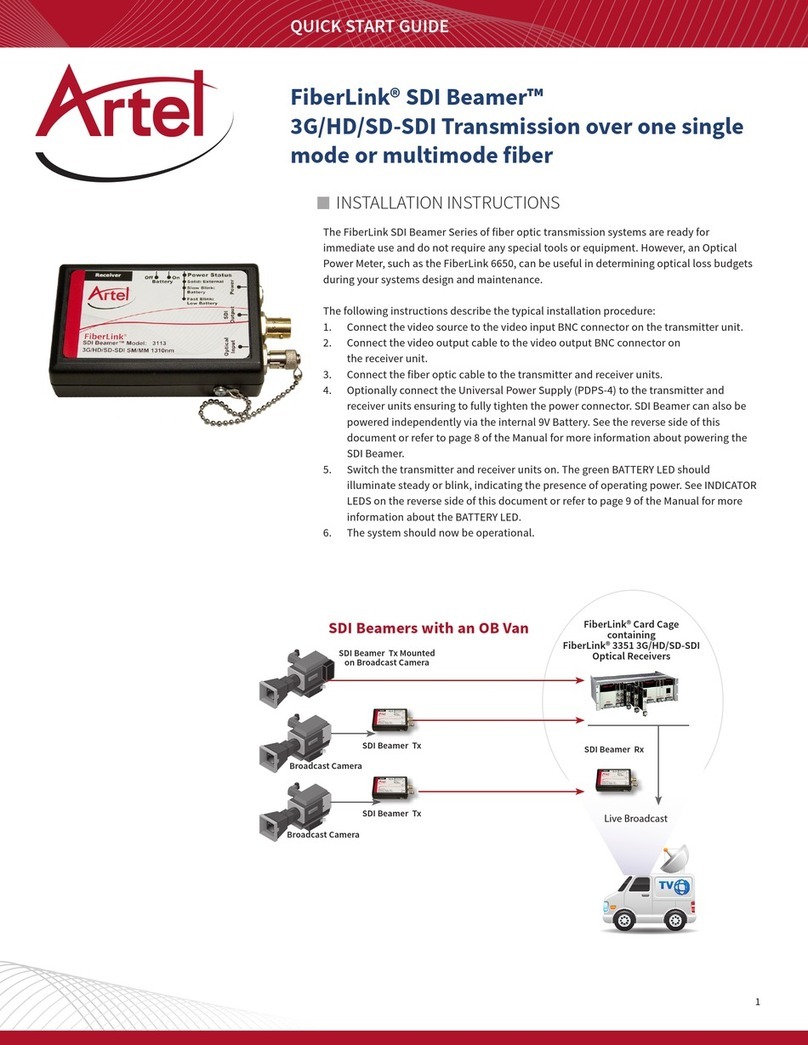

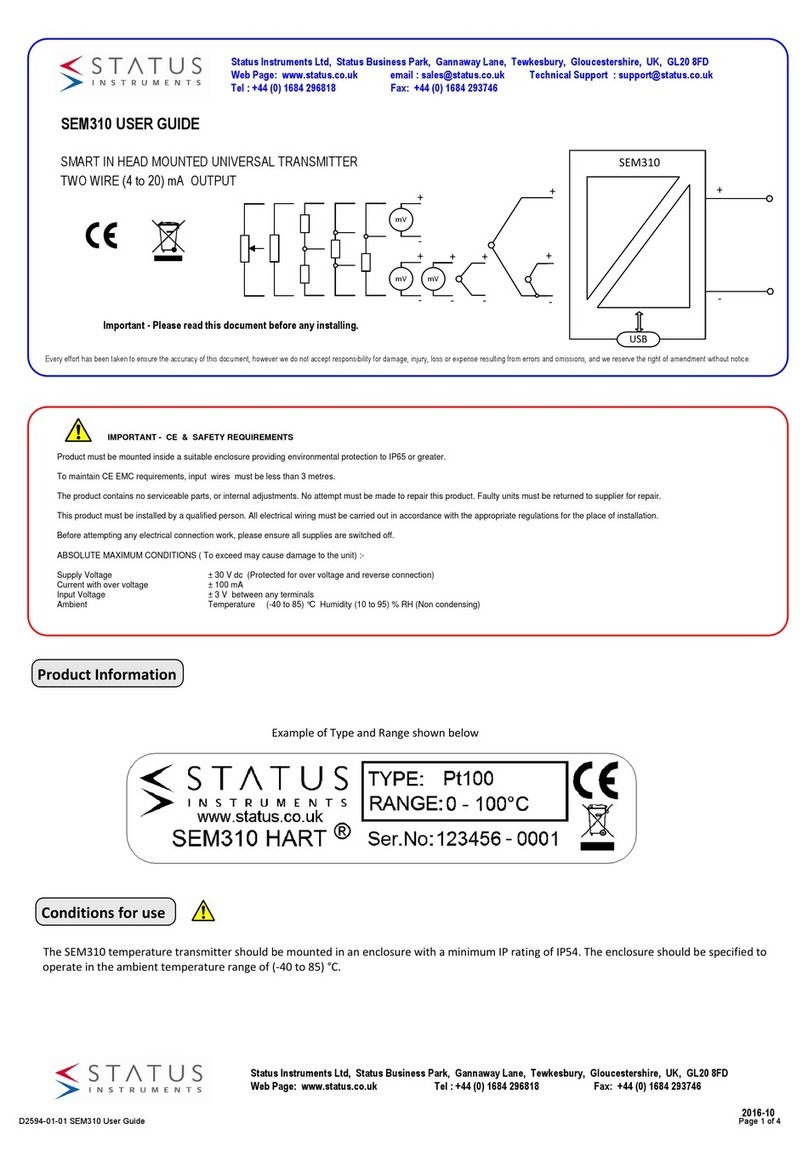

. Configuration – Only to be performed in the safe area

Once software is installed

remove protection cover from

device port , plug in configurator

plugs in to device ports and

connect PC to configurator using

USB cable.

In USBSpeedLink software, select Model type from

“Field Product – In Head TX” menu.

For further information on configuration please open

the help menu on the product configuration screen.

On completion of configuration remove USB cable

and replace protective cover over socket.

EX

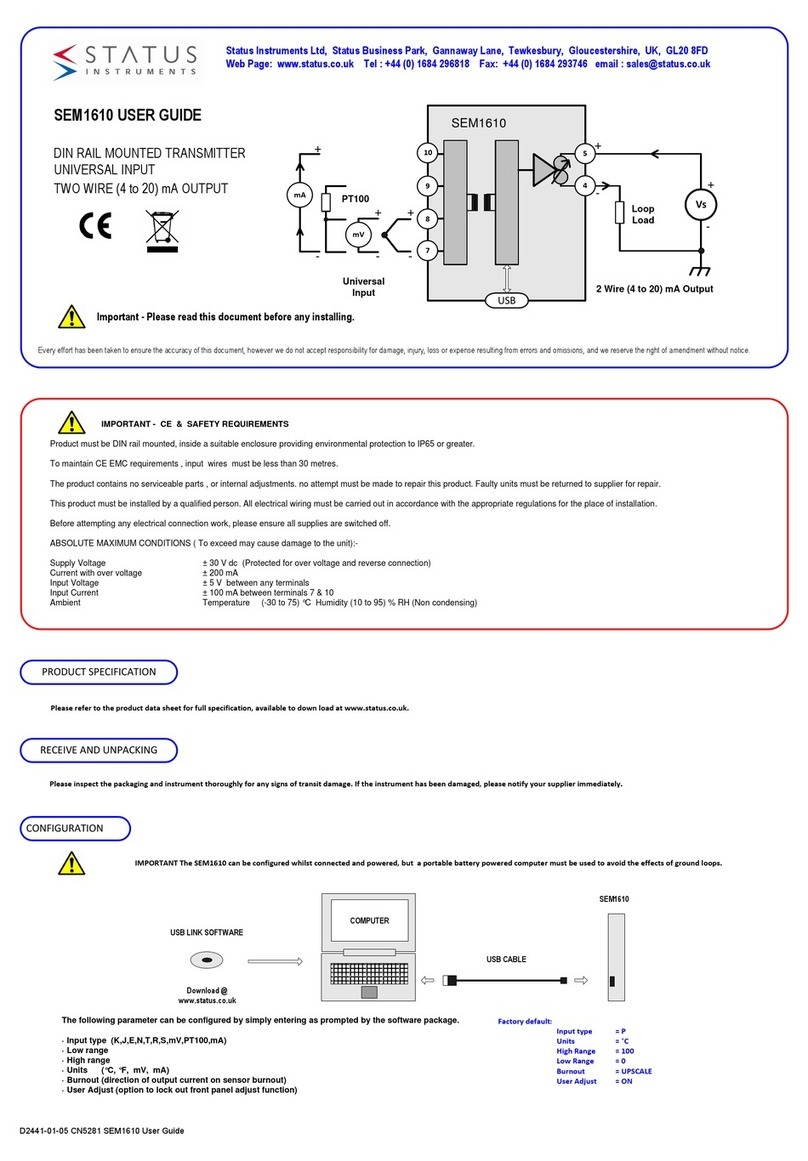

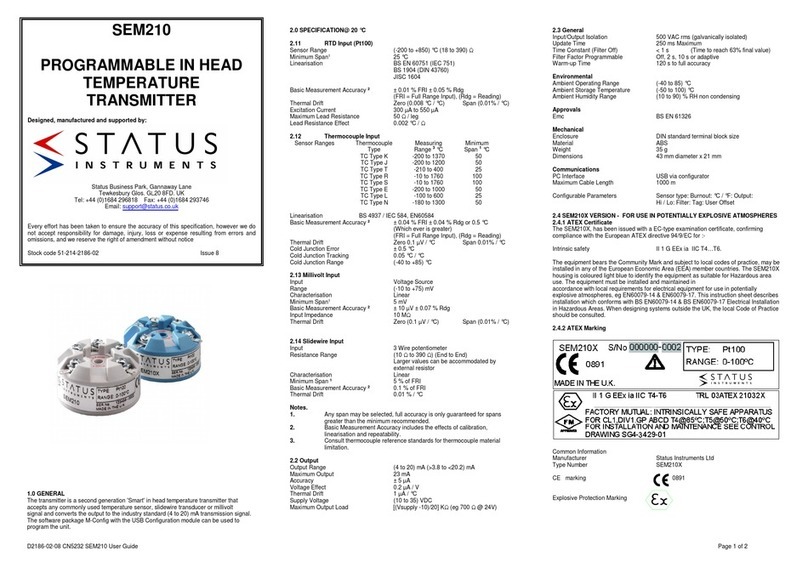

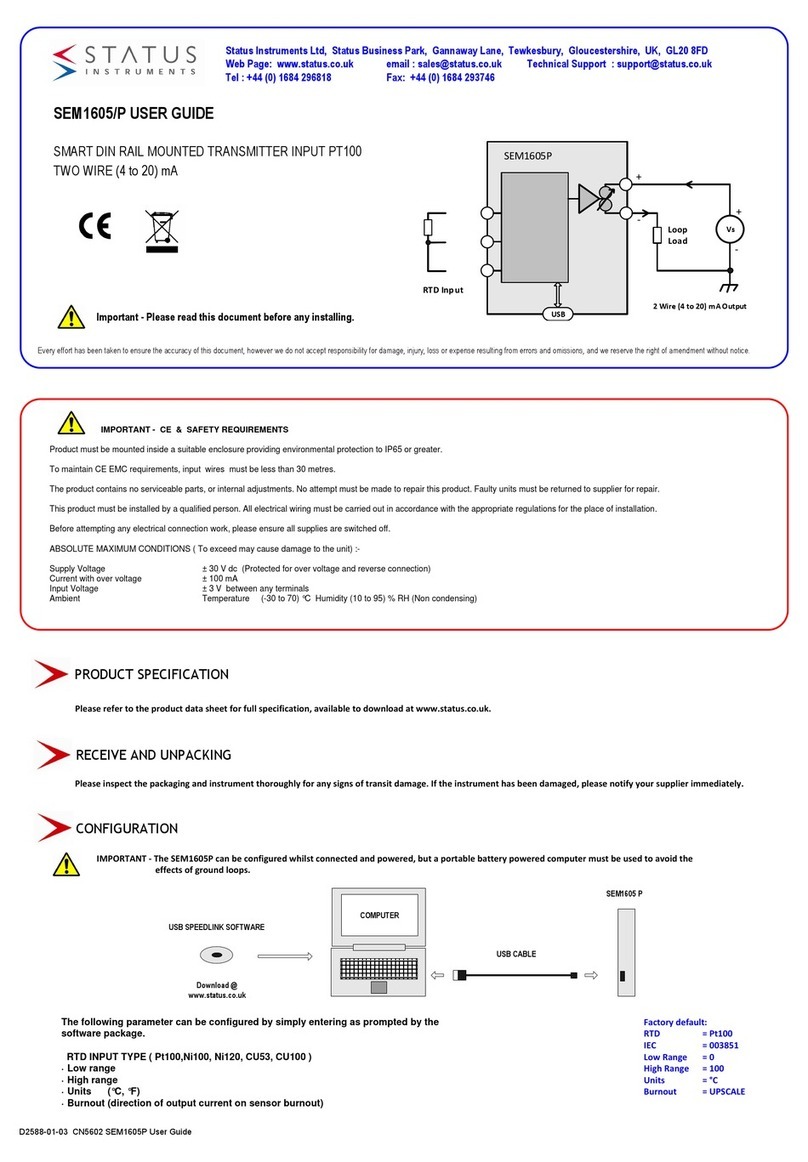

The main configuration is performed using the USB interface. The following parameters may be configured using the powerful USBSpeed link software tool,

which also provide operator diagnostics.

The following functions apply :-

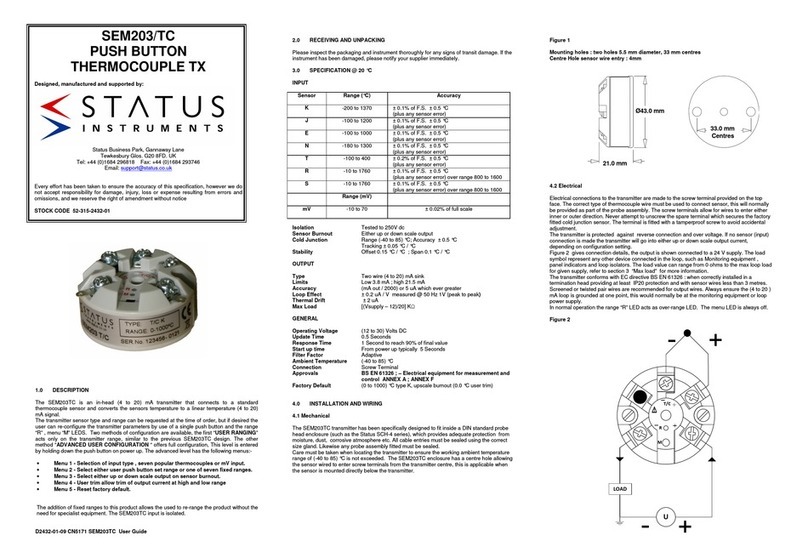

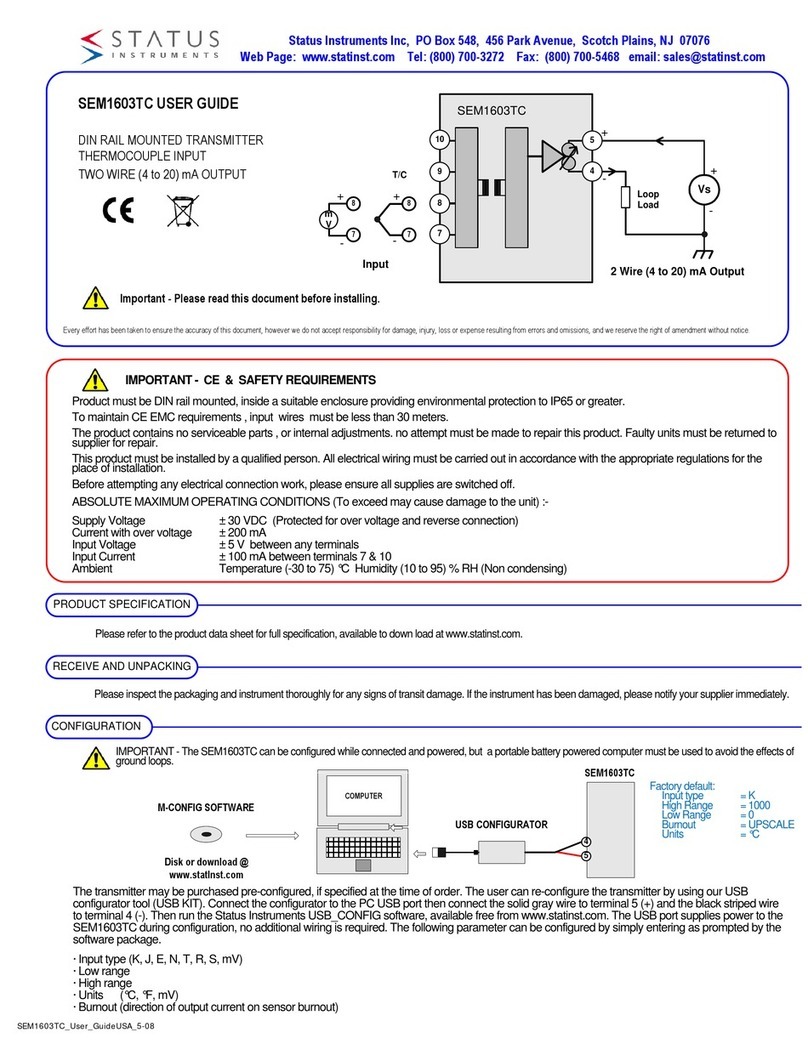

SENSOR

Sensor t pe mV, Dual mV, ohms, slide wire, thermocouple, dual thermocouple, RTD, dual RTD (2 wire).

Sensor wire (ohms and rtd ranges onl ) 2, 3, or 4 wire.

Thermocouple t pe Download from USBspeedlink expanding librar , common t pe K,J,T,E,R,S,N,B,U,G,C,D.

Thermocouple CJ Fixed or Auto.

RTD t pe Download from USBspeedlink expanding librar , common t pe PT100, PT1000, PT500, Ni, CU, KTY series.

Sensor(s) Fail Value on sensor A, (sensor B) fail.

Sensor Pre-set Override sensor signal with pre-set value, primar function diagnostics.

PROCESS

Scaling Scale sensor signal to PV, options - Off, Two point scaling or (4 to 22) step profile.

Units Set PV units

mA Output

Damping Profile out damping (0 to 32) seconds.

Range Range (PV units) For (4 to 20) mA output.

Fix Loop Current Fix loop current to pre-set value (Note resets on power up) . Primar use Diagnostics.

Set Max mA Set the maximum output current (20 to 23)mA.

Set min mA Set minimum output current (3.5 to 4.0) mA.

Trim Read set and reset (4 and 20) mA Trim values.

DIAGNOSTICS

Power ups Number of power ups from manufacture.

Min Max PV Minimum and maximum process variable value during operation with reset.

Operating times From manufacture and calibration. Calibration time is resettable.

Calibration Store Date, operator and certificate number.

Save Data Save transducer data to text file.

DIAGNOSTCS LOG

T pe 150 point non volatile Process Variable log, with power off indication and sensor fail (not time stamped).

Rates User set log periods seconds 5, 15, 30 minutes 1, 2, 5, 10, 20, 30, or 60.

Backup Save log to PC in CSV st le format (using semi colon delimiter) for eas export to text editor or spreadsheet.

PROCESS DATA

Data Live data for sensor (TV) ,pre-scaling, post scaling (PV), Untrimmed mA output, Actual mA output, % output signal

and device ambient temperature (SV) (cold junction).

Diagnostics Sensor wire error detect (not supported in mV mode), Loop power detect.

D2578-01-02 SEM210X User Guide Page 3 of 4

Red

Yellow

2016-11

Note: - The SEM2 0X can be configured whilst connected and powered, but a portable battery powered computer

must be used to avoid the effects of ground loops if the (4 to 20) mA loop is grounded. This may damage the

SEM2 0X. Only to be performed in the safe area.