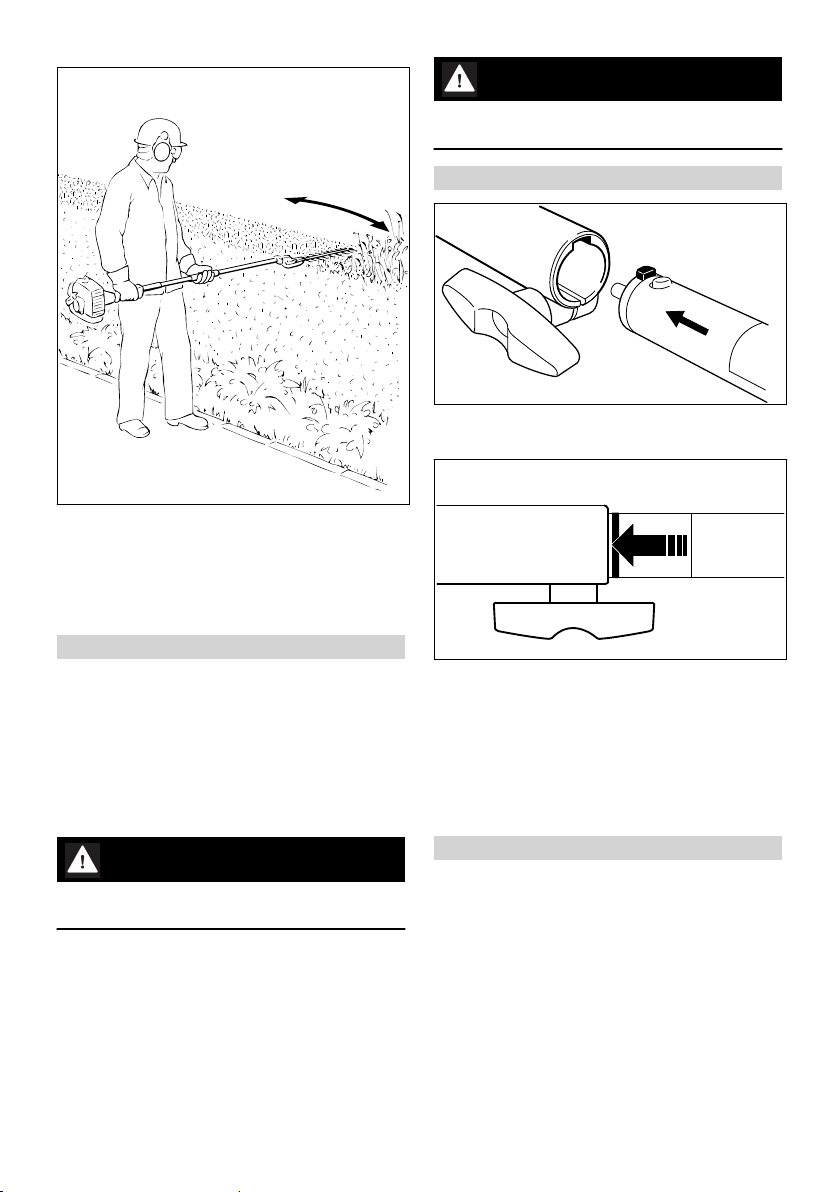

Make sure you always have good balance and

secure footing.

3.5.1 When working at heights:

–Always use a lift bucket

–Never work on a ladder or in a tree

–Never work on an insecure support

–Never operate your power tool with one hand

Be particularly alert and cautious when wearing

hearing protection because your ability to hear

warnings (shouts, alarms, etc.) is restricted.

To reduce the risk of accidents, take a break in

good time to avoid tiredness or exhaustion.

Work calmly and carefully – in daylight conditions

and only when visibility is good. Stay alert so as

not to endanger others.

Inspect the hedge and work area to avoid dam‐

aging the cutting blades:

–Remove stones, rocks, pieces of metal and

other solid objects.

–When working close to the ground, make sure

that no sand, grit or stones get between the

blades.

–Take particular care when cutting hedges next

to or against wire fences.

To avoid the risk of electrocution, do not touch

electric power lines – never cut through electric

power lines.

Do not touch the cutting blades while

the motor is running. If the cutting

blades become jammed by an object,

switch off the engine immediately

before attempting to remove the

object – there is otherwise a risk of

injury.

Opening the throttle while the blades are blocked

increases the load and reduces engine speed.

The clutch then slips continuously and this cau‐

ses overheating and damage to important com‐

ponents (e.g. clutch, polymer housing compo‐

nents) – and this can increase the risk of injury

from the cutting blades moving while the engine

is idling.

If your power tool is subjected to unusually high

loads for which it was not designed (e.g. heavy

impact or a fall), always check that it is in good

condition before continuing work – see also

"Before Starting". Make sure the safety devices

are working properly. Do not continue operating

your power tool if it is damaged. In case of doubt,

consult your servicing dealer.

If the hedge is very dusty or dirty, spray the

blades with STIHL resin solvent from time to time

during cutting. This helps greatly reduce blade

friction as well as the aggressive effects of sap

and the build-up of dirt particles.

Check the cutting attachment at regular short

intervals during operation or immediately if there

is a noticeable change in cutting behavior:

–Stopping the Engine

–Wait until the cutting blades have come to a

complete standstill.

–Check condition and tightness, look for cracks.

–Check sharpness.

3.6 After Finishing Work

After finishing work or before leaving the power

tool unattended: Shut off the engine.

Always clean dust and dirt off the machine – do

not use any grease solvents for this purpose.

Spray the blades with STIHL resin solvent. Run

the motor briefly to ensure that the solvent is

evenly distributed.

3.7 Maintenance and Repairs

Service the machine regularly. Do not attempt

any maintenance or repair work not described in

the KombiTool and KombiEngine instruction

manuals. Have all other work performed by a

servicing dealer.

STIHL recommends that you have servicing and

repair work carried out exclusively by an author‐

ized STIHL servicing dealer. STIHL dealers are

regularly given the opportunity to attend training

courses and are supplied with the necessary

technical information.

Only use high-quality replacement parts in order

to avoid the risk of accidents and damage to the

machine. If you have any questions in this

respect, consult a servicing dealer.

STIHL recommends the use of genuine STIHL

replacement parts. They are specifically

designed to match your model and meet your

performance requirements.

To reduce the risk of injury, always shut off the

engine before carrying out any maintenance or

repairs or cleaning the machine.

4 Using the Unit

4.1 Cutting Season

Observe country-specific or municipal rules and

regulations for cutting hedges.

4 Using the Unit English

0458-475-0121-E 5