The builder or council is to ensure the existing house or structure is of a suitable

structural integrity and complies with all the relevant Australian Building Codes and

Standards. For more information regarding the suitability of the house structure

to accommodate the Allure Louvre Patio, consult a structural engineer or a building

authority.It is the builder’s responsibility to ensure that the existing house roof structure

is strengthened correctly.

Rafter Strengthening & Fixing

Determine the number of rafters that need to be strengthened and their location

relative to the unit.You will have to lift some roof tiles or roof sheets to discover the

rafter positions and spacings.The number of rafters to be strengthened is determined

by the builder.

Note: It is the builder’s responsibility to ensure the existing rafters are adequately

reinforced and strengthened to accommodate any additional attached structure. The

reinforcing method must be approved by the appropriate council or engineer.

Fixing Rafter Strengthening Brackets

The adjustable rafter strengthening bracket allows for an adjustment of pitch in the

range of 15 to 30 degrees. The distance the bracket extends past the fascia is also

adjustable to allow for standard gutters with a width of up to 200mm.

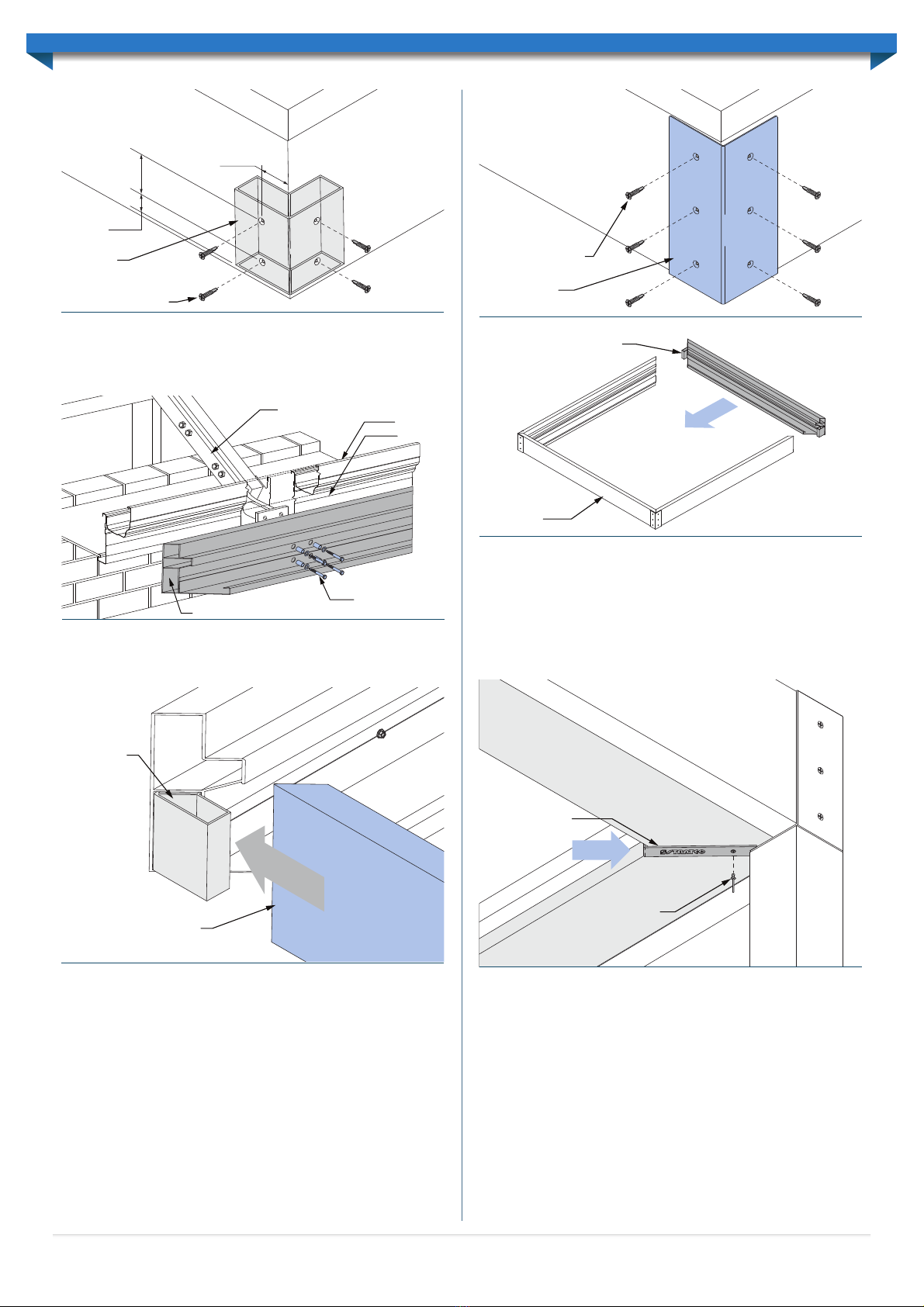

Initially the bracket T piece should be fixed to the bracket arm with two M12 cup head

bolts (hand tighten only). A spring washer is to be located between the standard M12

washer and nut (Figure 1.0). Mark the position of the bracket on the fascia and notch

a rectangular hole in the fascia allowing the bracket to be fed through the front of the

fascia. The hole may need to be enlarged slightly if the M12 cup head bolts interfere

with the fascia.

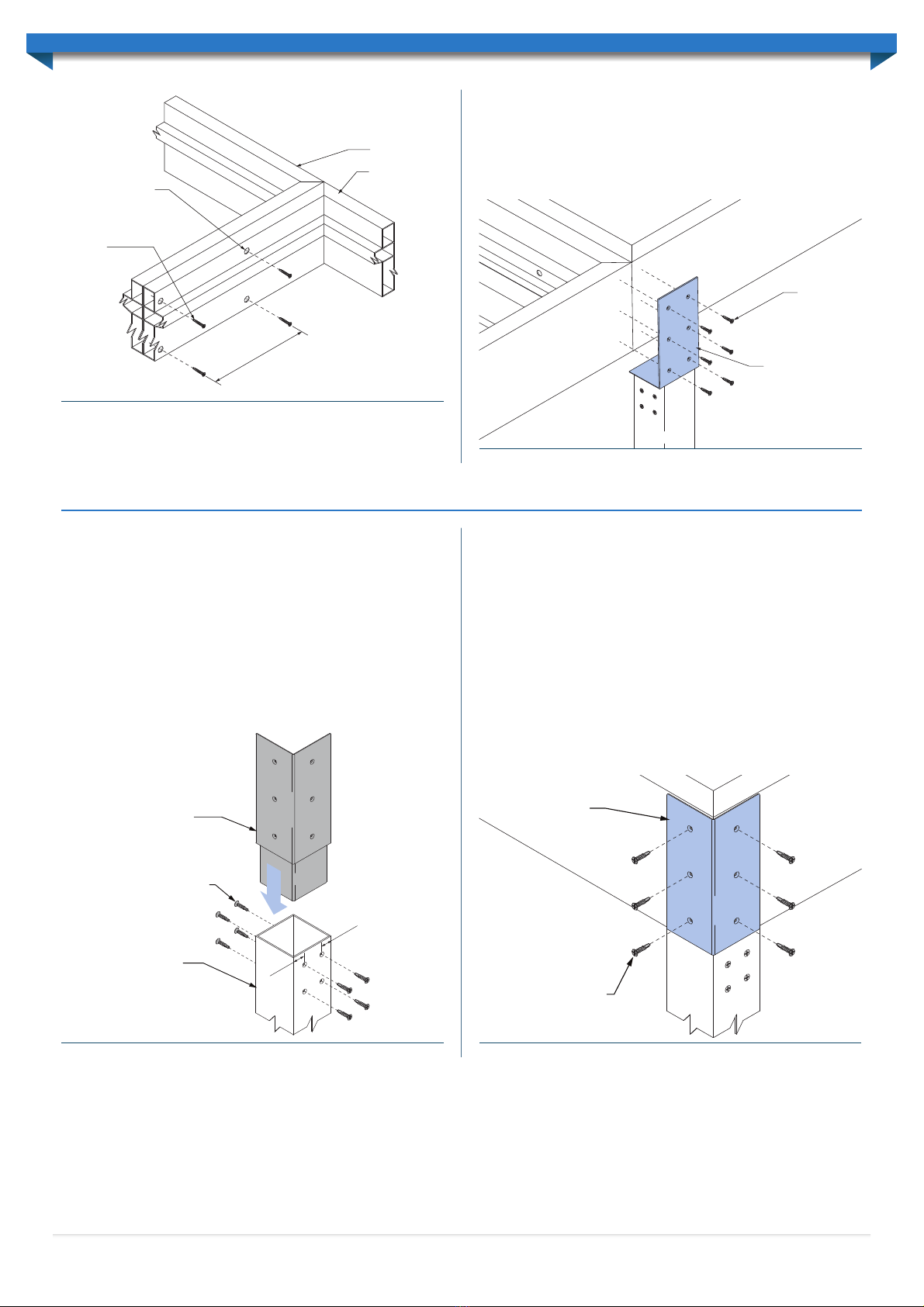

Insert the bracket through the fascia and fix to the house rafter using M12 hex head

bolts through the existing holes in the bracket.Adjust the T piece so it is horizontal and

has the appropriate extension past the fascia to allow for fixing of the attachment beam.

Tighten the T piece connection bolts to a minimum of 35Nm torque.

Fix the bracket as close to the base of the gutter as possible.The recommended distance

is 10mm from the lowest end of the gutter (Figure 1.1).

Fasten the Allure attachment beam to the rafter strengthening brackets through each

hole in the attachment plate. Fix using M12 bolts, washers, & spacers as per ‘Fascia Beam

Attachment’ details on page 5.

Wall Attachment

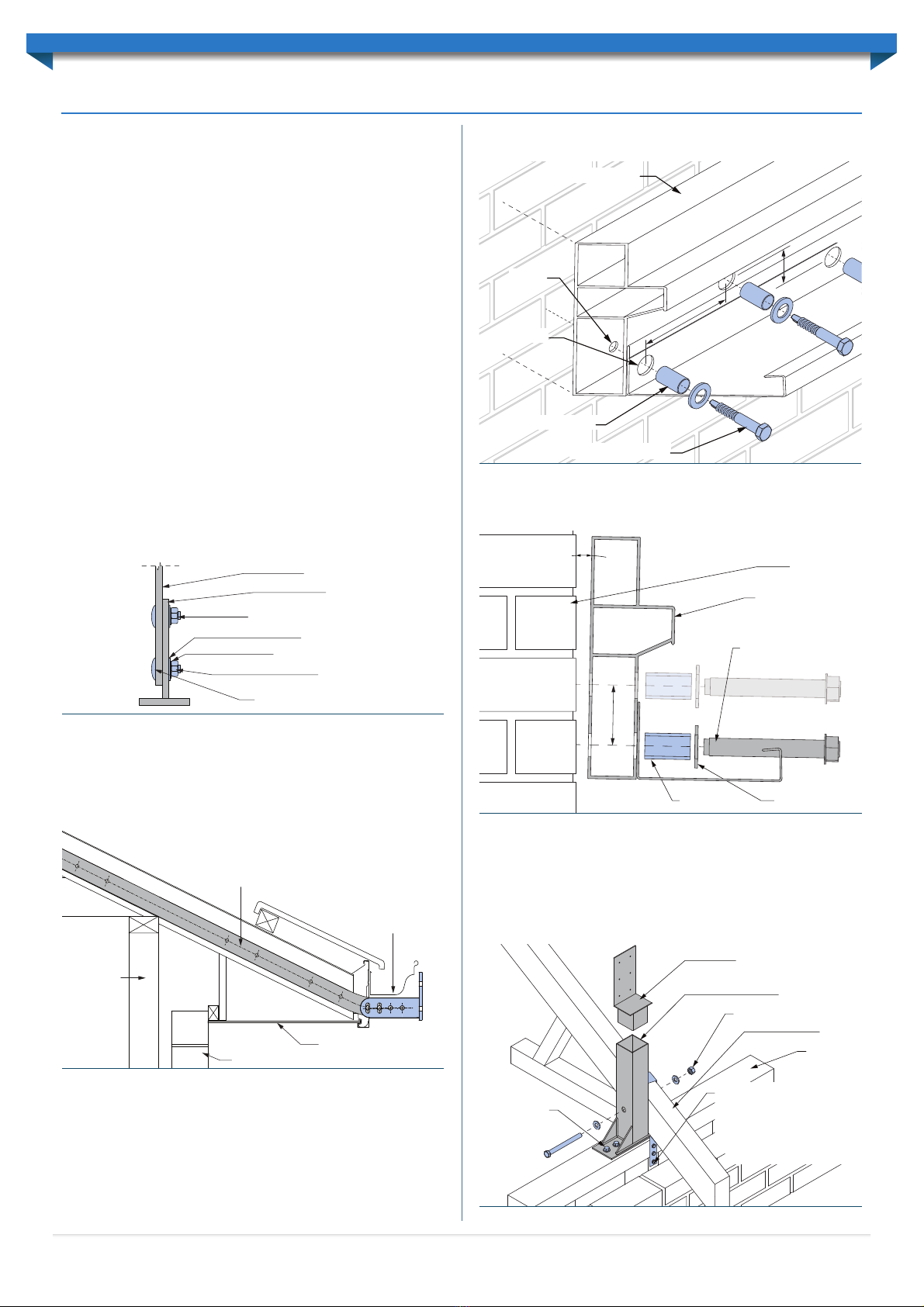

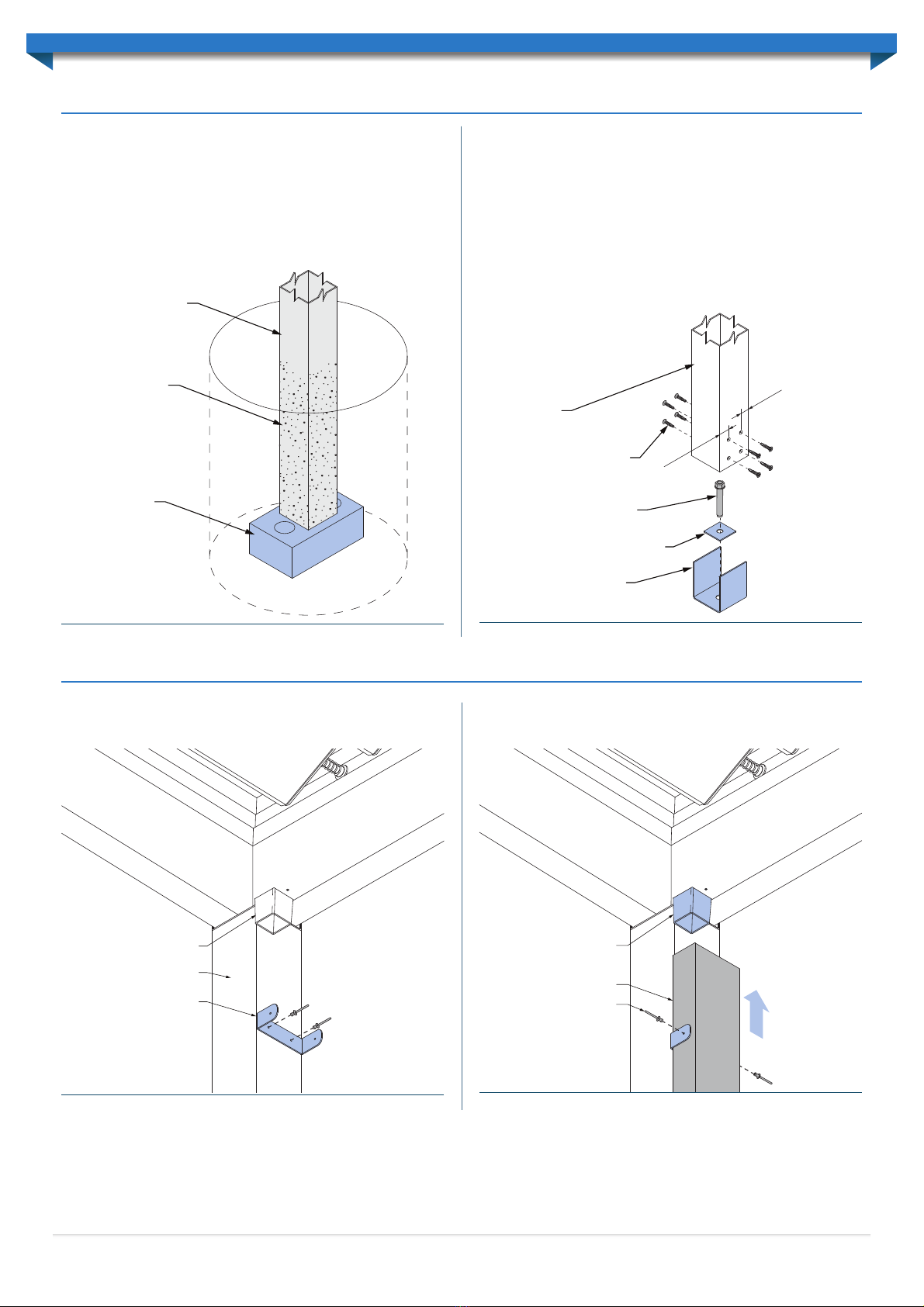

When a unit is attached directly to a wall the attachment beam must be fixed to the

wall using M10 Masonry anchors. Fasteners should be spaced at a maximum of 500mm

centres along the beam with a ø16mm pilot hole created though the internal face of the

beam, and a ø12mm pilot hole through the external face (Figure 1.2).

Note: The attachment beam gutter must be fixed prior to erecting the attachment

beam. See ‘Beam Preparation’ for instructions.

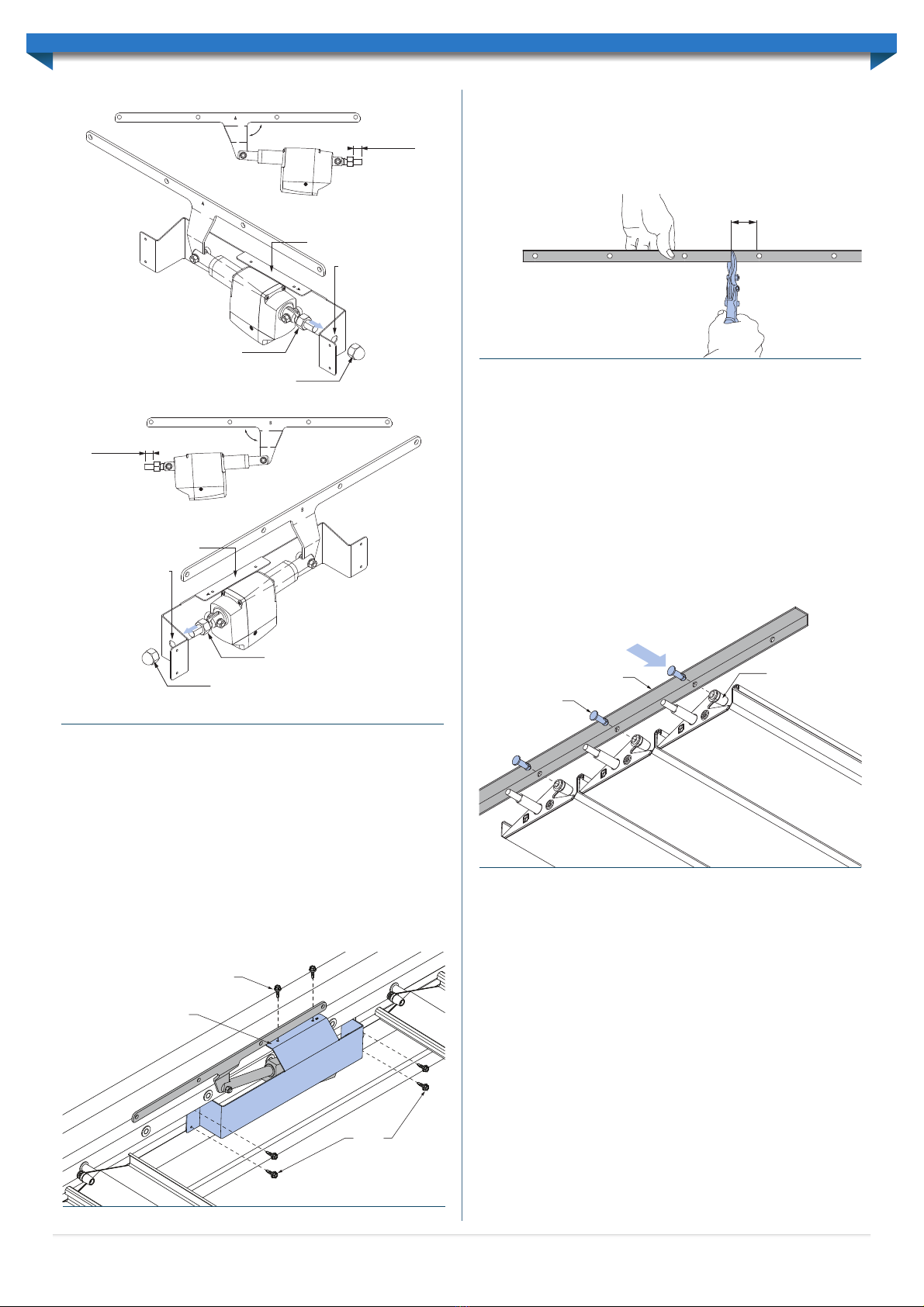

Every second fastener must be staggered at a vertical difference of approximately 85mm,

ensuring that each fastener is located centrally within runs of bricks (Figure 1.3).

Spacers must also be used with each masonry anchor (Figure 1.3).

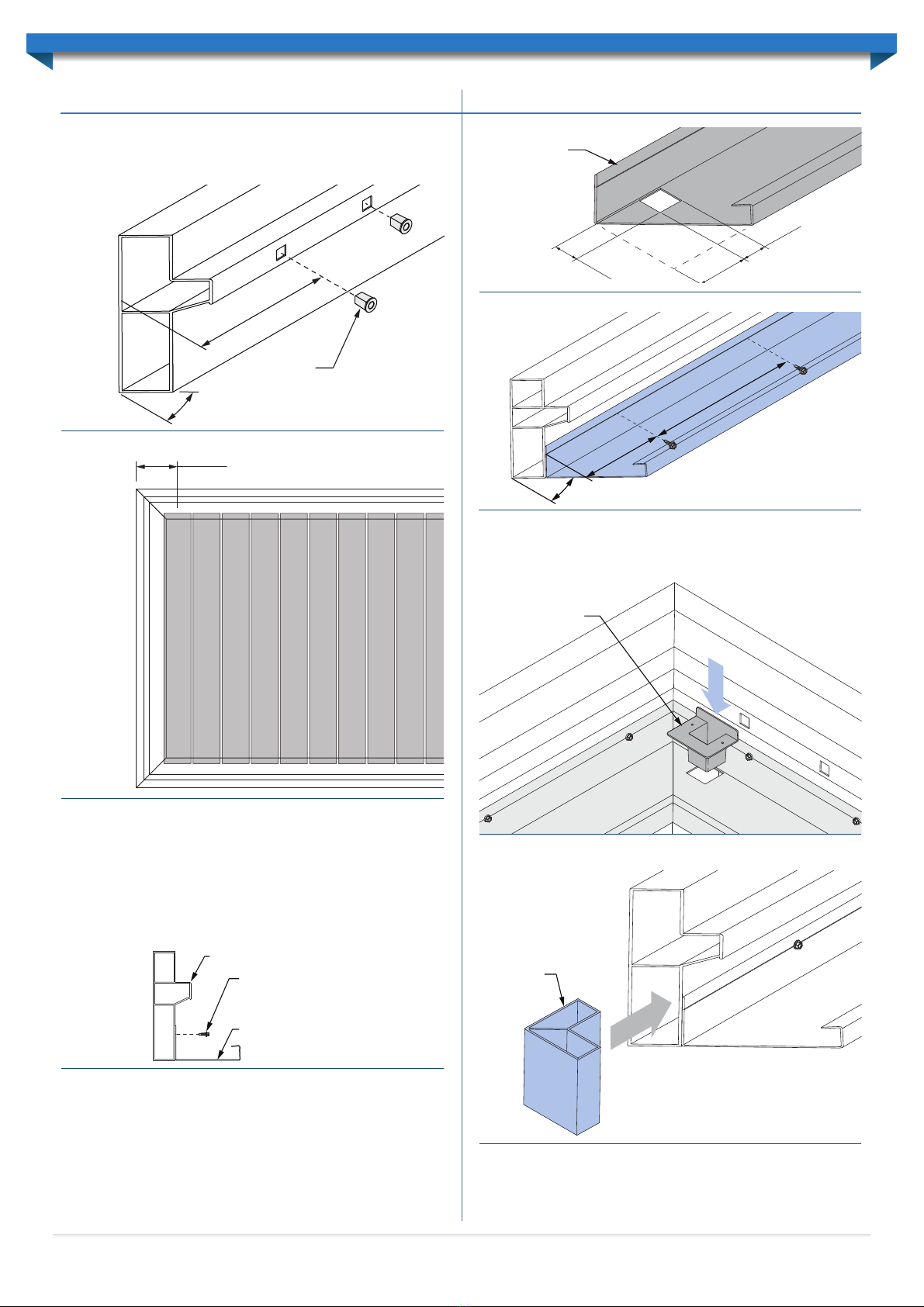

Flyover Attachment

The supplied Flyover Brackets must be secured to the structure atop the top plate and

against the rafter. Fix the Flyover Bracket to the top plate using two (2) M10 coach

screws a minimum 38mm into the top plate (Figure 1.4).The Flyover Bracket can then be

secured to the rafter using a single M12 bolt & lock nut though the centre of the rafter

(Figure 1.4). ø14mm pilot holes will need to be created through the Flyover Bracket and

rafter to accommodate the bolt.

Attachment Beam

M10 Masonry anchors

500mm

8

5mm

Beam Spacer

ø16mm

ø12mm

Figure 1.2

M10 Masonry Anchor

M10 WasherBeam Spacer

Attachment Beam

Brickwork

Approx.

85mm

1°

Figure 1.3

Top Plate

M10 x 38

Coach Screws

Rafter

M12 Bolt / Washers / Nut

Flyover Bracket

Post-Beam Inline Bracket

(refer Post Installation

32 x 1.2mm Galv metal strap

looped over truss and fixed

to stud wall with 3 M6 coach

screws each end into wallstud

and truss top chord/rafter.

(50mm min. embedment)

Figure 1.4

4

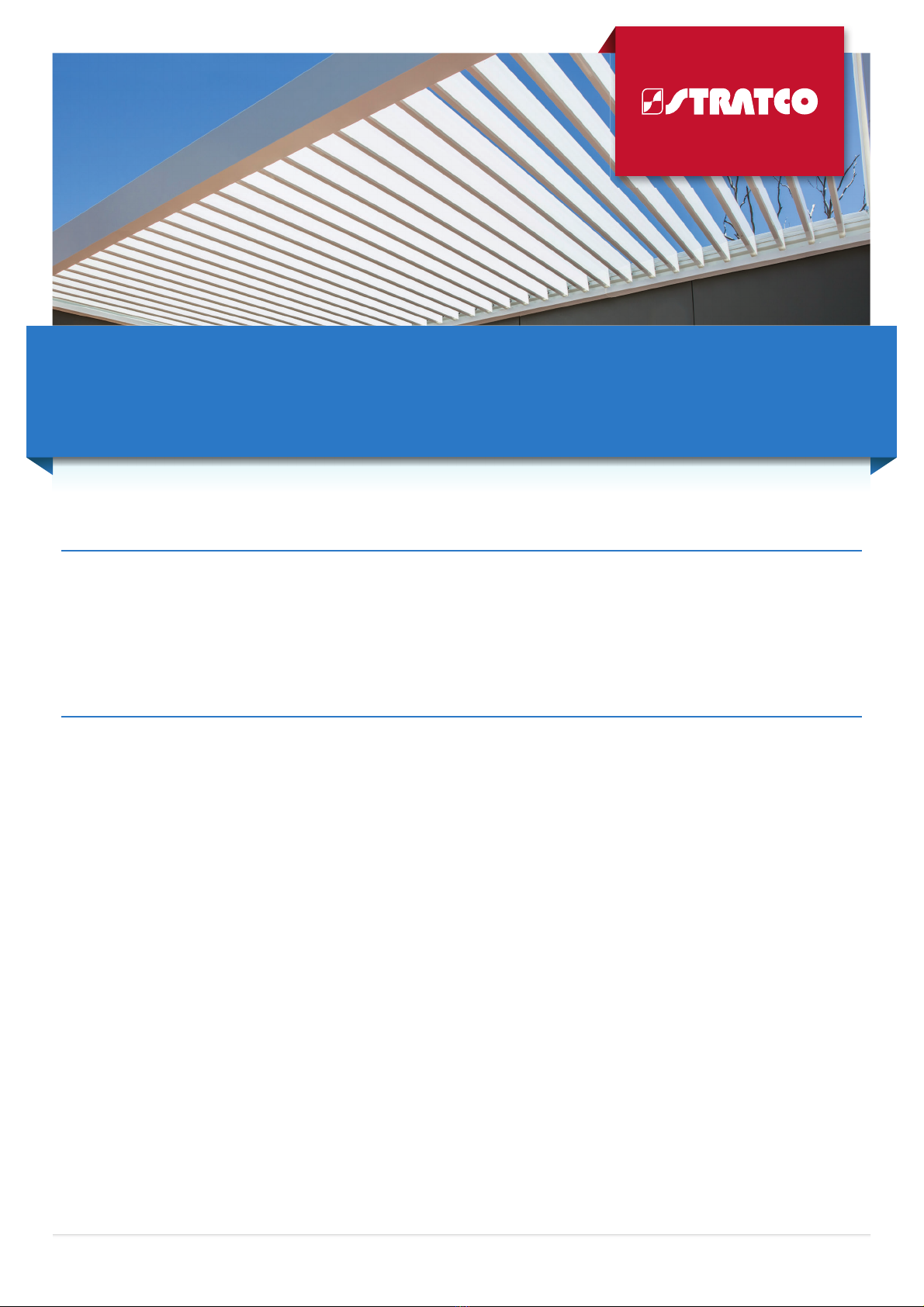

Bracket arm

M12x40 Cup head bolt

T-piece

Tighten to 35Nm torque

M12 Spring washer

M12 Nut

M12 Washer

Figure 1.0

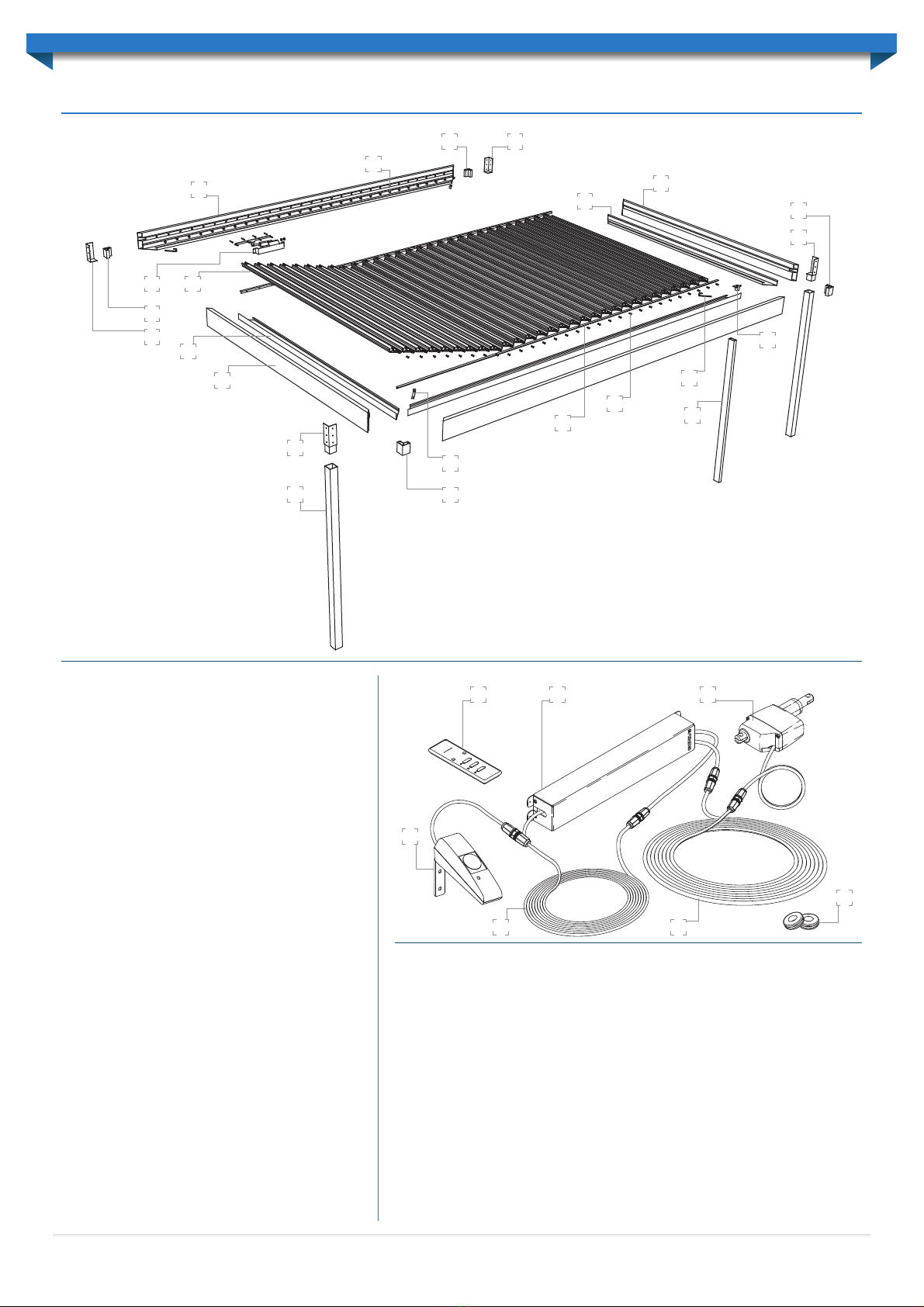

Stud wall

Gutter

Eaves overhang

Brick work

Rafter strengthening bracket attached

to rafter with six M12 hex head bolts

Figure 1.1

ATTACHING TO AN EXISTING STRUCTURE