3BT 360

English

Special safety

precautions must be

observed when working

with the earth auger

because of its high torque

and the high speed of the auger in

certain applications.

It is important that you

read and understand the

instruction manual before

using your earth auger for

the first time. Keep the

manual in a safe place for

future reference. Non-observance of the

safety precautions may cause serious or

even fatal injury.

Always observe local safety regulations,

standards and ordinances.

If you have never used this earth auger

model before:

Have your STIHL dealer show you how

to operate your earth auger or attend a

special course of training in earth auger

operation.

Minors should never be allowed to use

an earth auger. Children, bystanders

and animals should not be allowed in the

area where an earth auger is in use.

The earth auger user is responsible for

avoiding injury to third parties or damage

to their property.

Do not lend or rent your earth auger

without the instruction manual. Be sure

that anyone using your earth auger

understands the information contained

in this manual.

To operate the earth auger you must be

in good physical condition and mental

health and not under the influence of any

substance (drugs, alcohol) which might

impair vision, dexterity or judgment.

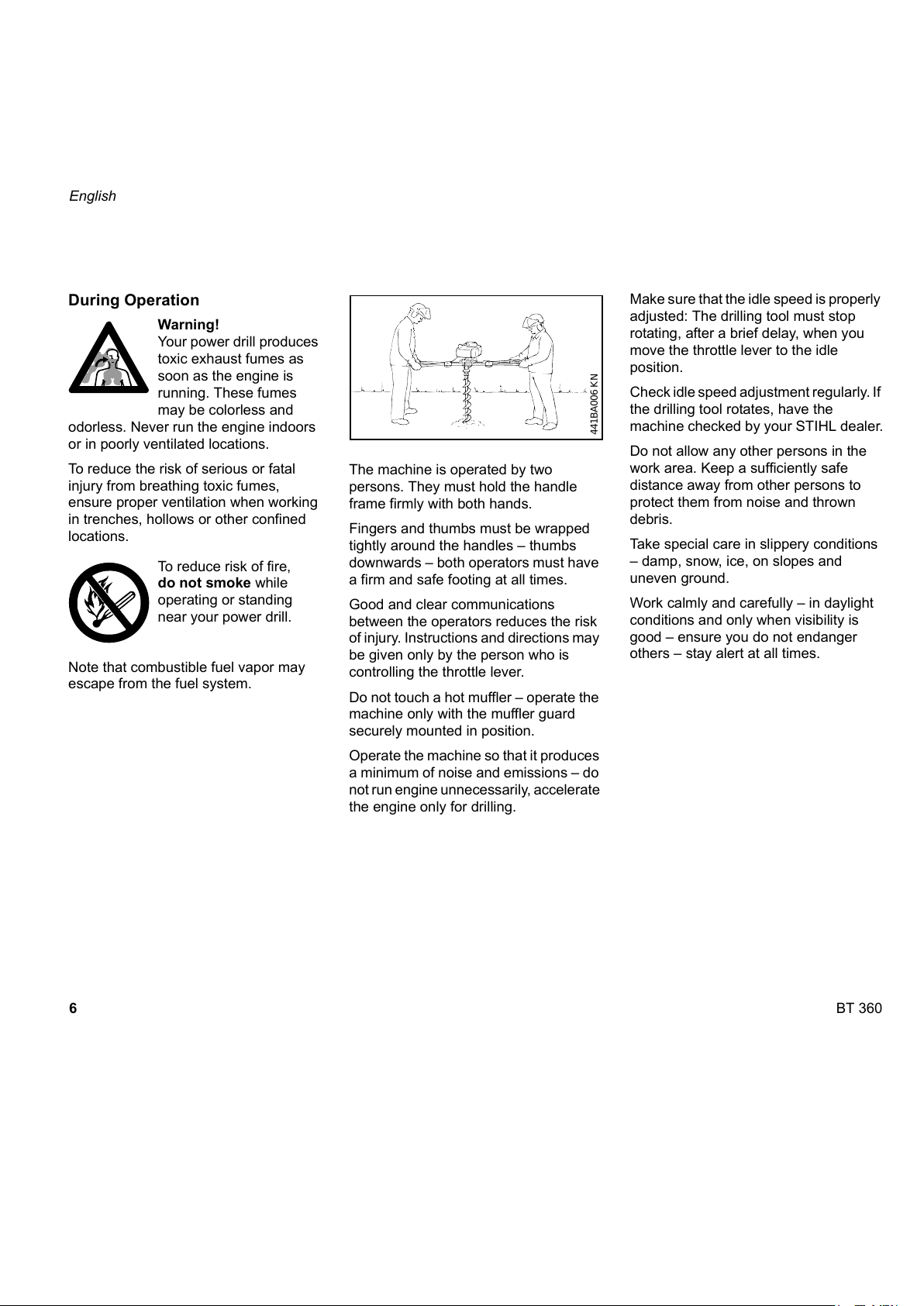

Do not work alone –

keep within calling distance of others in

case help is needed.

The user is responsible for third parties

in the work area of the power drill.

Only use augers and attachments

supplied by STIHL or explicitly approved

for your earth auger model by STIHL.

Other augers and attachments must not

be used because of the increased risk of

accidents.

STIHL cannot accept any liability for

personal injury or damage to property

caused by using non-approved

attachments.

Clothing and Equipment

Wear proper protective clothing and

equipment.

Clothing must be sturdy

and snug-fitting, but allow

complete freedom of

movement. Wear overalls

with a cut-retardant inlay -

a STlHL safety

combination is recommended.

Do not wear loose-fitting garments,

scarves, jewelry or anything that could

restrict movement or become entangled

with the drilling spindle or the work area.

Confine long hair (e.g.

with a hair net or similar

suitable means).

Wear steel-toed safety

boots with non-slip soles.

Safety Precautions