6

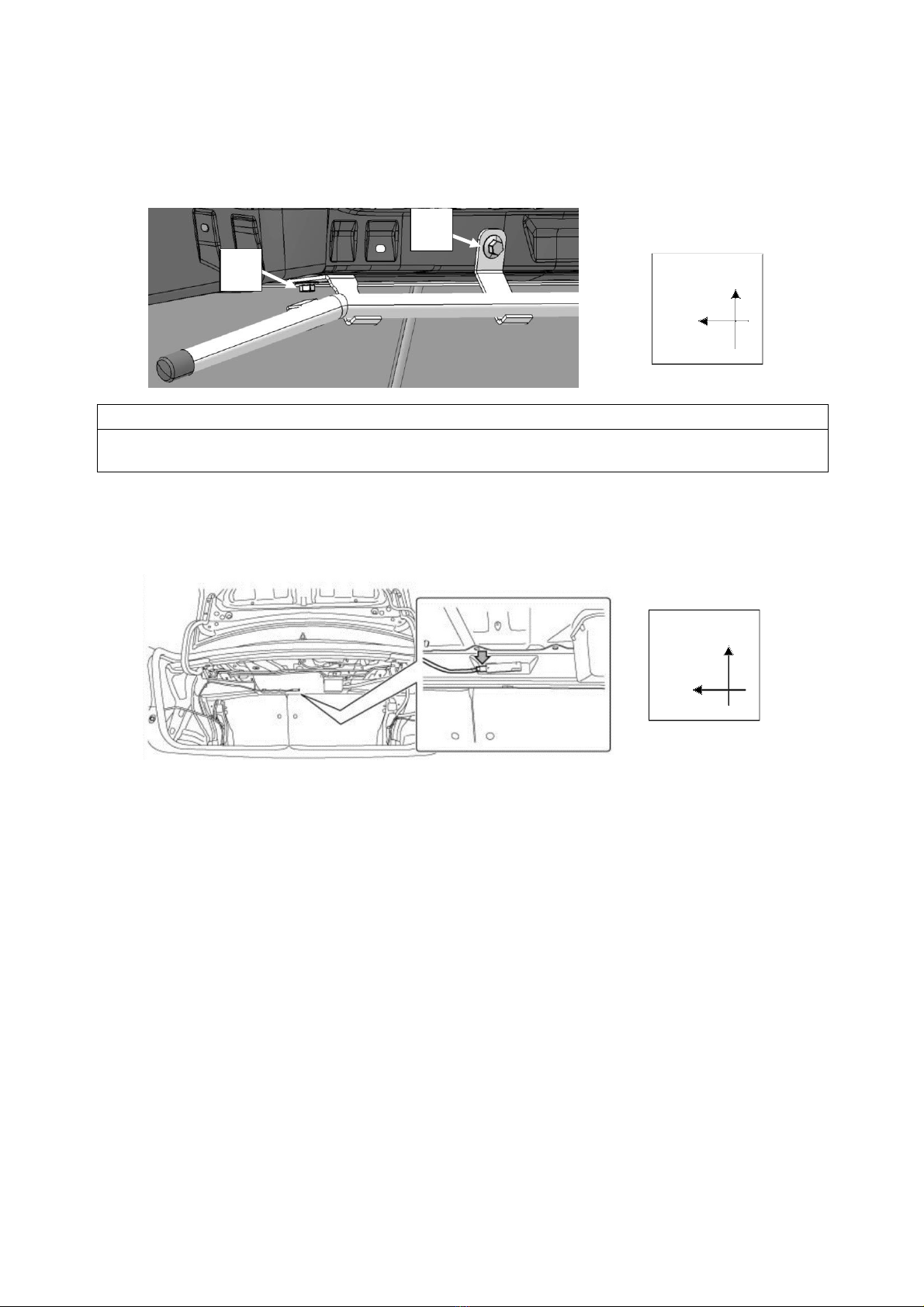

D: Processing of Vehicle Body

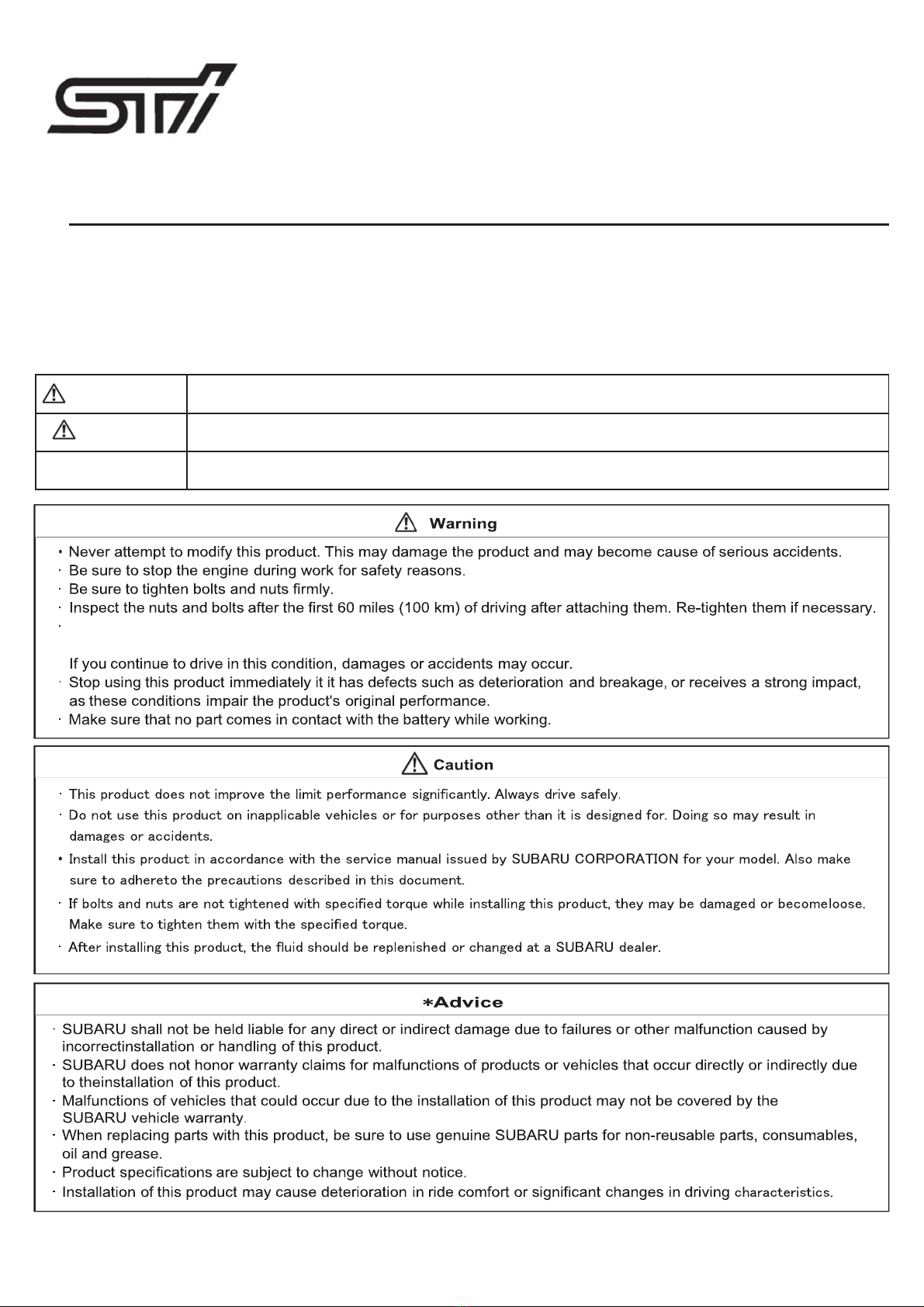

1) Positioning for drilling

Mark the center punch in the center of the cross-shaped cutout in the pattern. (2 locations,

left and right. The figure below is an example of the left side.) Once you have finished

marking the center punches, remove the pattern and pop nuts once.

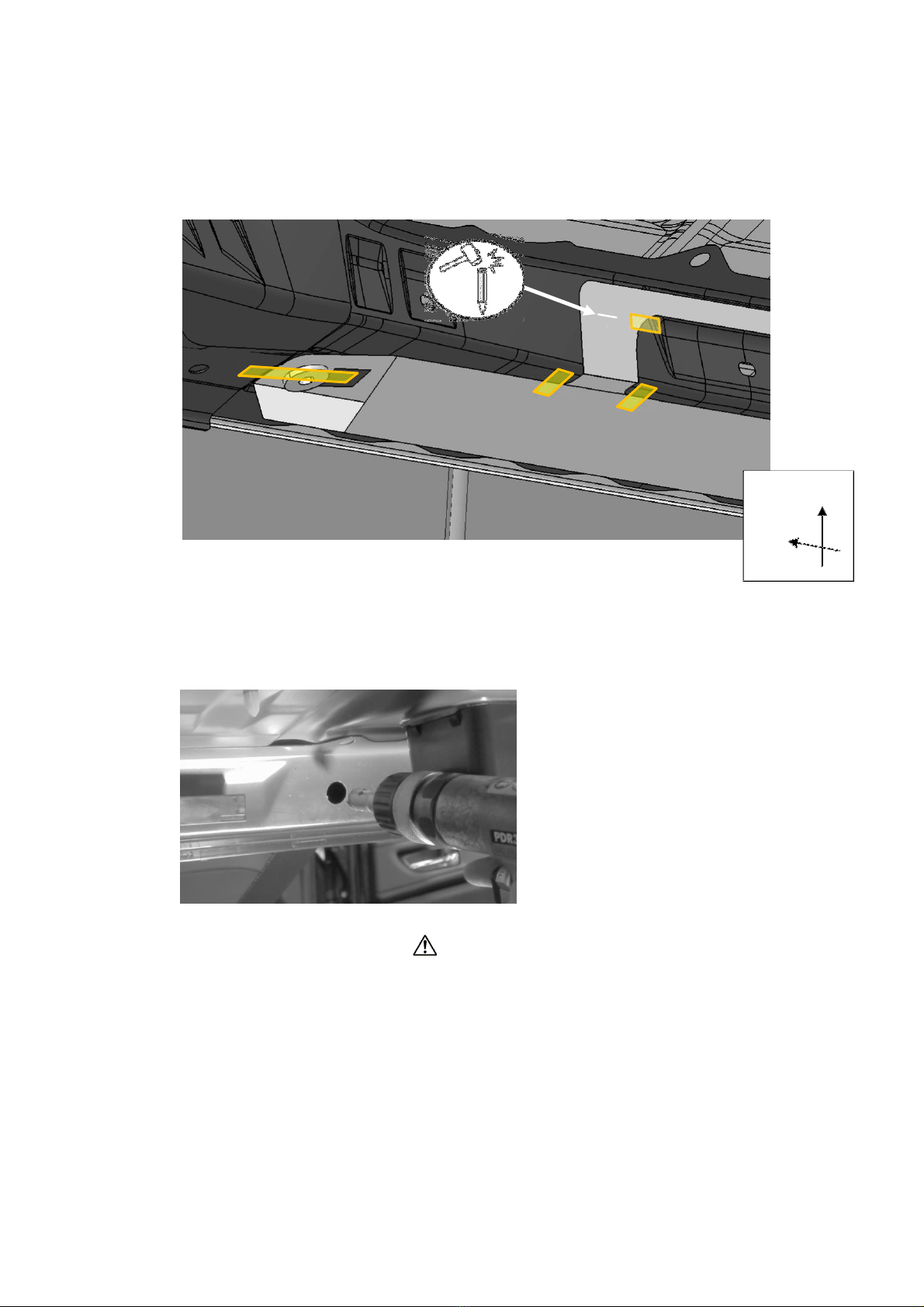

2) Drilling process

Drilling holes in the 2 positions of the center marking.

Use a φ5mm drill to drill a test hole and a φ16 hole saw to drill the mounting hole in the 2 locations.

(The figure below is an example of the right side.)

CAUTION

When drilling, pay attention to the following points in order to prevent abnormal noise and rust.

1. The trunk should be protected from flying chips.

2.The rear bulkheadhas a bag structure.Work carefully to prevent chipsand drill debris from

entering the inside of the bulkhead.

3. Position the hole saw orthogonally to the work surface.

4. To prevent damage from chips, remove them frequently during work.

Before the hole saw blade penetrates, move the hole saw away from the work area and

remove the chips inside the saw.

5. Remove all burrs from the inside and outside of the hole after drilling.

6. After drilling, remove any chips scattered inside the rear bulkhead and trunk.

For the inside of the rear bulkhead, use a flexible magnetic catch to thoroughly remove the

chips.

7. Apply touch-up paint to the processed area and allow it to dry thoroughly.

UPPER

LH