Safety

• 120 psi maximum operating pressure.

• Do not drop or let anything drop on the applicator.

• Do not damage or polish the piston rods.

• Store in a clean dry environment.

•Eye protection must be worn at all times when the applicator is in operation.

•Do not point the applicator at anyone while the tool is in operation.

•Do not place any part of your body either inside or in front of the material

chambers while the applicator is connected to an air supply.

• Read the material safety data sheets (MSDS) on the material being used.

Cleaning

Keeping the applicator clean is important for long life and trouble-free operation.

Due to the tool’s rugged construction, most solvents can be used to remove

material. It is not recommended to immerse the tool in a cleaning agent, as this

may adversely affect the internal seals of the applicator. Special care should be

taken to ensure no material residue is left on the piston rods.

General dispensing instructions

Note: It is highly recommended that you advance and retract the pistons in an

empty applicator until you are comfortable with its operation.

The dispensing rate of the applicator is determined by the air pressure used.

It is advised to begin at the lowest pressure setting and adjust the pressure

to your desired speed. Upper handle can be adjusted by loosening main nut.

To load twin cartridges

1. Dispenser is designed to dispense 600mL cartridges in both 1:1 and 2:1

ratios without the need to change ejectors. Note that 2:1 ratio cartridges

must be inserted into the applicator with the small side rst.

2. Retract the piston rods by switching the forward/reverse button and then

actuate the trigger to allow the rods to travel back into the barrel.

3. Insert the cartridge into the applicator, making sure the cartridge is secured

into the plastic cartridge retainer.

4. Ensure that the front of the cartridge is seated against the applicator’s front

plate before dispensing.

To dispense twin cartridges

1. Remove caps and/or plugs from the cartridge and install a new static mixer

on the end of the cartridge. Some static mixers require a plastic nut to secure

it to the cartridge; specify p/n 7702598.

2. With the regulator at low pressure, switch the forward/reverse button to

the forward position and then actuate the trigger to allow the rods to travel

forward to ensure the piston ejectors are properly seated against the

cartridge pistons.

3. Do not apply adhesive to the work area until the proper mixture is exiting the

static mixer.

4. To adjust the material ow, actuate the trigger and adjust the air pressure

with the regulator until your desired dispensing rate is achieved.

5. To stop dispensing, release the trigger to exhaust the air pressure within

the tool.

6. Note: Mixed compounds will harden in the static mixer if left unused for a few

minutes. To prevent rupturing of the cartridge, replace the static mixer.

Forward/Reverse

Button

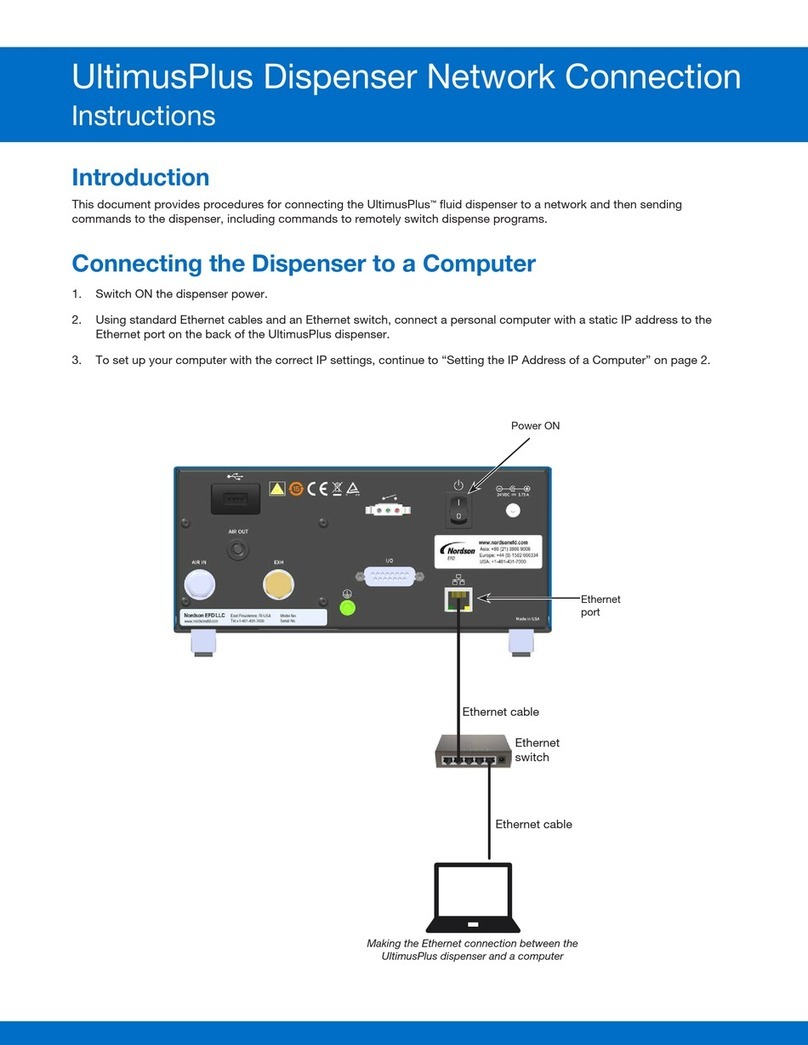

For Nordson EFD LLC sales and service in over 40 countries,

contact Nordson EFD or go to www.nordsonefd.com

Global

East Providence, RI USA

800-556-3484; +1-401-431-7000

Europe

Dunstable, Bedfordshire, UK

0800 585733; +44 (0) 1582 666334

Asia

©2015 Nordson Corporation 7363800 v020915