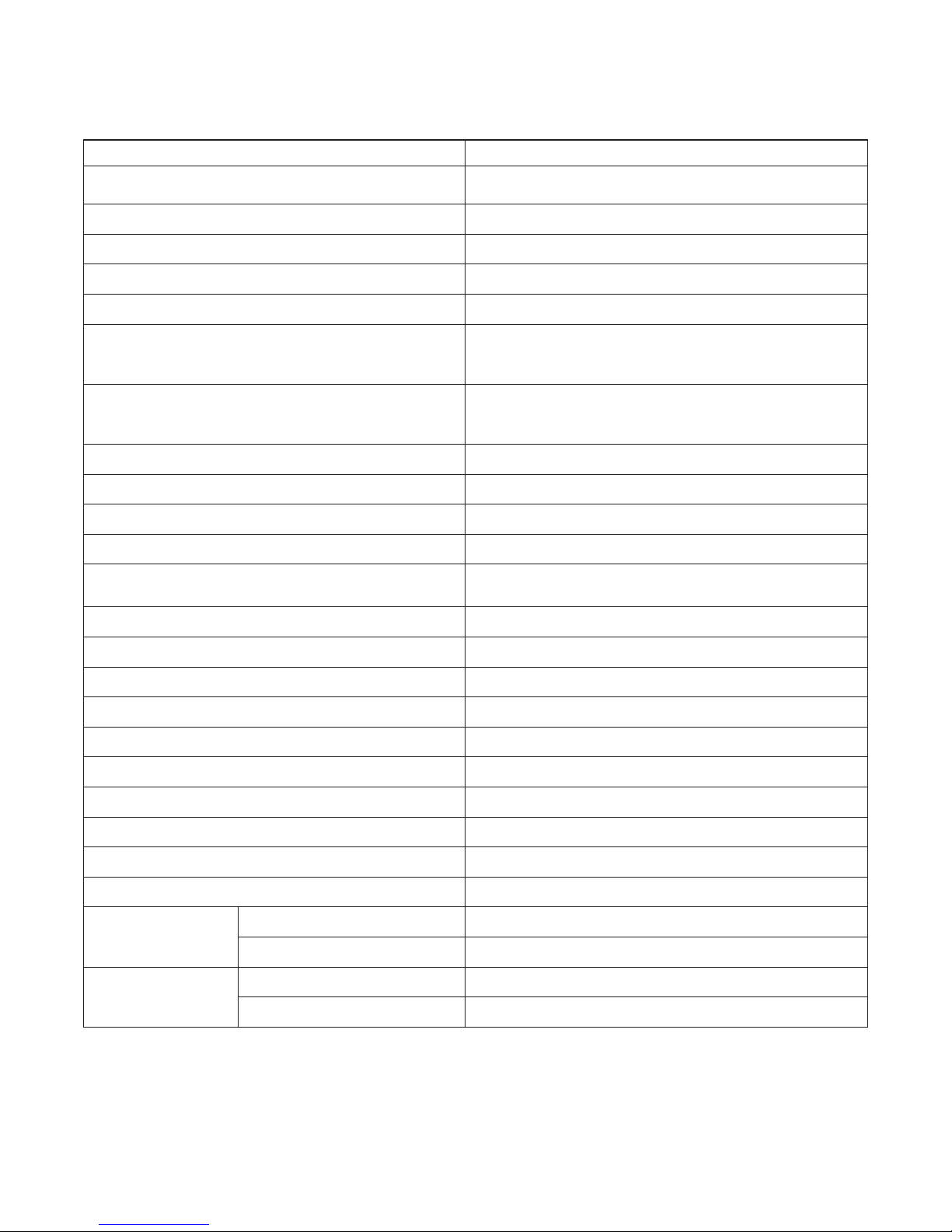

CONTENTS

Section Title Page

1. SPECIFICATIONS .............................................................1

2. FEATURES .................................................................2

3. DESCRIPTION OF FUEL SYSTEM.................................................3

4. DISASSEMBLY AND REASSEMBLY ...............................................4

4-1PREPARATIONSANDSUGGESTIONS...............................................4

4-2SPECIALTOOLS.................................................................4

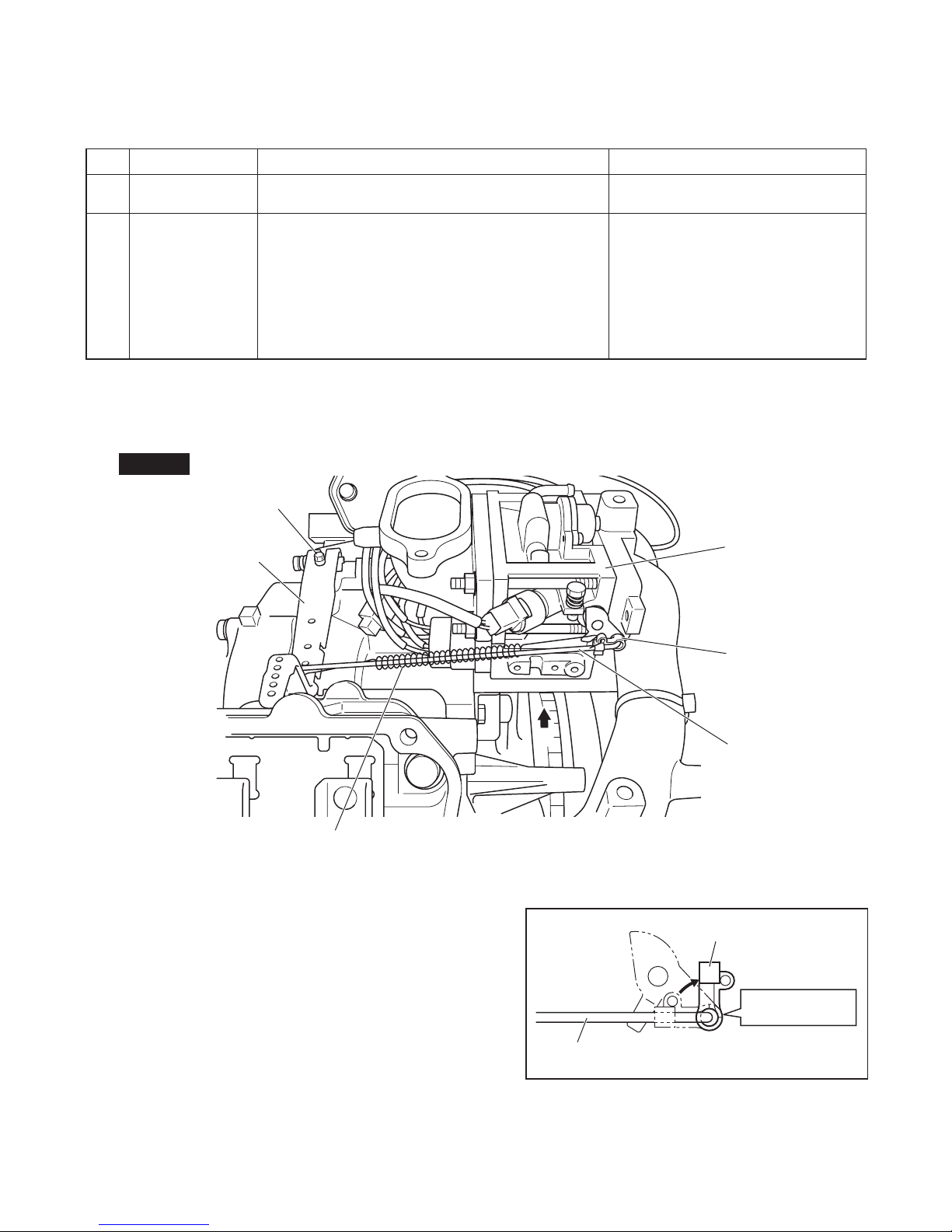

4-3DISASSEMBLYPROCEDURES(DIFFERENCE)........................................5

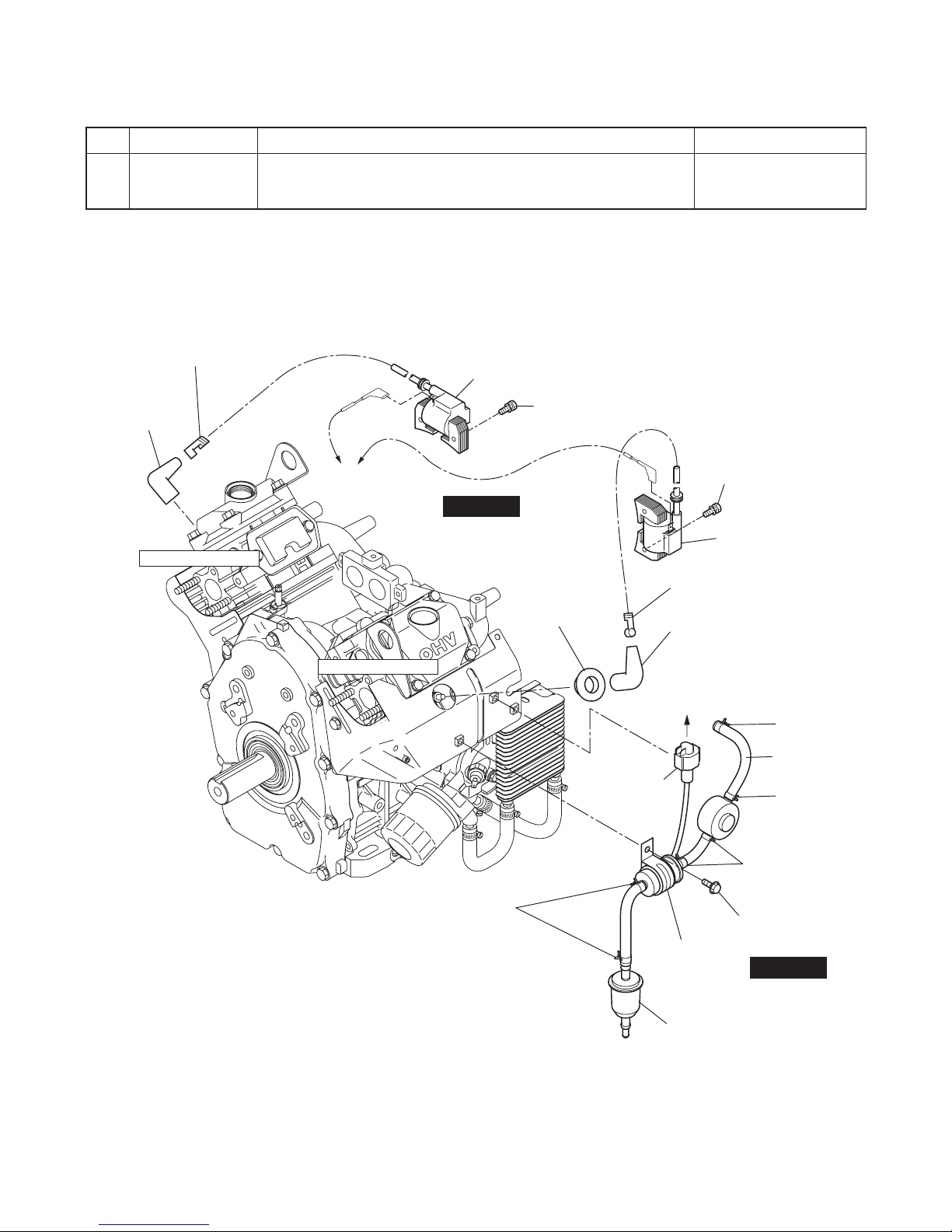

4-4 REASSEMBLY PROCEDURES (DIFFERENCE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4-5BREAK-INOPERATION..........................................................14

5. DIAGRAM..................................................................15

6. THROTTLE BODY............................................................16

6-1SPECIFICATIONS...............................................................16

6-2FUNCTIONSANDCONSTRUCTION................................................16

6-3FUELSYSTEMOUTLINE.........................................................17

6-4FUELSYSTEMTESTINGANDDIAGNOSIS..........................................17

7. INSTALLATION..............................................................18

7-1INSTALLING ...................................................................18

7-2VENTILATION .................................................................18

7-3EXHAUSTGASDISCHARGE .....................................................18

7-4FUELSYSTEM .................................................................19

7-5 POWER TRANSMISSION TO DRIVEN MACHINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

8. TROUBLESHOOTING .........................................................20

8-1NOENGINEOPERATION.........................................................20

8-2STARTINGDIFFICULTIES........................................................21

8-3INSUFFICIENTOUTPUT .........................................................22

8-4OVERHEAT....................................................................22

8-5ROUGHIDLING.................................................................23

8-6HIGHENGINEOILCONSUMPTION ................................................23

8-7HIGHFUELCONSUMPTION......................................................24

8-8DETONATION..................................................................24

8-9ENGINEMISFIRE...............................................................25

8-10DIAGNOSISCODE.............................................................26

9. MAINTENANCE AND STORAGE .................................................28

9-1DAILYMAINTENANCE...........................................................28

9-2PERIODICMAINTENANCESCHEDULE.............................................28

9-3SPARKARRESTER(OPTIONAL)...................................................30

9-4ENGINESTORAGE..............................................................31

PREFACE

This manual covers the service information, trouble shooting procedures and so on of

EH72 FI (Fuel injection) engine.

Careful observance of the instructions given herein will result in better, safer and faster

service work.

For more detailed instructions of disassembling and reassembling procedures, please

refer to the service manual for EH63, 64, 65 and 72.