General Description

The acid resistant hotplate consists of a

ceramic tile and heater assembly mounted in

a block of high grade PTFE. The hotplate is

controlled via a separate control unit which is

connected by a 2 metre lead (partly covered

with a PTFE sleeve). This allows the hotplate

to be located in a fume hood and the

controller outside, away from the corrosive

environment.

Controls

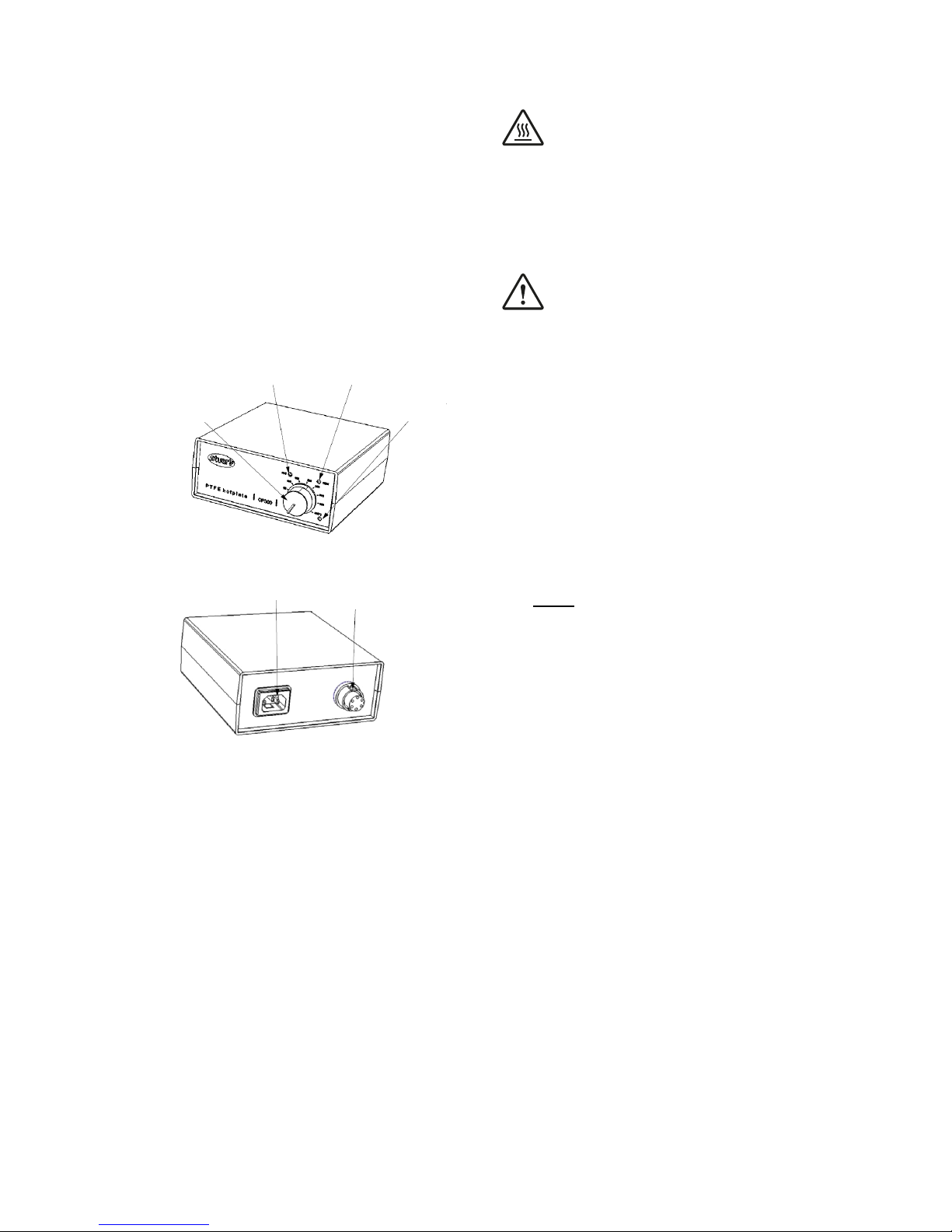

Front of control unit

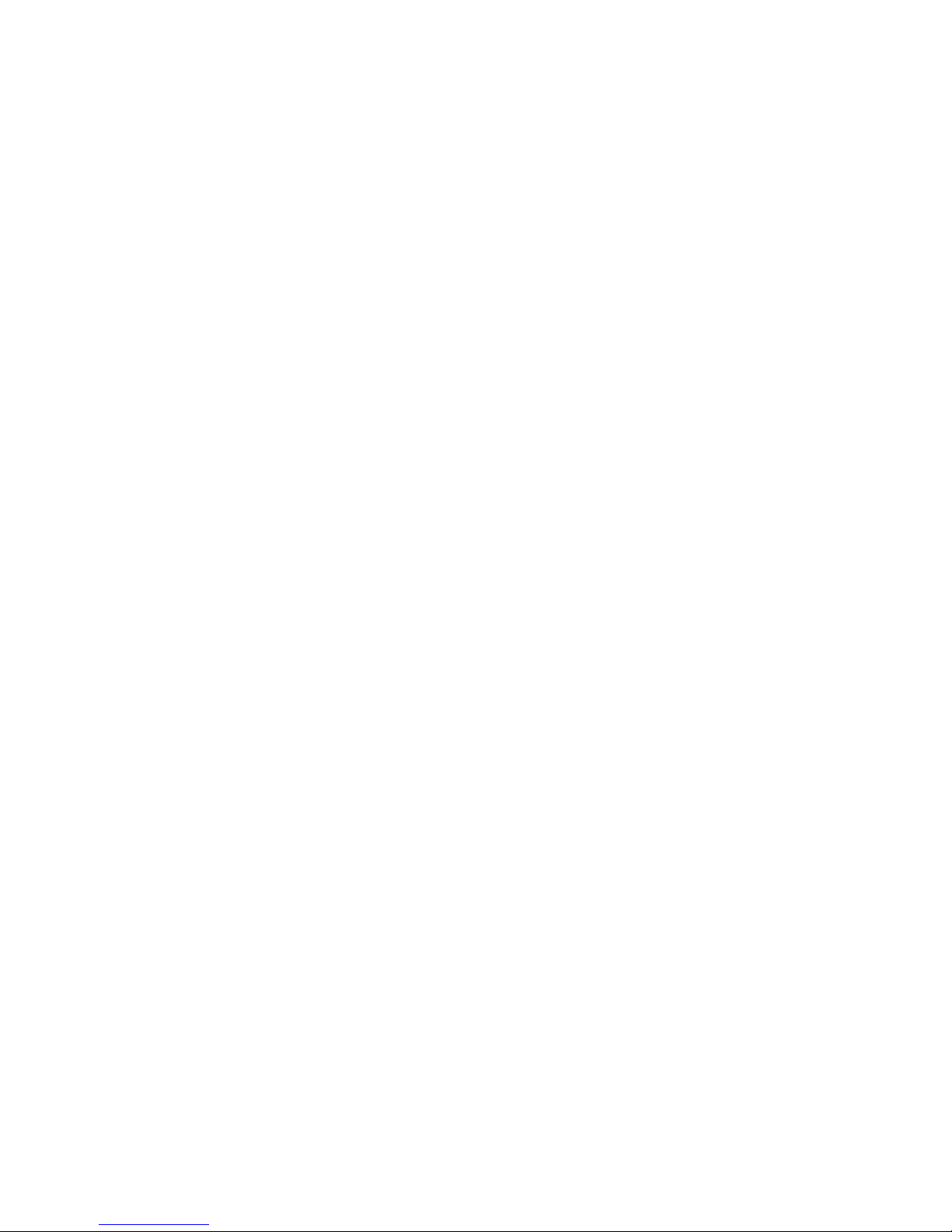

Rear of control unit

Rear of control unit

Operation

1. Position the hotplate unit on a firm level

surface away from any heat sensitive or

flammable material.

2. Plug the hotplate lead into the hotplate

inlet socket of the control unit.

3. Connect the control unit to the mains

supply (the green mains indicator light will

illuminate).

4. Position the control unit in the area it is to

be used (e.g. outside the fume hood).

5. Turn the control unit ON using the

temperature control knob and select the

temperature of the hotplate by using the

printed scale around the knob. The heater

on light will illuminate.

Maintenance

WARNING: Before attempting to

clean the unit, ensure that the

hotplate is cool and that the

control unit is disconnected from the

mains electricity supply.

The control unit should be cleaned using a

damp cloth and mild detergent solution. Do

not use harsh or abrasive cleaning agents.

The hotplate body can be cleaned with

almost any cleaning agent compatible with

PTFE. A damp cloth will remove most types

of contamination. For more difficult stains a

domestic cleaner is recommended.

Cleaning is made easier if spillages are

attended to promptly. In any case, spillages

of alkali, phosphoric acid and hydrofluoric

acid MUST be removed immediately as

these chemicals can attack and damage the

glass ceramic. Ensure the appropriate safety

precautions are observed.

NEVER immerse the hotplate unit in acid

or any other liquid. The unit has breather

holes in the base which will allow liquid

access that will destroy sensitive

components.

WARNING: A ceramic top which is

scratched, chipped, chemically etched or

damaged must not be used.

Temperature

control knob

Hot warning light Heater on light

Mains

indicator light

Temperature

control knob

Hot warning light Heater on light

Mains

indicator light

Main IEC inlet

socket Hotplate inlet

socket

Main IEC inlet

socket Hotplate inlet

socket

WARNING: When the hotplate surface

is hot (>50ºC) the hot warning light will

begin to flash red. This will continue to

flash while the plate temperature is above 50ºC

even after the hotplate has been switched off

(the control unit must remain connected to the

mains supply).