BLD-AC750S Brushless Driver

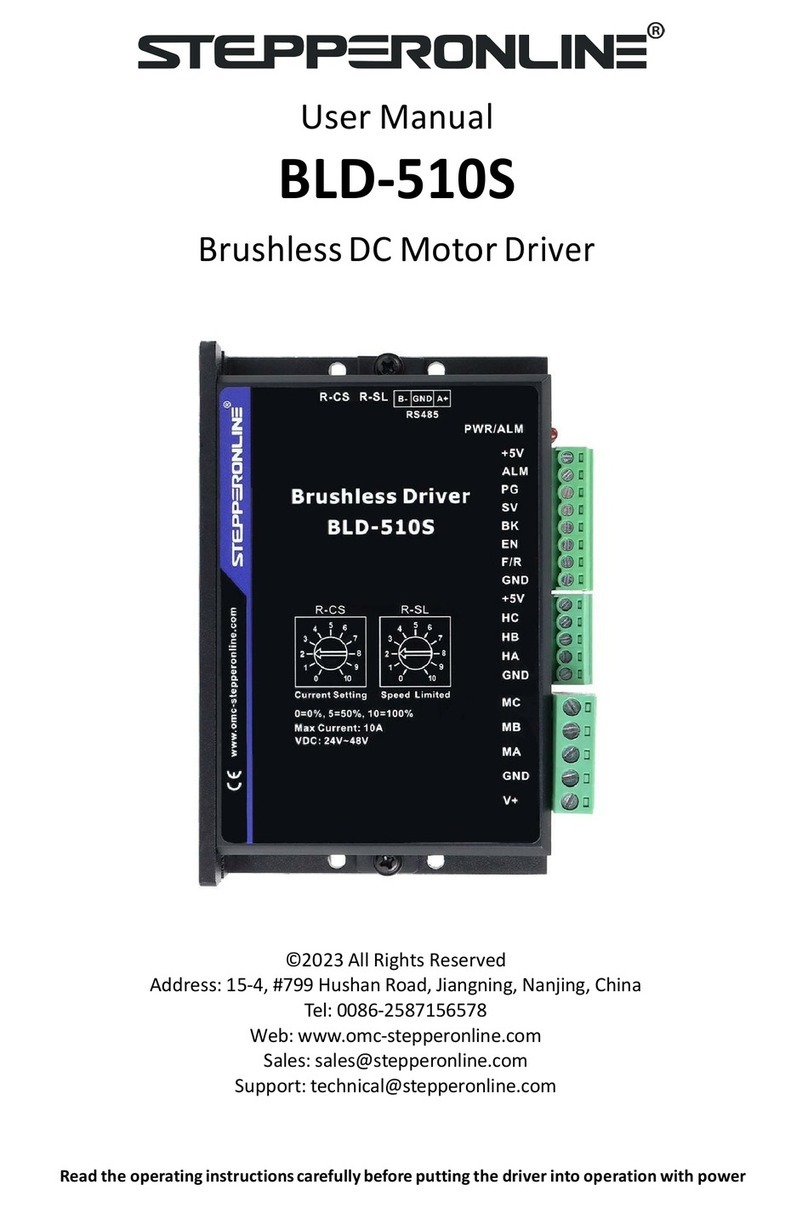

connecting. The motor will be running when we connect the terminal “EN” to “GND”; when

shut down, the motor will stop naturally, and the stopping time will be decided by the inertia

and load adding on the motor.

Motor rotation direction control ( F/R )

You can control the motor rotation direction by controlling the terminal “F/R” and “GND”

connecting. When connecting terminal “F/R” to terminal “GND”, the motor will run at CCW

(view from motor output side), and when shut down, the motor will run at another direction.

Attention: If you need to change the motor rotation direction, please stop the motor at

first, otherwise the driver shall be caused to damage.

Brake the motor to stop ( BK )

You can break the motor to stop if need. The motor will run when the terminal “

B

K” not

connects

to

“GND”, but if you connect these two terminals, the motor will stop quickly. And the

motor stopping time will be decided by inertia and load adding on the motor.

Attention: If you are not necessary to stop the motor quickly, please DO NOT use this function,

cause it has some electrical and mechanical impact on the motor and driver.

Speed signal output(PG)

The speed pulse output port is 0C, output 30V/10mA max. You can connect with a resistance

(3K ohm ~10K ohm) between signal and input power to get the pulse signal, this port will output

serial pulses which has fixed extent ( it is 50uS). This output pulse from every rotation of the

motor is 3 x N, “N” means the total pole number of the magnet. For example, 2 pair of poles,

means 4 poles motor, 12 pulses per turn, when the motor speed is 500rpm, the pulses out

from the PG is 6000.

Alarm output (ALM)

The alarm output port is 0C, output 30V/10mA max. You can connect a resistance (3K ohm

~10K ohm) with the input power to get the alarm signal. When alarm, this port is connecting

the

GND (Low voltage), and the driver will stop working and keep in alarm status.

Drive failure

Over-voltage or over-current will lead the driver to a protection status, the driver will

automatically stop working, the motor stop and blue light are flashing. As long as you enable