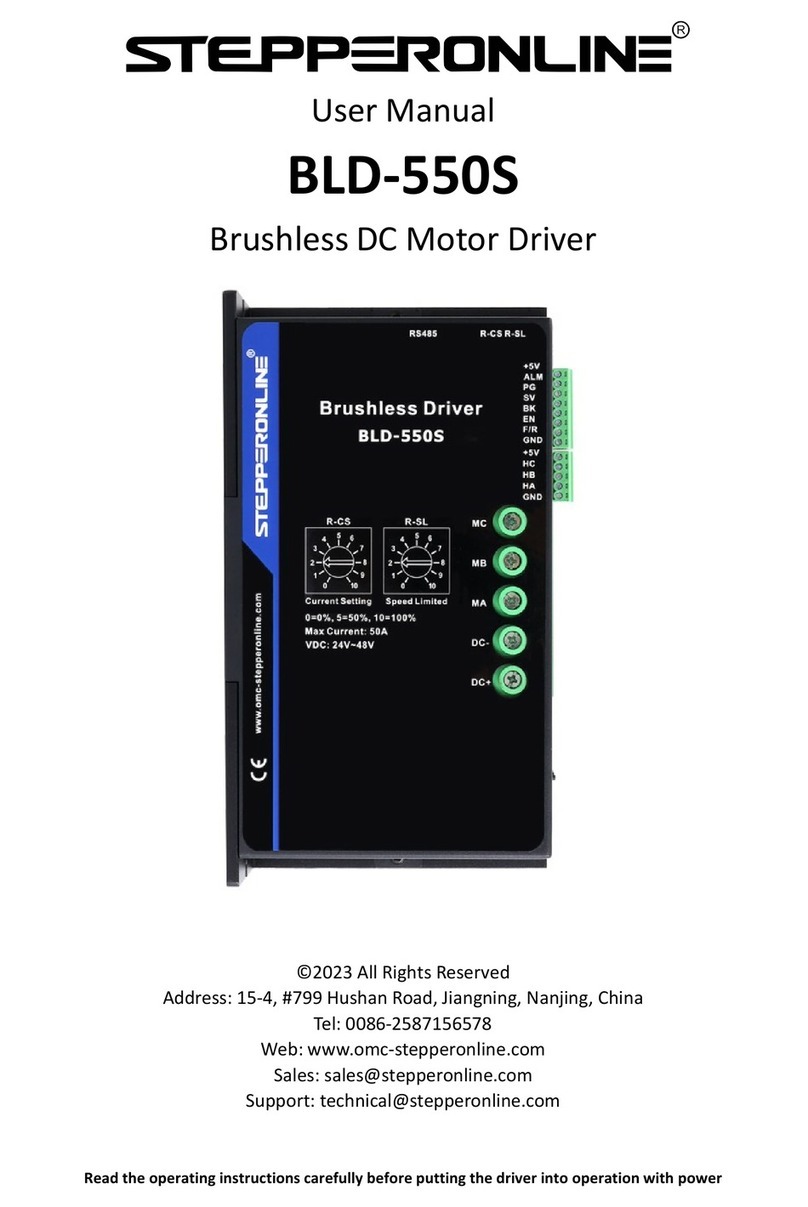

StepperOnline BLD-510S User manual

User

Manual

BL

D-

510S

Brushless

DC Motor

Driver

©2023 All Rights Reserved

Address: 15-4, #799 Hushan Road, Jiangning, Nanjing, China

Tel: 0086-2587156578

Web: www.omc-stepperonline.com

Sales: sales@stepperonline.com

Support: technical@stepperonline.com

Read the operating instructions carefully before putting the driver into

operation

with power

BLD-510S BLDC Driver

2

Introduction

This brushless motor driver is a driver independently developed by STEPPERONLINE to cooperate with the field of

modern industrial automatic control. It mainly uses high-performance dedicated brushless DC motor driver chips,

which have high integration, small size, complete protection, simple and clear wiring, and high reliability. The driver

is suitable for driving small and medium-sized brushless DC motors with a rated power below 200W. The driver

adopts a new type of PWM technology to make the brushless motor run at high speed, low vibration, low noise,

good stability and high reliability.

1. Features

High performance and low price

PID speed, current double loop regulator

20KHZ chopper frequency

2 times overloading capacity

Build with over-voltage, under-voltage, over-current, over-temperature, Hall signal illegal and other error alarm

functions

2. Specifications

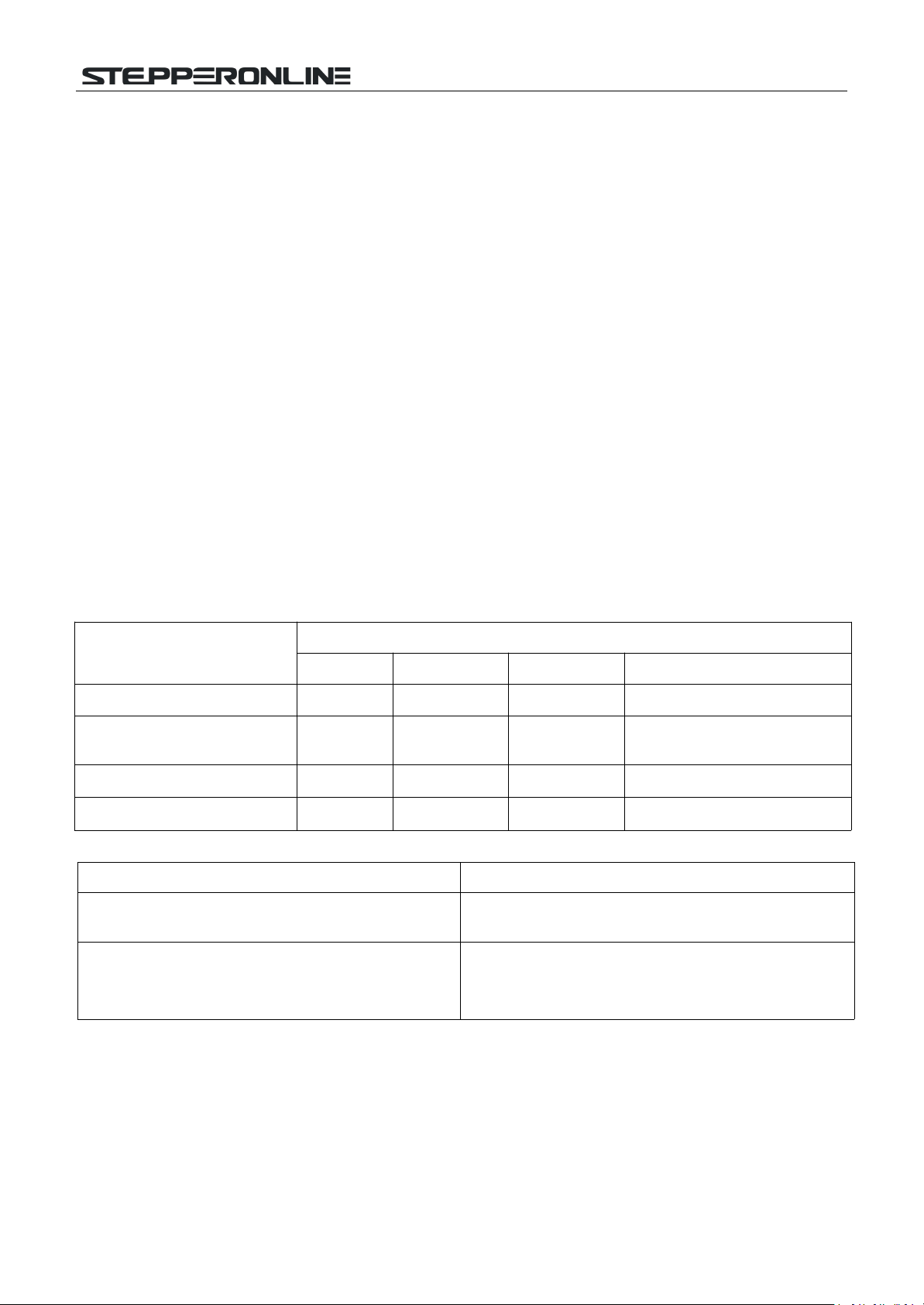

2.1 Electrical Specification

Parameters

BLD-510S

Min

Typical

Max

Unit

Input voltage

24

36

48

VDC

Continuous Output Current

8.3

5.5

4.2

A

Max. Output Power

200

200

200

W

Peak Output Current

13

13

13

A

2.2 Environment

Cooling

Radiator

Control Signal

I/O

Full Isolation

Protection Functions

Over-current, overheat, over-speed, over-voltage,

under-voltage, power supply abnormality control

BLD-510S BLDC Driver

3

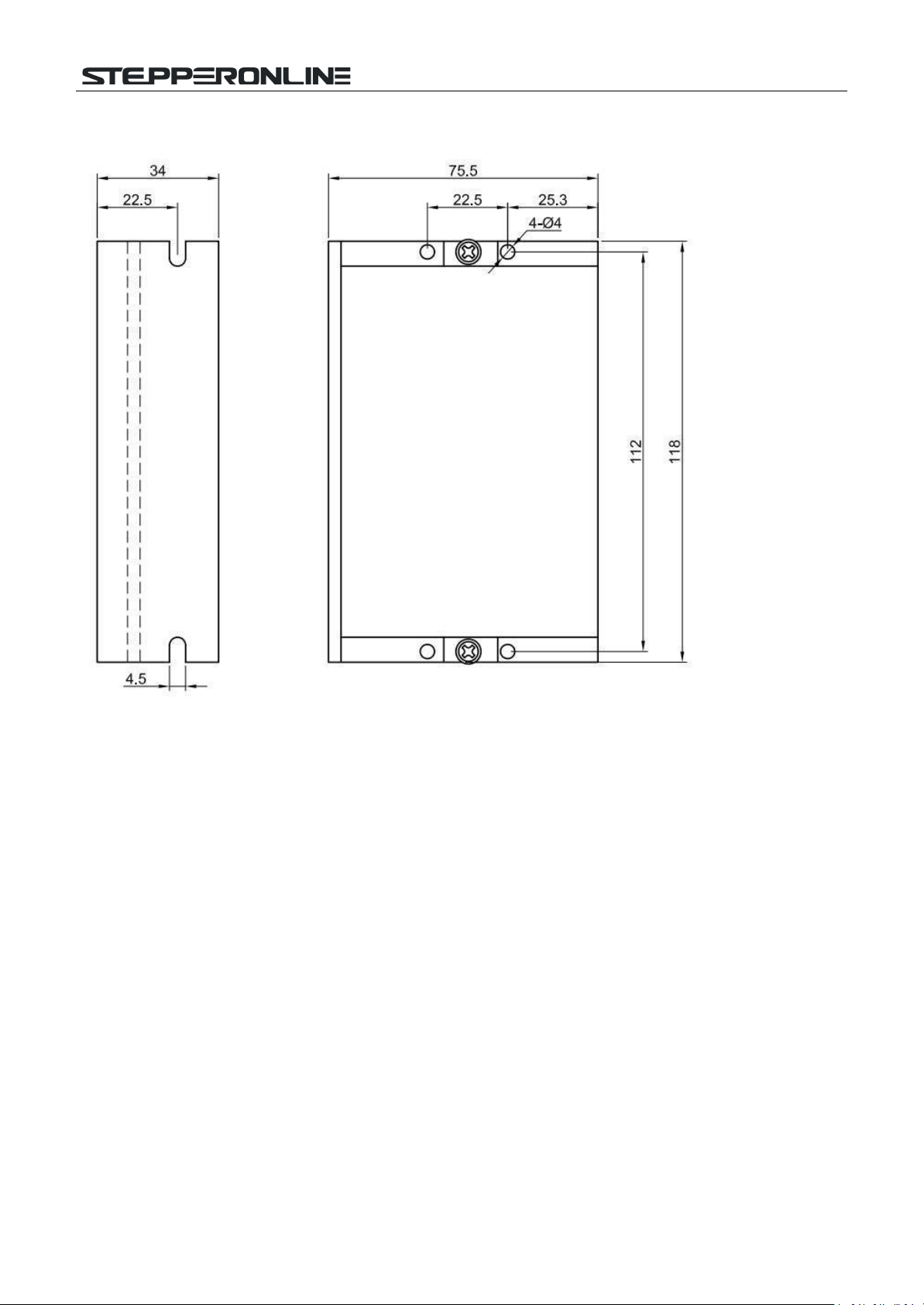

2.3 Mechanical Specification

(Unit: mm [1inch=25.4mm])

2.4 Safety Precautions

This product is professional electrical equipment and should be installed, debugged, operated and maintained by

professional

and technical personnel. Improper use will cause electric shock, fire, explosion and other dangers.

This product is powered by a DC power supply. Please confirm that the positive and negative poles of the power

supply are correct before powering on.

Do not plug or unplug the connecting cable when the power is on, and no

short-circuiting

of the cable is allowed

when the power is on, otherwise the product will be damaged.

If the motor needs to change direction while it is running, it must first decelerate till stop, and then change direction.

The driver is a power device and it is important to maintain good heat dissipation and ventilation in the working

environment.

BLD-510S BLDC Driver

4

3. Terminal Interface Description

3.1 Power Input

No.

Terminal Name

Description

1

V+

24VDC~48VDC input

2

GND

GND input

3.2 Motor Input

No.

Terminal Name

Description

1

MA

Motor A phase

2

MB

Motor B phase

3

MC

Motor C phase

4

GND

GND

5

HA

Hall signal A phase input

6

HB

Hall signal B phase input

7

HC

Hall signal C phase input

8

+5V

Hall signal power line

3.3 Control Signal

No.

Terminal Name

Description

1

GND

Signal ground

2

F/R

CW/CCW terminal

3

EN

Stop/Start terminal

4

BK

Brake terminal

5

SV

Analogy signal input terminal

6

PG

Speed output terminal

7

ALM

Alarm output terminal

8

+5V

+5V power output terminal

Built-in

potentiometer R-SL:

Adjust the motor speed gain, which can be adjusted from 0~100%.

Built-in potentiometer R-CS: Maximum protection current setting, built-in potentiometer can be set 0%~100%

continuous current protection.

4. Function and Usage

4.1 Speed Adjustment Method

The driver offers the following three speed adjustment methods, one of which can be selected by the user as follows:

Inner potentiometer speed adjustment: turn the potentiometer on the drive panel counterclockwise to reduce the

motor speed and clockwise to increase it. The potentiometer must be set to minimum when the user uses an

external input for speed adjustment.

External input speed adjustment: connect the two fixed terminals of the external potentiometer to the GND and

BLD-510S BLDC Driver

5

+5v terminals of the driver respectively, and connect the adjustment terminal to the SV terminal to adjust the speed

using the external potentiometer (10K~50K), or through other control units (e.g. PLC, microcontroller, etc.) to input the

analogue voltage to the SV terminal to achieve speed adjustment (relative to GND), the SV port accepts a range of DC

0V~+5V, corresponding to the motor rotation speed of 0~rated speed.

An external digital signal can also be used to regulate the speed: A pulse width digital signal (PWM) with amplitude of

5V and frequency of 1KHz to 2KHz can be applied between SV and GND for speed adjustment, and the motor speed is

adjusted linearly according to the duty cycle. In this case, the SV digital signal amplitude can be attenuated by

adjusting the R-SL potentiometer by a ratio of 0 to 1.0, usually by setting the R-SL to 1.0. No attenuation is applied to

the SV input digital signal.

The motor speed can also be changed by command via communication method.

4.2 Built-in

Potentiometer

Speed Control Wiring Diagram

Currently the driver has 2 versions, V2.0 and V2.4. For V2.0 Version, motor runs when the terminal is switched on and

conversely the motor stops. While for V2.4 version, motors only runs when the terminal is switched off and conversely

the motor stops.

4.3 Motor run/stop control (EN)

The motor can be controlled to run and stop by controlling the switch-on and switch-off of the terminal EN in

relation to GND. Currently the driver has 2 versions, V2.0 and V2.4. For V2.0 Version, motor runs when the

terminal is switched on and conversely the motor stops. While for V2.4 version, motors only runs when the

terminal is switched off and conversely the motor stops. When the motor is stopped using the run/stop

BLD-510S BLDC Driver

6

terminal control, the motor is stopped naturally. The law of motion is related to the load inertia.

4.4 Motor forward/reverse control (F/R)

The direction of motor operation can be controlled by controlling the connection of terminal F/R to terminal GND.

When F/R and terminal GND are not switched on, the motor runs clockwise (facing the motor shaft), and vice versa,

the motor runs

counterclockwise.

To avoid damage to the drive, when changing the motor steering, the motor should

be stopped before operating to change the steering. Changing the direction of operation while the motor is running

should be avoided.

4.5 Braking Stop (BK)

The braking stop of the motor can be controlled by the connection of control terminal BK to terminal GND. When

control terminal BK is disconnected from terminal GND, the motor runs, when it is switched on the motor quickly

brakes to a stop, braking stop is faster than natural stop, the specific stopping time is related to the load inertia of the

user's system.

Attention: As the brake stop has a bad impact on both the electrical and the mechanical, a natural stop should be

used if there are no special stopping requirements.

4.6 Motor Speed Signal Output (PG)

The speed pulse output is a 5V pulse output, to obtain the signal a pull-up resistor of 3K ohm ~10K ohm should be

connected to the power supply. The number of output pulses per revolution of the motor is 3 x N, N being the

number of pairs of poles of the motor. For example: 2 pairs of poles, i.e. a four-pole motor, 6 pulses per revolution.

When the motor speed is 500 rpm, the output pulse of the terminal PG is 3000.

4.7 Alarm Output (ALM)

Alarm output of the driver: this terminal is low during an alarm. To obtain a signal, a pull-up resistor of 3K ohm to

10K ohm should be connected to the power supply. When the alarm is on, this terminal is connected to GND (low

level) and the driver stops itself and is in alarm.

4.8 Driver Failure

If a fault occurs inside the driver such as overvoltage or overcurrent, the driver enters a protection state, the driver

will

automatically

stop working, the motor stops and the red light on the driver is always on. The driver can only

disarm the alarm if the enable terminal is reset (i.e. EN is disconnected from GND) or if power is cut off. Please check

the motor wiring or remove the load if this fault occurs.

BLD-510S BLDC Driver

7

4.9 Connection Diagram of Brushless Motor and Driver

4.10 Sensorless control mode

STEPPERONLINE drivers can be used for sensorless brushless motors.

But it should be noted that since our brushless driver is mainly used for our brushless motor with sensors, its built-in

program is also used for motors with sensors.

Although our brushless driver can be used for sensorless brushless motors, the program of the driver is not fully

compatible and can only be used in simple scenarios. Our brushless drives are not recommended if the motor needs to

be started and stopped frequently.

When using a brushless driver to drive a sensorless motor, it is necessary to use software to set the sensorless starting

torque according to the parameters of the motor.

BLD-510S BLDC Driver

8

5. Communication Method

The communication mode uses the standard Modbus protocol, which complies with the national standard GB/T

19582.1-2008. It uses a dual-line serial communication based on RS485, and the physical interface adopts a

conventional 3-pin 2.54 wiring terminal (A+, GND, B-) which is easy to connect in series. The transmission mode is

RTU, and the verification mode is CRC, with the CRC starting word being FFFFH. The data mode is 8-bit asynchronous

serial, with 1 stop bit and no parity bit. It supports multiple communication speeds (see parameter table for details)

Function parameter support 03H multi-register read, 06H single register write.

Site address: 00: Broadcast address

1-250: User address

251-255: Special address, not available to users

BLD-510S BLDC Driver

9

No.

Addre

ss

Name

Setting Range

Defau

lt

Uni

t

00

$8000

First byte: control bit state

Second byte: Hall angle

and number of pole pairs

of motors

First byte: Bit0: EN

Bit1: FR

Bit2:BK

Bit3: NW

NW=1: 485 control start stop

speed regulation,

NW=0: External IO control

start/stop, analog to adjust

speed Bit4: MDX(invalid)

Bit5:

X12(invalid)

Bit6: KH

Second byte:

Bit0-3: number of pole pairs 1-15

Bit4-7: hall angle 0:120

00H

04H

01

$8001

Maximum speed for

analogue speed

regulation

0-65535

6000

RPM

Jumper cap control

02

$8002

First byte: start torque

Second byte: sensorless

start speed

1-255

1-255

40H

04H

03

$8003

First byte: acceleration

time Second byte:

deceleration time

1-255

0

0

0.1s

04

$8004

First byte: maximum

current

Second byte: model

90H

0FH

144 corresponds

to 13A

15 Sensored,

16: Sensorless

05

$8005

Communicati

on speed

setting

Closed loop: 0-65535

Open loop: 0-255

2000

81%

RPM

06

$8006

Braking force

0-1023

1023

07

$8007

First byte: site address

Second byte: reserve

1-250

1

0

10-17

$8010-$8017

Reserved

18

$8018

Actual motor speed

Return value

hexadecimal to

decimal

multiplied by 20

divided by the

number of motor

poles

1B

$801B

First byte: fault state

Second byte:

motor running state

Bit0: Locked rotor

Bit1: Over-current

Bit2: Hall value

abnormal Bit3: Bus

voltage too low Bit4:

Bus voltage too high

Bit5: Current peak

alarm Bit6: Reserved

Bit7: Reserved

1C

$801C-$801F

Reserved

20

Over $8020 illegal

BLD-510S BLDC Driver

10

Pin

Function

1

A

2

GND

3

B

Address: 8000H-8017H are read and write registers

Address: 8018H-801FH are read-only registers

Other addresses are illegal

8000: First byte:

EN: At NW=0, 0: external EN low valid 1: external EN high valid

At NW=1, 0: EN not valid 1: EN valid

FR: At NW=0,

At NW=1,

0: external FR low valid

0: FR not valid

1: external FR high valid

1: FR valid

BK: At NW=0, 0: external BK low valid 1: external BK high valid

At NW=1,

KH:

0: BK not valid

0:

Speed closed-loop

mode

1: BK valid

1:

Speed open-loop

mode

NW

MDX

X12

Function

0

0

X

External analog speed

1

X

X

Internal

communication

control

2 pole pair start 01 06 80 00 09 02 27 9B

Write speed 1000 01 06 80 05 E8 03 BE 0A

Write

speed 1500 01 06 80 05 DC 05 28 C8

Natural

stop 01 06 80 00 08 02 26 0B

Braking

stop 01 06 80 00 0D 02 25 5B

6. Communication Wiring Method

RS-485 communications can be made by driving a conventional 3-pin 2.54 wiring port device.

The pinout of the conventional 3-pin 2.54 wiring port is defined as follows:

Table of contents

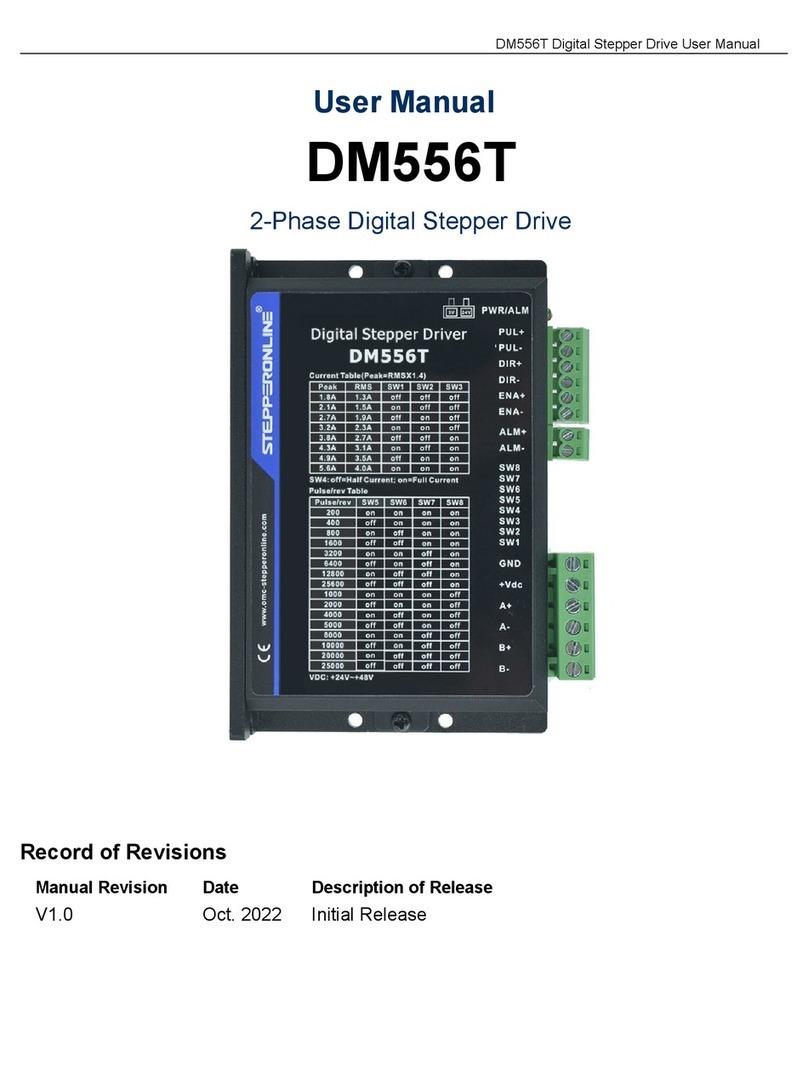

Other StepperOnline DC Drive manuals

StepperOnline

StepperOnline DM556T User manual

StepperOnline

StepperOnline BLD-AC750S User manual

StepperOnline

StepperOnline BLD-550S User manual

StepperOnline

StepperOnline DM556T User manual

StepperOnline

StepperOnline BLD-530S User manual

StepperOnline

StepperOnline DM860I User manual

StepperOnline

StepperOnline CLRS Series User manual

StepperOnline

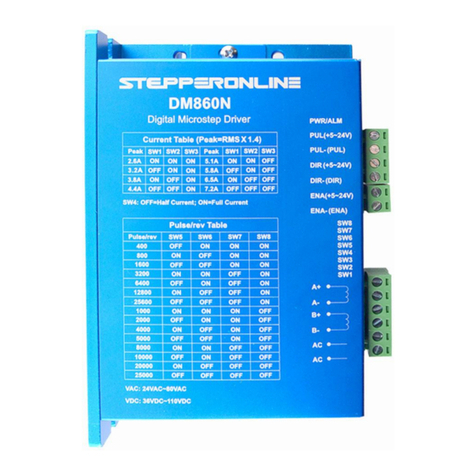

StepperOnline DM860N User manual

StepperOnline

StepperOnline CL57T User manual

StepperOnline

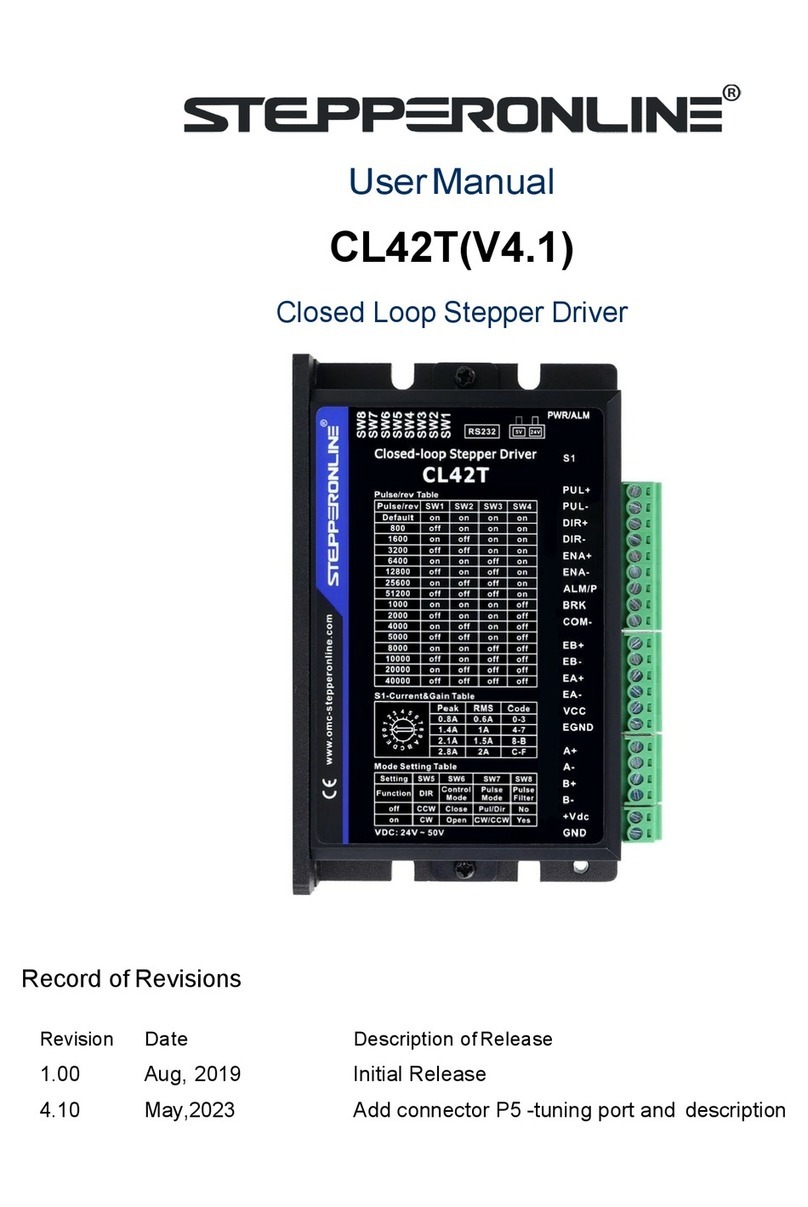

StepperOnline CL42T User manual