2 www.stryker.com

EN 7110-120-700 Rev-AB

Safety Directives

WARNINGS:

• Before using this equipment, or any

component compatible with this equipment,

read and understand the instructions for use.

Pay particular attention to safety information.

Become familiar with the equipment before

use.

• Only healthcare professionals trained and

experienced in the use of this medical device

should operate this equipment.

• The Stryker Universal Battery Charger

and Stryker F1 Universal Battery Charger

are limited to professional use within a

professional healthcare environment, excluding

near high frequency (HF) surgical equipment

and accessories. See the Electromagnetic

Compatibility section.

• Upon initial receipt and before each use,

operate the equipment and inspect each

component for damage. DO NOT use any

equipment if damage is apparent. See the

Inspection and Testing section for inspection

criteria.

• DO NOT use this equipment in areas in which

flammable anesthetics or flammable agents

are mixed with air, oxygen, or nitrous oxide.

• Take special precautions regarding

electromagnetic compatibility (EMC) when

using medical electrical equipment. Place this

equipment into service according to the EMC

information contained in this manual. Portable

and mobile radio frequency (RF) equipment

can affect the function of this equipment.

• ALWAYS use the appropriate battery charger to

charge battery packs.

• DO NOT operate the battery charger using a

voltage inconsistent with the rating on the back

of the unit.

• DO NOT operate the battery charger with a

damaged power cord or plug.

Introduction

This instructions for use manual contains

information intended to ensure the safe, effective,

and compliant use of your product. This manual is

intended for in-service trainers, physicians, nurses,

surgical technologists, and biomedical equipment

technicians. Keep and consult this reference

manual during the life of the product.

The following conventions are used in this manual:

• A WARNING highlights a safety-related issue.

ALWAYS comply with this information to

prevent patient and/or healthcare staff injury.

• A CAUTION highlights a product reliability

issue. ALWAYS comply with this information to

prevent product damage.

• A NOTE supplements and/or clarifies

procedural information.

For additional information, including safety

information, in-service training, or current literature,

contact your Stryker sales representative or call

Stryker customer service at 1-269-323-7700 or

1-800-253-3210. Outside the US, contact your

nearest Stryker subsidiary.

NOTE: The user and/or patient should report

any serious product-related incident to both the

manufacturer and the Competent Authority of the

European Member State where the user and/or

patient is established.

Trademarks not the property of Stryker

Corporation are the property of their respective

owners.

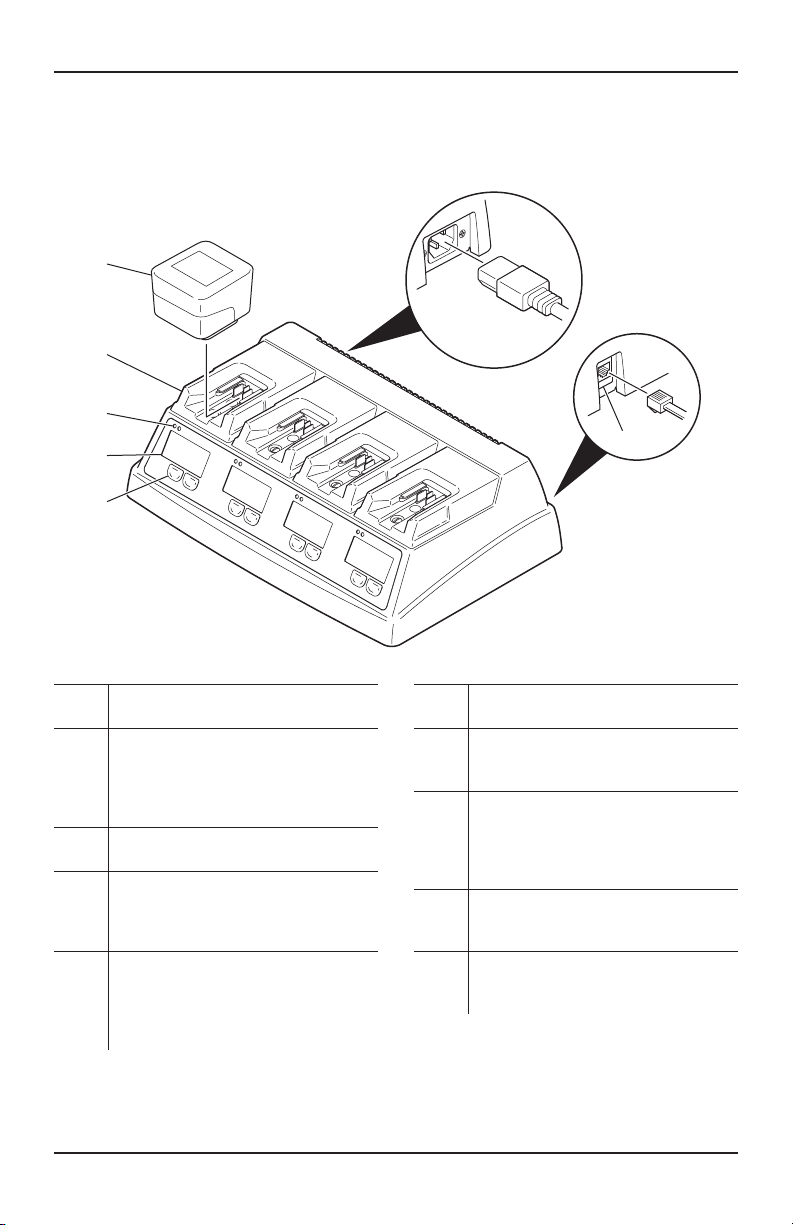

Indications For Use

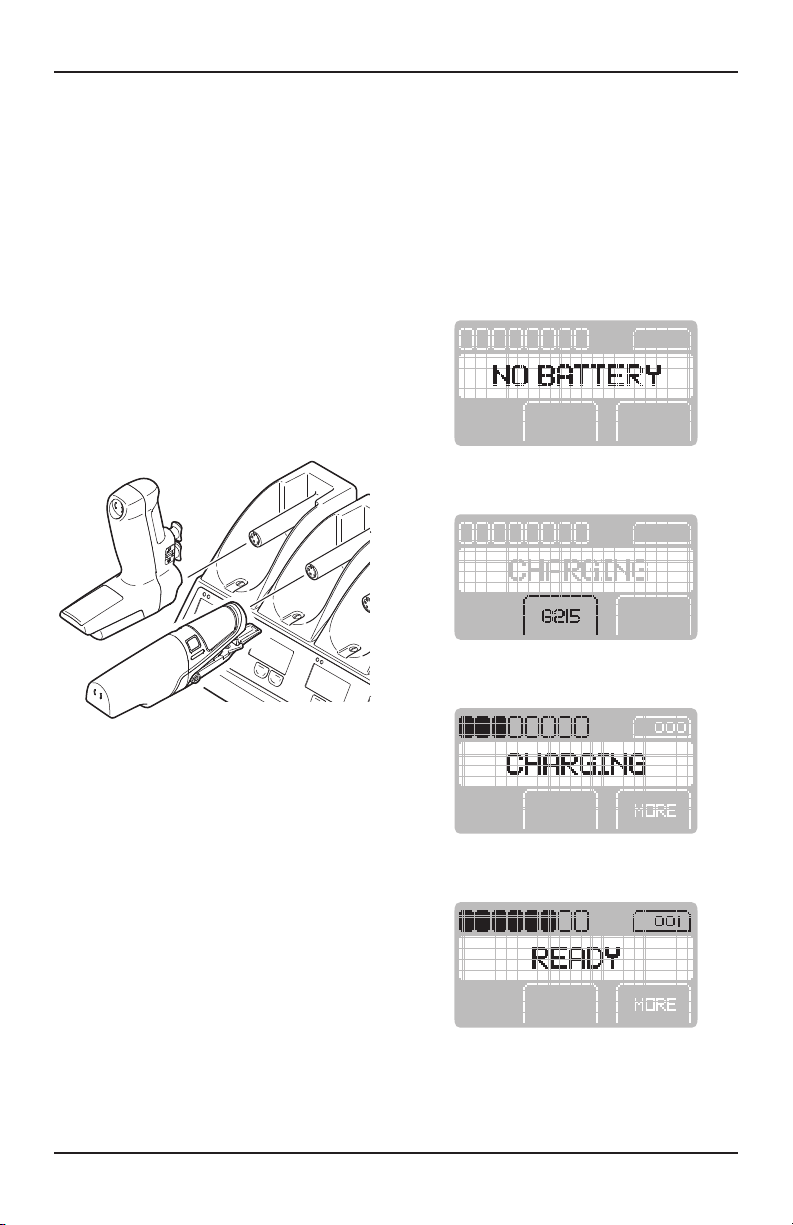

The Stryker Universal Battery Charger and Stryker

F1 Universal Battery Charger (battery chargers)

are four-station, modular battery chargers intended

to charge Stryker handpiece battery packs only.

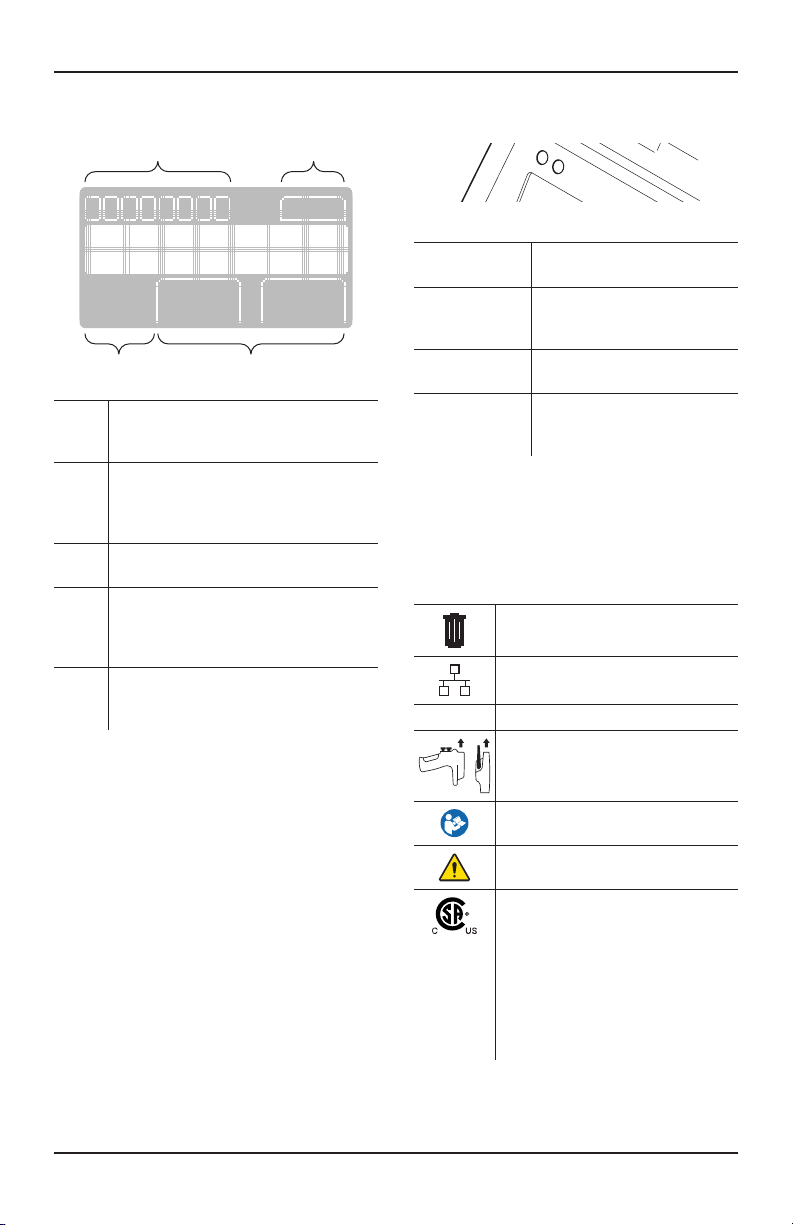

The battery chargers and battery packs are

specifically designed to work together so that the

battery charger’s information screen will provide

specific battery pack information.

Contraindications

None known.