Sullair RH Series Troubleshooting guide

Failure to follow the instructions

and procedures in this manual or,

misuse of this equipment will

VOID its warranty!

WARRANTY NOTICE

USER/SERVICE MANUAL

REFRIGERATED DRYERS

RH—HIGH TEMPERATURE

RN—NON-CYCLING

RD—DIGITAL CYCLING

PART NUMBER:

KEEP FOR

FUTURE

REFERENCE

©SULLAIR CORPORATION

02250195-401 R00

The information in this manual is current

as of its publication date, and applies to

compressor serial number:

(RH) 0611SA0198

(RN) 4810SA0001

(RD) 0711SA0263

and all subsequent serial numbers.

AIR CARE SEMINAR TRAINING

Sullair Air Care Seminars are courses that provide hands-on instruction for the proper operation, maintenance,

and servicing of Sullair products. Individual seminars on Industrial compressors and compressor electrical

systems are offered at regular intervals throughout the year at Sullair’s corporate headquarters training facility

located at Michigan City, Indiana.

Instruction includes training on the function and installation of Sullair service parts, troubleshooting common

faults and malfunctions, and actual equipment operation. These seminars are recommended for maintenance,

contractor maintenance, and service personnel.

For detailed course outlines, schedule, and cost information contact:

SULLAIR TRAINING DEPARTMENT

1-888-SULLAIR or

219-879-5451 (ext. 5623)

www.sullair.com

- Or Write -

Sullair Corporation

3700 E. Michigan Blvd.

Michigan City, IN 46360

Attn: Service Training Department.

TABLE OF CONTENTS

SECTION 1—SAFETY

7 1.1 SAFETY INFORMATION

SECTION 2—RH SERIES REFRIGERATED HIGH TEMPERATURE

COMPRESSED AIR DRYER

10 2.1 SPECIFICATIONS

10 2.2 INTRODUCTION

11 2.3 TYPICAL INSTALLATION

12 2.4 SAFETY REGULATIONS

15 2.5 REFRIGERANT DRYER FEATURES

17 2.6 DRYER OPERATION PROCEDURE

18 2.7 ED—RH15-50

20 2.8 ED—RH75-100

22 2.9 ID—RH15-50

24 2.10 ID—RH75-100

26 2.11 P&I—RH15-75

28 2.12 P&I—RH100

30 2.13 WIRING DIAGRAM

32 2.14 TROUBLESHOOTING

37 2.15 SETTINGS

38 2.16 SPARE PARTS

SECTION 3—RN & RD SERIES REFRIGERATED NON-CYCLING

COMPRESSED AIR DRYER

41 3.1 INTRODUCTION

41 3.2 SPECIFICATIONS

42 3.3 SAFETY INSTRUCTIONS

42 3.4 ISSUES TO AVOID

42 3.5 RECEIVING AND INSPECTION

42 3.6 TRANSPORTATION

43 3.7 INSTALLATION LAYOUT REQUIREMENTS

43 3.8 ENVIRONMENTAL PROTECTION

43 3.9 PRODUCT DESCRIPTION

TABLE OF CONTENTS

43 3.10 PRODUCT FEATURES

45 3.11 PRINCIPLE OF OPERATION

45 3.12 COMPRESSED AIR HEAT EXCHANGER

46 3.13 PIPE/CONNECTION REQUIREMENTS

46 3.14 ELECTRICAL CONNECTION REQUIREMENTS

46 3.15 OPERATING PRECAUTIONS

47 3.16 INSTALLATION

48 3.17 STEPS TO UNDERTAKE BEFORE OPERATING

48 3.18 OPERATING PROCEDURES

49 3.19 STARTUP AND SHUT DOWN PROCEDURE

50 3.20 ED—RN 5-15

52 3.21 ED—RN 25

54 3.22 ED—RN 35-50

56 3.23 ED—RN 75

58 3.24 ED—RN 100

60 3.25 ED—RN 125

62 3.26 ED—RN 150

64 3.27 ED—RN 175

66 3.28 ED—RN 200

68 3.29 ED—RN 250

70 3.30 ED—RN 325 (230)

72 3.31 ED—RN 325 (460)

74 3.32 ID—RN5-15

76 3.33 ID—RN25

78 3.34 ID—RN35/50

80 3.35 ID—RN75-100

82 3.36 ID—RN125

84 3.37 ID—RN150

86 3.38 ID—RN175-200

88 3.39 ID—RN250-400

90 3.40 P&I—RN5-10-15-25

92 3.41 P&I—RN35-75

94 3.42 P&I—RN100-200

96 3.43 P&I—RN250-325

97 3.44 P&I—RD400-500-700-850

98 3.45 P&I—RD700-850

99 3.46 P&I—RD1000-1200-1600-2000-2400-3000-3800-5000-6000

100 3.47 P&I—RD1000-1200-1600-2000-2400-3000-3800-5000-6000

102 3.48 WIRING DIAGRAM—RN5-10-15-20-25

104 3.49 WIRING DIAGRAM—RN35-50-75-100

106 3.50 WIRING DIAGRAM—RN125-150

108 3.51 WIRING DIAGRAM—RN175

110 3.52 WIRING DIAGRAM—RN200

TABLE OF CONTENTS

112 3.53 WIRING DIAGRAM—RN250-325

114 3.54 WIRING DIAGRAM—RN250-325 (230-3-60-A)

116 3.55 WIRING DIAGRAM—RN250-325 (230-3-60-A)

118 3.56 WIRING DIAGRAM—RN250-325 (460-3-60-A, 400-3-50-A)

120 3.57 WIRING DIAGRAM—RN250-325 (460-3-60-A, 400-3-50-A)

122 3.58 CONTROL CIRCUIT—RN250-325

124 3.59 POWER CIRCUIT—RN250-325

126 3.60 MAINTENANCE

127 3.61 REPLACEMENT PARTS

1283.62TROUBLESHOOTING

134 3.63 SETTINGS

144 3.64 SPARE PARTS LIST

SECTION 4—E-680 CONTROLLER FOR REFRIGERANT DRYERS

159 4.1 DESCRIPTION

159 4.2 OPERATION

166 4.3 ED—RD400

168 4.4 ED—RD500

170 4.5 ED—RD700

172 4.6 ED—RD700 AIR COOLED

174 4.7 ED—RD850

176 4.8 ED—RD850 AIR COOLED

178 4.9 ED—RD1000

180 4.10 ED—RD1000 AIR COOLED

182 4.11 ED—RD1200 AIR COOLED

184 4.12 ED—RD1600 AIR COOLED

186 4.13 ED—RD2000 AIR COOLED

188 4.14 ED—RD2400 AIR COOLED

190 4.15 ED—RD3000 AIR COOLED

192 4.16 ED—RD3800 AIR COOLED

194 4.17 ED—RD5000 AIR COOLED

196 4.18 ED—RD6000 AIR COOLED

1984.19ID—RD400

2004.20ID—RD500-850

202 4.21 ID—RD1000-1200 AIR COOLED

204 4.22 ID—RD1000-1200 WATER COOLED

206 4.23 ID—RD1600-2000 AIR COOLED

208 4.24 ID—RD1600-2000 WATER COOLED

210 4.25 ID—RD2400-3000 AIR COOLED

212 4.26 ID—RD2400-3000 WATER COOLED

214 4.27 ID—RD3800 AIR COOLED

216 4.28 ID—RD3800 WATER COOLED

218 4.29 P&I—RD400

TABLE OF CONTENTS

220 4.30 P&I—RD500-850

222 4.31 P&I—RD700-850

224 4.32 P&I—RD1000-6000

226 4.33 P&I—RD1000-6000

228 4.34 WIRING DIAGRAM—RD400 (230-3-60-A)

230 4.35 WIRING DIAGRAM—RD400 (230-3-60-A)

232 4.36 WIRING DIAGRAM—RD400 (460-3-60-A, 400-3-50-A)

234 4.37 WIRING DIAGRAM—RD400 (460-3-60-A, 400-3-50-A)

236 4.38 WIRING DIAGRAM—RD500/700 (230-3-60-A)

238 4.39 WIRING DIAGRAM—RD500/700 (230-3-60-A)

240 4.40 WIRING DIAGRAM—RD (500/700/850-1000-1200-1600-2000-2400-

3000-3800-5000-6000)-460-3-60-A, 400-3-50-A

242 4.41 WIRING DIAGRAM—RD (500/700/850-1000-1200-1600-2000-2400-

3000-3800-5000-6000)-460-3-60-A, 400-3-50-A

244 4.42 WIRING DIAGRAM—RD700-850 (230-3-60-W)

246 4.43 WIRING DIAGRAM—RD700-850 (230-3-60-W)

248 4.44 WIRING DIAGRAM—RD (700-850-1000-1200-1600-2000-2400-3000-

3800-5000-6000) 460-3-60-W, 400-3-50-W

250 4.45 WIRING DIAGRAM—RD (700-850-1000-1200-1600-2000-2400-3000-

3800-5000-6000) 460-3-60-W, 400-3-50-W

252 4.46 CONTROL CIRCUIT—RD400-500-700-850-1000-1200-1600-2000-2400-

3000-3800-5000-6000

254 4.47 POWER CIRCUIT—RD400-500-700-850-1000-1200-1600-2000-2400-

3000-3800-5000-6000

258 4.48 SPARE PARTS

Section 1

7

SAFETY

SAFETY

The dryer has been designed and constructed in

accordance with the generally recognized rules

pertaining to refrigeration technology as well as

industrial safety and accident prevention regulations.

The equipment design, development, production,

assembly and customer service fall under the Sullair

quality control system.

The dryer is state of the art. There are, however,

hazards to the body, equipment and life

accompanying this type of product if it is not operated

for the purpose which it is intended by trained and

specialized personnel.

The equipment supplied is intended exclusively for

drying compressed air. Any other use or one

exceeding this is considered unauthorized. Sullair

cannot be held liable for damages resulting from

incorrect or unauthorized use of the equipment. Any

such risk is carried solely by the end user.

Authorized use means complete compliance with all

of the conditions of operation, servicing and

maintenance prescribed by Sullair in this Instruction

and Operation Manual.

The dryer is only to be operated, serviced and

repaired by trained personnel who are familiar with

this type of equipment and understand fully its

operation and any potential dangers.

1.1 SAFETY INFORMATION

The end user and operator must observe all National,

State, and Local industrial and safety regulations

dealing with the operation of pressure vessels under

compressed air service. Also all “end user” safety

rules for the same type of service must be adhered

to. The following points list some of the important

factors dealing with this type of equipment.

• Never make any constructional changes to

the equipment

• Use only original spare parts and accesso-

ries

• Never weld on any pressure vessel or mod-

ify it in any way

• All maintenance on “pressure parts” must

be carried out with the equipment shut-

down, depressurized and locked out. Any

in plant procedures or work permits regard-

ing pressure vessels are to be adhered to.

• Do not operate the equipment with the con-

trol panel door open, the electrical system

energized and live parts exposed.

• Disconnect the dryer from the electrical

supply when any electrical work is per-

formed. Lock out the safety disconnect and

obtain any required work permits.

8

NOTES

Section 2

9

RH SERIES—HIGH TEMPERATURE

RH SERIES REFRIGERATED HIGH TEMPERATURE

COMPRESSED AIR DRYER

RH-0015-115-60-A RH-0025-115-60-A RH-0035-115-60-A RH-0075-115-60-A RH-0100-115-60-A

RH SERIES—HIGH TEMPERATURE SECTION 2

10

2.1 SPECIFICATIONS

Pay attention to the Minimum and Maximum

operating conditions before installing and operating

the dryer.

If your application does not match the above criteria,

contact your Sullair distributor and they will be able to

provide the right dryer for your application.

2.2 INTRODUCTION

The RH series of Non-cycling Refrigerated Air Dryers

are specially designed for compressed air systems

that do not use an after cooler. The hot compressed

air from the compressor enters the downstream

receiver tank where condensed moisture is removed

with an automatic drain. The hot saturated air is then

passed directly into the RH series of dryers.

RH series of non-cycling refrigerant compressed air

dryers have been designed to remove water vapor

from industrial compressed air that is free of reactive

contaminants like ammonia, gaseous acid, dust, rust

or any other chemical or mineral products capable of

reacting or clogging the heat exchanger. The dryers

are designed and recommended for indoor

applications.

Normal Operating Pressure 175 PSIG

Normal Operating Temperature 200 Deg. F

Normal Ambient Temperature 100 Deg. F

Maximum Operating Pressure 230 PSIG

Minimum Operating Pressure 80 PSIG

Maximum Ambient Temperature 120 Deg. F

Minimum Ambient Temperature 40 Deg. F

Maximum Operating Temperature 240 Deg. F

SECTION 2 RH SERIES—HIGH TEMPERATURE

11

2.3 TYPICAL INSTALLATION

The RH series of Dryers operate without the need for any after-coolers.

RH SERIES—HIGH TEMPERATURE SECTION 2

12

2.4 SAFETY REGULATIONS

2.4.1 IMPORTANT SAFETY NOTES:

1. When operating the air dryer the operator

must employ safe working methods and

observe all recommended/local safety

instructions and applicable regulations.

2. Prior to installation, the dryer and the com-

pressed air system must be depressurized

and disconnected from the electrical main

supply.

3. The user is responsible for safe operating

conditions. Parts and accessories must be

replaced if inspection shows that safe opera-

tion cannot be assured.

4. Installation, operation, maintenance and

repair are to be performed only by autho-

rized, trained and certified technicians.

5. DO NOT exceed the minimum and maximum

values of all the parameters mentioned on

the Main data label, Electrical data label and

accompanying specification sheets if any.

6. All safety precautions mentioned in this

manual must be adhered to at all times and

by all personnel working on the dryer

2.4.2 TRANSPORTATION

1. Use care and caution when transporting the

dryer. Avoid sudden jerks, tilting, dropping

and other physical abuse.

2. A forklift can be used to transport the dryer

provided the forks are long enough to sup-

port the full width or length. Caution must be

used throughout the move.

2.4.3 POSITIONING

1. The dryer must be installed horizontally. A

minimum of at least 1 ½ feet clearance

around the dryer is necessary to allow free

air circulation and easy access for servicing.

2. The ambient temperature in the room

should not exceed 120° F and should not

be below 40° F, taking into account the

heat radiated by the dryer. (About 18 watts

for each SCFM under ISO 7183-5 condition

or 40 watt for each liter/sec under ISO 7183-

A condition).

2.4.4 INSTALLATION

In addition to the general mechanical construction

procedures and local regulations, the following

instructions need to be emphasized:

1. Only authorized, trained and skilled engi-

neers should install the compressed air

dryer.

2. Safety devices, protecting covers or insula-

tions in the dryer are never to be removed or

modified. Each pressure vessel or acces-

sory installed outside the dryer with com-

pressed air (Any pressure above

atmospheric pressure) must be fitted with

individual pressure relief safety valves.

3. Optional air by-pass valve: Install one (1) air

by-pass valve and two (2) switch off valves in

the line before the dryer to allow easy main-

tenance and for possible isolation of the

dryer without interrupting the compressed air

flow.

4. In Line Filter: install one compressed air filter

in line before the dryer to protect it against

dirt and possible clogging of heat exchanger.

Contact your Sullair representative/dealer for

suitable filter.

2.4.5 STEPS TO UNDERTAKE BEFORE

OPERATING

1. Read this manual completely.

2. Review all safety precautions.

3. Use recommended pipe sizes as per specifi-

cations.

4. Never operate the dryer at pressures above

the maximum specified on the dryer label

(check the technical specifications).

SECTION 2 RH SERIES—HIGH TEMPERATURE

13

2.4.6 MAINTENANCE BY AN ENGINEER/

TECHNICIAN

1. Maintenance and repairs should only be

performed when the air dryer is shut down

and depressurized and when the main

power switch is turned OFF.

2. Use only the appropriate tools for mainte-

nance and repair.

3. Before dismantling any part that has been

pressurized, disconnect the pressure

sources and depressurize the system com-

pletely. Shut off all valves and isolate the

dryer.

4. Proceed carefully during maintenance and

repair. Prevent dirt from entering by covering

parts and orifices with a clean cloth, paper or

tape.

5. Receiver tanks should never be welded or

modified in any way.

6. Never leave tools, loose parts or cleaning

rags in or on the air dryer.

7. Before connecting the dryer back online,

check the setting of the control and safety

devices as well as the pressure and the tem-

perature of the compressed air circuit.

2.4.7 MAINTENANCE BY THE USER

1. Keep the dryer clean.

2. In case of more than 4 pounds of refriger-

ant, the dryer should be regularly checked

to be leak free by qualified refrigerant

engineer. Refer to section “Environmental

protection” of this manual.

3. Every six months— check the correct

operation of the condenser drain trap.

Replace timer or solenoid valve in case of

clogging or malfunctioning.

4. Every six months—check and clean the

drain strainer or the electronic sensor by

undoing the access screw and rinsing the

filter with tap water to remove the trapped

dirt from the inside.

5. Clean the air condenser with a brush or

compressed air as soon as it’s dirty or

clogged: Take care not to bend the fins of

the condenser heat exchanger.

6. Check the troubleshooting list in case of

maintenance issues.

7. Check operating pressures, temperatures

and time settings after maintenance. If oper-

ating and safety devices function properly,

the air dryer may be used.

2.4.8 ENVIRONMENTAL PROTECTION

1. US/EU laws protect the environment against

refrigerant being released into the atmo-

sphere.

2. An annual leak control test at less than 5.0

gr/year should be performed by a qualified

engineer if the refrigerant dryer contains

more than 4.4 lbs/ 2 kg of refrigerant. This

control test has to be done twice a year if the

dryer contains more than 66 lbs/30 kg.

3. Prior to dryer disposal, the refrigerant must

be properly recovered by a qualified engi-

neer.

RH SERIES—HIGH TEMPERATURE SECTION 2

14

2.4.9 REFRIGERANT CIRCUIT:

The refrigerant circuit can be divided into 3 parts:

1. Low pressure section with an evaporator

(heat exchanger)

2. High pressure section including: Condenser,

liquid receiver, (if installed) and the filter

dryer.

3. Control circuit including: Compressor, expan-

sion valve, by-pass valve (if installed), fan

pressure switch, safety high pressure switch.

2.4.10 THE REFRIGERANT CIRCUIT OPERATES

AS FOLLOWS:

1. The compressor compresses gaseous refrig-

erant.

2. The hot refrigerant gas condenses in the

condenser. Being liquefied, it is stored in the

liquid receiver (if existing).

3. The liquid is taken out of the storage receiver

vessel and injected into the evaporator (heat

exchanger) by an expansion valve. This

expansion valve is protected by a filter dryer,

that retains particles and humidity that could

be in the circuit.

4. The injected liquid fills in the refrigerant sec-

tion of the Air-Refrigerant heat exchanger

and evaporates due to the heat from the

incoming air. The gaseous refrigerant is

sucked in the compressor and the cycle car-

ries on.

5. In order to keep the evaporation pressure

steady, and thus the refrigerant temperature

in the heat exchanger, a by-pass valve

injects hot gaseous refrigerant into the cir-

cuit. On certain dryers, an automatic pres-

sure expansion valve regulates this process.

2.4.11 COMPRESSED AIR CIRCUIT

1. The hot, saturated, compressed air from the

compressor is forced into the air-cooled

after-cooler where it is pre-cooled to approxi-

mately ambient temperature.

2. This pre-cooled compressed air enters the

high-efficiency moisture separator where

condensed moisture is stripped from the air

stream and purged out via the electronic

timer drain.

3. The air then enters the first stage of the heat

exchanger (air to air pre-cooler/re-heater)

where the outgoing chilled air cools the

incoming hot air. This energy saving heat

exchanger provides significant advantages,

such as a reduction of the heat load imposed

on the refrigerant compressor and con-

denser, re-heating the outlet air, and prevent-

ing condensation of moisture in the plant air

distribution lines.

4. From the air-to-air heat exchanger, air enters

the air-to-refrigerant heat exchanger where

further cooling occurs and the air tempera-

ture is reduced to the desired pressure dew

point (PDP). As the air is cooled, the mois-

ture condenses into a liquid and is then sep-

arated in the integrated high efficiency

separator and discharged through the con-

densate drain.

5. The cooled air then re-enters the air-to-air

heat exchanger, in a direction opposite to the

flow of the warm, saturated incoming air and

pre-cools the hot air. During this process the

outgoing air is reheated thereby minimizing

the chances of moisture condensation in the

compressed air distribution lines.

SECTION 2 RH SERIES—HIGH TEMPERATURE

15

2.5 REFRIGERANT DRYER

FEATURES

2.5.1 COMPRESSOR TYPE

The High Temperature Inlet Refrigerated

compressed air dryers use the sealed Hermetic type

of compressors and require no periodic servicing.

2.5.2 CONDENSER

The air-cooled condenser is equipped with

helicoidally fans controlled by a pressure switch the

controls the fan cycling in order to maintain the

refrigerant high pressure at the correct level.

Air cooled aftercooler is integrated to the condenser.

The fan motor of the air cooled aftercooler is

separate and it only starts to function when the inlet

air temperature is equal or above 95°F. This is

controlled by a thermostatic switch.

2.5.3 REFRIGERANT CIRCUIT PROTECTION

OVERLOAD PROTECTOR:

The single phase compressors are equipped with an

overload protector which is a thermal sensitive

switch controlling the temperature of the compressor

and overheating. In case of malfunction, the

protector trips out. However, it switches on again

automatically as soon as the compressor has cooled

down.

HIGH PRESSURE SECURITY SWITCH:

Refrigerant circuits are protected against excessive

pressure by a security switch that stops the

compressor in case of too high a pressure. In case

this safety switch has tripped, it has to be manually

reset before switching on the dryer.

2.5.4 FILTER DRYER

In order to keep the refrigerant circuit void of all

moisture, a filter drier is used in line. This filter also

traps any solid particles that may have migrated in

the circuit during operation. To avoid problems, the

refrigerant circuit must be vacuumed before filling it

with the recommended refrigerant.

2.5.5 REFRIGERANT CIRCUIT REGULATION

1. The evaporating pressure is kept constant

by controlled injection of hot gas from the

high-pressure side into the low-pressure

section of the circuit through a by-pass valve.

This constant pressure corresponds to a sta-

ble evaporating temperature adjusted as

close to 32°F as possible.

2. The liquid refrigerant is injected into the

evaporator through a thermostatic expansion

valve keeping the superheat of the refriger-

ant constant at the outlet of the evaporator.

3. The mix of hot gas from by-pass valve and

cold gas from evaporator is called superheat.

2.5.6 CONDENSATE DRAIN—TRAP ASSEMBLY

Disassembling the drain is easy because it can be

isolated from the air circuit under pressure with a ball

valve. The drain has to be isolated before being

dismantled.

RH SERIES—HIGH TEMPERATURE SECTION 2

16

2.5.7 COMPACT 3-IN-1 HEAT EXCHANGER

The dryers are equipped with compact heat

exchangers. This compact 3-in-1 setup has been

specially designed to dry compressed air and is

made of the following components:

1. An air-to-air heat exchanger which pre-cools

the incoming hot air with the outgoing cold

air, thereby saving a significant load on the

compressor.

2. An Evaporator which is an air-to- refrigerant

heat exchanger that cools the pre-cooled

compressed air.

3. An integrated separator that removes all

condensates and requires no additional

maintenance.

AIR/REF.

AIR INLET

DRAIN PORT

AIR OUTLET

REFRIGERANT

GAS OUTLET

REFRIGERANT

GAS INLET

AIR/AIRWATER SEPARATOR

17

NOTES

2.6 DRYER OPERATION

PROCEDURE

1. Starting of a Single phase dryer for the first

time

a. Make sure all air connections are intact and

have no leaks

b. Double check wiring connections

c. Set the rocker switch to “I”

2. Daily starting and shut-down

a. Push on the green button to start the dryer.

b. The start light will indicate that the dryer is

running.

3. To stop the dryer, first stop the airflow (either

shut-down the air compressor or close the

inlet/outlet or by-pass valve). When the air

flow is stopped, push the green button to the

stop position.

NOTE

1. Avoid turning OFF the dryer when com-

pressed air is still flowing through it.

2. To switch the already preheated dryer

on again, simply push the green start

button.

RH SERIES—HIGH TEMPERATURE SECTION 2

18

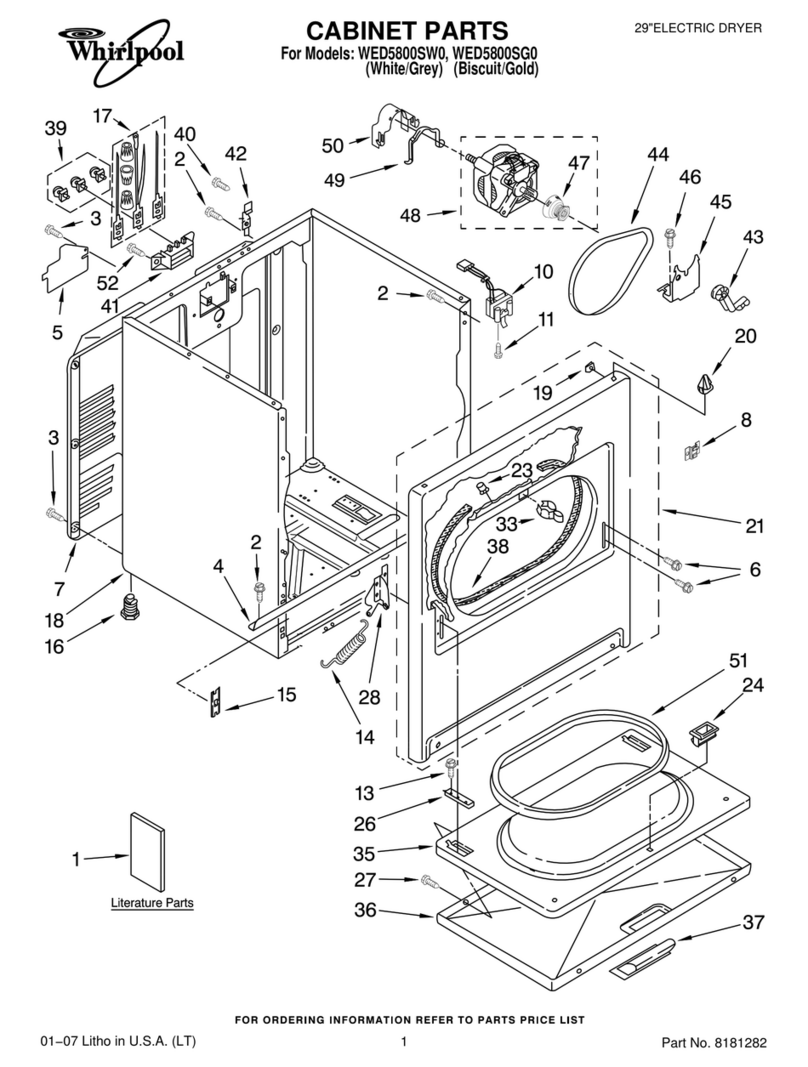

2.7 ED—RH15-50

02250195-252 R00

SECTION 2 RH SERIES—HIGH TEMPERATURE

19

2.7 ED—RH15-50

KEY PART NUMBER DESCRIPTION QTY

1 SEE REF. TABLE COMPRESSOR 1

2 M-CON-0050H CONDENSOR 1

3 M-FMT-0150-115-1-60-A FAN MOTOR 2

4 M-FAN-0150 FAN BLADE 2

5 M-GRL-0150 FAN GRILL 2

6 M-DRI-0200 DRIER DEHYDRATOR 1

7 M-EXC-0035 HEAT EXCHANGER 1

8 TMR-3000 TIMER 2

9 M-SLV-0150-115 SOLENOID VALVE 1

10 M-WSP-050 WATER SEPARATOR 1

11 M-EXV-0075 EXPANSION VALVE 1

12 M-HPS-0200 HIGH PRESSURE SWITCH 1

13 M-FNS-0200 FAN ON/OFF SWITCH 1

14 M-THS-0325 THERMOSTATIC SWITCH 1

15 M-THG-0325 THERMOSTATIC GUAGE 1

16 M-ONB-0200 ON/OFF BUTTON 1

17 M-CFR-0050H CABINET FRONT 1

18 M-CLE-0050H CABINET SIDE-LEFT 1

19 M-CRI-0050H CABINET SIDE-RIGHT 1

20 M-CRE-0050H CABINET REAR 1

21 M-CTO-0050H CABINET TOP 1

22 M-CBA-0050H CABINET BASE 1

23 M-CBL-0050H CABINET LEG 4

24 M-HP1-0050H CABINETHORIZONTAL PROFILE 1 2

25 M-HP2-0050H CABINET HORIZONTAL PROFILE 2 2

26 M-CTC-3000 CABINET TOP CORNER 4

27 M-CPS-3000 CABINET HANDLE 3

28 M-PDC-0200 PLASTIC DISPLAY COVER 1

29 M-SCR-3000 SCREW TYPE 1 24

30 M-STU-3000 CABINET STUD AND NUT 12

31 M-FAS-3000 CABINET FASTENER 12

32 M-CSC-0050-115-1-60 COMPRESSOR START CAPACITOR 1

33 SEE REF. TABLE

COMPRESSOR OVERLOAD

PROTECTOR 1

34 M-STR-0050-115-1-60 COMPRESSOR START RELAY

KEY PART NUMBER DESCRIPTION QTY

RH SERIES—HIGH TEMPERATURE SECTION 2

20

2.8 ED—RH75-100

02250195-253 R00

This manual suits for next models

167

Table of contents

Other Sullair Dryer manuals

Sullair

Sullair SR-250 User manual

Sullair

Sullair DMD Series Troubleshooting guide

Sullair

Sullair SRL-1200 User manual

Sullair

Sullair SR-125 User manual

Sullair

Sullair SAR 180 User manual

Sullair

Sullair SRL Series User manual

Sullair

Sullair SRV-250 User manual

Sullair

Sullair DEX Series Troubleshooting guide

Sullair

Sullair SRC Series User manual

Sullair

Sullair SR-5 User manual