GB

Operating Instructions

Please keep carefully for future use

Diaphragm-/

Piston Pressure Switch

with connector

Series 0184

Series 0185

Installation and commissioning must be carried out

in accordance with these Operating Instructions

and by authorized, qualified personnel only.

SUCO Robert Scheuffele GmbH & Co. KG

Keplerstraße 12-14

74321 Bietigheim-Bissingen, Germany

Phone: + 49-7142-597- 0

Fax: + 49-7142-980151

e-Mail: info@suco.de

www.suco.de

Operation and use

The series 0184/0185 switch opens or closes an electrical circuit when a certain

(adjustable) pressure is reached. A diaphragm or piston is moved by the increase

in pressure. The amount of diaphragm deflection or piston travel depends on

the force of the pressure applied and the (adjustable) spring tension. At a prede -

termined deflection of the diaphragm or movement of the piston, a microswitch

is actuated which opens or closes the electrical contacts (changeover).

The pressure switch monitors a preset pressure.

Conditions governing the use of the product

The following general instructions are to be observed at all times to ensure the

correct, safe use of the pressure switch:

• Observe without fail the warning notices and other instructions laid

down in the operating instructions.

• Observetheapplicablesafetyregulationslaiddownbytheregulatory

bodies in the country of use.

• Use the switch only for monitoring fluid and gaseous medias.

• Donotexceedthespeciedlimitsfore.g.pressures,forces,momentsor

temperatures under any circumstances.

• Give due consideration to the prevailing ambient conditions

(temperature, atmospheric humidity, atmospheric pressure, etc.).

• Never expose the pressure switch to severe side impacts or vibrations.

• Usetheproductonlyinitsoriginalcondition.Donotcarryoutany

unauthorized modifications.

• Remove all items providing protection in transit such as foils,

caps or cartons.

• Disposaloftheabove-namedmaterialsinrecyclingcontainersis

permitted.

Operating conditions

Media temperatures other than room temperature (20 °C):

•The effects of extreme temperatures (relative to room temperature) can

lead to pronounced variations in the switching point or the failure of the

pressure switch.

Type of protection IP65:

Type testing does not apply to all ambient conditions without limitations.

The user is responsible for verifying that the plug-and-socket connection com-

plies with the specified rules and regulations of CE, or whether it may be used

for specialized purposes other than those intended by us.

Use with oxygen:

Diaphragm Pressure Switch:

If oxygen is used, the applicable accident prevention regulations must be

observed. In addition, we recommend a maximum operating pressure of 10

bar, which should not be exceeded.

Piston Pressure Switch:

Piston Pressure Switches are not suitable for gaseous media, particulary

oxygen.

Protection against overpressure:

The static overpressure safety is included in the technical data.

The overpressure safety corresponds to the hydraulic, pneumatic part of the

pressure switch. The dynamic rating of the overpressure safety is smaller than

30 to 50%.

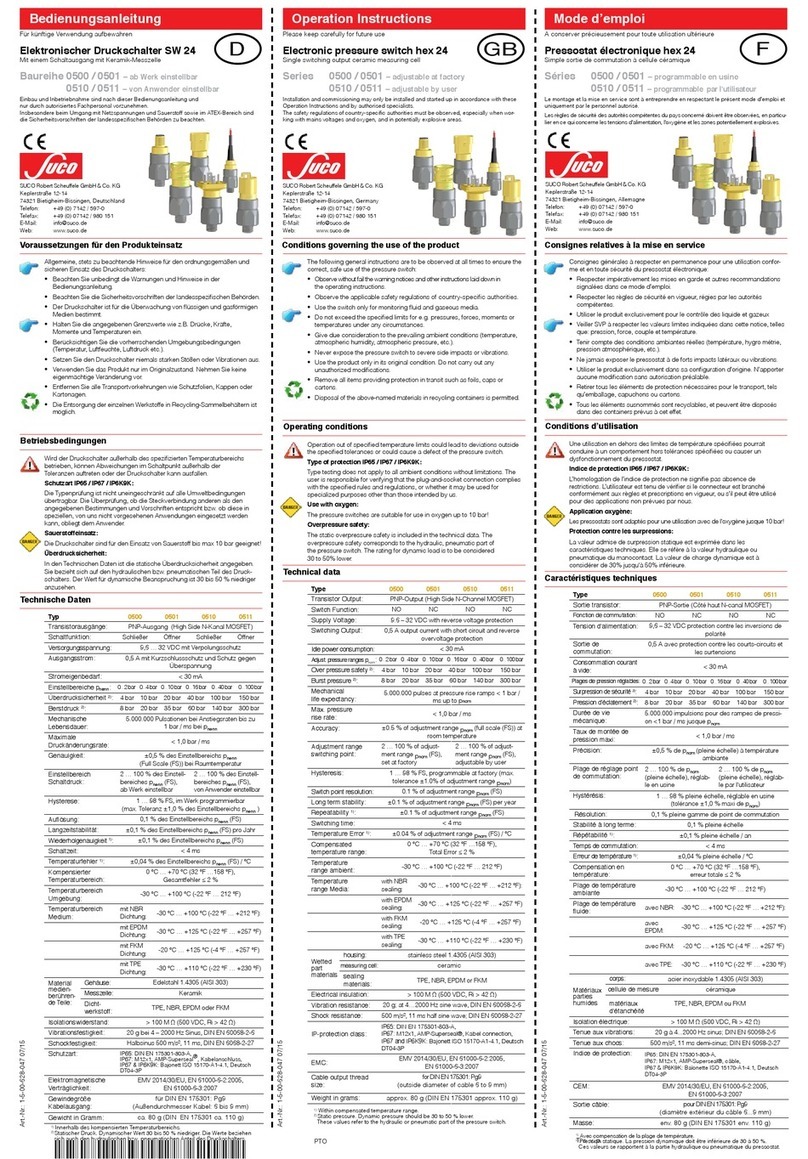

Technical data

Rated operating

voltage Ue

Rated operating

current Ie

Utilization

category

250 Volt AC 50/60 Hz 4 Ampere AC 12

250 Volt AC 50/60 Hz 1 Ampere AC 14

30VoltDC 4 / 4 Ampere DC12/DC13

50VoltDC 2 / 1 Ampere DC12/DC13

75VoltDC 1 / 0.5 Ampere DC12/DC13

125VoltDC 0.3 / 0.2 Ampere DC12/DC13

250VoltDC 0.25 / 0.2 Ampere DC12/DC13

Rated insulation voltage Ui300 Volt

Rated surge capacity Uimp: 2.5 kV

Rated thermal current Ithe: 5 Ampere

Switching overvoltage: < 2.5 kV

Ratedfrequency: DCund50/60Hz

Rated current of short-circuit protective decvice: Up to 5 Ampere

Rated short-circuit current: < 350 Ampere

IP-protection to EN 60 529:1991: IP65 with plug

Tightening torque for terminal screws: < 0.35 Nm

Connection size: 0.5 to 1.5 mm2

Cable screw coupling: Pg 9

ConnectorwithLED: Pg11

Cable size: Pg 9: 6 to 9 mm

Pg 11: 6 to 11 mm

Operating frequency: < 200 min-1

Switching hysteresis: 10 to 30% adjustable

by the factory

Mechanical life 106 operating cycles

Diaphragmtype(0184): (atatrippressuresupto

50 bar)

Piston type (0184): 106operating cycles

Body material: Zinc-plated steel

(Fe//ZnNi(12)6//A/T2)

Temperature range: NBR -30 °C to +100 °C

EPDM -30°Cto+120°C

FKM -5 °C to +120 °C

Overpressure safety

DiaphragmPressureSwitch(0184): 100bar(0.3to1.5bar)

300 bar (restidual pressure)

Piston Pressure Switch (0185): 600 bar

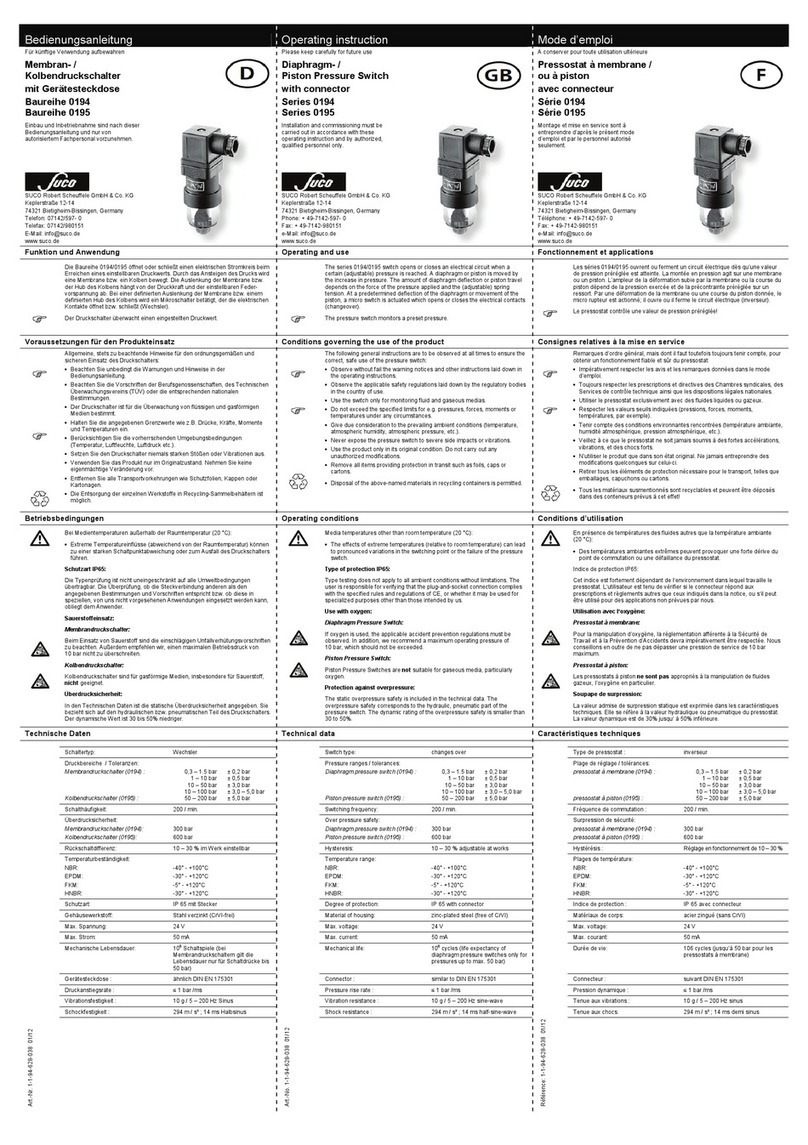

Operating controls and connections

7

max. 0.5 Nm 4

7

P

24

1

(1) Pressure connection

(2) Electrical connection

(3) Adjusting screw

(4) Fastening screw

(5) Plug housing

(6) Gasket

(7) Terminal board

(8) Pg gland

Fig. 3

Fig. 2

Fig. 4

Fig. 1

2

3

3

1

4

58

6

7