76

S I C H E R H E IT S H I N W E I S E

Safety instructions!

In order to avoid injuries to

persons and damage to the

equipment, it is mandatory to

observe instructions marked

with this symbol.

Note/Tip!

This symbol always gives you

technical information or useful

tips regarding the VOLCANO

vaporization system.

Read the following safety

information carefully and

completely before operating

the device!

This operating manual is a signifi-

cant part of the vaporizer and must

be provided to the user.

The instructions given in this ope-

rating manual must be strictly ob-

served as they are extremely im-

portant to ensure safety during

installation, use and maintenance

of the vaporizer.

S A F E T Y I N S T R U C T I O N S

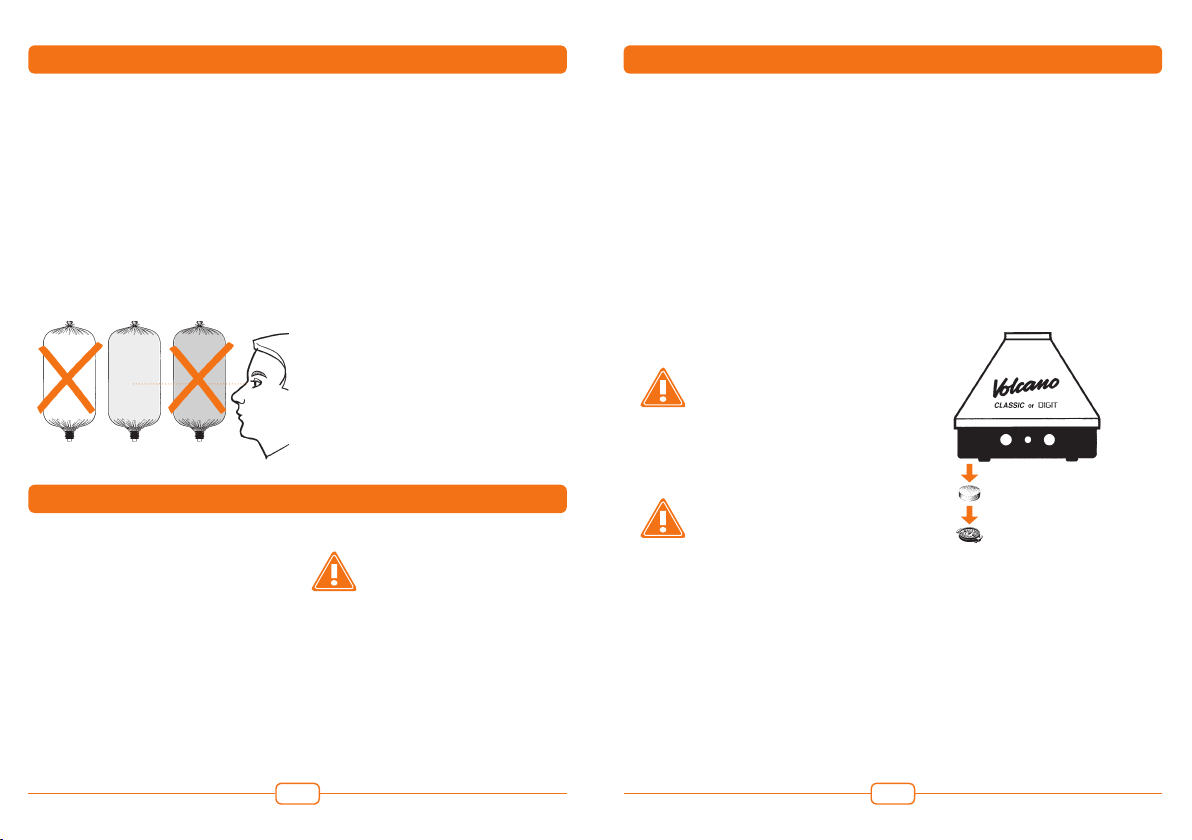

�The packing material (plastic bags,

styrofoam material, boxes etc.) must

be kept out of the reach of children

as it is a potential source of danger.

�Before connecting the vaporizer,

make sure that the information gi-

ven on the type plate on the under-

side of the device corresponds to

the supply mains at the place of

installation.

�If there are any problems during

operation, immediately pull out the

main plug from the socket.

�The power cord must be unwound

over its entire length (avoid rolling

up the cable and looping it). It must

not be exposed to any shocks and

must be kept out of the reach of

children. Also, it must not be kept

near liquids or sources of heat and

must not be damaged. Do not pull

the mains cable over sharp edges

and never crush or bend it. If the

cable is damaged, contact our cus-

tomer service department to have

it replaced.

�The use of multiple sockets and/or

extension cables is not recommen-

ded. However, if this is absolutely

necessary, only products with a

quality certificate (such as UL, IMQ,

VDE, +S etc.) may be used, pro-

vided the specified power exceeds

the power required (A = Ampere)

by the devices that are connected.

�If you have any doubts, ask a spe-

cialist to check whether the electri-

cal system is in accordance with

the local safety regulations.

�Install the vaporizer on a stable and

dry surface at a sufficient distance

from sources of heat (oven, stove,

fireplace etc.) and in a place where

the ambient temperature cannot

drop below 5°C (41°F).The vapori-

zer must be stored in a protected

and dry place and must not be in-

stalled in damp rooms (such as

bathrooms etc.).

S A F E T Y I N S T R U C T I O N S

�The hot air generator may only be

repaired by our Customer Service.

Incorrectly performed repairs with-

out the use of original spare parts

can prove dangerous to the user.

�Danger to life when opening the

vaporizer as live components and

connections are exposed.

�The vaporizer must never be re-

paired or transported when the

main plug is plugged in.

�To pull the plug from the socket,

pull the plug directly, never pull the

main cable.

�The vaporizer must never be ope-

rated when the main cable is de-

fective.

�Do not put any objects into the ope-

nings of the device.

�Do not leave the vaporizer unatten-

ded while it is being operated. After

use, switch off the heater and the

air pump.

�The ventilation slots as well as the

exhaust vent of the vaporizer must

not be closed, caped or obstructed

when the device is being operated

or is cooling down.

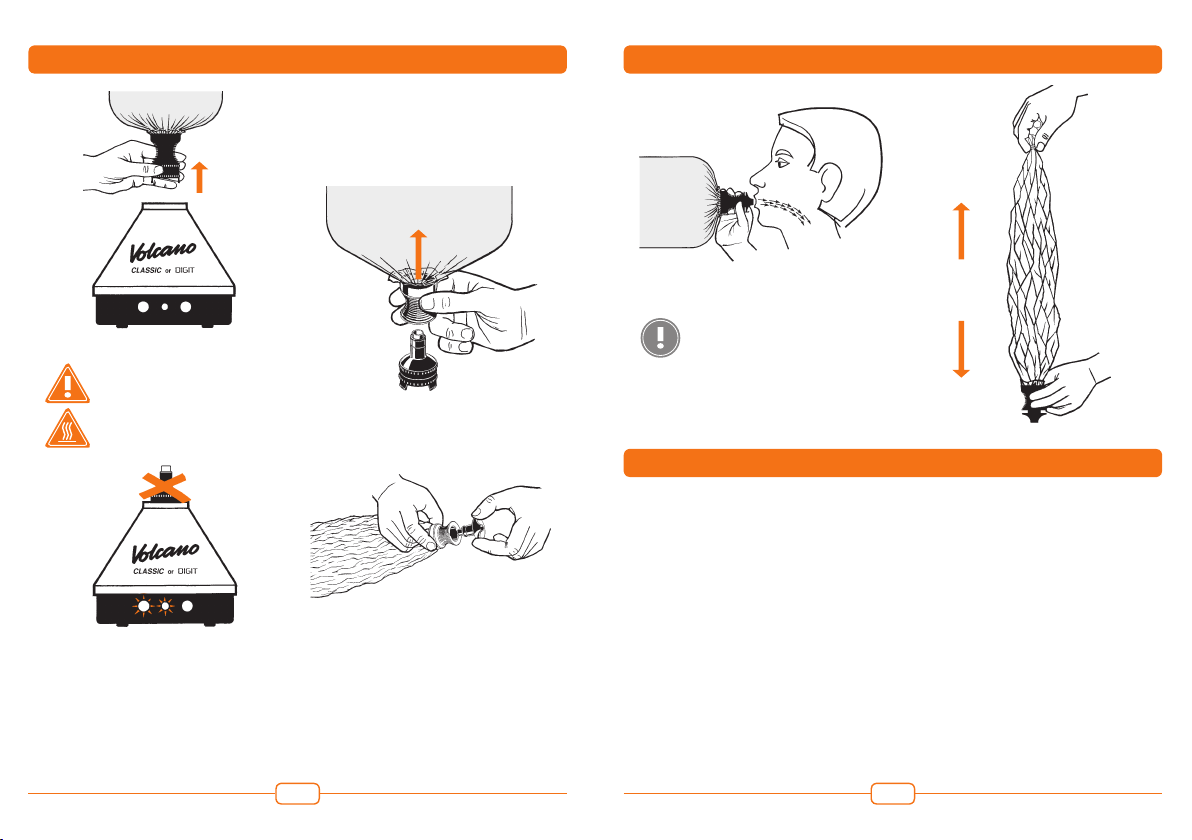

Danger of burning!

�Do not touch the exhaust vent and

the filling chamber when they are

hot.

�The filling chamber may only be

placed on the exhaust vent while

filling the balloon. After filling the

balloon, the filling chamber must

be removed from the hot air gene-

rator in order to avoid overheating

of the filling chamber (danger of

burning).

�Do not put any body parts or ob-

jects in the hot air jet.

�The vaporizer must only be clean-

ed with a dry cloth. If need be, use

a damp cloth for cleaning. Before

cleaning, pull out the main cable

from the socket. Never immerse

the vaporizer in water or in other

liquids or clean it with a direct wa-

ter or steam jet.

�The vaporizer must not be used in

damp or wet conditions.

�Do not expose the vaporizer to rain.

Do not use in the bathroom or over

water.

�Never touch the vaporizer with wet

or damp body parts.

�Never put containers containing

liquids on the vaporizer.

�Never operate the vaporizer when

it is wet or damp. If the vaporizer

becomes wet, it must be checked

by our Customer Service for dama-

ge to electrical components.

�Do not use in an atmosphere with

risk of explosion or ignition.

�Never allow the vaporizer to be

used by children or unqualified

persons.

�Only use original Storz & Bickel

accessories and spare parts.

Please keep this brochure in a safe

place for future reference.

The manufacturer is not re-

sponsible for any damage

or personal injury caused

by inappropriate, incorrect

or irresponsible use.