Safety

4

On safety decals, this symbol and the

signal words Danger, Warning, Caution

and Notice draw your attention to

important instructions regarding safety.

They indicate potential hazards and levels of intensity.

RED - DANGER indicates an

imminently hazardous

situation which, if not avoided, will result in death or

serious injury.

ORANGE - WARNING

indicates a potentially

hazardous situation which, if not avoided, could result

in death or serious injury.

YELLOW - CAUTION

indicates a potentially

hazardous situation which, if not avoided, may result

in minor or moderate injury.

BLUE - NOTICE alerts you to

practices unrelated to personal

injury, such as messages related to property damage.

IMPORTANT: To prevent serious injury or death to

you or your family, it is essential that safety decals

are clearly visible, in good condition, and applied to

the appropriate equipment.

FOLLOW MANUAL & SAFETY DECAL MESSAGES

Carefully read this manual and

all safety decals on your

equipment. Safety decals must

be kept in good condition.

Replace missing or damaged

safety decals by contacting Sukup

Manufacturing Co. via mail at PO

Box 677, Sheffield, Iowa USA, 50475; by phone at

641-892-4222; or by e-mail at info@sukup.com.

It is the responsibility of the owner/operator to know

what specific requirements, precautions, and work

hazards exist. It is also the responsibility of the

owner/operator to inform anyone operating or

working in the area of this equipment of hazards and

safety precautions that need to be taken to avoid

personal injury or death. Always keep children away

from bins and vehicles with flowing grain.

Make no unauthorized modifications to machine.

Modifications may endanger function and/or safety of

unit. Keep unit in good working condition. Keep shields

in place. Replace worn or missing shields free of

charge by contacting Sukup Manufacturing Co.

GRAIN BIN SAFETY

Owners/operators are responsible for developing

site-specific confined space entry procedures.

OSHA’s confined space entry procedures (29CFR

1910.146) can be found at www.osha.gov.

If you must enter bin for repair or maintenance:

Use a safety harness, safety line and respirator

Station another person outside of bin

Avoid the center of the bin

Wear appropriate personal protective equipment

Keep clear of all augers and moving parts

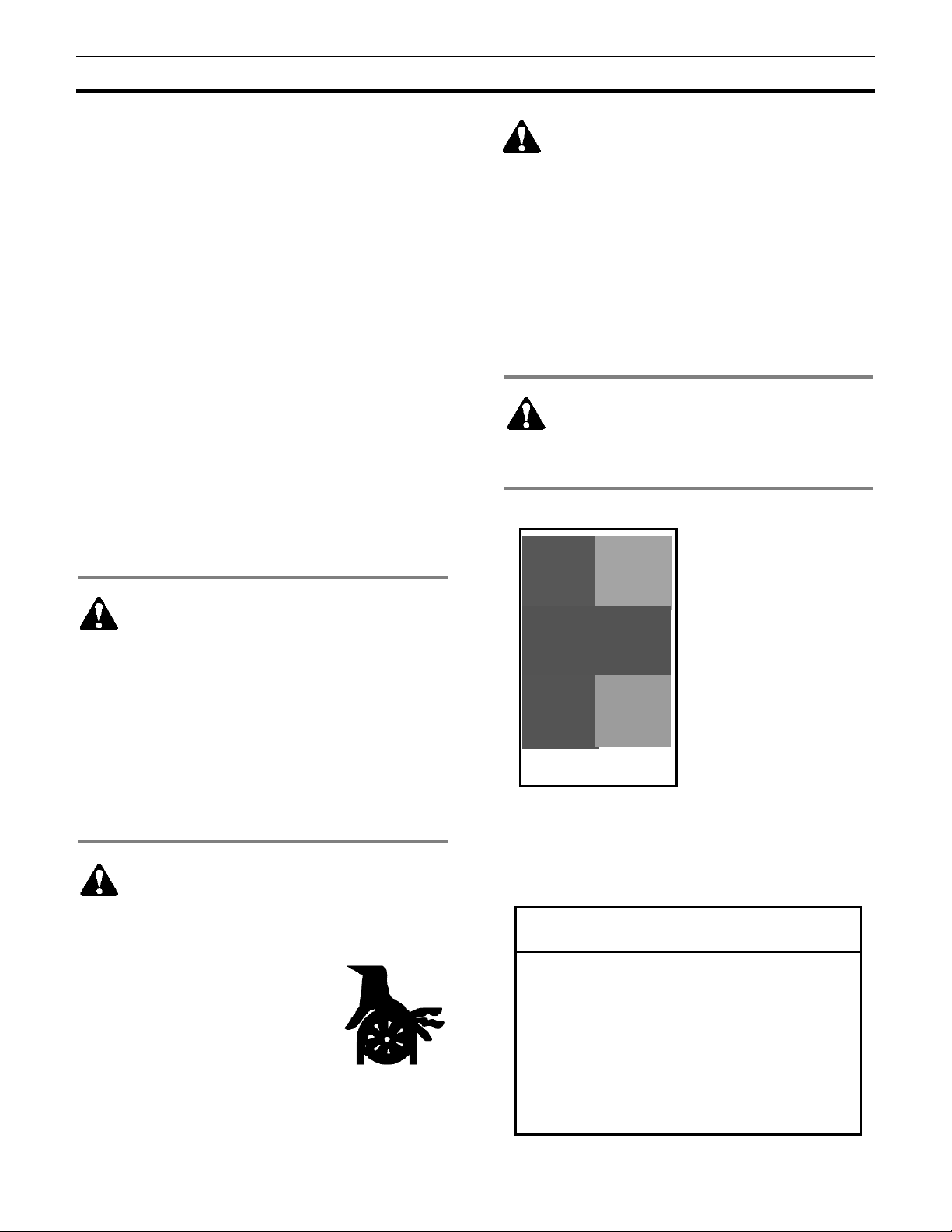

DANGER: Never enter bin unless all power is

locked out and another person is present.

Rotating augers

can kill or

dismember!

NEVER enter bin when augers are running!

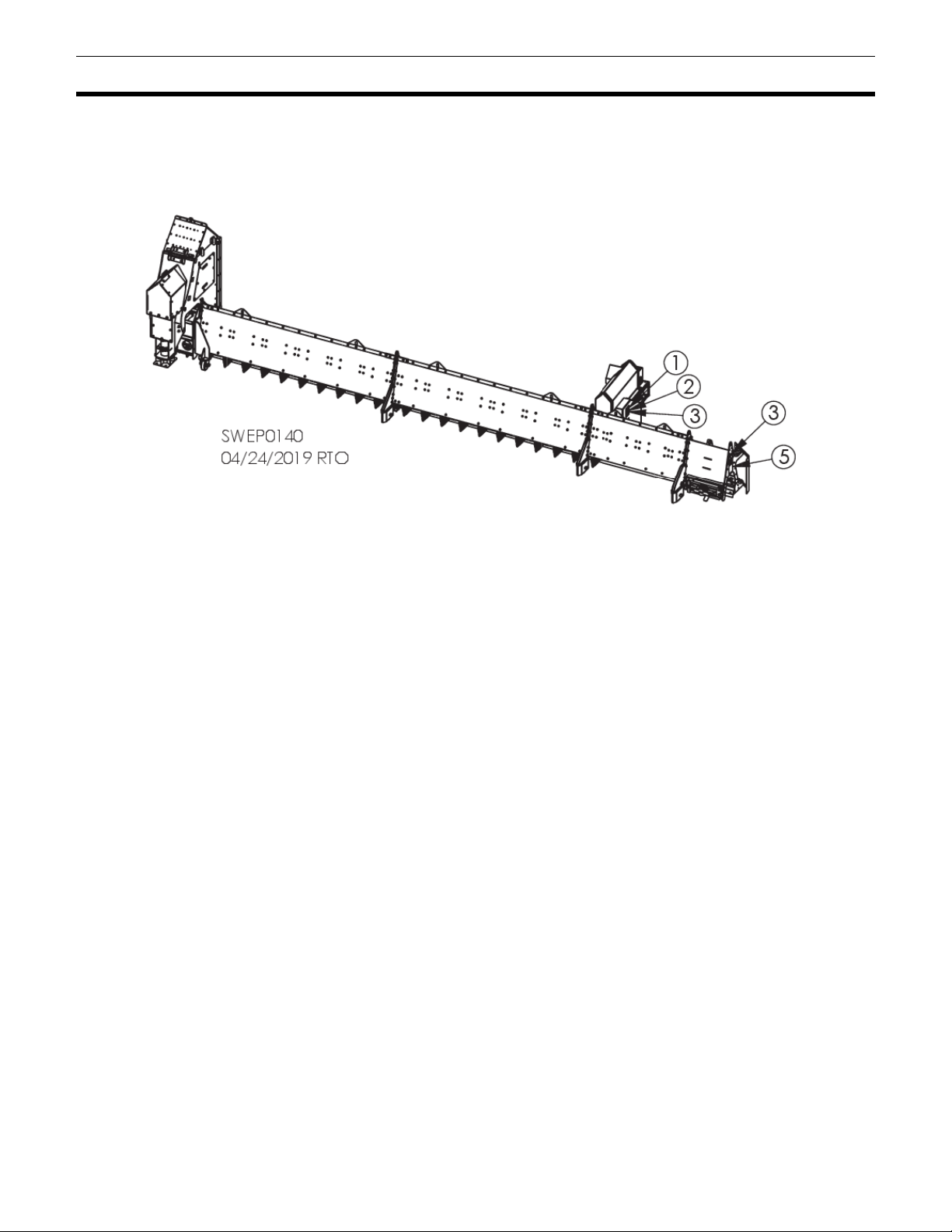

When bin is nearly empty, sweep auger will travel at an

increasingly fast speed. Keep away from sweep and

sump augers to avoid entanglement.

Failure to follow precautions above will result in death

or serious injury.

DANGER: Flowing grain

may trap and suffocate. If

you enter a bin of flowing grain

you can be completely submerged

in grain in about 8 seconds.

Failure to heed this warning will

result in death or serious injury.

Read manual before installing or using product. Failure to follow instructions and safety precautions in

manual can result in death or serious injury. Keep manual in a safe location for future reference.