Web: www.sti-usa.com

USA - Headquarters

2306 Airport Road • Waterford, Michigan 48327-1209

Phone: 248-673-9898 • Fax: 248-673-1246

Tel: 44 (0) 1527 520 999 Fax: 44 (0) 1527 501 999

E-mail: info@sti-emea.com • Web: www.sti-emea.com

European Office

Taylor House • 34 Sherwood Road • Bromsgrove

Worcestershire • B60 3DR • England

ID_SS2_02_05_08_09_Rev0919

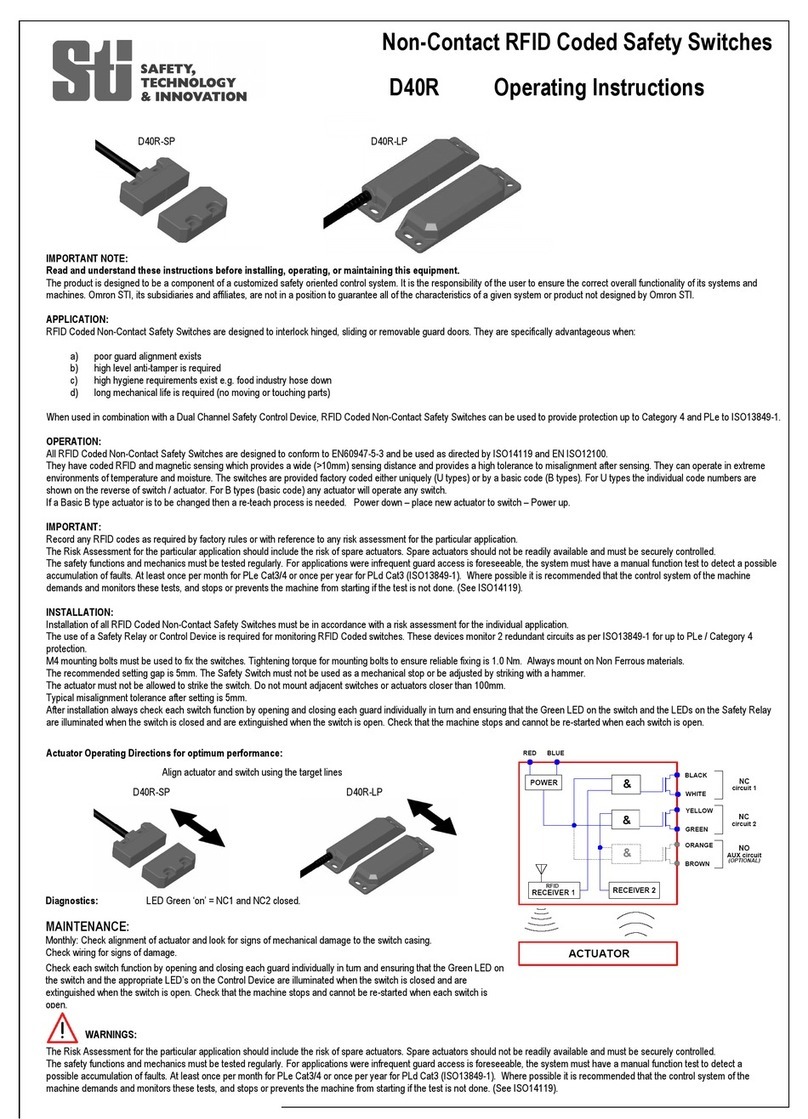

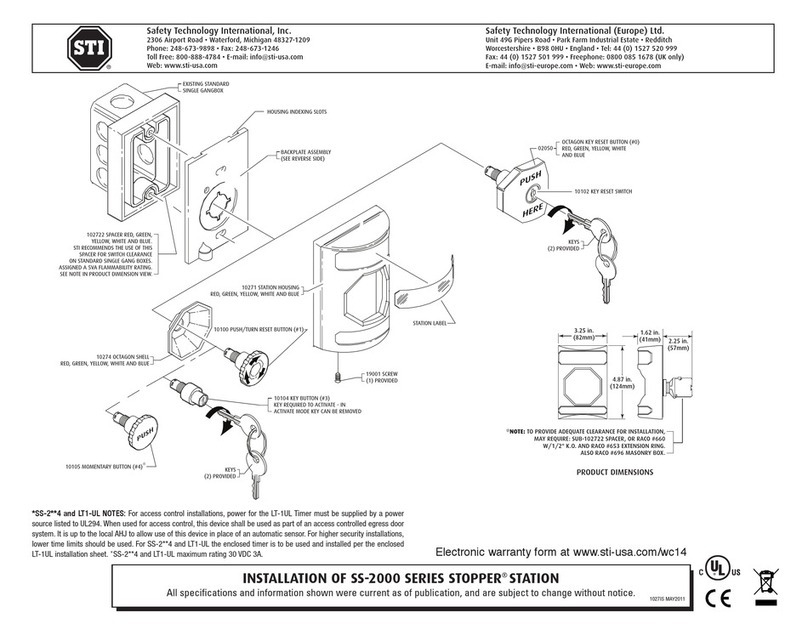

INSTALLATION OF SS-2xx2, 2xx5, 2xx8 and 2xx9 SERIES STOPPER®STATION

All specifications and information shown were current as of publication and are subject to change without notice.

Safety Notice to Installers and Users

SS2xx2, SS2xx5 & SS2xx9 models

This push button has been tested according to UL2017. It is important to read, understand and follow all instructions provided with this product. Non-

fire alarm initiating devices are listed in UL category UEHX. It is the installer’s responsibility to comply with NEC and Canadian electrical code, mounting

specifications according to ADA and other applicable fire and electrical codes. To avoid electrical shock, DO NOT attempt to install this product when

power is on. To avoid possible confusion with fire alarm initiating devices, do not mount a red stopper station near a manual fire alarm initiating device.

ADA mounting compliance requires the operable part of the initiating device shall not be less than 1.1m (3 1/2 ft.) or greater than 1.37m (4 1/2 ft.) above

finished floor service. After installation and testing are complete, provide a copy of this manual to all personnel responsible for testing and maintenance

of this product. Push buttons for outdoor use must be mounted with STI outdoor rated covers.

SS2xx8 models

This push button has been tested according to UL2017. Non-fire alarm initiating devices are listed in UL category UEHX. It is important to read,

understand and follow all instructions provided with this product. It is the installer’s responsibility to comply with NEC, Canadian Electrical Code,

mounting specifications according to ADA and other applicable fire and electrical codes. After installation and testing are complete, provide a copy of

this manual to all personnel responsible for testing and maintenance of this product. To avoid electrical shock, DO NOT attempt to install this product

when power is on. Note: To reduce potential risk, STI discourages use of a pneumatic timer button as an emergency power disconnect or any control

that may restart automatically at the end of the timing sequence.

NOTE For LTUL Models, Form “C” contacts on timer, Rated 30 VDC 3A, the enclosed timer is to be used and installed per the enclosed LT-1UL

installation sheet. LTUL Models, Form “C” contacts on timer, Rated 30 VDC 3A maximum rating 30 VDC 3A. For access control installations, power

for the LT-1 Timer must be supplied by a power source listed to UL294. When used for access control, this device shall be used as part of an access

controlled egress door system. It is up to the local AHJ to allow use of this device in place of an automatic sensor. For higher security installations,

lower time limits should be used.

Compliant

Housing Removal

PULL BOTTOM OF HOUSING OUT AND LIFT UP UNTIL TABS ARE

RELEASED FROM SLOTS IN TOP OF SWITCH ASSEMBLY.

ONCE INSTALLATION IS COMPLETE, SECURE COVER WITH

SCREW AND HEX WRENCH (SHOWN).

3/32” HEX WRENCH

(1) PROVIDED

ALLEN HEAD SCREW

#8-32 x 3/8 in.

(1) PROVIDED

SWITCH HOUSING

BUTTON AND SWITCH ASSEMBLY

WHITE

BLACK

GREEN

RED

INSULATING

BUSHING

SCREW #6-32 x 1 in.

(2) PROVIDED

BUTTON CAP

(PUSH SHOWN)

SCREW

#6 x 1-1/4 in.

(4) PROVIDED

BUTTON AND SWITCH ASSEMBLY

RAWL PLUGS

(4) PROVIDED

DRILL (4)

3/16 in. DIA. HOLES

OPTIONAL SURFACE

MOUNT BACK BOX

KIT-71100A-*COLOUR*

DRILL POINT LOCATION PROVIDED TOP AND BOTTOM

FOR CONDUIT FITTINGS. DRILL AS NEEDED.

BUTTON ILLUMINATION*

ASSEMBLY

BUTTON CAP

ALIGNMENT HOLE

BUTTON ILLUMINATION WIRES*

NOTE

ADA MOUNTING COMPLIANCE REQUIRES THE OPERABLE

PART OF THE INITIATING DEVICE SHALL NOT BE LESS THAN

1.1 m (3 ½ ft.) OR GREATER THAN 1.37m (4 ½ ft.) ABOVE

FINISHED FLOOR SURFACE.

Installation

*BUTTON ILLUMINATION WIRING

12-24 VAC/VDC, 21mA EACH COLOR

BLACK - GROUND

WHITE - WHITE LED (+)

GREEN - GREEN LED (+)

RED - RED LED (+)

Product Dimensions

PRODUCT DIMENSIONS

25mm

(1 in.)

82mm

(3.22 in.)

123mm

(4.86 in.)

COM

NO

NC

41mm

(1.62 in.)

40mm

(1.58 in.)

DIMENSIONS WITH

KIT-71100A-*COLOUR*

DIMENSIONS WITH

KIT-102720-*COLOUR*

1.62 in.

(41mm)

1.58 in.

(40mm)

MODELS WITH

OPTIONAL BACK BOX

41mm

(1.62 in.)

41mm

(1.62 in.)

25mm

(1 in.)

COM

NO

NC

12mm

(.47 in.)

On Site Button Reconguration

Stopper Station button is configured as ordered. If needed, installer can

reconfigure function to: Key-to-Reset, Momentary or Turn-to-Reset.

Changing Push Button Function

1. Remove contact block screws from

mounting plate.

2. To change button function remove the

plate and use directions provided.

3. Reassemble backplate and contact

box (ensure contact tabs are facing up

as shown).

4. If reconfiguring from Turn-to-Reset,

remove Turn-to-Reset label.

Note: If you remove stop pin and wedge

block, consider keeping for potential

future use.

REMOVE SCREWS,

MOUNTING PLATE

AND SWITCH ASSEMBLY

MOUNTING PLATE

SWITCH ASSEMBLY

CONTACT TABS

Wire Connections

CONTACT

SET 1

CONTACT

SET 2

CONTACT BOX CONTAINS

TWO CONTACT SWITCHES

NC

NO

NC

NO

COM

COM

NO

NC

COM

9 in. QUICK CONNECT WIRE LEAD

(6) PROVIDED

MAKE SURE LEAD IS

FULLY CONNECTED TO

MOUNTING TAB