The user is responsible for accidents or risks

involving third parties or their property.

Do not lend or rent your power tool without the

User Manual. Be sure that anyone using it under‐

stands the information contained in this manual.

The use of machines that emit noise may be limi‐

ted to certain hours of the day as specified by

national and/or regional or local regulations.

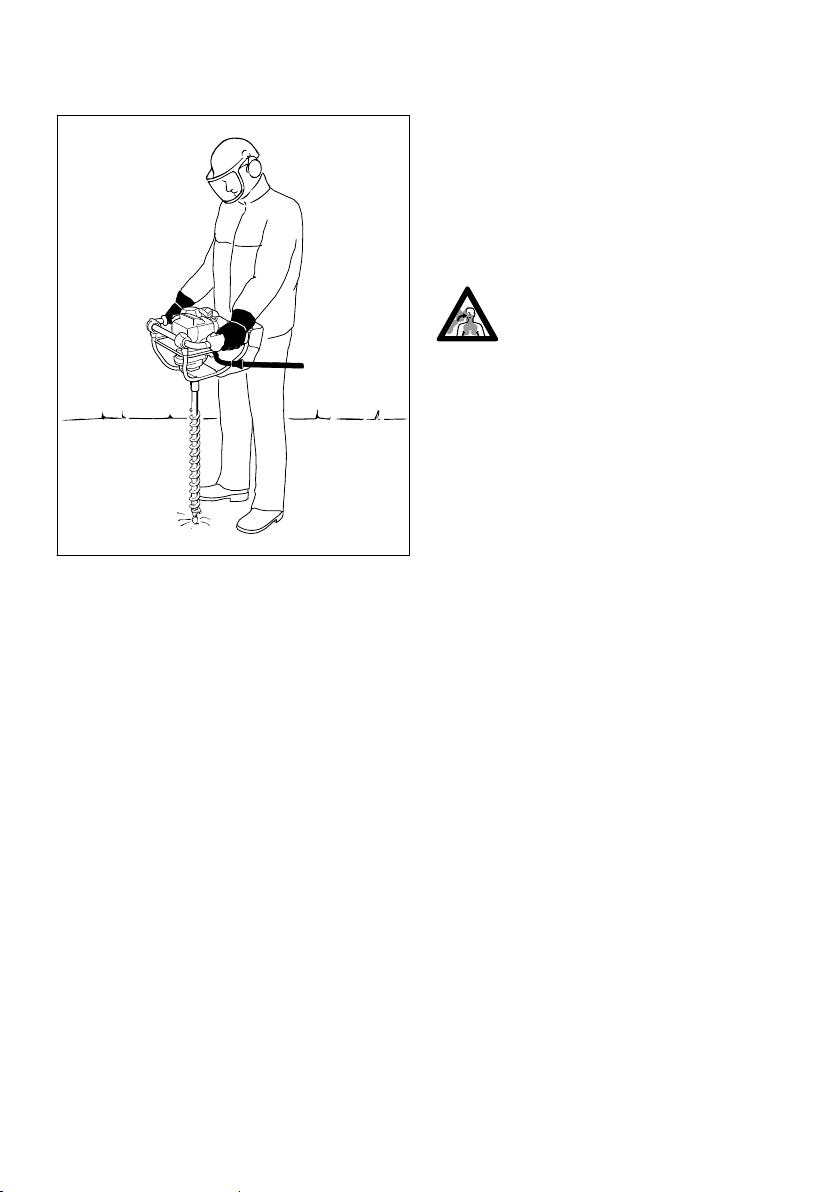

Anyone operating the machine must be well res‐

ted, in good physical health and in good mental

condition.

If you have any condition that might be aggrava‐

ted by strenuous work, check with your doctor

before operating a machine.

If you have a pacemaker: The ignition system of

your machine produces an electromagnetic field

of very low intensity. This field may interfere with

some pacemakers. STIHL recommends that per‐

sons with pacemakers consult their physician

and the pacemaker manufacturer to reduce any

health risk.

Anyone who has consumed alcohol or drugs or

medicines affecting their ability to react must not

operate a power tool.

Use your power tool only for drilling holes in soil,

ice and wood – depending on the drilling tool

mounted. Select the drill axis so that the lever of

the drill brake can be supported on the thigh of

the operator at any time during drilling.

It must not be used for any other purposes.

Before drilling, make sure that there are no lines

(e. g. for gas, water, electricity) at the drilling

sites:

–Obtain information from the local utility compa‐

nies

–If in doubt, check the existence of lines with

detectors or test excavations

Only use augers or accessories which have been

approved by STIHL for this machine or which are

technically equivalent. If you have any questions

in this respect, consult your dealer. Use only high

quality parts and accessories. in order to avoid

the risk of accidents and damage to the machine.

STIHL recommends the use of original STIHL

tools and accessories. They are specifically

designed to match the product and meet your

performance requirements.

Never attempt to modify your power tool in any

way since this may increase the risk of personal

injury. STIHL excludes all liability for personal

injury and damage to property caused while

using unauthorized attachments.

Do not use a high-pressure washer to clean the

power tool. The solid jet of water may damage

parts of the unit.

2.1 Clothing and equipment

Wear proper protective clothing and equipment.

Clothing must be sturdy but allow

complete freedom of movement.

Wear close-fitting clothes such as a

boiler suit, not a loose jacket.

Do not wear clothing which could become trap‐

ped in wood, brush or moving parts of the

machine. Do not wear a scarf, necktie or jewelry.

Tie up and confine long hair above

your shoulders.

Wear sturdy shoes with non-slip

soles.

WARNING

To reduce the risk of eye injuries,

wear close-fitting safety glasses in

accordance with European Standard

EN 166. Make sure the safety

glasses are a snug fit.

Wear hearing protection, e.g. ear defenders.

Wear a safety hard hat where there is a danger

of head injuries from falling objects.

Wear sturdy protective gloves made

of a resistant material (e. g. leather).

STIHL can supply a comprehensive range of per‐

sonal protective equipment.

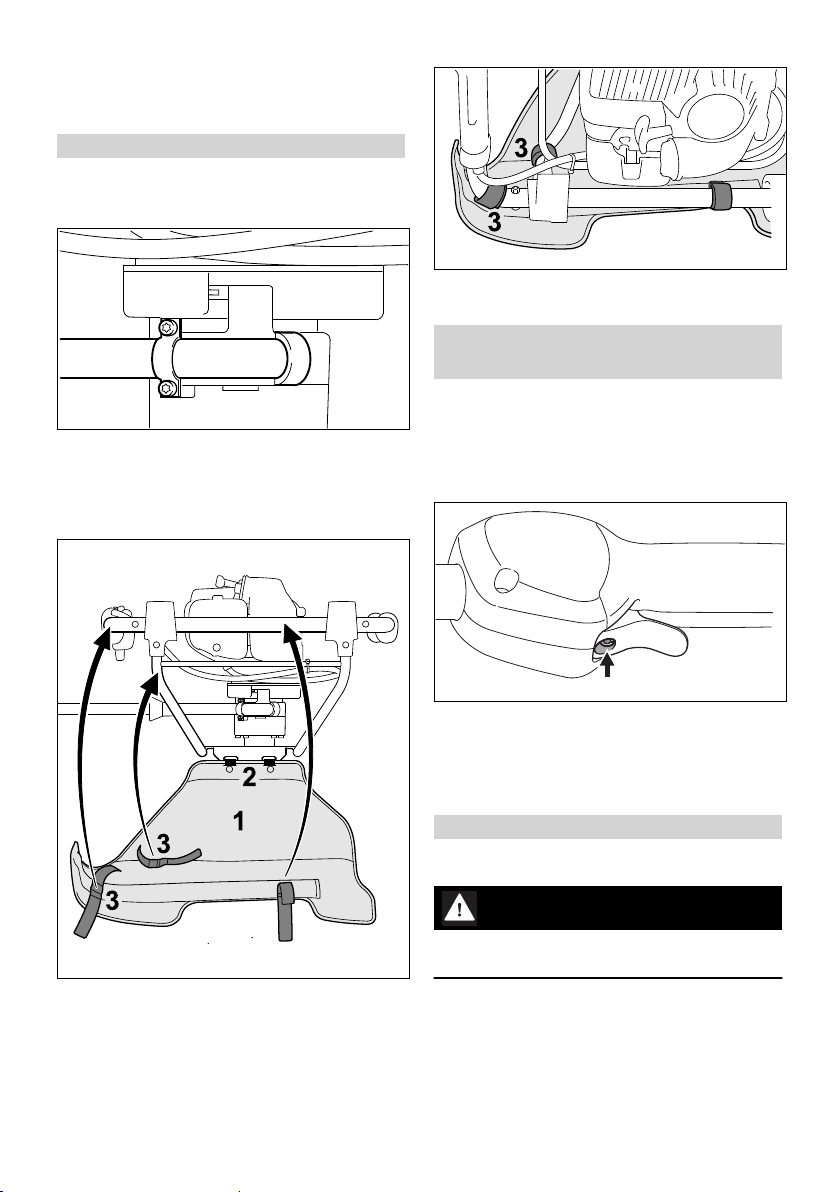

2.2 Transporting the machine

Always stop the engine.

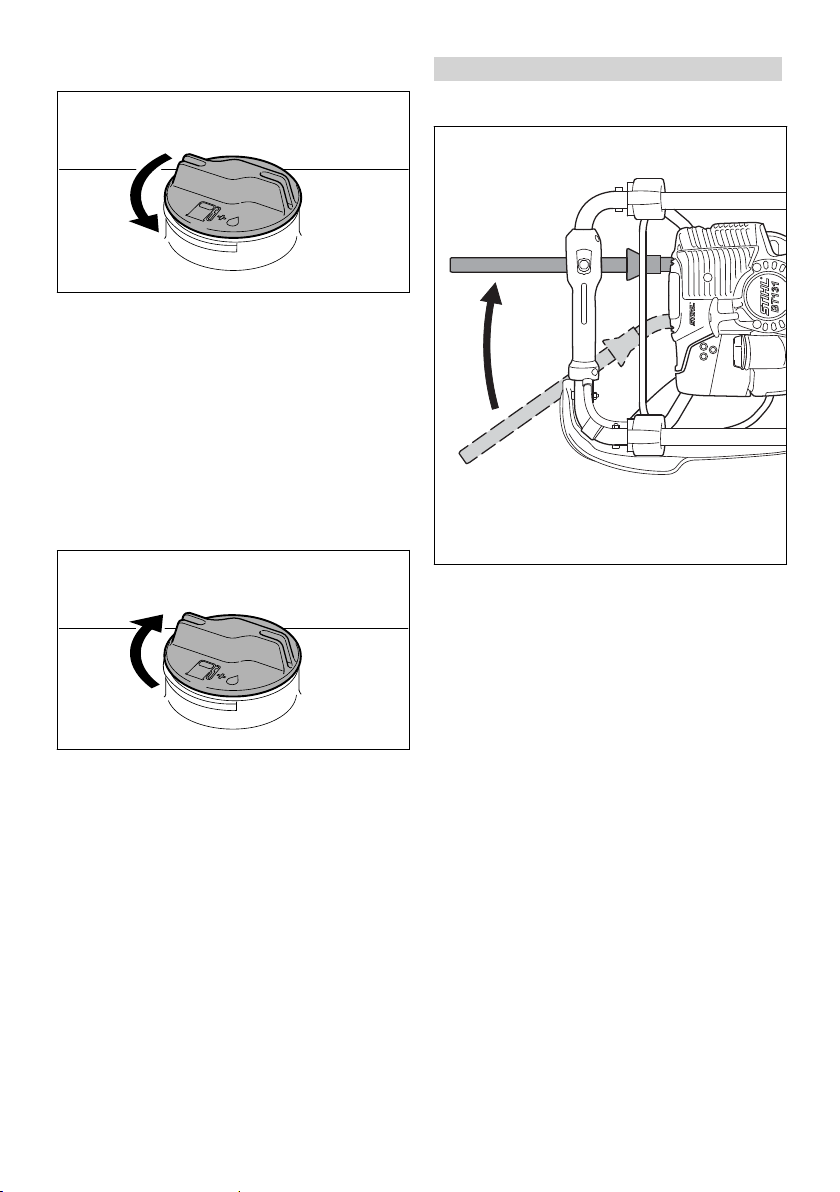

Remove the auger before transporting the power

tool long distances. To reduce the risk of burn

injury, carry the unit by the handle frame with hot

parts of the machine (e.g. gearbox) away from

your body.

By vehicle: When transporting in a vehicle, prop‐

erly secure your machine to prevent turnover,

damage and fuel spillage.

2 Safety Precautions and Working Techniques English

0458-529-8321-B 3