4.10 20141208( )

vii

TABLE OF CONTENTS

DISCLAIMER .........................................................................................................................................iii

SAFETY WARNINGS AND PRECAUTIONS ....................................................................................iii

Electrical .................................................................................................................................................iii

Avoiding Electrical Shock and Fire-related Injury.............................................................................iii

Electromagnetic Interference ...............................................................................................................iv

Operational .............................................................................................................................................iv

Other ........................................................................................................................................................ v

Handling Micropipettes.......................................................................................................................... v

1. GENERAL INFORMATION..............................................................................................................1

1.1 Introduction.......................................................................................................................................1

1.2 About This Manual...........................................................................................................................1

1.3 Technical Support.............................................................................................................................1

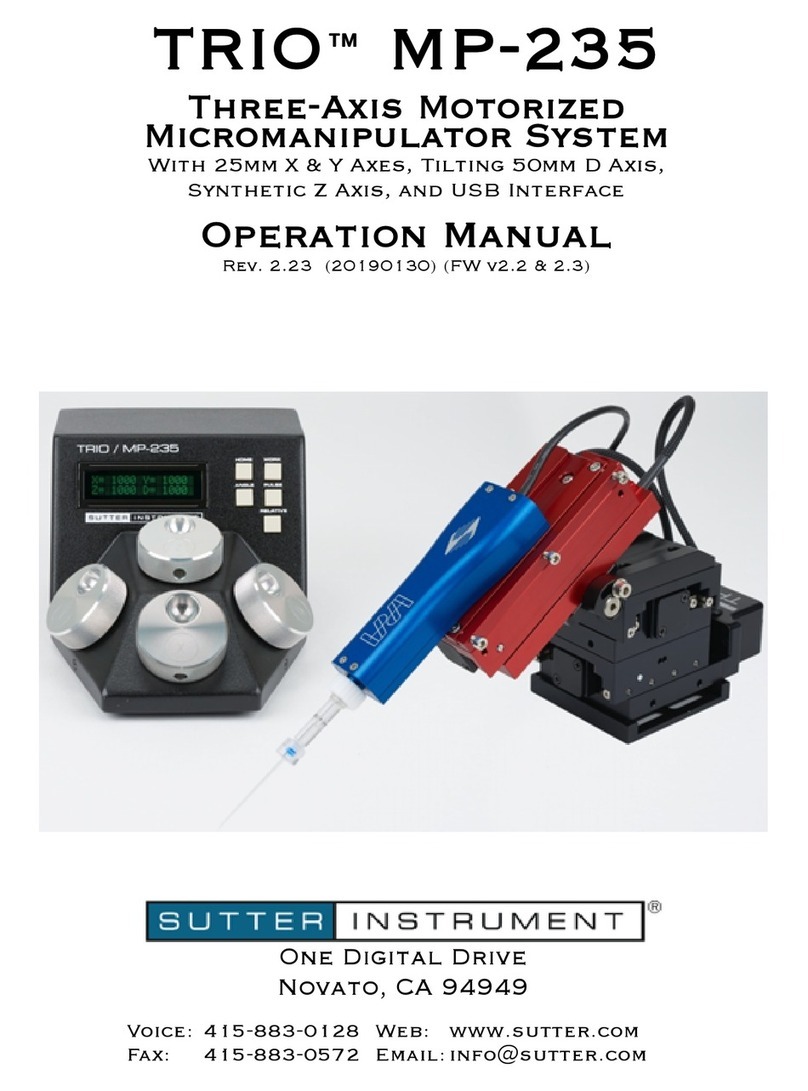

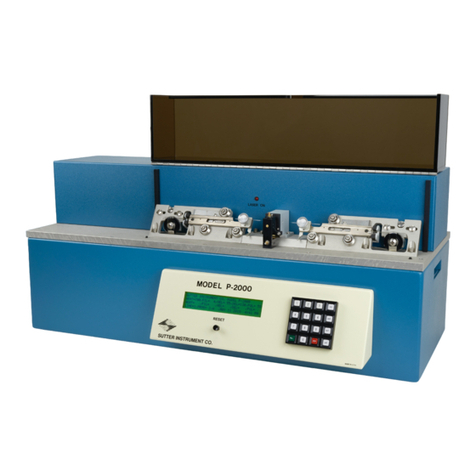

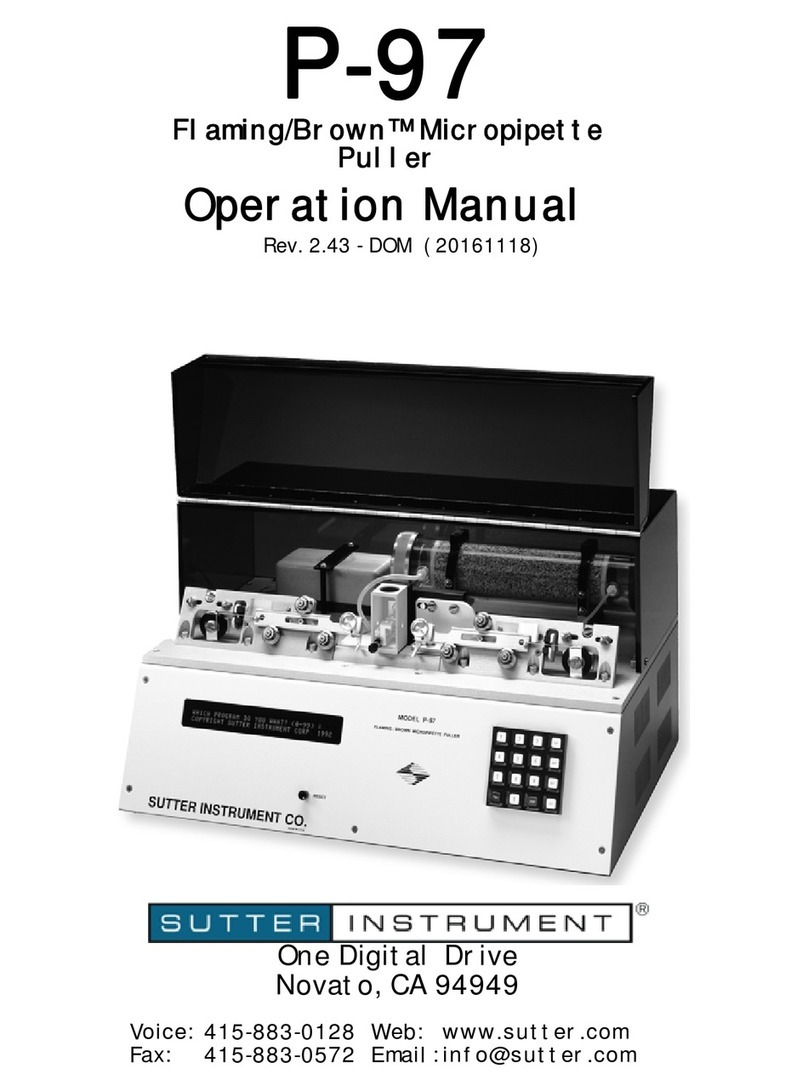

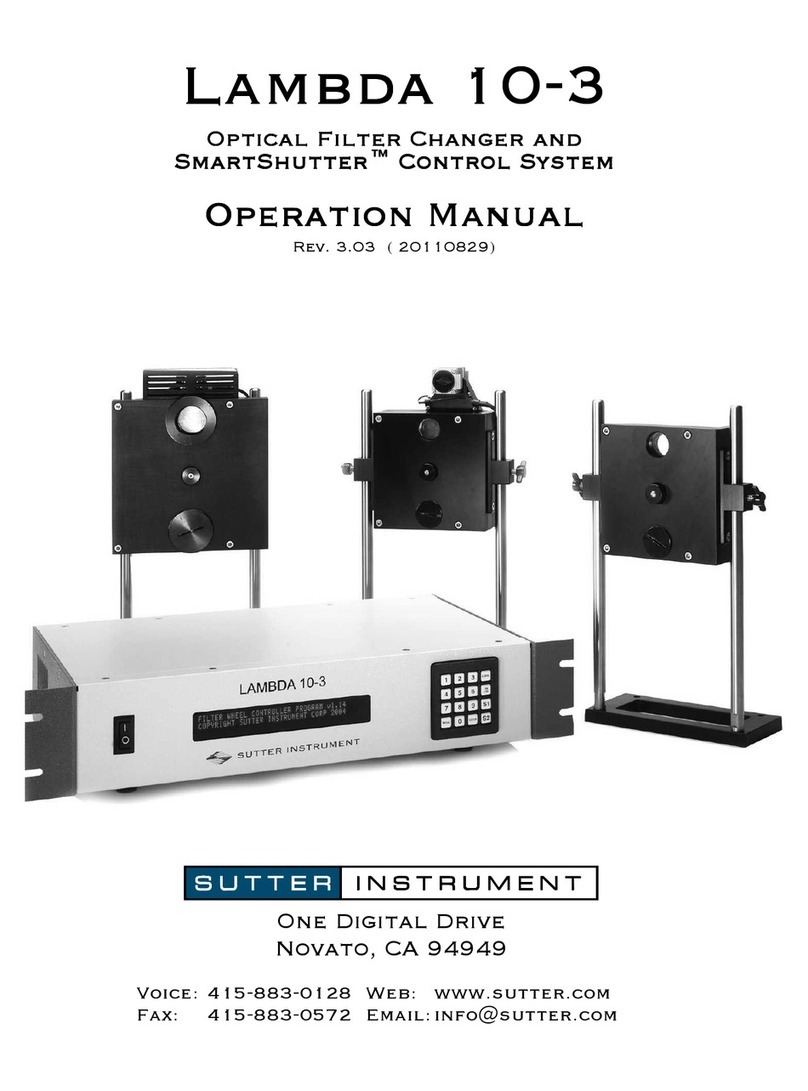

1.4 Product Description..........................................................................................................................1

1.4.1 Packing List ................................................................................................................................1

1.4.2 Joystick Controls and Features ................................................................................................2

1.4.2.1 X- and Y-Axis Control .........................................................................................................3

1.4.2.2 Y-Axis On/Off .......................................................................................................................4

1.4.2.3 Z-Axis Control ......................................................................................................................4

1.4.2.4 Joystick Declutch Mechanism............................................................................................4

1.4.2.5 Height Adjustment..............................................................................................................4

1.4.2.6 Joystick Tension Ring.........................................................................................................4

1.4.2.7 ‘Work’ Position ....................................................................................................................5

1.4.2.8 ‘Home’ Position ...................................................................................................................5

1.4.2.9 Speed.....................................................................................................................................5

1.4.2.10 ‘Z-floor’ ...............................................................................................................................5

1.4.2.11 Micropipette Holder Clamp..............................................................................................5

1.4.2.12 Swing Gate .........................................................................................................................6

1.4.3 Additional Features and Functions..........................................................................................6

1.4.3.1 ‘Setup’ ...................................................................................................................................6

1.4.3.2 Axis Polarity.........................................................................................................................7

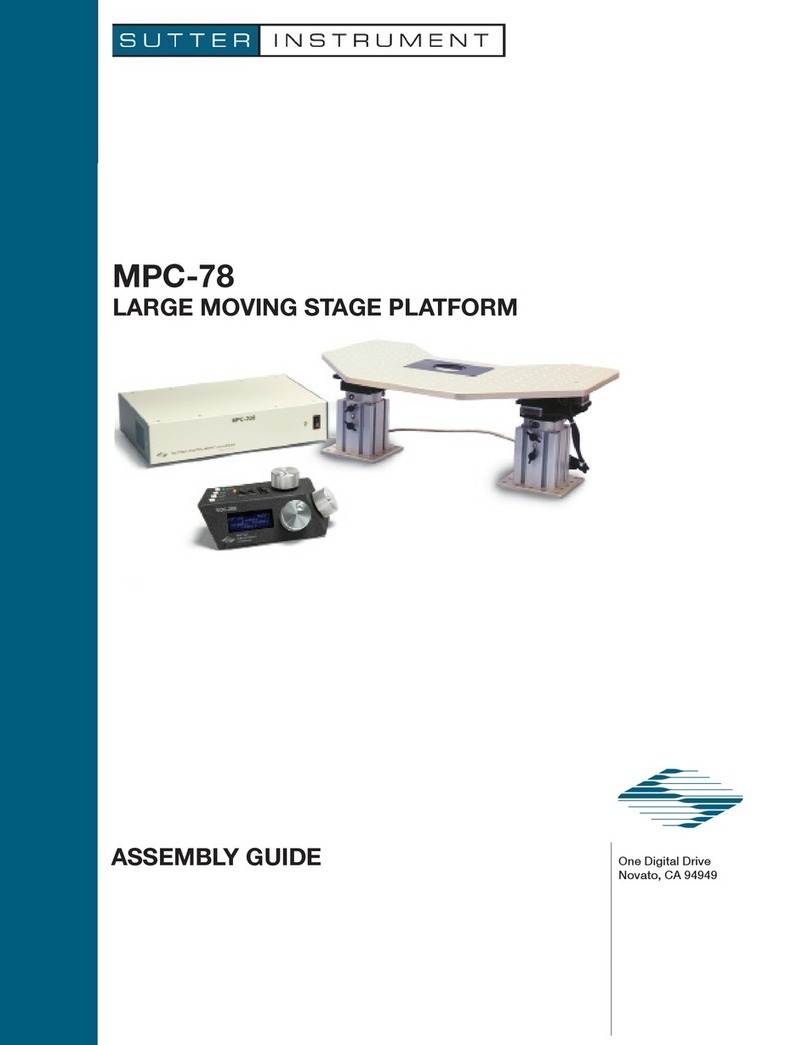

2. INSTALLATION .................................................................................................................................9

3. OPERATING INSTRUCTIONS......................................................................................................13

3.1 General.............................................................................................................................................13

3.1.1 Moving the Micropipette with the Joystick...........................................................................13

3.1.2 Centering the Micropipette with Respect to the Joystick....................................................13

3.1.3 Setting the Angle of Approach of the Micropipette..............................................................14

3.1.3.1 Microinjection Chamber ...................................................................................................14

3.1.3.2 Applications and Suggested Setups .................................................................................14

3.1.3.3 Micropipette Type .............................................................................................................16

3.1.3.4 Working Distance ..............................................................................................................16

3.1.3.5 Piezo Impact Drive ............................................................................................................16

3.1.4 Memorizing the ‘Work’ Position ............................................................................................16

3.1.5 Using the ‘Home’ Function.....................................................................................................16

XENOWORKS MICROMANIPULATOR SYSTEM (TOUCHDECLUTCH) OPERATION MANUAL – REV.