-

7

-

3. FEATURES

3-1 EXTREMELY SILENT - SOFTTONE QUALITY

EX engines are 2dBA quieter and softer in tone than other engines in the same class.

This quiet and soft tone is achieved by:

- A reduction in mechanical noise realized by employing sophisticated OHC system.

- Employment of an optimized capacity Rigid Muffler.

3-2 EXTREMELY EASY START - NO KICK-BACK

Reliable Starting and Less Pulling Force are achieved by:

- Sophisticated Mechanical Compression Release System as well as newly designed Combustion Chamber.

- EX engines start instantly even at minus (-) 10°C, without any perceptible kick-back.

3-3 EXTREMELY EASY MAINTENANCE

Extreme ease of maintenance is realized by:

- High Parts Commonality

simplifies maintenance & lowers repair cost due to fewer parts for service.

More than 90% of component parts are in common between more than two models, in such as Muffler,

Intake and Exhaust Valves,Valve Springs, etc.

Furthermore, more than 50% of component parts are in common among EX13, EX17 and EX21, in

such as Chain Guide, Air Cleaner, Ignition Coil, etc.

- Only with ordinary tools, routine maintenance, assembly and disassembly can be performed.

3-4 EXTREMELY ADVANCEDTECHNOLOGY

Extreme reliability and durability are achieved by:

- Heavy Duty Chain Driven OHC System

Oval type case-hardened steel links enhance performance and resist stretching, which result in extended

maintenance free operation.

- Completely New Main Bearing Cover’s Design

Flush-mounted main bearing cover with lower moment of deformation significantly increases reliability and

engine life.

- Superior Cooling and Lubrication System

Heat reduction is achieved by more efficient, larger and more numerous cooling fins on crankcase, cylinder

and mounting base, as well as by outstanding oil delivery system.

- Large Ball Bearings on both ends of crankshaft for maximum stability under demanding loads.

- Cast Iron Cylinder Liner resists wear

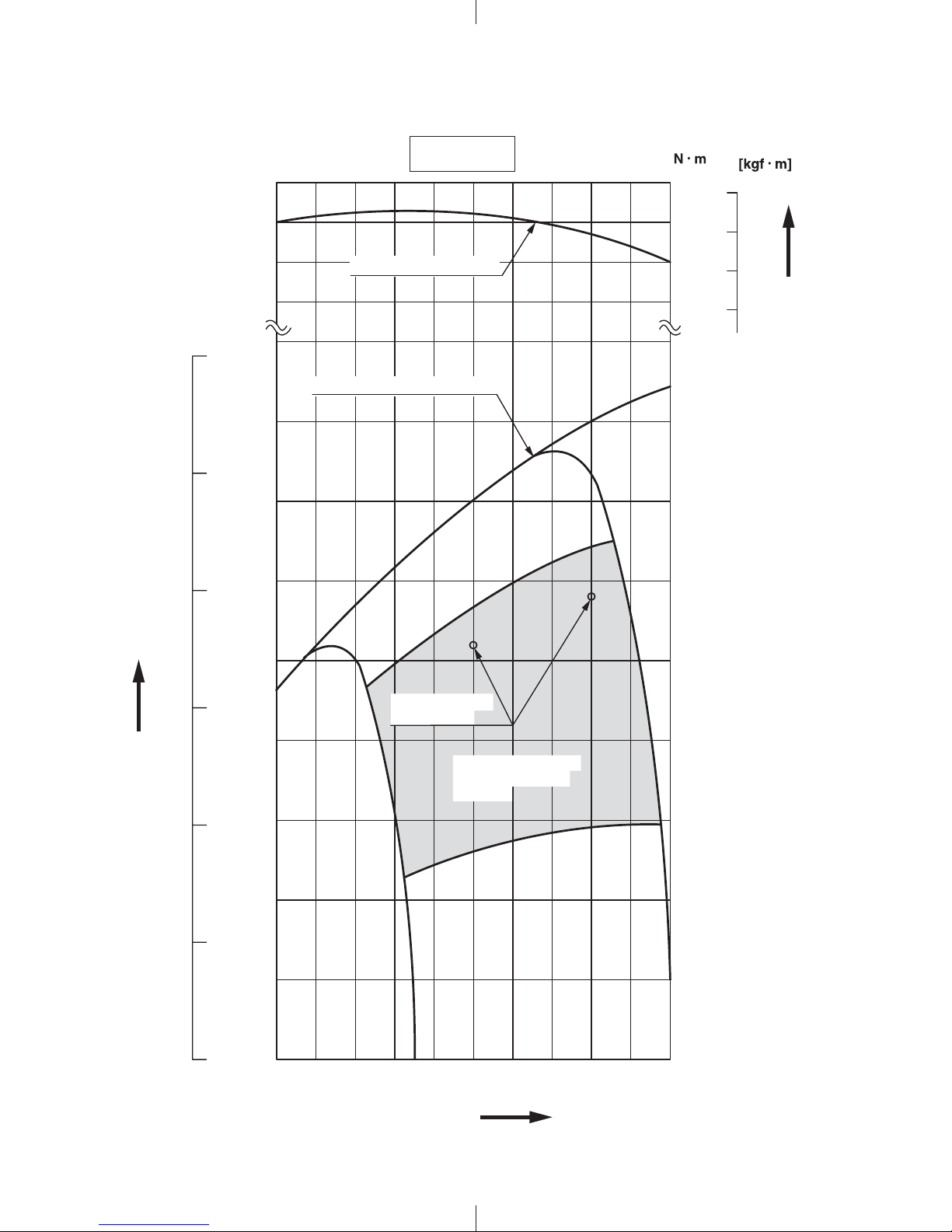

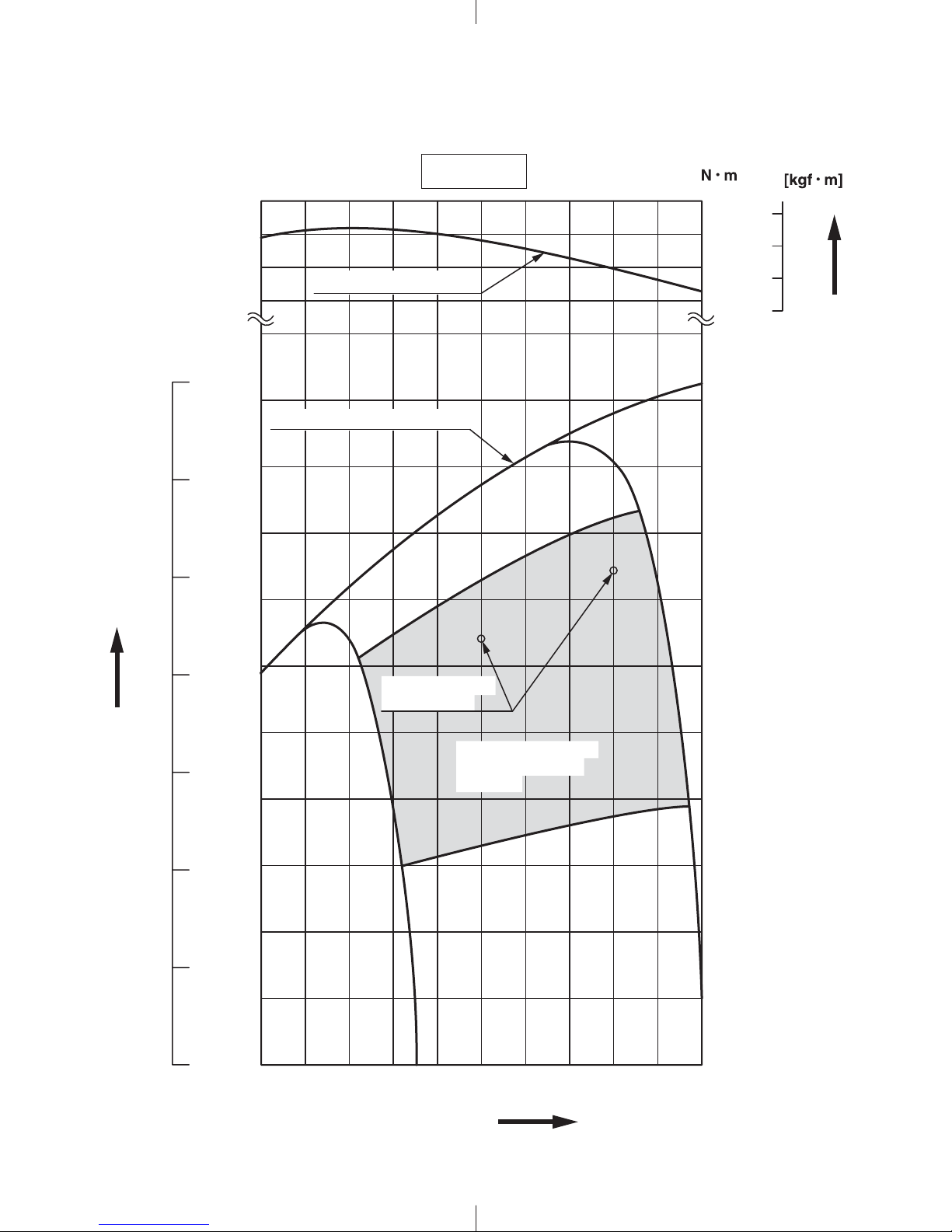

3-5 EXTREME POWER AND PERFORMANCE

Extremely Higher Power and Lower Fuel Consumption are realized by:

- High speed and homogeneous combustion achieved by sophisticated Pentroof Combustion Chamber which

includes Intake and ExhaustValves located at optimum angle.

- Straight Intake Port with minimal air flow resistance.

Environmentally friendly

EX engines comply with EPA Phase 2 and CARB Tier II Emission Regulations in the USA.

Extreme application compatibility

With four versatile models, existing slant-cylinder engines can be easily replaced.