Read all these safety instructions before operating this product and save these instructions.

The tool has been manufactured in conformity with the instruction of EU machine directive. The EU mark will be considered void in the event

of inexpert repairs, the use of non-original parts and in case of non-observance of the safety instructions in the user’s manual.

Possible direct or indirect consequential damages are not the responsibility of SUMAKE Industrial co., Ltd.

General safety rules:

1. Watch the tool at all times when in use.

2. People under the influence of alcohol or drugs are not allowed to use, repair or maintain the tool.

3. Keep unqualified persons, children, etc. away from the tool.

4. Keep work area clean and with sufficient daylight or artificial lighting. The work area on which the machine is used must be cleaned up.

Disorder is a potential cause of accidents.

5. Danger of explosion. Never use oxygen and combustible gas as an air supply for the tool which many be ignited by spark and cause fire

or explosion.

6. Never use gasoline or other flammable liquids to clean the tool.

7. Do not use air tools in potentially explosive atmospheres such as in the presence of flammable liquids, cleaning solvents, fluid energy or

stored gases.

8. Do not expose air tools to rain. Do not use air tools in damp or wet locations.

9. When a fault or failure is detected, the tool must immediately be disconnected from the air supply and returned for repair.

10. It is not permitted to modify the tool in any way.

11. When not in use, keep tools in a dry place, either locked up or in a high place, out of the reach of children.

12. Do not force small air tools to do the job of a heavy –duty task. Do not use air tool for purpose of which was not intended.

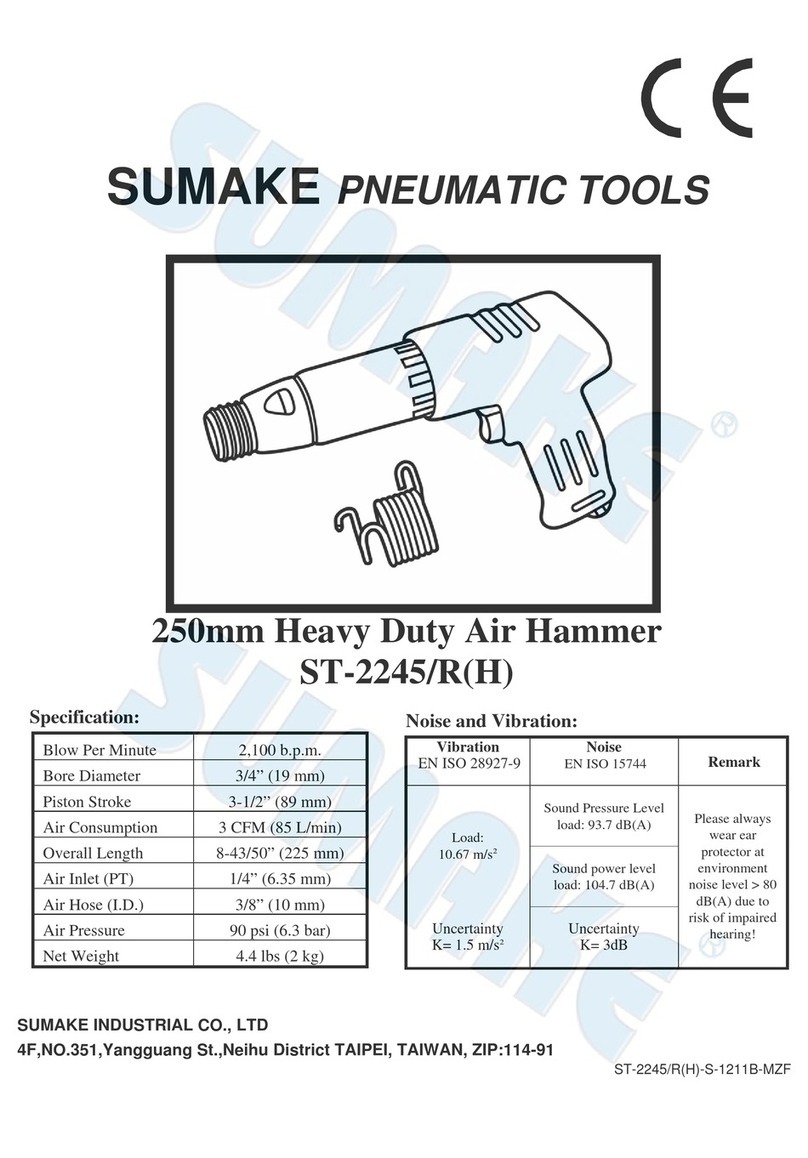

13. Wear suitable ear protection at environment noise level >80dB(A) and safety spectacles when using the tool. Always wear approved

safety goggles if work in dusty. This also applies to other persons in the nearby vicinity.

14. Do not wear loose clothing or jewelry. They can be caught in moving parts. Rubber gloves and non-skid foot wear are recommended

when working outdoors. Wear protective hair covering to contain long hair.

15. Keep proper footing and balance at all times.

16. Use clamps or a vice to hold work-piece. It is safer than using your hand and free both hands to operate the air tool.

17. When not use, before performing service or changing accessories, please disconnect tool from air compressor.

18. Do not carry plugged in air tool with your finger on the switch trigger. Be sure switch is in the “OFF” position when connecting to air

supply.

19. Watch what you are doing. Use common sense, even unsafe situation or unbalanced positions, particularly when you are tired.

20. Air powered tools can vibrate in use. Vibration, repetitive motions or uncomfortable positions may be harmful to your hands or arms.

Stop using any tool if discomfort, tingling feeling or pain occurs. Seek medical advice before resuming use.

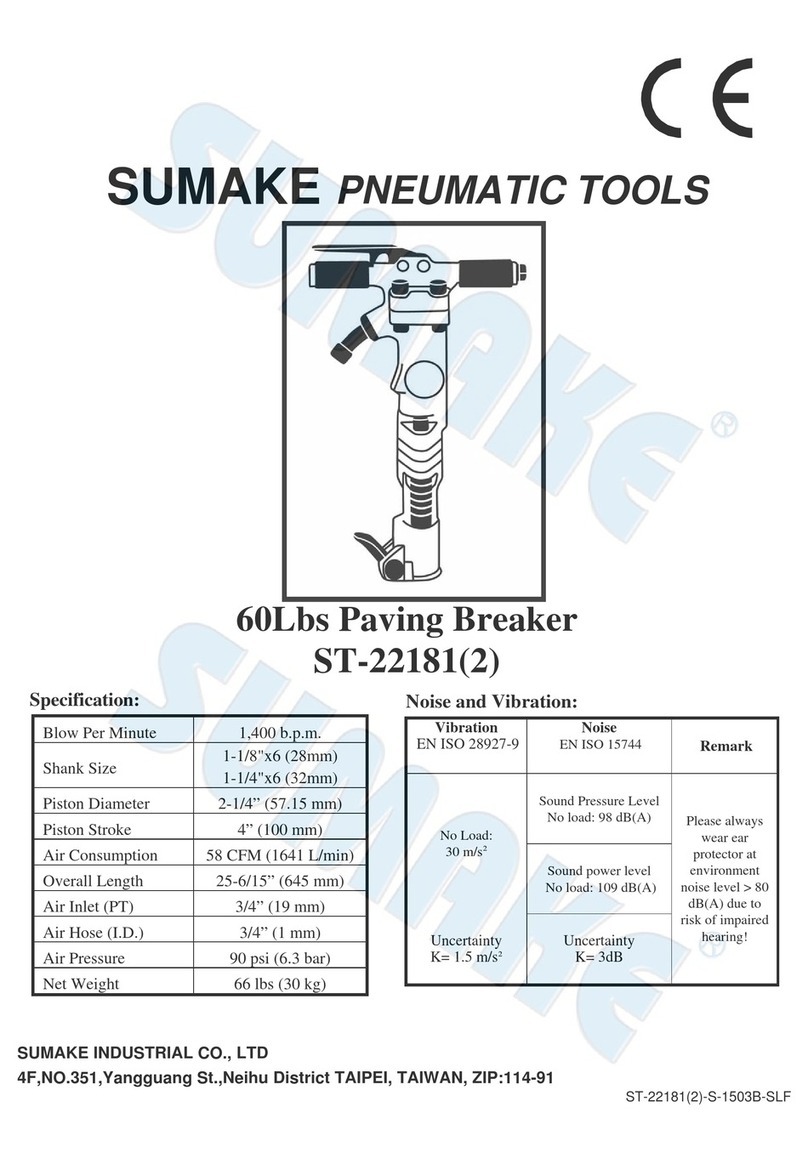

21. For multiple hazards, read and understand the safety instructions before installing, operating, repairing, maintaining, changing

accessories on, or working near the non-rotary percussive power tool. Failure to do so can result in serious bodily injury.

22. Only qualified and trained operators should install, adjust or use the non-rotary percussive power tool.

23. Do not modify this non-rotary percussive power tool. Modifications can reduce the effectiveness of safety measures and increase the

risks to the operator.

24. Do not discard the safety instructions; give them to the operator.

25. Do not use the non-rotary percussive power tool if it has been damaged.

26. Tools shall be inspected periodically to verify that the ratings and markings required by this part of EN ISO 11148 are legibly marked on

the tool. The employer/user shall contact the manufacturer to obtain replacement marking labels when necessary.

Safety precautions for projectile hazards

1. Failure of the workpiece, of accessories or even of the inserted tool itself can generate high-velocity projectiles. Disconnect the non-rotary

percussive power tool from the energy source when changing inserted tool or accessories.

2. Be aware that failure of the workpiece, or accessories, or even of the inserted tool itself can generate high-velocity projectiles.

3. Always wear impact-resistant eye protection during the operation of the non-rotary percussive power tool.

4. The grade of protection required should be assessed for each use.

5. For overhead work, wear a safety helmet.

6. The risks to others should also be assessed at this time.

7. Ensure that the workpiece is securely fixed.

8. Never operate a tool unless the inserted tool is retained in the tool with a proper retainer.

9. To avoid injury, retainer parts shall be replaced when they become worn, cracked or distorted.

10. Hold the inserted tool firmly against the work surface before starting the tool.

Safety precautions for operating hazards

1. Use of the tool can expose the operator's hands to hazards, including impacts, cuts and abrasions and heat. Wear suitable gloves to

protect the hands.

2. Operators and maintenance personnel shall be physically able to handle the bulk, weight and power of the tool.

3. Hold the tool correctly; be ready to counteract normal or sudden movements and have both hands available.

4. Maintain a balanced body position and secure footing.

5. Release the start-and-stop device in the case of an interruption of the energy supply.

6. Use only lubricants recommended by the manufacturer.

7. Avoid direct contact with the inserted tool during and after use as it can become hot.

8. Personal protective safety glasses shall be used; suitable gloves and protective clothing are recommended.

Safety precautions for repetitive motions hazards

1. When using a non-rotary percussive power tool to perform work-related activities, the operator can experience discomfort in the hands,

arms, shoulders, neck or other parts of the body.

2. While using a non-rotary percussive power tool, the operator should adopt a comfortable posture whilst maintaining a secure footing and