Strahman DV Series User manual

Last Updated: May 18, 2009

VL Series

SOFT SEAL PISTON VALVES

PROCESS VALVES

VESSEL & REACTOR VALVES

The Strahman family of products include:

S A M P L I N G V A L V E S

Strahman has a full line of sampling valves that produce live samples without exception.

Our sampling valves unique design prevent failure caused by sediment or clogging.

D R A I N V A L V E S

Strahman Drain Valves are designed to prevent clogging. They are ideal for use in liquid and gas

service or with slurries, polymers, and high viscosity fluids that tend to solidify at room temperature.

W A S H D O W N E Q U I P M E N T

Strahman offers a full line of mixing units, hose stations, hoses, nozzles and wash down accessories.

Our wash down line is designed for industrial use and is used in a wide variety of industries including

food, beverage, pharmaceutical, chemical and other applications.

L I N E B L I N DS

Strahman Line Blinds provide zero leakage down stream and total isolation on process pipelines,

vessels, and maritime applications. No pipeline movement is required when blind position is

changed.

Please contact your local Strahman representative for further details

or

visit our website: www.strahmanvalves.com

VALVES, INC.

Corporate Headquarters:

Strahman Valves, Inc. 2801 Baglyos Circle, Bethlehem, PA 18020

Tel: 484. 893.5080 ƔFax: 484.893.5099

Strahman France:

Savoie Hexapole, F-73420, Mery, France

Tel: + 33 4 79 35 78 00 ƔFax: + 33 4 79 35 78 20

Strahman MG Gmbh

Eisenbahnstrasse 104a

D-77833 Ottersweier, Germany

Tel: + 49 7223 22057 ƔFax: +49 7223 20165

ISO 9001 CERTIFIED

E s t a b l I s h e d 1 9 2 1

SOFT SEAL PISTON VALVES

VESSEL & REACTOR VALVES

DV & VL SERIES

SERIES DV, STANDARD RANGE

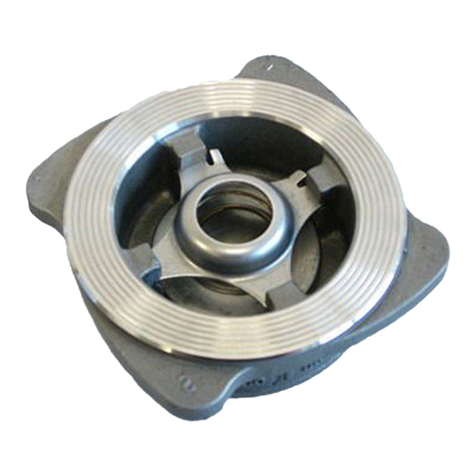

ORIGINAL STRAHMAN RAM-TYPE DRAIN VALVE

FEATURES

316L MAX

Pressure psig 275 235 215 195 170 140 110 80 50 35 65

316 CL 150 (barg) (19.0) (16.2) (14.8) (13.4) (11.7) (9.7) (7.6) (5.5) (3.4) (2.4) (4.5)

& 316L Temperature Deg. F 100 200 300 400 500 600 700 800 900 950 850

(Deg. C) (37.8) (93.3) (148.9) (204.4) (260.0) (315.6) (371.1) (426.7) (482.2) (510.0) (454.4)

316L MAX

Pressure psig 720 620 560 515 480 450 430 420 415 385 420

316 CL 300 (barg) (49.7) (42.8) (38.6) (35.5) (33.1) (31.0) (29.7) (29.0) (27.6) (26.6) (29.0)

& 316L Temperature Deg. F 100 200 300 400 500 600 700 800 900 950 850

(Deg. C) (37.8) (93.3) (148.9) (204.4) (260.0) (315.6) (371.1) (426.7) (482.2) (510.0) (454.4)

316L MAX

Pressure psig 1440 1240 1120 1025 955 900 870 845 830 775 835

316 CL 600 (barg) (99.3) (85.5) (77.2) (70.7) (65.9) (62.1) (60.0) (58.3) (57.2) (53.4) (57.6)

& 316L Temperature Deg. F 100 200 300 400 500 600 700 800 900 950 850

(Deg. C) (37.8) (93.3) (148.9) (204.4) (260.0) (315.6) (371.1) (426.7) (482.2) (510.0) (454.4)

SERIES DV, STANDARD RANGE

1” & 1½” HAND OPERATED RISING STEM RAM-TYPE DRAIN VALVES

CAUTION

Part No. Description Std. Material

701 Hand Wheel Nut 304SST

702 Hand Wheel Cast Iron

704 Bushing Lock Screw 304SST

705 Bushing Bronze (SST Avail.)

706 Bonnet 304SST

707 Stem * 416SST

708 Gland 304SST

712 Bonnet Nut 316SST

713 Bonnet Stud 304SST

714 Gland Ring * Braided TFE

715 Cage † 316SST

716 Split Nut * 316SST

717 Piston * † 316SST

718 Inlet Ring * † TFE

720 Body † 316SST

724 Gland Nut 316SST

725 Gland Stud 304SST

731 Cage Lock † 316SST

740 Cage Lock Gasket * † TFE

741 Opening Indicator 304SST

* Indicates recommended spare parts

† Denotes wetted parts

1” Drain Valve with Standard 60 Degree Straight Neck Discharge

Pressure

Class A Closed A Open B ± ⅛”* C ± .002” D E F

ANSI 12 ¼” 16 ½” 2” 0.984” 4 ⅛” 3 ¾” 4 ¼”

Class 150 14 ¼” 20 ½” 4” 0.984” 4 ⅛” 3 ¾” 4 ¼”

16 ¼” 24 ½” 6” 0.984” 4 ⅛” 3 ¾” 4 ¼”

18 ¼” 28 ½” 8” 0.984” 4 ⅛” 3 ¾” 4 ¼”

22 ¼” 36 ½” 12” 0.984” 4 ⅛” 3 ¾” 4 ¼”

ANSI 13” 17 11

/

16” 2” 0.984” 4 13

/

16”4 9

/

16” 4 ⅞”

Class 300 15” 21 11

/

16” 4” 0.984” 4 13

/

16”4 9

/

16” 4 ⅞”

17” 25 11

/

16” 6” 0.984” 4 13

/

16”4 9

/

16” 4 ⅞”

19” 29 11

/

16” 8” 0.984” 4 13

/

16”4 9

/

16” 4 ⅞”

23” 37 11

/

16” 12” 0.984” 4 13

/

16”4 9

/

16” 4 ⅞”

ANSI 13 3

/

16”18 1

/

16” 2” 0.984” 5” 4 ⅞” 4 ⅞”

Class 600 15 3

/

16”22 1

/

16” 4” 0.984” 5” 4 ⅞” 4 ⅞”

17 3

/

16”26 1

/

16” 6” 0.984” 5” 4 ⅞” 4 ⅞”

19 3

/

16”30 1

/

16” 8” 0.984” 5” 4 ⅞” 4 ⅞”

23 3

/

16”38 1

/

16” 12” 0.984” 5” 4 ⅞” 4 ⅞”

1” Drain Valve with Standard 45 Degree Straight Neck Discharge

Pressure

Class A Closed A Open B ± ⅛”* C ± .002” D E F

ANSI 14” 18 ⅞” 2” 0.984 4 ½” 6 ¼” 4 ¼”

Class 150 16” 22 ⅞” 4” 0.984 4 ½” 6 ¼” 4 ¼”

18” 26 ⅞” 6” 0.984 4 ½” 6 ¼” 4 ¼”

20” 30 ⅞” 8” 0.984 4 ½” 6 ¼” 4 ¼”

24” 38 ⅞” 12” 0.984 4 ½” 6 ¼” 4 ¼”

ANSI 14” 18 ⅞” 2” 0.984 4 ⅝” 6 ⅜” 4 ⅞”

Class 300 16” 22 ⅞” 4” 0.984 4 ⅝” 6 ⅜” 4 ⅞”

18” 26 ⅞” 6” 0.984 4 ⅝” 6 ⅜” 4 ⅞”

20” 30 ⅞” 8” 0.984 4 ⅝” 6 ⅜” 4 ⅞”

24” 38 ⅞” 12” 0.984 4 ⅝” 6 ⅜” 4 ⅞”

ANSI 14” 18 ⅞” 2” 0.984 4 ¾” 6 ⅜” 4 ⅞”

Class 600 16” 22 ⅞” 4” 0.984 4 ¾” 6 ⅜” 4 ⅞”

18” 26 ⅞” 6” 0.984 4 ¾” 6 ⅜” 4 ⅞”

20” 30 ⅞” 8” 0.984 4 ¾” 6 ⅜” 4 ⅞”

24” 38 ⅞” 12” 0.984 4 ¾” 6 ⅜” 4 ⅞”

1 ½” Drain Valve with Standard 60 Degree Straight Neck Discharge

Pressure

Class A Closed A Open B ± ⅛”* C ± .002” D E F

ANSI 13 ⅝” 18 7

/

16” 2” 1.181” 5 ” 4 ⅝” 5”

Class 150 15 ⅝” 22 7

/

16” 4” 1.181” 5 ” 4 ⅝” 5 ”

17 ⅝” 26 7

/

16” 6” 1.181” 5 ” 4 ⅝” 5 ”

19 ⅝” 30 7

/

16” 8” 1.181” 5 ” 4 ⅝” 5 ”

23 ⅝” 38 7

/

16” 12” 1.181” 5 ” 4 ⅝” 5 ”

ANSI 14 5

/

16” 19 ½” 2” 1.181” 5 ⅝” 5 ¼” 6 ⅛”

Class 300 16 5

/

16” 23 ½” 4” 1.181” 5 ⅝” 5 ¼” 6 ⅛”

18 5

/

16” 27 ½” 6” 1.181” 5 ⅝” 5 ¼” 6 ⅛”

20 5

/

16” 31 ½” 8” 1.181” 5 ⅝” 5 ¼” 6 ⅛”

24 5

/

16” 39 ½” 12” 1.181” 5 ⅝” 5 ¼” 6 ⅛”

ANSI 14 ⅝” 20 ⅛” 2” 1.181” 5 ⅞” 5 ¼” 6 ⅛”

Class 600 16 ⅝” 24 ⅛” 4” 1.181” 5 ⅞” 5 ¾” 6 ⅛”

18 ⅝” 28 ⅛” 6” 1.181” 5 ⅞” 5 ¾” 6 ⅛”

20 ⅝” 32 ⅛” 8” 1.181” 5 ⅞” 5 ¾” 6 ⅛”

24 ⅝” 40 ⅛” 12” 1.181” 5 ⅞” 5 ¾” 6 ⅛”

1 ½” Drain Valve with Standard 45 Degree Straight Neck Discharge

Pressure

Class A Closed A Open B ± ⅛”* C ± .002” D E F

ANSI 15 9

/

16”21 1

/

16” 2” 1.181” 5 ¼” 7 7

/

16” 5”

Class 150 17 9

/

16”25 1

/

16” 4” 1.181” 5 ¼” 7 7

/

16” 5”

19 9

/

16”29 1

/

16” 6” 1.181” 5 ¼” 7 7

/

16” 5”

21 9

/

16”33 1

/

16” 8” 1.181” 5 ¼” 7 7

/

16” 5”

25 9

/

16”41 1

/

16” 12” 1.181” 5 ¼” 7 7

/

16” 5”

ANSI 15 9

/

16”21 1

/

16” 2” 1.181” 5 5

/

16”7 9

/

16” 6 ⅛”

Class 300 17 9

/

16”25 1

/

16” 4” 1.181” 5 5

/

16”7 9

/

16” 6 ⅛”

19 9

/

16”29 1

/

16” 6” 1.181” 5 5

/

16”7 9

/

16” 6 ⅛”

21 9

/

16”33 1

/

16” 8” 1.181” 5 5

/

16”7 9

/

16” 6 ⅛”

25 9

/

16”41 1

/

16” 12” 1.181” 5 5

/

16”7 9

/

16” 6 ⅛”

ANSI 15 ½” 21 2” 1.181” 5 ½” 7 ⅝” 6 ⅛”

Class 600 17 ½” 25 4” 1.181” 5 ½” 7 ⅝” 6 ⅛”

19 ½” 29 6” 1.181” 5 ½” 7 ⅝” 6 ⅛”

21 ½” 33 8” 1.181” 5 ½” 7 ⅝” 6 ⅛”

25 ½” 41 12” 1.181” 5 ½” 7 ⅝” 6 ⅛”

STANDARD DIMENSIONS FOR 1” & 1½” HAND OPERATED RISING

STEM RAM-TYPE DRAIN VALVES

1

/

16

3

/

161

/

16

3

/

16

SERIES DV, STANDARD RANGE

HAND OPERATED TELESCOPING STEM RAM-TYPE DRAIN VALVES

CAUTION

Part No. Description Std. Material

701 Hand Wheel Nut 304SST

702 Hand Wheel Cast Iron

704 Bushing Lock Screw 304SST

705 Bushing * 303SST

706 Bonnet Carbon Steel

707 Stem * 416SST

708 Gland 304SST

711 Crosshead* Bronze (SST Avail.)

712 Bonnet Nut 316SST

713 Bonnet Stud 304SST

714 Gland Ring * Braided TFE

715 Cage † 316SST

717 Piston * † 316SST

718 Inlet Ring * † TFE

720 Body † 316SST

724 Gland Nut 316SST

725 Gland Stud 304SST

726 Bearing Collar 303SST

727 Bearing * Carbon Steel

731 Cage Lock † 316SST

732 Stop Collar 303SST

733 Collar Pin 304SST

734 Stem Guide 304SST

735 Guide Screws 304SST

737 Bearing Retainer 303SST

738 Bearing Seal TFE

739 Piston Set Screw 304SST

740 Cage Lock Gasket * † TFE

773 Grease Fitting Steel

* Indicates recommended spare parts

† Denotes wetted parts

STANDARD DIMENSIONS FOR HAND OPERATED TELESCOPING

STEM RAM-TYPE DRAIN VALVES

ANSI Class 150 Drain Valve with standard 60 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛”* C ± .002” D E F H A Max. B Max.

2” 23” 6” 1.575” 5 13

/

16” 5 ¼” 6” 8 ⅛” 29” 12”

2 ½ 23 ⅞” 6” 1.968” 6 ¼” 5 ¾” 7” 8 ⅛” 29 ⅞” 12”

3” 26 ⅞” 6” 2.362” 7 3

/

16” 6 ⅝” 7 ½” 10 ¾” 32 ⅞” 12”

4” 29 ⅝” 6” 3.149” 8 3

/

16” 7 ½” 9” 10 ¾” 35 ⅝” 12”

6” 39 ¼” 6” 4.921” 11” 10 ½” 11” 18” 42 ¼” 9”

ANSI Class 150 Drain Valve with standard 45 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛”* C ± .002” D E F H

2” 26 3

/

16” 6” 1.575” 6 ½” 8 ⅜” 6” 8 ⅛”

3” 31 ⅜” 6” 2.362” 8 ⅝” 11” 7 ½” 10 ¾”

4” 34 7

/

16” 6” 3.149” 10 ⅜” 12 ¾” 9” 10 ¾”

6” 45 13

/

16” 6” 4.921” 13 ⅝” 17 ⅜” 11” 18”

ANSI Class 150 Drain Valve with standard 90 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛”* C ± .002” D E F H A Max. B Max.

4” 38 ⅞” 6” 3.149” 6 ¾” 6 ¾” 9” 10 ¾” 38 ½” 6”

6” 39 9

/

16” 0” 4.921” 8 ¾” 7 ¼” 11” 18” 39 5

/

16” 7 ½”

ANSI Class 300 Drain Valve with standard 60 Degree Straight Neck Discharge

Valve Size A Std. B ± 1

/

16”* C ± .002” D E F H A Max. B Max.

2” 23 ½” 5 ½” 1.575” 6 ⅛” 5 15

/

16” 6 ½” 8 ⅛” 29 ½” 11 ½”

3” 27 ⅜” 5 ½” 2.362” 7 ¼” 7” 8 ¼” 10 ¾” 33 ⅜” 11 ½”

4” 30 ⅛” 5 ½” 3.149” 8 ¾” 8 ⅜” 10” 10 ¾” 36 ⅛” 11 ½”

6” 39 5

/

16” 5 ⅞” 4.921” 12” 11” 12 ½” 18” 39 5

/

16” 5 ⅞”

ANSI Class 300 Drain Valve with standard 45 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛”* C ± .002” D E F H

2” 26 ⅜” 6” 1.575” 6 ½” 8 ½” 6 ½” 8 ⅛”

3” 31 ½” 6” 2.362” 8 ⅝” 11 ¼” 8 ¼” 10 ¾”

4” 34 ¾” 6” 3.149” 10 ⅜” 13 1

/

16” 10” 10 ¾”

6” 46 ⅜” 6” 4.921” 13 ⅝” 17 ¾” 12 ½” 18”

ANSI Class 600 Drain Valve with standard 60 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛”* C ± .002” D E F H A Max. B Max.

2” 25 ½” 6” 1.575” 6 11

/

16”6 9

/

16” 6 ½” 8 ⅛” 25 ½” 6”

3” 29 ½” 6” 2.362” 8 7

/

16” 8” 8 ¼” 10 ¾” 29 ½” 6”

4” 33 ½” 6” 3.149” 10” 9 ⅝” 10 ¾” 10 ¾” 33 ½” 6”

6” 44 ⅛” 6” 4.921” 12 ⅞” 12” 14” 18” 44 ⅛” 6”

ANSI Class 600 Drain Valve with standard 45 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛”* C ± .002” D E F H

2” 26 ½” 6” 1.575” 6 ½” 8 ¾” 6 ½” 8 ⅛”

3” 31 11

/

16” 6” 2.362” 8 ⅝” 11 7

/

16” 8 ¼” 10 ¾”

4” 35” 6” 3.149” 10 ⅜” 13 7

/

16” 10 ¾” 10 ¾”

6” 46 ⅞” 6” 4.921” 13 ⅝” 18 ¼” 14” 18”

* Strahman piston extensions are measured from the height of the RF for an ANSI standard ange. For ANSI 600 class valves the extension is equal to the actual RF provided

by Strahman. For ANSI 150 and 300 class valves the ANSI standard RF height is 1

/

16” while Strahman provides 3

/

16” height for piloting as standard. Customers can request

a 1

/

16” RF height for RF-to-RF ange installation and the piston extension will equal the actual distance from the RF. For the Strahman standard (3

/

16” height) the distance

measured from the RF to the tip of the piston will be ⅛” less than the description. Example: 2” ANSI 150 Drain Valve with 6” piston extension will measure 5 ⅞” from a

standard Strahman RF to the tip of the piston. Piston Extension tolerances tighter than ⅛” available upon request.

SERIES DV, STANDARD RANGE

AIR CYLINDER OPERATED RAM-TYPE DRAIN VALVES

CAUTION

Part No. Description Std. Material

706 Bonnet Carbon Steel

708 Gland 304SST

712 Bonnet Nut 316SST

713 Bonnet Stud 304SST

714 Gland Ring * Braided TFE

715 Cage † 316SST

717 Piston * † 316SST

718 Inlet Ring * † TFE

720 Body † 316SST

724 Gland Nut 316SST

725 Gland Stud 304SST

731 Cage Lock † 316SST

739 Piston Set Screw 304SST

740 Cage Lock Gasket * † TFE

753 Piston Connector * Bronze (SST Avail.)

757 Air Cylinder

759 Cylinder Stud 304SST

760 Cylinder Nut 316SST

* Indicates recommended spare parts

† Denotes wetted parts

ANSI Class 150 Drain Valve with standard 60 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛” C ± .002” D E F G*(NPT) H*(NPT) L* DIA.

1” 22” 2” 0.984” 4 ¼” 3 15

/

16” 4 ¼” ⅛” ½” 5 ½” 9

/

16”

1 ½” 24” 2” 1.181” 5” 4 ⅝” 5” ⅛” ½” 6 ⅞” 13

/

16”

2” 34 ⅞” 6” 1.575” 5 13

/

16” 5 ⅜” 6” ⅛” ¾” 7 ⅞” 13

/

16”

2 ½” 38 9

/

16” 6” 1.968” 6 13

/

16” 6 ⅝” 7” ⅛” ¾” 7 ⅞” 13

/

16”

3” 40” 6” 2.362” 7 ½” 6 ¾” 7 ½” ¼” ¾” 9 ⅞” 13

/

16”

4” 46 1

/

16” 6” 3.149” 8 13

/

16”7 15

/

16” 9” ¼” 1” 12 ⅜ 1 1

/

16”

6” 56 ⅛” 6” 4.921” 11” 10 ⅜” 11” ¼” 1” 14 ½” 1 1

/

16”

8” 66 15

/

16” 6” 5.905” 12 13

/

16” 11 ⅞” 13 ½” ¼” 1” 14 ½” 1 1

/

16”

ANSI Class 150 Drain Valve with standard 45 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛” C ± .002” D E F G*(NPT) H*(NPT) L* DIA.

1” 24 ⅜” 2” 0.984” 4 ½” 6 ¼” 4 ¼” ⅛” ½” 5 ½” 9

/

16”

1 ½” 26 ¾” 2” 1.181” 5 ¼” 7 7

/

16” 5” ⅛” ½” 6 ⅞” 13

/

16”

2” 37” 6” 1.575” 6 ½” 8 ⅜” 6” ⅛” ¾” 7 ⅞” 13

/

16”

3” 48” 6” 2.362” 8 ⅝” 11” 7 ½” ¼” ¾” 9 ⅞” 13

/

16”

4” 49 ⅛” 6” 3.149” 10 ⅜” 12 ¾” 9” ¼” 1” 12 ⅜ 1 1

/

16”

6” 60 ⅝” 6” 4.921” 13 ⅝” 17 ⅜” 11” ¼” 1” 14 ½” 1 1

/

16”

ANSI Class 300 Drain Valve with standard 60 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛” C ± .002” D E F G*(NPT) H*(NPT) L* DIA.

1” 23 ¼” 2” 0.984” 4 ⅞” 4 ⅝” 4 ⅞” ⅛” ½” 5 ½” 9

/

16”

1 ½” 24 ¼” 2” 1.181” 5 ⅝” 5 ¼” 6 ⅛” ⅛” ½” 6 ⅞” 13

/

16”

2” 35 ⅛” 5 ⅝” 1.575” 6 ⅛” 5 15

/

16” 6 ½” ⅛” ¾” 7 ⅞” 13

/

16”

2 ½” 38 13

/

16” 6” 1.968” 6 ⅞” 6 13

/

16” 7 ½” ⅛” ¾” 7 ⅞” 13

/

16”

3” 40 ⅜” 5 ⅝” 2.362” 8 1

/

16” 7 ½” 8 ¼” ¼” ¾” 9 ⅞” 1 1

/

16”

4” 46 ⅞” 5 ⅜” 3.149” 9 7

/

16”8 13

/

16” 10” ¼” 1” 12 ⅜” 1 1

/

16”

6” 56 ⅛” 6” 4.921” 12” 11” 12 ½” ¼” 1” 14 ½” 1 1

/

16”

ANSI Class 300 Drain Valve with standard 45 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛” C ± .002” D E F G*(NPT) H*(NPT) L* DIA.

1” 24 ⅜” 2” 0.984” 4 ⅝” 6 ⅜” 4 ⅞” ⅛” ½” 5 ½” 9

/

16”

1 ½” 27” 2” 1.181” 5 5

/

16”7 9

/

16” 6 ⅛” ⅛” ½” 6 ⅞” 13

/

16”

2” 37 ⅜” 6” 1.575” 6 ½” 8 ½” 6 ½” ⅛” ¾” 7 ⅞” 13

/

16”

3” 48 ⅜” 6” 2.362” 8 ⅝” 11 ¼” 8 ¼” ¼” ¾” 9 ⅞” 1 1

/

16”

4” 49 ½” 6” 3.149” 10 ⅜” 13 1

/

16” 10” ¼” 1” 12 ⅜” 1 1

/

16”

6” 61 ½” 6” 4.921” 13 ⅝” 17 ¾” 12 ½” ¼” 1” 14 ½” 1 1

/

16”

ANSI Class 600 Drain Valve with standard 60 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛” C ± .002” D E F G*(NPT) H*(NPT) L* DIA.

1” 23 ⅝” 2” 0.984” 5” 4 ⅞” 4 ⅞” ⅛” ½” 5 ½” 9

/

16”

1 ½” 25 ⅞” 2” 1.181” 5 ⅞” 5 ¾” 6 ⅛” ⅛” ½” 6 ⅞” 13

/

16”

2” 36 15

/

16” 6” 1.575” 6 11

/

16”6 9

/

16” 6 ½” ⅛” ¾” 7 ⅞” 13

/

16”

3” 47 15

/

16” 6” 2.362” 8 7

/

16” 8” 8 ¼” ¼” 1” 9 ⅞” 1 1

/

16”

4” 53 ⅞” 6” 3.149” 10” 9 ⅝” 10 ¾” ¼” 1” 12 ⅜” 1 1

/

16”

ANSI Class 600 Drain Valve with standard 45 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛” C ± .002” D E F G*(NPT) H*(NPT) L* DIA.

1” 24 ½” 2” 0.984” 4 ¾” 6 ⅜” 4 ⅞” ⅛” ½” 5 ½” 9

/

16”

1 ½” 26 ⅝” 2” 1.181” 5 ½” 7 ⅝” 6 ⅛” ⅛” ½” 6 ⅞” 13

/

16”

2” 37 ⅞” 6” 1.575” 6 ½” 8 ¾” 6 ½” ⅛” ¾” 7 ⅞” 13

/

16”

3” 50 ½” 6” 2.362” 8 ⅝” 11 7

/

16” 8 ¼” ¼” 1” 9 ⅞” 1 1

/

16”

4” 51” 6” 3.149” 10 ⅜” 13 7

/

16” 10 ¾” ¼” 1” 12 ⅜” 1 1

/

16”

6” 62 ⅝” 6” 4.921” 13 ⅝” 18 ¼” 14” ¼” 1” 14 ½” 1 1

/

16”

* Dimensions G, H, L are for Air-Operated Drain Valves. For Hydraulic Drain Valve dimensions, please consult factory. Strahman piston extensions are measured from the height of the

RF for an ANSI standard ange. For ANSI 600 class valves the extension is equal to the actual RF provided by Strahman. For ANSI 150 and 300 class valves the ANSI standard RF

height is 1

/

16” while Strahman provides 3

/

16” height for piloting as standard. Customers can request a 1

/

16” RF height for RF-to-RF ange installation and the piston extension will equal the

actual distance from the RF. For the Strahman standard (3

/

16” height) the distance measured from the RF to the tip of the piston will be ⅛” less than the description. Example: 2” ANSI

150 Drain Valve with 6” piston extension will measure 5 ⅞” from a standard Strahman RF to the tip of the piston. Piston Extension tolerances tighter than ⅛” available upon request.

DIMENSIONS FOR AIR OPERATED RAM-TYPE DRAIN VALVES

7

SERIES DV, STANDARD RANGE

AIR AND HYDRAULIC OPERATED RAM-TYPE DRAIN VALVES

WITH INDICATOR SWITCHES

CAUTION

Part No. Description Std. Material

706 Bonnet Carbon Steel

708 Gland 304SST

712 Bonnet Nut 316SST

713 Bonnet Stud 304SST

714 Gland Ring * Braided TFE

715 Cage † 316SST

717 Piston * † 316SST

718 Inlet Ring * † TFE

720 Body † 316SST

724 Gland Nut 316SST

725 Gland Stud 304SST

731 Cage Lock † 316SST

733 Collar Pin ** 304SST

735 Switch Trip Screw 304SST

739 Piston Set Screw 304SST

740 Cage Lock Gasket * † TFE

753 Piston Connector * Bronze (SST Avail.)

754 Indicator Switch

755 Switch Bracket 304SST

757 Cylinder

759 Cylinder Stud 304SST

760 Cylinder Nut 316SST

761 Switch Trip 304SST

762 Piston Connector Nut** 304SST

780 Bracket Mtg. Screw 304SST

781 Switch Mtg. Screw 304SST

* Indicates recommended spare parts

** Collar Pin #733 and Piston Connector Nut #762 not shown,

only for Hydraulic.

† Denotes wetted parts

ANSI Class 150 Drain Valve with standard

45 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛” C ± .002” D E F

1” 35 ⅞” 6” 0.984” 4 ½” 6 ¼” 4 ¼”

1 ½” 38 13

/

16” 6” 1.181” 5 ¼” 7 7

/

16” 5”

2” 43 ½” 6” 1.575” 6 ½” 8 ⅜” 6”

3” 48” 6” 2.362” 8 ⅝” 11” 7 ½”

4” 53 15

/

16” 6” 3.149” 10 ⅜” 12 ¾” 9”

6” 66 ⅞” 6” 4.921” 13 ⅝” 17 ⅜” 11”

ANSI Class 300 Drain Valve with standard

45 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛” C ± .002” D E F

1” 35 ⅞” 6” 0.984” 4 ⅝” 6 ⅜” 4 ⅞”

1 ½” 38 13

/

16” 6” 1.181” 5 5

/

16”7 9

/

16” 6 ⅛”

2” 43 ⅞” 6” 1.575” 6 ½” 8 ½” 6 ½”

3” 48 ⅜” 6” 2.362” 8 ⅝” 11 ¼” 8 ¼”

4” 54 9

/

16” 6” 3.149” 10 ⅜” 13 1

/

16” 10”

6” 67 ¾” 6” 4.921” 13 ⅝” 17 ¾” 12 ½”

ANSI Class 600 Drain Valve with standard

45 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛” C ± .002” D E F

1” 35 ⅞” 6” 0.984” 4 ¾” 6 ⅜” 4 ⅞”

1 ½” 38 ¾” 6” 1.181” 5 ½” 7 ⅝” 6 ⅛”

2” 44 ⅜” 6” 1.575” 6 ½” 8 ¾” 6 ½”

3” 50 ¼” 6” 2.362” 8 ⅝” 11 7

/

16” 8 ¼”

4” 55 13

/

16” 6” 3.149” 10 ⅜” 13 7

/

16” 10 ¾”

6” 68 ⅞” 6” 4.921” 13 ⅝” 18 ¼” 14”

DIMENSIONS FOR AIR AND HYDRAULIC CYLINDER OPERATED

RAM-TYPE DRAIN VALVES WITH SWITCHES

Air Switch with 60 Degree

Straight Neck Discharge

Valve Size A Std. B ± ⅛”

1” 33 13

/

16” 6”

1 ½” 36 ⅜” 6”

2” 42 11

/

16” 6”

2 ½” 43 ⅜” 6”

3” 45 ¼” 6”

4” 51 ⅛” 6”

6” 62 ⅜” 6”

8” 66 15

/

16” 6”

Hydraulic Operated with

60 Degree Straight Neck

Valve Size A Std. B ± ⅛”

1” 33 13

/

16 6”

1 ½” 36 ⅜” 6”

2” 42 11

/

16 6”

2 ½” 41 11

/

16 6”

3” 43 5

/

16” 6”

4” 46 5

/

16” 6”

6” 57 ⅜” 6”

8” 64 ½” 6”

10” 75 7

/

16” 6”

12” 96” 6”

Hydraulic Operated with

60 Degree Straight Neck

Valve Size A Std. B ± ⅛”

1” 34 ¾” 6”

1 ½” 37 5

/

16” 6”

2” 43 3

/

16” 6”

2 ½” 41 11

/

16 6”

3” 44 1

/

16” 6”

4” 47 9

/

16” 6”

6” 57 ⅜” 6”

8” 65 ½” 6”

10” 75 7

/

16” 6”

12” 96 6”

Hydraulic Operated with

60 Degree Straight Neck

Valve Size A Std. B ± ⅛”

1” 35 ⅛” 6”

1 ½” 37 15

/

16” 6”

2” 43 7

/

16” 6”

3” 44 11

/

16” 6”

4” 50 ⅜” 6”

6” 59 ⅜” 6”

Air Switch with 60 Degree

Straight Neck Discharge

Valve Size A Std. B ± ⅛”

1” 34 ¾” 6”

1 ½” 37 5

/

16” 6”

2” 43 3

/

16” 6”

2 ½” 43 ⅜” 6”

3” 45 11

/

16” 5 ⅝”

4” 52 ¼” 6”

6” 62 ⅜” 6”

Air Switch with 60 Degree

Straight Neck Discharge

Valve Size A Std. B ± ⅛”

1” 35 ⅛” 6”

1 ½” 37 15

/

16” 6”

2” 43 7

/

16” 6”

3” 47 ¼” 5 5

/

16”

4” 54 “ 6”

* Strahman piston extensions are measured from the height of the RF for an ANSI standard ange. For ANSI 600 class valves the extension is equal to the

actual RF provided by Strahman. For ANSI 150 and 300 class valves the ANSI standard RF height is 1

/

16” while Strahman provides 3

/

16” height for piloting as

standard. Customers can request a 1

/

16” RF height for RF-to-RF ange installation and the piston extension will equal the actual distance from the RF. For the

Strahman standard (3

/

16” height) the distance measured from the RF to the tip of the piston will be ⅛” less than the description. Example: 2” ANSI 150 Drain

Valve with 6” piston extension will measure 5 ⅞” from a standard Strahman RF to the tip of the piston. Piston Extension tolerances tighter than ⅛” available

upon request.

SERIES DV, STANDARD RANGE

ELECTRIC ACTUATOR AND AIR MOTOR OPERATED

RAM-TYPE DRAIN VALVES

CAUTION

Part No. Description Std. Material

704 Brushing Lock Screw 304SST

705 Insert/Bushing Bronze /303SST

706 Bonnet Carbon Steel

707 Stem * 416SST

708 Gland 304SST

711 Crosshead * Bronze (SST Avail.)

712 Bonnet Nut 316SST

713 Bonnet Stud 304SST

714 Gland Ring * Braided TFE

715 Cage † 316SST

717 Piston*† 316SST

718 Inlet Ring* † TFE

720 Body † 316SST

724 Gland Nut 316SST

725 Gland Stud 304SST

726 Bearing Collar 303SST

727 Bearing* Carbon Steel

731 Cage Lock † 316SST

732 Stem Stop 303SST

733 Stem Stop Pin 304SST

734 Crosshead Guide * 303SST

735 Switch Trip Screw * 304SST

737 Retaining Ring * 303SST

738 Bearing Seal * TFE

739 Piston Set Screw 304SST

740 Cage Lock Gasket* RTFE

754 Indicator Switch

755 Switch Bracket 304SST

761 Switch Trip 304SST

763 Reducer Coupling

764 Motor

765 Gear Reducer

773 Grease Fitting Steel

780 Bracket Mtg. Screw 304SST

781 Switch Mtg. Screw 304SST

783 Key

784 Reducer Mtg.Stud 304SST

785 Reducer Mtg. Nut 316SST

786 Reducer Mtg, Washer 304SST

787 Safety Shield 304SST

788 Safety Shield Screw 304SST

789 Safety Shield Washer 304SST

790 Stem Coupling

791 Insert Bronze

* Denotes recommended spare parts

† Denotes wetted parts

ANSI Class 150 Drain Valve with standard 60 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛” C ± .002” D E F G A Max. B Max.

2” 41 13

/

16” 6” 1.575” 5 13

/

16” 5 ⅜” 6” 18 13

/

16”41 13

/

16” 6”

3” 46” 6” 2.362” 7 ½” 6 ¾” 7 ½” 18 13

/

16” 46” 6”

4” 47” 6” 3.149” 8 13

/

16”7 15

/

16” 9” 18 13

/

16” 47” 6”

6” 55 ⅜” 6” 4.921” 11” 10 ⅜” 11” 18 13

/

16” 61 ⅜” 12”

8” 61” 6” 5.905” 12 13

/

16” 11 ⅝” 13 ½” 18 13

/

16” 61” 6”

10” 72 ¾” 6” 7.480” 16 ⅝” 15 ⅝” 16” 18 13

/

16” 72 ¾” 6”

ANSI Class 150 Drain Valve with standard 45 Degree Straight Neck Discharge

Contact Strahman factory for details

ANSI Class 300 Drain Valve with standard 60 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛” C ± .002” D E F G A Max. B Max.

2” 42 3

/

16” 6” 1.575” 6 ⅛” 5 15

/

16” 6 ½” 18 13

/

16”42 13

/

16” 6”

3” 46 ⅜” 6” 2.362” 8 1

/

16” 7 ½” 8 ¼” 18 13

/

16” 46 ⅜” 6”

4” 47 ½” 5 ½ 3.149” 9 7

/

16”8 13

/

16” 10” 18 13

/

16” 47 ½” 5 ½”

6” 55 ⅜” 6” 4.921” 12” 11” 12 ½” 18 13

/

16” 61 ⅜” 12”

8” 61 ½” 6” 5.905” 13 9

/

16”12 13

/

16” 15” 18 13

/

16” 61 ½” 6”

10” 72 ¾” 6” 7.480” 16 ⅝ 15 ⅝” 17 ½” 20 9

/

16” 72 ¾” 6”

ANSI Class 600 Drain Valve with standard 60 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛” C ± .002” D E F G A Max. B Max.

2” 42 13

/

16” 6” 1.575” 6 11

/

16”6 9

/

16” 6 ½” 18 13

/

16”42 13

/

16” 6”

3” 46 9

/

16” 6” 2.362” 8 7

/

16” 8” 8 ¼” 18 13

/

16”46 9

/

16” 6”

4” 48 1

/

16”4 15

/

16” 3.149” 10” 9 ⅝” 10 ¾” 18 13

/

16”48 1

/

16”4 15

/

16”

6” 59 3

/

16” 6” 4.921” 12 ⅞” 12” 14” 18 13

/

16”59 3

/

16” 6”

* Strahman piston extensions are measured from the height of the RF for an ANSI standard ange. For ANSI 600 class valves the extension is equal to the actual

RF provided by Strahman. For ANSI 150 and 300 class valves the ANSI standard RF height is 1

/

16” while Strahman provides 3

/

16” height for piloting as standard.

Customers can request a 1

/

16” RF height for RF-to-RF ange installation and the piston extension will equal the actual distance from the RF. For the Strahman

standard (3

/

16” height) the distance measured from the RF to the tip of the piston will be ⅛” less than the description. Example: 2” ANSI 150 Drain Valve with

6” piston extension will measure 5 ⅞” from a standard Strahman RF to the tip of the piston. Piston extension tolerances tighter than ⅛” available upon request.

STANDARD DIMENSIONS FOR ELECTRIC AND AIR MOTOR

OPERATED RAM-TYPE DRAIN VALVES

SERIES DV, STANDARD RANGE

ROTORK OPERATED RAM-TYPE DRAIN VALVES

CAUTION

Part No. Description Std. Material

706 Bonnet Carbon Steel

707 Stem * 416SST

708 Gland 304SST

711 Crosshead * Bronze (SST Avail.)

712 Bonnet Nut 316SST

713 Bonnet Stud 304SST

714 Gland Ring * † Braided TFE

715 Cage † 316SST

717 Piston *† 316SST

718 Inlet Ring * † TFE

720 Body † 316SST

724 Gland Nut 316SST

725 Gland Stud 304SST

731 Cage Lock † 316SST

732 Stop Collar 303SST

733 Collar Pin 304SST

734 Crosshead Guide* 304SST

735 Guide Screw* 304SST

739 Piston Set Screw 304SST

740 Cage Lock Gasket* TFE

768 Rotork Actuator

769 Rotork Mtg. Stud 304SST

770 Rotork Mtg. Nut 316SST

771 Stem Washer 302SST

772 Stem Nut 304SST

* Denotes recommended spare parts

† Denotes wetted parts

ANSI Class 150 Drain Valve with standard 60 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛” C ± .002” D E F

2” 35 11

/

16” 6” 1.575” 5 13

/

16” 5 ⅜” 6”

3” 43 ⅛” 6” 2.362” 7 ½” 6 ¾” 7 ½”

4” 45 7

/

16” 6” 3.149” 8 13

/

16”7 15

/

16” 9”

6” 54 3

/

16” 6” 4.921” 11” 10 ⅜” 11”

8” 62 ⅜” 6” 5.905” 12 13

/

16” 11 ⅞” 13 ½”

10” 70 ⅜” 6” 7.480” 16 ⅝” 15 ⅝” 16”

ANSI Class 150 Drain Valve with standard 45 Degree Straight Neck Discharge

Contact Strahman factory for details

ANSI Class 300 Drain Valve with standard 60 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛” C ± .002” D E F

2” 36 ⅝” 6” 1.575” 6 ⅛” 5 15

/

16” 6 ½”

3” 43 13

/

16” 6” 2.362” 8 1

/

16” 7 ½” 8 ¼”

4” 46 1

/

16” 6” 3.149” 9 7

/

16”8 13

/

16” 10”

6” 56 1

/

16” 6” 4.921” 12” 11” 12 ½”

8” 64 13

/

16” 6” 5.905” 13 9

/

16”12 13

/

16” 15”

10” 70 ⅜” 6” 7.480” 16 ⅝ 15 ⅝” 17 ½”

ANSI Class 600 Drain Valve with standard 60 Degree Straight Neck Discharge

Valve Size A Std. B ± ⅛” C ± .002” D E F

2” 36 11

/

16” 6” 1.575” 6 11

/

16”6 9

/

16” 6 ½”

3” 45 11

/

16” 6” 2.362” 8 7

/

16” 8” 8 ¼”

4” 49” 6” 3.149” 10” 9 ⅝” 10 ¾”

6” 59 9

/

16” 6” 4.921” 12” 12” 14”

* Strahman piston extensions are measured from the height of the RF for an ANSI standard ange. For ANSI 600 class valves the extension

is equal to the actual RF provided by Strahman. For ANSI 150 and 300 class valves the ANSI standard RF height is 1

/

16” while Strahman

provides 3

/

16” height for piloting as standard. Customers can request a 1

/

16” RF height for RF-to-RF ange installation and the piston extension

will equal the actual distance from the RF. For the Strahman standard (3

/

16” height) the distance measured from the RF to the tip of the piston

will be ⅛” less than the description. Example: 2” ANSI 150 Drain Valve with 6” piston extension will measure 5 ⅞” from a standard Strahman

RF to the tip of the piston. Piston extension tolerances tighter than ⅛” available upon request.

STANDARD DIMENSIONS FOR ROTORK OPERATED

RAM-TYPE DRAIN VALVES

ANSI Class 150 Adapters

Flange

Size

Flange

Thickness

C D E F B Std G

1” ½” 1.031” ⅛” 2.007” 4 ¼” 2”

1 ½” ⅝” 1.230” 11

/

64” 2.882” 5” 2”

2” 11

/

16” 1.630” 11

/

64” 3.632” 6” 6”

2 ½” ¾” 2.031” 11

/

64” 4.132” 7” 6”

3” ¾” 2.420” 3

/

16” 5.007” 7 ½” 6”

4” ⅞” 3.211” 3

/

16” 6.194” 9” 6”

6” 15

/

16” 4.983” 3

/

16” 8.507” 11” 6”

8” 1 1

/

16” 5.967” 3

/

16” 10.632” 13 ½” 6”

10” 1 ⅛” 7.541” 3

/

16” 12.757” 16” 6”

12” 1 3

/

16” 11.062” 3

/

16” 15.007” 19” 6”

ANSI Class 300 Adapters

Flange

Size

Flange

Thickness

C D E F B Std G

1” ½” 1.031” ⅛” 2.007” 4 ⅞” 2”

1 ½” ⅝” 1.230” 11

/

64” 2.882” 6 ⅛” 2”

2” 11

/

16” 1.630” 11

/

64” 3.632” 6 ½” 5 ½”

2 ½” ¾” 2.031” 11

/

64” 4.132” 7 ½” 5 ½”

3” ¾” 2.420” 3

/

16” 5.007” 8 ¼” 5 ½”

4” ⅞” 3.211” 3

/

16” 6.194” 10” 5 ½”

6” 15

/

16” 4.983” 3

/

16” 8.507” 12 ½” 5 ½”

8” 1 1

/

16” 5.967” 3

/

16” 10.632” 15” 6”

10” 1 ⅛” 7.541” 3

/

16” 12.757” 17 ½” 6”

12” 1 3

/

16” 11.062” 3

/

16” 15.004” 20 ½” 6”

ANSI Class 600 Adapters

Flange

Size

Flange

Thickness

C D E F B Std G

1” 9

/

16” 1.031” 15

/

64” 2.007” 4 ⅞” 2 3

/

16”

1 ½” ⅝” 1.230” 15

/

64” 2.882” 6 ⅛” 2 3

/

16”

2” 11

/

16” 1.630” 15

/

64” 3.632” 6 ½” 6 3

/

16”

3” ¾” 2.420” 15

/

64” 5.007” 8 ¼” 6 3

/

16”

4” ⅞” 3.211” 15

/

64” 6.194” 10 ¾” 6 3

/

16”

6” 15

/

16” 4.983” 15

/

64” 8.507” 14” 6 3

/

16”

8” 1 1

/

16” 5.967” 15

/

64” 10.632” 16 ½” 6 3

/

16”

Adapter Drilling: ANSI standard, bolt holes straddle centerlines.

For adapters with sampling valves contact Strahman direct.

SERIES DV, STANDARD RANGE

OPTIONAL ADAPTERS FOR DEAD SPACE FREE CONNECTION TO PROCESS

ANSI Class 150 Nozzles

Flange

Size

Flange

Thickness

C D E F B Std G

1” 1” 1.031” ⅛” 2.007” 4 ¼” 6” 1 ⅞”

1 ½” 1” 1.230” 11

/

64” 2.882” 5” 6” 2 ⅛”

2” 1 ⅛” 1.630” 11

/

64” 3.632” 6” 6” 2 ½”

2 ½” 1 ⅛” 2.031” 11

/

64” 4.132” 7” 6” 2 15

/

16”

3” 1 3

/

16” 2.420” 3

/

16” 5.007” 7 ½” 6” 3 ⅜”

4” 1 3

/

16” 3.211” 3

/

16” 6.194” 9” 6” 4 ⅜”

6” 1 ¼” 4.983” 3

/

16” 8.507” 11” 6” 6 ⅛”

8” 1 ⅜” 5.967” 3

/

16” 10.632” 13 ½” 6” 7 ¼”

10” 1 7

/

16” 7.541” 3

/

16” 12.757” 16” 6” 9 ⅛”

12” 1 ½” 11.062” 3

/

16” 15.007” 19” 6” 13 ¼”

ANSI Class 300 Nozzles

Flange

Size

Flange

Thickness

C D E F B Std G

1” 1 ⅛” 1.031” ⅛” 2.007” 4 ⅞” 6” 1 15

/

16”

1 ½” 1 ⅛” 1.230” 11

/

64” 2.882” 6 ⅛” 6” 2 ⅛”

2” 1 ⅛” 1.630” 11

/

64” 3.632” 6 ½” 6” 2 ½”

2 ½” 1 ¼” 2.031” 11

/

64” 4.132” 7 ½” 6” 2 15

/

16”

3” 1 ⅜” 2.420” 3

/

16” 5.007” 8 ¼” 6” 3 ⅜”

4” 1 ½” 3.211” 3

/

16” 6.194” 10” 6” 4 ⅜”

6” 1 11

/

16” 4.983” 3

/

16” 8.507” 12 ½” 6” 6 ⅛”

8” 1 ⅞” 5.967” 3

/

16” 10.632” 15” 6” 7 ¼”

10” 2 ⅛” 7.541” 3

/

16” 12.757” 17 ½” 6” 9 ⅛”

12” 2 ¼” 11.062” 3

/

16” 15.007” 20 ½” 6” 13 ¼”

ANSI Class 600 Nozzles

Flange

Size

Flange

Thickness

C D E F B Std G

1” 1 ⅛” 1.031” 15

/

64” 2.007” 4 ⅞” 6 3

/

16”1 15

/

16”

1 ½” 1 ⅛” 1.230” 15

/

64” 2.882” 6 ⅛” 6 3

/

16” 2 ⅛”

2” 1 ¼” 1.630” 15

/

64” 3.632” 6 ½” 6 3

/

16” 2 ½”

3” 1 ½” 2.420” 15

/

64” 5.007” 8 ¼” 6 3

/

16” 3 ⅜”

4” 1 ¾” 3.211” 15

/

64” 6.194” 10 ¾” 6 3

/

16” 4 ⅜”

6” 2 ⅛” 4.983” 15

/

64” 8.507” 14” 6 3

/

16” 6 ⅛”

Nozzle Drilling: ANSI standard, bolt holes straddle centerlines.

For nozzles with sampling valves contact Strahman direct.

SERIES VL, CUSTOM MADE RANGE

TECHNICAL AND GENERAL INFORMATION

FEATURES

RANGE DEFINITION

VL

Manufacturing

Range

PN 10

Fig. 020

Fig. 025

PN 16

I PN 20-150 lbs.

PN 150/160-900 lbs.

I PN 25

I PN 40

PN 50 300 lbs.

PN 64 400 lbs.

PN 100 600 lbs.

PN 250 - 1500 lbs.

PN 320

PN 420 - 2500 lbs.

PN 630 - 4500 lbs.

⅜” - DIN10

½” - DIN15

¾” - DIN20

1” - DIN25

1 ¼” - DIN32

1 ½” - DIN40

2” - DIN50

2 ½” - DIN65

3” - DIN80

4” - DIN100

5” - DIN125

6” - DIN150

8” - DIN200

10” - DIN250

12” - DIN300

14” - DIN350

16” - DIN400

18” - DIN450

20” - DIN500

24” - DIN600

Soft Seal Piston Valve

NO DEAD SPACE SOFT SEAL PISTON VALVES

Code: VL4S - VL6S

Large size valves utilize

a non-rising stem to

minimize overall length

Mechanical

position indicator

An extended stuffing box

eliminates dead space and

improves piston alignment

Lantern positioning

screw

Standard branch angle:

45° & 60°

90°, and other

specific angles available

upon request

Piston is seat-less to

maximize self-cleaning

design

Fig. 025S

Strahman bodies are

designed to allow full bore

with a high rigidity lantern

TECHNICAL & GENERAL INFORMATION

Design Code & Construction

•Design standard compliant with ASME B16.34

•International standards include ANSI, DIN, JIS, API etc.

•Wide range of material selections including carbon steel / stainless steel / Titanium / Hastelloy / Duplex /

Monel / Tantalum / Zirconium

•Fabricated, cast, forged and bar stock designs

•Combinations of fabricated, sand and investment casings, and bar stock available

Surface Finish

•For polymer applications, Strahman recommends a surface finish of 300 (Ra 0.4) for all parts are in

contact with the medium

Quality assurance & testing

•ISO 9001 compliant

•PED / ATEX / CE marking

LINE & BRANCH CONNECTIONS

Flanges ANSI,

DIN, JIS

ACTUATION OPTIONS

Hand Wheel Electric Actuator Air Motor

Double or single

acting Air Cylinder Double or single acting Air

Cylinder with Safety Hand Wheel

Hydraulic

Cylinder

Double or single acting Air

Cylinder with side mounted

Safety Hand Wheel

•TUV / HPO / TA Luft

•Standard testing procedures

Threaded

connections

NPT & BSP

Soft Seal Valves can be equipped with the following end connections

Bevel Gear

Live loaded packing

arrangement is standard

on Strahman Valves

SERIES VL, CUSTOM MADE RANGE

All packing arrangements

use a lantern ring that:

•Provides better stem

piston guiding

•Avoids dead space in

body cavities

Typical Packing Materials:

•PTFE

•PTFE / Aramide Braid

•Carbon / Graphite Braid

•Graphite Braid

•PTFE / Aramide Braid + Graphite

•Lamellar + Expanded Graphite

•Pure Graphite

Live loaded packing

arrangement

minimizes valve

maintenance

Optional 1/4 inch NPTF available for leak

detection or inert gas injection to avoid

leakage to atmosphere by creating an

over pressure

Bottom ring material is

selected with a differential

hardness from the piston

to prevent piston damage

•PTFE

•Aramide / Nitrile

•Carbon / Aramide

•Laminated Graphite

•Laminated Graphite / 316

•Spiral Wound 316L / PTFE

•Spiral Wound 316L / Graphite

•Spiral Wound 321 / Graphite

•Spiral Wound Inconel / Graphite

•Spiral Wound Titanium / Graphite

•Perfluoroelastomer (Kalrez) O

Ring

PACKING DEFINITION

Valve Coding System

PPiston

DDisc

RRising Disc

AAccessories

445oBranch Angle

660oBranch Angle

990oBranch Angle

SStraight

$Special

BExtended Body

PExtended Plunger c

DDismountable Seat

$Special

V P 4 S B -

VVessel Reactor Valves

SSoft Seated

MM Seal

CM Control

DDual Seal

RM Ring Seal

JJacketed

- Non-Jacketed

Strahman has two Soft Seal Piston Valve styles available:

•Figure 020 for smaller and utilize a rising stem design.

•Figure 025 for large sizes use a non-rising stems to minimize overall length.

BODY ARRANGEMENTS

Strahman Bottom Disc design is a vessel outlet valve. When opening, the disc retracts completely

into the valve body. This provides an unrestricted full flow. In combination with maximized port sizes, this

design offers maximum flow capacity.

Strahman valves are available in a choice of options including material of construction, seat

arrangements, sealing systems to atmosphere, actuators and customized or standard connections to

piping. Other specific features are full jacketing, vacuum package and dead space free connections

to vessels.

Typical applications include the draining of viscous products especially in combination with low pres-

sure and/or vacuum processes.

Fig. 020 Fig. 025

•Welded Lips

•Metallic O Ring Helicoflex

Gasket Aluminium/316

•Metallic O Ring Helicoflex

Gasket Nickel/Nimonic 90

•316L RTJ

•Nitrile O Ring

•EPDM O Ring

•Silicone O Ring

•Fluorocarbon (Viton) O Ring

•Silicone FEP Jacketed O

Ring

STANDARD BODY GASKET RANGE

•PTFE

•Aramide / Nitrile

•Carbon / Aramide

•Laminated Graphite

•Laminated Graphite / 316

•Spiral Wound 316L / PTFE

•Spiral Wound 316L / Graphite

•Spiral Wound 321 / Graphite

•Spiral Wound Inconel /

Graphite

•Spiral Wound Titanium /

Graphite

•Welded Lips

STANDARD PAD GASKET RANGE

Fig. 025

SERIES VL, CUSTOM MADE RANGE

BODY ARRANGEMENTS

D

H

D

H

H

D

R

H

D

Vessel Pad Vessel Nozzle Pipe Assembly Pad

Custom Vessel Pad

To connect valves to existing vessels or reactors, there are two possibilities: a nozzle or a pad

connection. In both cases, the customer must specify the following vessel connection details:

« D» (inside diameter), « H» (height), DN (nominal size), PN (pressure rating) and connection

standard (ISO, ANSI, DIN, etc.). To eliminate retention areas radius « R» can be specified for

optional contouring. For new projects Strahman can supply valves with easy-to-fit standardized

pads that are ready to be installed.

VESSEL CONNECTIONS

SEALING SYSTEM

Soft Seal-The Soft Seal

is a seat-less sealing system

that assures superior per-

formance. While closing, the

plunger moves through the

valve bore and effectively

rods any remaining product

out of the valve.

Temperature

Min: -50o C / -60o F

Max: 200o C / 390o F

Pressure

Max: 100 bar / 1450 psig

Step 2

Valve is raised to

break through the

crust in the bottom

of the vessel

Step 3

Valve is opened

to the sampling

position

MULTI-POSITION & BOTTOM VESSEL SAMPLING

Strahman Soft Seal Valves allow the valve

to operate in multiple positions while main-

taining a seal between the process and the

outlet. It is a multi-position valve that serves

as a multi-purpose process tool.

RANGE DEFINITION

RANGE DEFINI-

VL

Manufacturing

Range

3/8”- DIN10

1/2”- DIN15

3/4”- DIN20

1”- DIN25

1 1/4”- DIN32

1 1/2”- DIN40

2”- DIN50

2 1/2”- DIN65

3”- DIN80

4”- DIN100

5”- DIN125

6”- DIN150

8”- DIN200

10”- DIN250

12”- DIN300

14”- DIN350

16”- DIN400

18”- DIN450

20”- DIN500

24”- DIN600

PN 10

PN 16

PN 20– 150 lbs.

PN 25

PN 40

PN 50 300 lbs.

PN64 400 lbs.

PN 100 600 lbs.

PN 150/ 160 -900 lbs.

PN 250 -1500 lbs

PN 320

PN 420—2500 lbs

PN 630 –4500 lbs

Fig. 020

Fig. 047

Step 1

Valve is closed and flush with

vessel bottom

Step 4

Valve is open

to the drain

position

PN 20– 150 lbs.

PN 25

PN 40

Bottom Vessel Sampling

A Strahman sampling valve combined with a

sampling assembly can be used to sample

product prior to tank draining

The standard live loaded

packing arrangement avoids

over-compression of the upper

seal ring while the valve is in

the open position

Valve Body

A second lantern gland packing

arrangement improves piston

guidance and minimizes

retention areas

Rigid soft seat ring

provides dimensional

stability with

temperature variations

High rigidity lantern is

designed to avoid

distortion or contact

with the piston

Greater piston hardness resists

scratches that are the primary

cause of damage to the seal and

resulting in leakage

Top Hat

Extended PistonPTFE Sleeve

SERIES VL, CUSTOM MADE RANGE

C B

B

B

B

B

C

C

C

C

All packing arrangements

use a lantern ring that:

•Provides better stem

piston guiding

•Avoids dead space in

body cavities

Typical Packing Materials:

•PTFE

•PTFE / Aramide Braid

•Carbon / Graphite Braid

•Graphite Braid

•PTFE / Aramide Braid + Graphite

•Lamellar + Expanded Graphite

•Pure Graphite

Live loaded packing

arrangement

minimizes valve

maintenance

Optional 1/4 inch NPTF available for leak

detection or inert gas injection to avoid

leakage to atmosphere by creating an

over pressure

Bottom ring material is

selected with a differential

hardness from the piston

to prevent piston damage

•PTFE

•Aramide / Nitrile

•Carbon / Aramide

•Laminated Graphite

•Laminated Graphite / 316

•Spiral Wound 316L / PTFE

•Spiral Wound 316L / Graphite

•Spiral Wound 321 / Graphite

•Spiral Wound Inconel / Graphite

•Spiral Wound Titanium / Graphite

•Perfluoroelastomer (Kalrez) O

Ring

PACKING DEFINITION

Valve Coding System

PPiston

DDisc

RRising Disc

AAccessories

445oBranch Angle

660oBranch Angle

990oBranch Angle

SStraight

$Special

BExtended Body

PExtended Plunger c

DDismountable Seat

$Special

V P 4 S B -

VVessel Reactor Valves

SSoft Seated

MM Seal

CM Control

DDual Seal

RM Ring Seal

JJacketed

- Non-Jacketed

Strahman has two Soft Seal Piston Valve styles available:

•Figure 020 for smaller and utilize a rising stem design.

•Figure 025 for large sizes use a non-rising stems to minimize overall length.

BODY ARRANGEMENTS

Strahman Bottom Disc design is a vessel outlet valve. When opening, the disc retracts completely

into the valve body. This provides an unrestricted full flow. In combination with maximized port sizes, this

design offers maximum flow capacity.

Strahman valves are available in a choice of options including material of construction, seat

arrangements, sealing systems to atmosphere, actuators and customized or standard connections to

piping. Other specific features are full jacketing, vacuum package and dead space free connections

to vessels.

Typical applications include the draining of viscous products especially in combination with low pres-

sure and/or vacuum processes.

Fig. 020 Fig. 025

•Welded Lips

•Metallic O Ring Helicoflex

Gasket Aluminium/316

•Metallic O Ring Helicoflex

Gasket Nickel/Nimonic 90

•316L RTJ

•Nitrile O Ring

•EPDM O Ring

•Silicone O Ring

•Fluorocarbon (Viton) O Ring

•Silicone FEP Jacketed O

Ring

STANDARD BODY GASKET RANGE

•PTFE

•Aramide / Nitrile

•Carbon / Aramide

•Laminated Graphite

•Laminated Graphite / 316

•Spiral Wound 316L / PTFE

•Spiral Wound 316L / Graphite

•Spiral Wound 321 / Graphite

•Spiral Wound Inconel /

Graphite

•Spiral Wound Titanium /

Graphite

•Welded Lips

STANDARD PAD GASKET RANGE

Fig. 025

All packing arrangements

use a lantern ring that:

•Provides better stem

piston guiding

•Avoids dead space in

body cavities

Typical Packing Materials:

•PTFE

•PTFE / Aramide Braid

•Carbon / Graphite Braid

•Graphite Braid

•PTFE / Aramide Braid + Graphite

•Lamellar + Expanded Graphite

•Pure Graphite

Live loaded packing

arrangement

minimizes valve

maintenance

Optional 1/4 inch NPTF available for leak

detection or inert gas injection to avoid

leakage to atmosphere by creating an

over pressure

Bottom ring material is

selected with a differential

hardness from the piston

to prevent piston damage

•PTFE

•Aramide / Nitrile

•Carbon / Aramide

•Laminated Graphite

•Laminated Graphite / 316

•Spiral Wound 316L / PTFE

•Spiral Wound 316L / Graphite

•Spiral Wound 321 / Graphite

•Spiral Wound Inconel / Graphite

•Spiral Wound Titanium / Graphite

•Perfluoroelastomer (Kalrez) O

Ring

PACKING DEFINITION

Valve Coding System

PPiston

DDisc

RRising Disc

AAccessories

445oBranch Angle

660oBranch Angle

990oBranch Angle

SStraight

$Special

BExtended Body

PExtended Plunger c

DDismountable Seat

$Special

V P 4 S B -

VVessel Reactor Valves

SSoft Seated

MM Seal

CM Control

DDual Seal

RM Ring Seal

JJacketed

- Non-Jacketed

Strahman has two Soft Seal Piston Valve styles available:

•Figure 020 for smaller and utilize a rising stem design.

•Figure 025 for large sizes use a non-rising stems to minimize overall length.

BODY ARRANGEMENTS

Strahman Bottom Disc design is a vessel outlet valve. When opening, the disc retracts completely

into the valve body. This provides an unrestricted full flow. In combination with maximized port sizes, this

design offers maximum flow capacity.

Strahman valves are available in a choice of options including material of construction, seat

arrangements, sealing systems to atmosphere, actuators and customized or standard connections to

piping. Other specific features are full jacketing, vacuum package and dead space free connections

to vessels.

Typical applications include the draining of viscous products especially in combination with low pres-

sure and/or vacuum processes.

Fig. 020 Fig. 025

•Welded Lips

•Metallic O Ring Helicoflex

Gasket Aluminium/316

•Metallic O Ring Helicoflex

Gasket Nickel/Nimonic 90

•316L RTJ

•Nitrile O Ring

•EPDM O Ring

•Silicone O Ring

•Fluorocarbon (Viton) O Ring

•Silicone FEP Jacketed O

Ring

STANDARD BODY GASKET RANGE

•PTFE

•Aramide / Nitrile

•Carbon / Aramide

•Laminated Graphite

•Laminated Graphite / 316

•Spiral Wound 316L / PTFE

•Spiral Wound 316L / Graphite

•Spiral Wound 321 / Graphite

•Spiral Wound Inconel /

Graphite

•Spiral Wound Titanium /

Graphite

•Welded Lips

STANDARD PAD GASKET RANGE

Fig. 025

SERIES VL, CUSTOM MADE RANGE

PACKING DEFINITION

This manual suits for next models

1

Table of contents

Other Strahman Control Unit manuals

Popular Control Unit manuals by other brands

Armstrong

Armstrong 3750 Installation and operating instructions

GSS

GSS PHDQ 1000 ASI DF Assembly instructions

Spirax Sarco

Spirax Sarco DCV1 Installation and maintenance instructions

JM Concept

JM Concept EOLIS 3000 Series user manual

AERMEC

AERMEC MODUCONTROL Usage manual

Grundig

Grundig GSS SID 162 A Assembly instruction