MS 500i2

18 Fly wheel 30

18.1 Special Servicing Tools, Servicing Aids 30

18.2 Removing the Flywheel 30

18.3 Installing the Flywheel 30

19 Controller, Ignition Lead 32

19.1 Special Servicing Tools, Servicing Aids 32

19.2 Testing the Ignition System 32

19.3 Removing the Ignition Lead 32

19.4 Disassembling the Ignition Lead 33

19.5 Assembling the Ignition Lead 33

19.6 Installing the Ignition Lead 33

19.7 Removing the Controller 33

19.8 Installing the Controller 34

20 Fuel Hoses, Impulse Hose 35

20.1 Tools, Servicing Aids 35

20.2 Removing Fuel Suction Hose Outside the

Tank 35

20.3 Installing Fuel Suction Hose Outside the Tank 35

20.4 Removing Fuel Hose 35

20.5 Installing the Fuel Hose 36

20.6 Removing the Fuel Return Hose 36

20.7 Installing the Fuel Return Hose 36

20.8 Removing the Impulse Hose 36

20.9 Installing the Impulse Hose 37

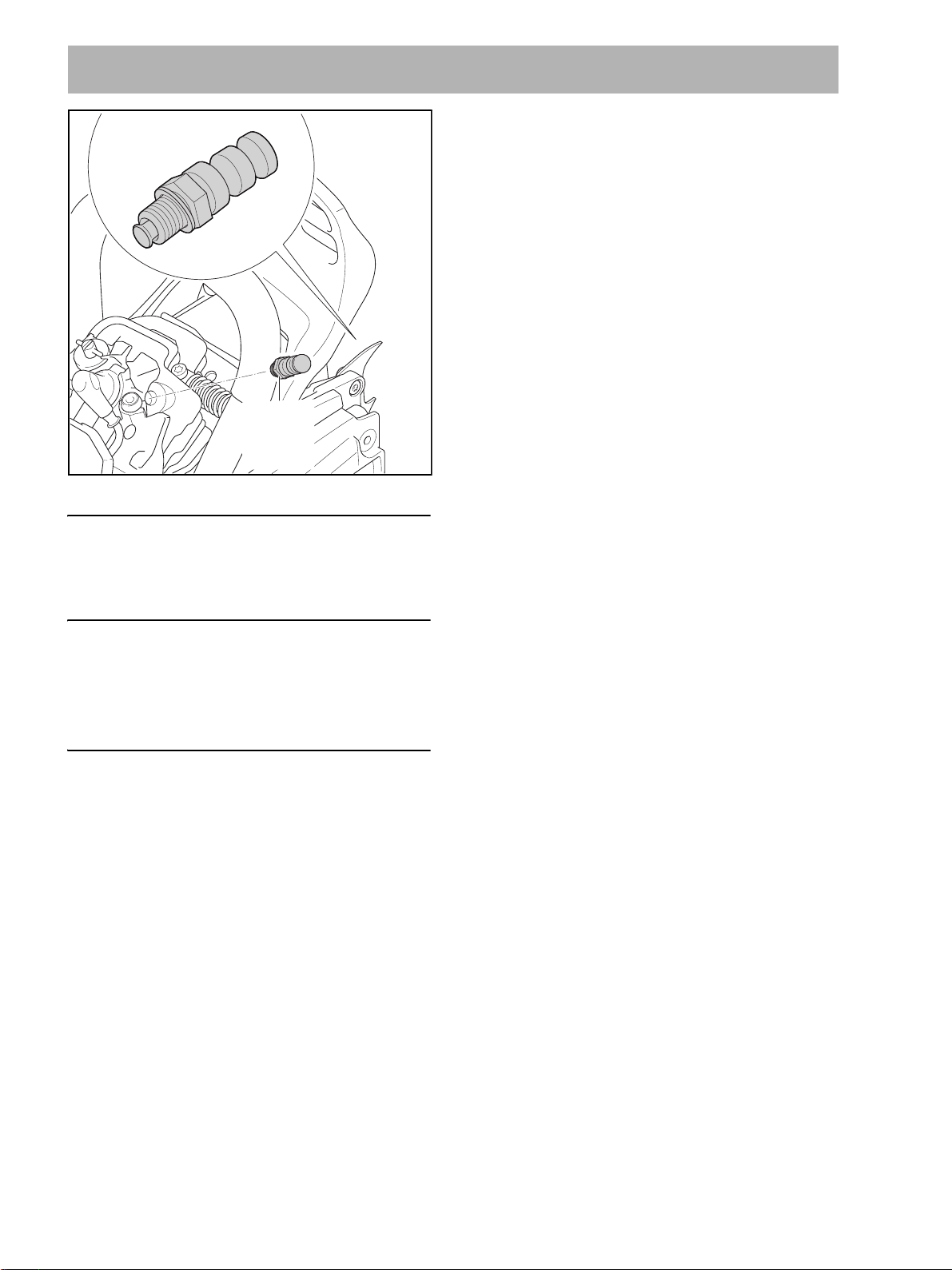

21 Injection Pump, Stop Switch 39

21.1 Special Servicing Tools, Servicing Aids 39

21.2 Removing the Injection Pump 39

21.3 Removing the Stop Switch 39

21.4 Removing Cap and Spring from Injection

Pump 39

21.5 Removing the Injection Pump 39

21.6 Installing the Injection Pump 40

21.7 Installing Cap and Spring on Injection Pump 40

21.8 Installing the Stop Switch 40

21.9 Installing the Injection Pump 40

22 Generator, Sensor 41

22.1 Special Servicing Tools, Servicing Aids 41

22.2 Removing the Generator 41

22.3 Removing the Sensor 41

22.4 Installing the Sensor 42

22.5 Installing the Generator 42

23 Tank Housing 44

23.1 Tools, Servicing Aids 44

23.2 Removing Pickup Body from Fuel Tank 44

23.3 Installing Pickup Body In Fuel Tank 44

23.4 Removing Tank Vent from Fuel Tank 44

23.5 Installing Tank Vent in Fuel Tank 44

23.6 Removing Fuel Suction Hose Inside the Tank 45

23.7 Installing Fuel Suction Hose Inside the Tank 45

23.8 Removing Fuel Return Hose Grommet 45

23.9 Installing Fuel Return Hose Grommet 45

23.10 Removing the Tank Housing 45

23.11 Installing the Tank Housing 45

24 Stop Buffer, Grommets 47

24.1 Tools, Servicing Aids 47

24.2 Removing Grommet from Airflow Shroud 47

24.3 Installing Grommet in Airflow Shroud 47

24.4 Removing Grommets from Crankcase 47

24.5 Installing Grommets in Crankcase 47

24.6 Removing Crankcase Stop Buffers 47

24.7 Installing Crankcase Stop Buffers 48

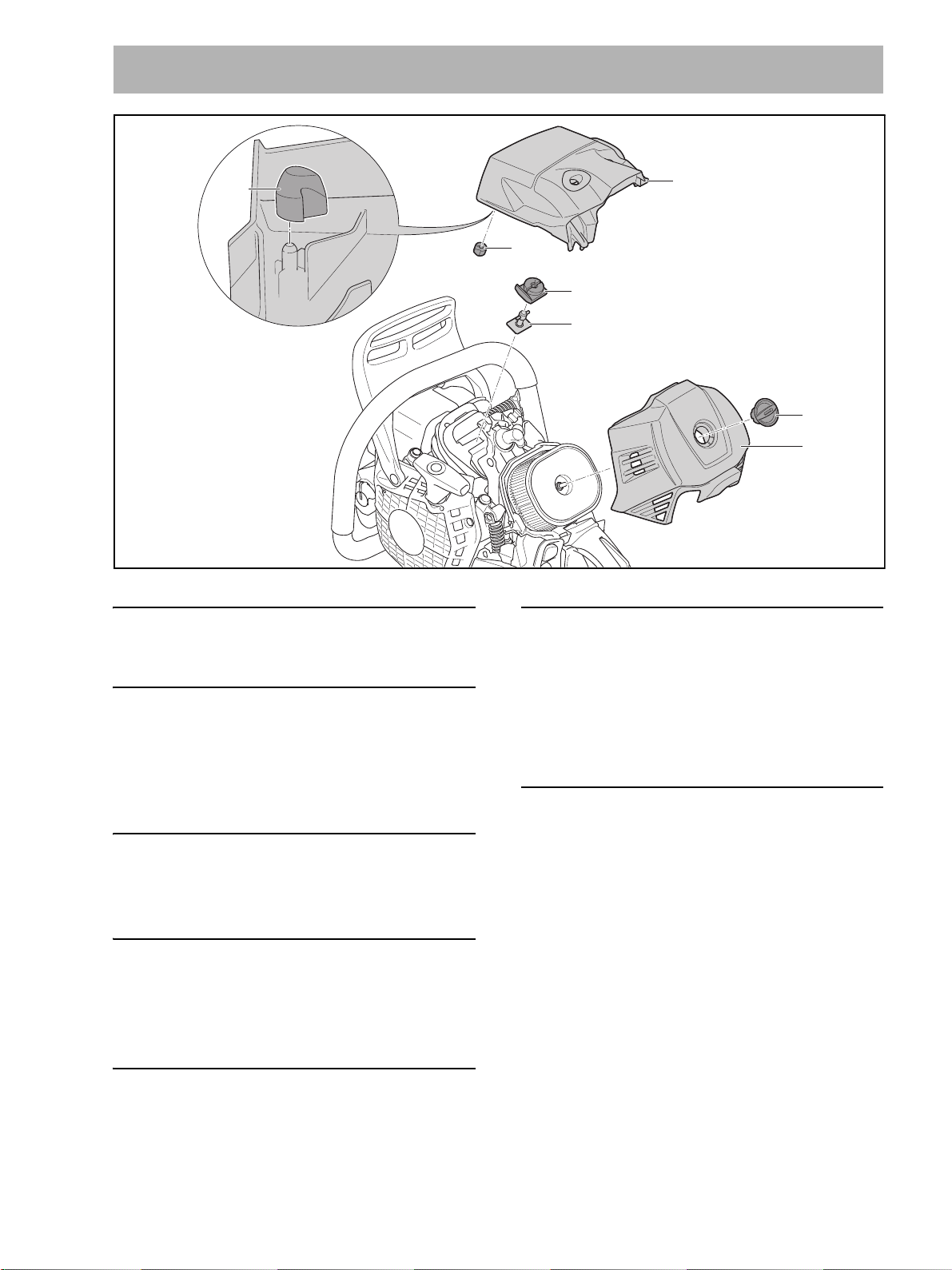

25 Manifold, Injection Module 49

25.1 Tools, Servicing Aids 49

25.2 Removing the Airflow Shroud 49

25.3 Removing the Manifold 49

25.4 Installing the Manifold 50

25.5 Installing the Airflow Shroud 50

25.6 Removing the Contact Strip 50

25.7 Installing the Contact Strip 50

25.8 Removing the Injection Module 50

25.9 Installing the Injection Module 50

25.10 Removing the Injection Valve 51

25.11 Installing the Injection Valve 51

26 Muffler, Heat Shield 53

26.1 Tools, Servicing Aids 53

26.2 Removing Muffler and Heat Shield 53

26.3 Installing Muffler and Heat Shield 53

27 Cylinder, Piston 54

27.1 Tools, aids 54

27.2 Removing the cylinder 54

27.3 Removing the piston 55

27.4 Installing the piston 55

27.5 Installing cylinder 56

28 Crankcase, Crankshaft, Oil Seals 58

28.1 Tools, Servicing Aids 58

28.2 Removing Oil Seals 58

28.3 Installing the Oil Seals 59

28.4 Disassembling Crankcase and Removing

Crankshaft 60

28.5 Removing the Ball Bearings 61

28.6 Installing the Ball Bearings 61

28.7 Installing Crankshaft and Assembling

Crankcase 62

29 Tools, Servicing Aids 64

29.1 Tools, aids 64