Staubli SensoGate WA 130 H User manual

SensoGate® WA 130 H

User Manual

Retractable Fitting

2

Table of Contents

SensoGate® WA 130 H Retractable Fitting

Safety Information ................................................................................3

Intended Use .......................................................................................... 5

Package Contents ..................................................................................8

SensoGate® WA 130 H Product Coding ................................................9

Function Description ........................................................................... 10

Build-up of the Retractable Fitting ....................................................11

SensoLock ............................................................................................13

Installing the Media Connection ........................................................14

Identifying the SERVICE Position ......................................................15

Identifying the PROCESS Position ..................................................... 16

Installing and Removing a Sensor .....................................................17

Installing a Gel-Electrolyte Sensor ..................................................... 18

Removing a Gel-Electrolyte Sensor ...................................................20

Installing a Liquid-Electrolyte Sensor ...............................................21

Removing a Liquid-Electrolyte Sensor ..............................................22

Maintenance Work on the Drive Unit ................................................23

Removing the Drive Unit ....................................................................24

Installing the Drive Unit ...................................................................... 25

Replacing the Immersion Tube ...........................................................26

Removing the Immersion Tube ..........................................................26

Installing the Immersion Tube ...........................................................27

Removing and Installing the Calibration Chamber ..........................28

Installation Dimensions ......................................................................29

WA 130 H for sensors with gel electrolyte ...............................................................29

WA 130 H for sensors with liquid electrolyte .........................................................30

Immersion Depths ...............................................................................31

SensoGate® WA 130 H process adaptations dairy pipe, TriClamp ..................31

SensoGate® WA 130 H process adaptation Varivent ............................................32

SensoGate® WA 130 H process adaptations Ingold socket, BioControl .......33

Specifications ....................................................................................... 34

Maintenance Intervals .......................................................................35

Lubricants, O-Rings .............................................................................36

Accessories / Spare Parts ....................................................................37

Accessories ...........................................................................................38

Sealing Kits for Maintenance and Servicing .....................................43

Process adaptation dairy pipe, Tri-Clamp, Varivent, BioControl ......................44

Process adaptation Ingold socket H1, Ingold socket H0....................................45

Declaration of Contamination ............................................................46

Return of Products

Please contact our Service Team before returning a defective device. Ship the cleaned device to

the address you have been given. If the device has been in contact with process fluids, it must

be decontaminated/disinfected before shipment. In that case, please attach a corresponding

Declaration of Contamination (see Page 46), for the health and safety of our service personnel.

Safety Information

SensoGate® WA 130 H Retractable Fitting

Process-Related Risks

Knick Elektronische Messgeräte GmbH & Co. KG assumes no liability for damages

caused by process-related risks known to the operator, which would in fact not

permit the use of the WA 130 H retractable fitting.

Be sure to observe:

Work on the retractable fitting must only be performed by personnel authorized by

the operating company and specially trained for handling and operating the retract-

able fitting.

3

Safety Information

SensoGate® WA 130 H Retractable Fitting

Operation in Explosive Atmospheres

The SensoGate WA130H-X is certified for operation in explosive atmospheres.

• EU-Type Examination Certificate KEMA04ATEX4035X

Exceeding the standard atmospheric conditions within the manufacturer’s specifications, such as ambient tem-

perature, process pressure and temperature, does not impair the durability of the retractable fittings.

Related certificates are included in the product’s scope of delivery and are available at www.knick.de in the cur-

rent version.

Observe all applicable local and national codes and standards for the installation of equipment in explosive at-

mospheres. For further guidance, consult the following:

•IEC60079-14

• EU directives 2014/34/EU and 1999/92/EC(ATEX)

Possible Ignition Hazards During Installation and Maintenance

To avoid mechanically generated sparks, handle the SensoGate WA130H-X with care and apply suitable mea-

sures, e.g., use covers and pads.

The metallic parts of the SensoGate WA130H-X must be connected to the plant’s equipotential bonding using

the metallic process connection and the grounding connection provided for that purpose.

When components are replaced with genuine Knick spare parts made of other materials (e.g. O-rings), the infor-

mation given on the nameplate may deviate from the actual version of the SensoGate WA130H-X. The operating

company must assess and document this deviation.

Electrostatic charging

The drive unit of specific versions of the SensoGate WA130H-X contains housing components made of non-con-

ductive plastic. Due to their surface, the housing components may build up an electrostatic charge. To prevent

this charge from becoming an effective ignition source in Zone0, ensure that the following conditions are met:

• Highly efficient charge generating mechanisms are excluded

• Non-metallic components are cleaned with a moist cloth only

Mechanically generated sparks

Single impacts on metal parts or collisions between metal parts of the SensoGate WA130H-X are not a potential

ignition source only if the following conditions are met:

• Possible impact velocity is less than 1 m/s

• Possible impact energy is less than 500 J

If these conditions cannot be ensured, the operating company must reassess single impacts on metal parts or

collisions between metal parts as potential sources of ignition. The operating company must implement suitable

risk minimization measures, e.g., by ensuring a non-explosive atmosphere.

Possible Ignition Hazards During Operation

When using non-water-based cleaning, rinsing, or calibration media with a low conductivity of less than 1nS/m,

electrostatic charging of internal, conductive components may occur. The operating company must assess the

associated risks and implement appropriate measures.

The sensors that are used must be approved for operation in hazardous locations. Further information can be

found in the sensor documentation.

4

5

Intended Use

SensoGate® WA 130 H Retractable Fitting

Intended Use

The SensoGate® WA 130 H pneumatic retractable fitting is used for installing a sensor for mea-

surements in liquids. The sensor can be cleaned, calibrated or replaced under process conditions

(pressure and temperature).

The modular concept allows simple installation, operation and maintenance.

The operator can exchange process adaptations or convert the fitting for the use with gel sensors

or liquid-electrolyte sensors.

The retractable fitting is suitable for sensors with an outer diameter of 12 mm:

•with gel electrolyte, length 225 mm, sensor head with PG 13.5

•with liquid electrolyte, length 250 mm

The SensoGate® WA 130 H retractable fitting allows:

•inserting and retracting the sensor under process pressure (retractable fitting)

•calibrating or adjusting the measuring system and cleaning the sensor in the running process

(different options available)

•replacing the sensor in the running process (in SERVICE position)

•variable process adaptation by the operator at any time

Take account of the influences of humidity, ambient temperature, chemicals and corrosion.

Safe use

If you are not sure whether the retractable fitting can be safely used for your intended

application, please contact the manufacturer.

To ensure safe use of the equipment, you must follow the instructions given in this manual and

observe the specified temperature and pressure ranges.

The SensoGate® WA 130 H retractable fitting has been developed and manufactured in compli-

ance with the applicable European guidelines and standards. Compliance with the European

Harmonized Standards for use in hazardous locations is confirmed by the EC-Type-Examination

Certificate. Compliance with the European guidelines and standards is confirmed by the EC

Declaration of Conformity.

Hygienic Design

With regard to hygienic design and sterilizability, the retractable fitting complies with the recom-

mendations of EHEDG. This was established and verified in the TNO report V7942 dated February

25, 2008. If required, the TNO report can be viewed or obtained from the manufacturer.

For hazardous-area applications, the sensors used must ensure proper separation of the ATEX

zones. When the retractable fitting is in SERVICE position and the SensoLock ring has been locked,

the sensor may be replaced within a Zone 0 hazardous location.

There is no particular direct hazard caused by the operation of the device in the specified

environment.

6

Intended Use

SensoGate® WA 130 H Retractable Fitting

NOTICE!

Observe the general requirements of protection devices to prevent pollution of potable water

(EN1717) when drawing water from drinking water pipes.

We recommend installing a check valve on the water supply to protect the drinking water from

pollution.

We recommend installing a check valve on the water inlet e.g. on the water valve provided by the

customer or on the rinse connection of the retractable fitting (inlet to calibration chamber) to pre-

vent backflow of rinse or process medium or compressed air into the water pipe.

Suitable check valves made from different materials are available from Knick.

Rating plates

SensoGate® WA 130 H-N

Drive

Process

SensoGate® WA 130-X

Drive

Process

66

IP

Max. pressure

Temperature range

14163 Berlin Made in Germany

SensoGate ®

Retractable Fitting / Drive Unit

Type

No.

14163 Berlin Made in Germany

SensoGate®

Type

No.

Process Unit

66

IP

Max. pressure

Temperature range

14163 Berlin Made in Germany

Sensogate ®

Retractable Fitting / Drive Unit

Type

No.

0044

KEMA 04 ATEX 4035X

II 1 G Ex h IIC T6 ... T3 Ga

II 1 D Ex h IIIC T80°C ... 140°C Da

Tamb

No self-heating

Special conditions

WARNING - Potential electrostatic charging hazard

-- see instruction

-10 ... 70 °C

Max. pressure

Temperature range

Type No.

See Drive Unit

for Ex marking

0044

SensoGate®

Process Unit

14163 Berlin

Made in Germany

7

Properties and Features

SensoGate® WA 130 H Retractable Fitting

Hygienic design and sterilizability apply not only to the process side but also to the rinsing cham-

ber. The only part of the immersion tube which comes into contact with the process is that part

which was previously sterilized in the rinsing chamber.

This means that its suitability for use in pharmaceutical and food applications is proven, which

allows validation in FDA-regulated production processes.

Properties and Features

• With regard to hygienic design and sterilizability, all process-wetted parts incl. the rinsing/

calibration chamber comply with the recommendations of EHEDG (TNO report V7942 dated

February 25, 2008)

• Directed flow rinses the process seal from the process side as well as from the inside

of the fitting

• Prevention of re-contamination and safe separation to the process during probe movement

• Double sealings with leakage bores prevent microbial contamination of the drive

• Cost reduction by simple installation, operation and maintenance

• Protective rinsing of the seals for a long service life

• SensoLock for high safety of operation

• Integrated limit switches

• Fast and uncomplicated replacement of calibration chamber and immersion tube

• Cyclone rinsing for optimum cleaning effect

• Superior sensor immersion depth

• Standard sensor length (225 mm) even for large immersion depths

• Process-wetted parts made of electropolished stainless steel 1.4404

• Special version for sensors with pressurizable liquid electrolyte

• SIP and CIP capable process side

8

Package Contents

SensoGate® WA 130 H Retractable Fitting

Check the shipment for transport damage and completeness.

The package should contain:

• Retractable fitting

• Documentation

• Test certificates

9

SensoGate® WA 130 H Product Coding

* Material combinations: Process-wetted part of calibration chamber / rinse-wetted part of calibration chamber /

immersion tube

WA 130 H - -

Explosion

protection

Hazardous area Zone 0 X

Without N

Sensor Solid electrolyte 0

Liquid electrolyte (pressurization possible) 1

Gasket material Elastomeric ring set F, FKM (Viton) FDA F

Elastomeric ring set E, EPDM FDA E

Elastomeric ring set G, FFKM/EPDM FDA G

Elastomeric ring set H, FFKM/FFKM FDA H

Process-wetted

materials *)

1.4404 / 1.4404 / 1.4404 (electropolished) G

Process adaptation Dairy pipe DN 50 C 1

Dairy pipe DN 65 C 2

Dairy pipe DN 80 C 3

Ingold socket 1.4404, 25 mm (G 1 1/4") H 0 A

Ingold socket 1.4404, 25 mm (G 1 1/4“), hygienic H 1 A

Clamp 1.5“, 1.4404 J 1 A

Clamp 2“, 1.4404 J 2

Clamp 2.5“, 1.4404 J 3

Clamp 3“, 1.4404 J 4

Clamp 3.5“, 1.4404 J 5

Varivent, 1.4404, for pipe, DN 50 or larger V 1 A

Varivent, 1.4404, for pipe, ≥ DN 65 short, ≥ DN 80 long V 2

BioControl size 50 L 1 A

BioControl size 65 L 2 A

Immersion depth Short A

Long B

Connection Media connection, PEEK B

Media connection, PEEK, with integr. connector for additional medium C

Free hose connection, PEEK (meas air, service air,

rinse-medium connection, additional-medium connection) E

Special variant Without 000

Equipped with special grease (provided by customer) 001

With pneumatic limit signal for Unical 79(X)-2 004

10

Assembly

• Possible mounting angle 15° above horizontal:

• Mounting angle 360° (i.e. even upside down)

for special sensors only containing thickened

electrolytes which thus cannot flow.

15°

15°

Function Description

SensoGate® WA 130 H Retractable Fitting

The pneumatically operated retractable fitting allows calibrating or adjusting the measuring

system and cleaning the sensor in the running process. For that purpose, the retractable fitting

can be moved between two positions using compressed air:

• PROCESS position: Sensor located in the process medium.

• SERVICE position: Sensor located in the calibration chamber.

In SERVICE position you can clean, maintain, calibrate or adjust the measuring system.

A control unit, such as the Unical® 9000, moves the probe to SERVICE or PROCESS position and

leads different calibration and/or cleaning liquids to the sensor located in the calibration chamber.

For operation of the SensoGate®, you must connect control air, rinsing or calibration media, and

the electrical check-back signal for display of the probe position with the SensoGate®.

There are two basic options for this.

In conjunction with the UNICAL® or UNICLEAN® electro-pneumatic controllers and the PROTOS®

measuring system, air pressure, rinsing, or calibration media, and the check-back cable are com-

bined in a single hose with just one plug connection (multiplug, in the following referred to as

media connection).

This media connection is installed on the SensoGate® together with the outlet hose.

When you do not use a probe controller (UNICAL® or UNICLEAN® and the PROTOS® measuring

system), you can connect the supply lines for control air, rinsing or calibration media and elec-

trical check-back with a free hose connection via an adapter (ZU 0742 / ZU 0733 / ZU 0734, see

Accessories Page 41).

These liquids leave the calibration chamber through an outlet hose, i.e. they are displaced from

the calibration chamber by following liquids or by compressed air.

To replace the sensor, you must move the retractable fitting into SERVICE position.

With Unical® 9000 probe controller, all media, control air and the check-back cable for position

indication of the probe are connected to the retractable fitting through a compact connector

(multiplug).

11

Process adaptation

(e.g. Ingold socket).

Build-up of the Retractable Fitting

SensoGate® WA 130 H Retractable Fitting

The SensoGate® retractable fitting consists of 2 main units: drive unit and process unit.

The drive unit performs the required movements to move the sensor into and out of the process.

The process unit comprises the process-wetted calibration chamber as well as the process

adaptation. Drive unit and process unit can be separated by the operator (see Page 24).

Drive unit

Process unit

Sensor holder

Holding bracket

SensoLock

Coupling nut

Immersion tube

Media connection

to Unical® 9000(X)

probe controller

(not included with

retractable fitting)

Connection

Outlet port

Multiplug

Outlet

Rinsing / calibration media

(outlet hose not included with

retractable fitting)

Leakage hole

Calibration chamber

upper part

Calibration chamber

lower part

Build-up of the Retractable Fitting

Modules available: Rotary drives, immersion tubes, process adaptations

Sensors with

gel electrolyte

Sensors with

liquid electrolyte

Rotary drives

Available material:

• 1.4404

Immersion tube

Process adaptations

Dairy-pipe screw joint

Ingold socket

BioControl

Varivent

Tri-Clamp

12

13

SensoLock

Optionally, the WA 130 H is equipped with a SensoLock ring. SensoLock securely blocks the

retractable fitting in SERVICE position. Turning the SensoLock ring to “LOCK“ position mechanically

locks the internal lift piston and thus prevents the retractable fitting from moving to PROCESS

position.

The SensoLock ring can only be turned in SERVICE position. In PROCESS position and all

intermediate positions the SensoLock ring is blocked.

This prevents operation errors. Before starting maintenance work or replacing a sensor,

you must activate SensoLock (LOCK) to:

• make sure that the retractable fitting is in SERVICE position.

• prevent that the retractable fitting is accidentally moved to PROCESS position.

Turning the SensoLock ring to

“LOCK“ position prevents the

immersion in the process when

the sensor has been removed.

(blocking the travel function,

safety function)

After the sensor has been

installed, you can unlock the

travel movement by turning the

SensoLock ring to “UNLOCK”.

14

Installing the Media Connection

Using the media connection and the Unical® 9000(X) probe controller with multiplug

1) Screw mounting bracket (A) of media connec-

tion to holding bracket (B) of retractable fitting.

One of three possible arrangements is shown

here. (3 x 2 threaded holes on the holding

bracket (B) allow 3 different arrangements

of the hose.)

2) Screw multiplug (C) of the media connection to

connector (D) of the retractable fitting.

3) Screw coupling nut (E) of the outlet hose (F) to

outlet port (G) of the retractable fitting.

C

D

EG

B

A

F

15

Identifying the SERVICE Position

SensoGate® WA 130 H Retractable Fitting

SERVICE position –

indicated by the sensor

connector (A) protruding

out of the drive unit.

SERVICE position –

indicated by the rubber

bellows (A) being

expanded

Solid-electrolyte sensor Liquid-electrolyte sensor

AA

16

Identifying the PROCESS Position

SensoGate® WA 130 H Retractable Fitting

Short immersion depth

Solid-electrolyte sensor

Short immersion depth

Liquid-electrolyte sensor

PROCESS position –

indicated by the sensor

connector not protruding

out of the drive unit.

PROCESS position –

indicated by the rubber

bellows (B) being

compressed.

B

17

Installing and Removing a Sensor

SensoGate® WA 130 H Retractable Fitting

Sensors must only be installed or removed by trained personnel authorized by the

operating company. Make sure that the retractable fitting is in SERVICE position

(see “Function Description” on Page 10).

Be sure to follow the assembly instructions step by step.

Preparations:

• Check whether the sensor is damaged (glass broken?).

Never install a damaged sensor.

• Check whether slide washer or O-ring on the sensor are damaged and replace if required.

• Remove watering cap from the sensor tip and rinse sensor with water.

• Internally pressurized sensors might have a silicone seal on the diaphragm (as transport

protection). Remove this seal using the knife shipped with the sensor.

18

Installing the sensor

1) The sensor must only be installed in SERVICE

position.

2) Use appropriate sensors (A) only:

Diameter: 12 mm Length: 225 mm

Observe pressure resistance of the sensor.

3) Check whether slide washer (C) or O-ring (D) on

the sensor are damaged.

Installing a Gel-Electrolyte Sensor

4) Screw in the sensor head (B)

(19 mm, PG 13.5) with a max. torque of 3 Nm

(recommended tool: 19 mm, e.g. Knick ZU0647

wrench).

A

B

C

D

ZU 0647

19

6) Connect equipotential bonding cable to

terminal (F) (if required).

Installing a Gel-Electrolyte Sensor

5) Connect cable socket with cable (G).

Hold the cable in a loop and fix it using

clamp (E).

CAUTION! The cable loop must be long

enough so that the cable does not impede

the stroke movement of the fitting.

E

F

G

E

20

Removing a Gel-Electrolyte Sensor

Removing the sensor

1) The sensor must only be removed in SERVICE

position.

2) Remove cable socket with cable (G)

3) Before removing the sensor, check that there is

no liquid leaking from the outlet (process sealing

might be defective).

4) Remove the sensor (recommended tool: 19 mm,

e.g. Knick ZU0647 wrench).

5) Check whether slide washer (C) or O-ring (D) on

the sensor are damaged.

CAUTION!

When replacing damaged sensors (glass break-

age), you must check the sensor seal in the im-

mersion tube and replace it if required.

(See section “Replacing the Immersion Tube” on

Page 26)

G

C

D

ZU 0647

Table of contents

Other Staubli Accessories manuals

Popular Accessories manuals by other brands

BLIP

BLIP BLN2i-WF installation manual

Metalfrio Solutions

Metalfrio Solutions VN50C Use and care guide

SECO-LARM

SECO-LARM ENFORCER E-931-S33PRGQ manual

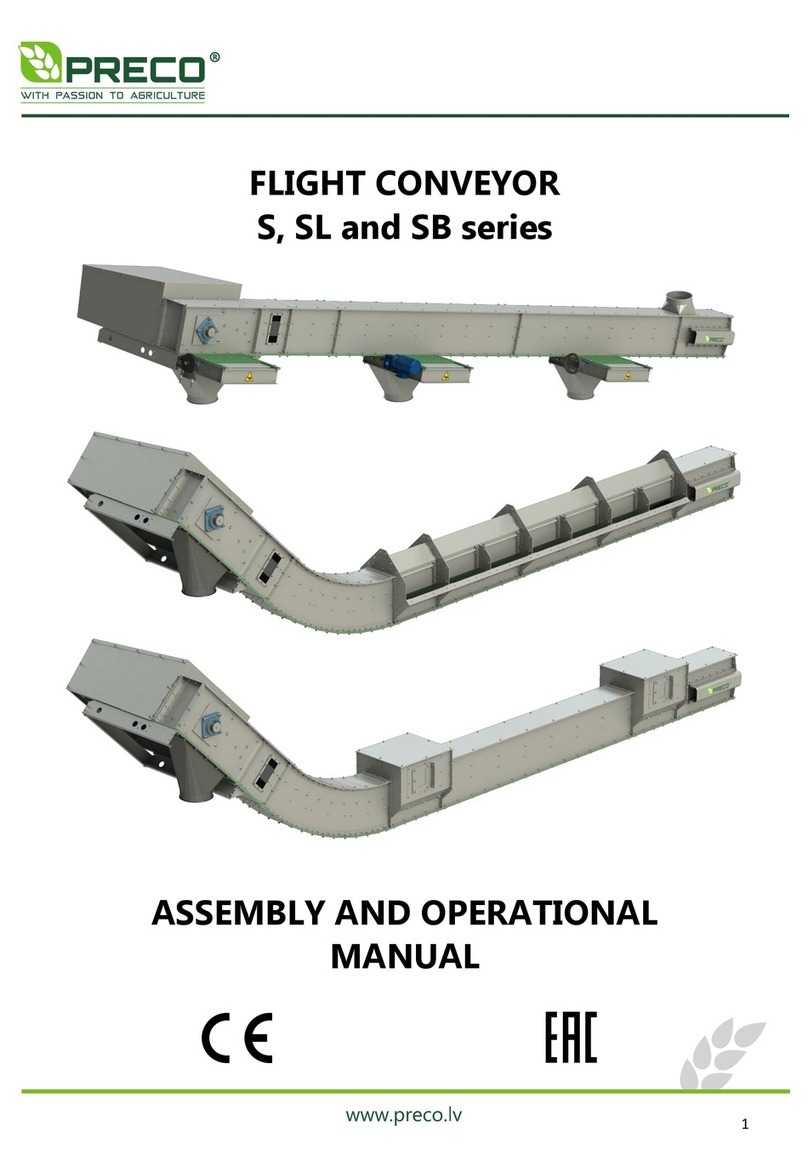

Preco

Preco S Series Assembly and operational manual

S+S Regeltechnik

S+S Regeltechnik THERMASGARD HFTM-Q Operating Instructions, Mounting & Installation

Monnit

Monnit ALTA MNS2-4-W2-GS-C2 user guide